What is a snow blower and where is it used?

Snowblowers are considered a versatile technique that can be used to clear large areas of snow. The main purpose of such devices is to facilitate labor for a person and save time. The field of application of snow removal equipment has a wide range.

The main places of application include highways, areas near shops and cafes, private areas, cottage settlements, summer cottages, etc. The places most requiring cleaning are highways.

Types of snow plows

Today, there are many different types of cleaning mechanisms. The choice should be based on the economic component (the amount of investment) and the technical characteristics of the unit. Do not forget about the size of the area that will need to be cleaned.

The snowblower tractor is presented on the market in several types that are in demand:

- Utility tractor for clearing snow. These tractors are most often found on our city roads during snowfall. They are irreplaceable in the work of public utilities during heavy snowfalls.

- Mini tractor for cleaning snow. With its small size, such a device has high power and copes with large volumes of snow. Companies that have a large territory most often use a mini tractor to remove snow.

- Mixed tractors. With the help of such tractors, you can sweep and remove snow debris without replacing attachments, which saves the owner.

- Snowblowers. The function of such machines is not only to remove snow from the ground, but also to sweep fresh snow that has not yet packed.

Snowblower ShRS (FRS-200M)

Snow tractors help to load and carry out the removal of snow outside the area where the cleaning took place. The big advantage of this technique is the ability to de-icy roads and sidewalks.

Attachments for snow blowers

In case of heavy snowfalls, the standard equipment is not always enough to effectively cope with cleaning, especially on the roadway. It is necessary not only to shovel the snow into a pile, but also to get rid of the ice. In this case, hinged nozzles are used.

List of attachments:

- Blade snow blower brush. This set is popular. The snow plow is placed in front of the tractor and serves to collect it, and the brush is behind. She removes what is left of the snow cover. Both of these parts are removable and replaceable parts. It is better to choose hydraulic blades, they remove snow at a certain angle. In winter, a mechanical brush is used, it rotates in only one direction. Its cost is cheaper than hydraulic, but its efficiency is not less than hydraulic.

- A bucket is installed instead of a blade. The bucket not only performs the function of cleaning, but also loading the removed snow for removal to storage areas.

- A mounted snow blower is used for a tractor, which throws snow to the side. It is located either in front or behind the tractor. The most common is a rotary snow blower for a mini tractor. To crush the piled snow layer, you can purchase a rotary auger snow blower. If the snow blower is installed at the rear of the tractor, the blade is mounted at the front. A brush is installed behind the tractor. Cleaning with this brush will be cleaner.

- It is preferable to use a grader knife with the blade. When paired, they do an excellent job with freshly fallen snow. The thickness of the layer does not matter for such a pair, on the contrary, the thicker the layer, the cleaner the cleaning.

Snowblower SU 2.1 OPM

More recently, it became possible to purchase all these attachments for mini tractors. Thus, snow clearing with a tractor or mini tractor becomes more productive.

Varieties

The main groups of sweeping equipment are divided into separate types with a description of additional functions. Devices are purchased to perform specific tasks.

Mechanical

The budget option, which is a device on wheels that needs to be pushed in front of you. Garbage collection takes place due to the work of the side rotating brushes. The brushes begin to rotate due to the start of the action of the side wheels.

The advantage of this type of technology lies in the absence of the need to use additional power supplies. Manual mechanical devices are completely environmentally friendly, safe for the people around.

Gasoline

The streets are being cleaned with the help of gasoline-based technology. They have high performance, withstand heavy loads and regular use. The thrust of an internal combustion engine provides a high performance indicator, but at the same time is a disadvantage of the device. During the operation of gasoline equipment, exhaust gases are emitted into the air.

Vacuum

The principle of operation of a vacuum machine is the basis for the operation of a conventional vacuum cleaner. The vacuum helps to quickly and easily remove layers of dust. Vacuum sweepers are purchased for cleaning large areas. They run on a turbo engine and show high performance results.

Rechargeable electric

Rechargeable devices are often purchased to clean indoor spaces. The peculiarity of working with battery machines lies in the control over the battery charge. Usually one charge is enough for a cleaning session lasting 3-4 hours.

What to look for when choosing snow removal equipment

Before buying a unit, it is necessary to more precisely determine the choice. First, you need to calculate the expected amount of work. If you need to clean only paths and small areas (up to 4-6 hectares), then you can purchase a machine equipped with a low-power gasoline engine (up to 1-2 kW). These include PATRIOT PS 301 and Efco ARTIK 55 S.

If the territory is quite large (more than 10,000 square meters) and has complex entrances, elevation changes and vegetation, it is worth giving preference to more productive equipment, such as Caliber SNUB-11.0 / 70 E.

The second parameter of choice is the frequency of use (once a week, daily or a couple of times per season), based on it, select a tracked or wheeled, self-propelled or non-self-propelled unit with a certain power and fuel tank volume.

