In the storerooms of each owner of a private house, there must be at least one additional or 2-sectional staircase. This simple, and in some ways even primitive device can be useful in many situations, from any high-altitude work to harvesting.

Ladders of this type are presented in a very wide range of construction and hardware stores. On the other hand, if you want to make such a structure with your own hands, then in this article you will find many useful tips on this matter.

Portable ladders

Main types

Factory-made sectional staircases are in most cases made of either steel or aluminum:

- Steel stairs are characterized by high mechanical strength and can be quite large. On the other hand, the significant mass of steel pipes limits the mobility of the product, and therefore most models are produced in very modest dimensions. The exception is prefabricated structures, which consist of several separate fragments.

- Aluminum one-, two-, three-section ladders have less weight, but are somewhat inferior in strength. To increase the stability of aluminum stairs, a special shape metal profile with numerous stiffeners is used for their manufacture.

- Also on the market you can find structures made of wood or polymer materials, but their variety is poor. In the case of plastic stepladders, the fragility of the raw material itself plays the main role. As for wooden ones, it is easier and cheaper to make them yourself, which we will discuss in the appropriate section.

As for the configuration, here you can distinguish the following varieties:

- Single-section ladders are the simplest added structures. They are two vertical bowstrings connected by steps. Such ladders are used almost everywhere, but reliable support is required to work on them.

- Two-section ladders - more complex, but at the same time differing in versatility. Their design includes two ladder segments connected by hinges and special fixing devices.

- Three-section ladders consist of the usual aluminum step-ladder with an additional ladder section fixed on it. The high complexity of the design is offset by significant strength and ease of use.

A separate category is made up of sliding models, in which the component parts do not fold, but slide into the corresponding grooves. In fact, the sliding device is an oversized attachment structure.

What should you pay attention to when buying?

For most of the models on sale, the price is quite affordable.

And yet, in order not to waste money, it is worth considering in advance what kind of design you need:

- First of all, you need to choose the size... As a rule, any two-piece ladder at the top has a work platform that you simply cannot climb above. Adding 2 meters to the distance from the platform to the ground (namely, at this distance, on average, you can reach with a raised hand), we get the so-called "working height".

- Load bearing capacity Is the second most important parameter.The minimum allowable indicator is equal to 150 Kg, but if you expect to subject the ladder to heavy loads, choose a more durable option.

- The width and distance between the stairs depends, first of all, on your preferences. Most models are produced with a width at the base 70-80 cm and steps with step 20-25 cm.

Note! In order for you to use the device with the proper level of comfort and safety, the support parts must be equipped with rubber or polymer attachments. Also, it will not be superfluous to install steps with a corrugated surface or equip them with rubber linings.

Self-production

What are we going to make of?

Buying a quality folding ladder with the specified parameters will not be difficult today. However, you can significantly reduce costs if you make it yourself. If there is a welding machine available, then the manufacture of a metal structure becomes quite real. Well, in this section we will describe a simpler scheme that almost everyone can do.

So how do you make a wooden sectional staircase?

First of all, we need material:

- Wooden beam or board for making supports. A section of 50x100 mm is best suited. The length of the bar depends on the planned dimensions of the product.

- Material for making steps. As a rule, the steps are made of thinner boards, so you can buy several sections with a section of 40x80 mm.

- Metal corners.

- Steel plates for connecting sections to each other.

- Steel bolts or studs with a diameter of 10 mm.

- Self-tapping screws, wood glue, varnish or paint for outdoor use.

A set of tools that will be useful to us can be found, probably, at any carpenter:

- Saw on wood (you can use a "grinder" with the appropriate circle).

- Plane.

- Drill and cordless screwdriver.

- Chisels.

- Hammer and mallet.

- Grinder and a set of skins.

- Measuring tools.

- Paint brushes and rollers.

Cut out the details

The instructions for making a sectional staircase are quite simple:

- First, we prepare the support parts. We cut the bars to size, carefully process them with a plane and perform rough grinding. If a wide board is used for the manufacture of supports, we dissolve it lengthwise using a circular saw.

- To increase the mechanical strength, one segment should be made shorter than the other: it will be used as a support.

- We cut the lower parts of the supports so that in the unfolded state the future structure stands on flat edges.

- We put the bowstrings on the ground in pairs and connect them using temporary strips. We fix the lower ends at a distance of about 80 cm from each other, the upper ends we bring a little closer.

Note! Both segments must have the same configuration. You can check this by attaching the blanks to each other before starting the assembly.

- We apply markings on the supports for the installation of steps. The distance between the horizontal axes of the horizontal strips should be about 300 mm.

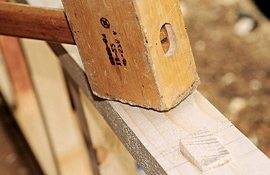

- According to the markings on the inner sides of the supports, we make grooves for installing steps. A sharpened chisel is suitable for gouging them.

Next, we turn to the manufacture of steps:

- Cut off fragments of the appropriate size from the workpiece.

- We lay out the future steps on the bowstrings in the places of the planned installation and be sure to number them. You can trim to length if necessary.

- We process the steps with a plane and grind. We remove chamfers from the edges so that they do not cut into the sole when moving.

- At the ends, using a circular saw, we form thorns. The size of the thorn should be slightly larger than the size of the groove in the string.

Assembly of workpieces

We need to assemble the elements prepared in this way into a single structure:

- First, we install the blanks of the steps in the grooves on the supports. The groove is pre-lubricated with wood glue.

Advice! A correctly fitted workpiece enters the groove with little force. To facilitate the work, you can help yourself by tapping on the blanks with a mallet.

- After the glue has dried, we carefully sand the resulting structures, and then paint them or open them with varnish.

- At the top of the ladder, we fix metal corners and plates. We connect improvised hinges with bolts and nuts.

- In the middle part of the segment, we attach either a composite metal lintel or a short steel chain. This simple device will prevent parts of the ladder from moving apart.

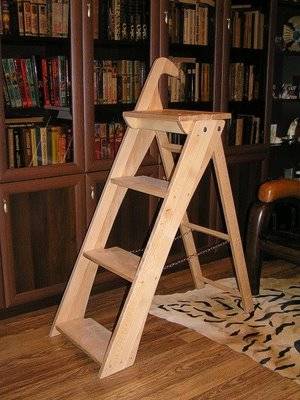

In principle, a sectional structure of almost any size can be manufactured using this scheme. And you should not limit yourself only to the needs of a private courtyard: for example, such a ladder will also find use in a library.

Output

Sectional stairs are structures that are distinguished by their versatility. They are compact, reliable, convenient, but most importantly, they are quite simple to manufacture. So if you have at least minimal carpentry skills, then you can easily take on the manufacture of this device. In the video presented in this article, you will find additional information on this topic.