Pay attention also to the presence of headlights, type of start (manual or electric). Depending on the planned budget, choose the required degree of automation and the number of speeds

Also, speaking about snow removal equipment, it is worth mentioning that you can use attachments: plows and special buckets. Initially, they were developed for garden tractors and motor-cultivators, but today there are models for cars.

Advantages and disadvantages of self-propelled and non-self-propelled snow blowers

Depending on the mode of movement, there are two types of snow harvesters that differ from each other in many respects.

Non-self-propelled

Non-self-propelled harvesters are manually operated, that is, they are driven by pushing force. You will also have to adjust the direction and throw distance (no more than 10 m) by yourself, turning the handle attached to the rotor. The performance of such snow removal equipment depends on the condition of the snow carpet, if it is dense and wet, you will have to exert considerable physical force to clean it.

The benefits include:

- light weight (up to 40 kg);

- rubberized lumps of metal augers, which prolongs the life of the friezes and prevents damage to smooth, fragile surfaces.

This group includes the household PATRIOT PS 301, intended for cleaning snow drifts from paths and small summer cottages.

Self-propelled

Powered by wheel or track drive. If the surface of the area that you want to clean is flat, you should give preference to tracked vehicles, but if, on the contrary, winding, and even covered with vegetation, it is better to choose a unit on wheels.

Self-propelled snow blowers have a lot of advantages:

- equipped with a separate snow grab system, which allows you to throw snow masses over a considerable distance (14-18 m) and crush even densely compressed snowdrifts using special teeth;

- have an automated speed control system;

- are started not only with a cord, but also from an electric starter powered by a side battery.

Self-propelled mechanisms differ in class. For example, PATRIOT PRO 981 ED belongs to the middle class, since according to its characteristics it is intended for daily use in small areas, but the Husqvarna ST 276EP is a more high-class equipment designed for cleaning large areas.

Device and principle of operation

Possible complete set with a sweeping machine.

Possible complete set with a sweeping machine.

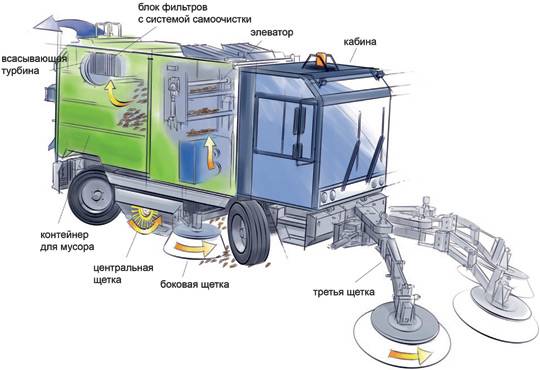

Sweeping equipment consists of the following elements:

- Brushes.

- Pick-up.

- Water tank.

- Spray nozzles.

- Garbage bin.

The unit moves over the contaminated area and wets it with water from the tank. At the same time, the brushes rotate and direct the dirt towards the pick-up. He grabs it and moves it to the trash bin. Thus, the cleaning of the contaminated area takes place.

It should be borne in mind that due to the principle of operation of the sweeper, some of the dirt scatters and does not fall into the waste bin. Therefore, the ideal frequency cannot be achieved. However, there is a technique equipped with a vacuum pick-up that sucks debris into the tank by creating negative pressure. It is more expensive and less economical, but much more efficient.

Types of petrol snowblowers

There are quite a few approaches to the classification of self-propelled snow plows. Fundamental differences are associated with the technical features of the mechanism, the weight of the structure and its consumer characteristics.

One- and two-stage

Depending on the operation of the mechanism, the following devices are distinguished:

- Single-stage - the equipment works in 1 cycle: rotating augers carry away the snow mass and immediately direct it into a chute, through which it is thrown several meters. The faster the augers rotate, the further the snow is thrown. Therefore, the fuel consumption of such a machine will be higher, and the service life will be shorter.

- Two-stage are more expensive but also more popular models. In them, the production cycle is divided into 2 processes - the augers only carry away the snow, and it is thrown away with the help of a special blade rotor. Therefore, the service life of such units is noticeably longer.

Based on the design features of the mechanism, one- and two-stage machines can be compared as follows.

Table 1. Comparison of one-stage and two-stage mechanisms.

| comparison criterion | single stage | two-stage |

|---|---|---|

| snow features | loose | any, including rammed |

| surface | cobbled | paved or gravel |

| bucket grab | up to 50 cm | up to 110 cm |

| snow throwing distance | 7-10 m | 10-15 m |

| snow depth | up to 15 cm | up to 50 cm |

Two-stage snow blower is more efficient than one-stage

Two-stage snow blower is more efficient than one-stage

Light, medium and heavy

By weight, all gasoline cleaners are conventionally divided into 3 categories:

- Lightweight - up to 55 kg.

- Medium - 55-80 kg.

- Heavy - over 80 kg.

On wheels and tracks

On this basis, models are distinguished:

- Wheeled type.

- Caterpillar type.

Wheels are mounted on all non-self-propelled and on some self-propelled models. The tread has a specific pattern that improves traction and thereby reduces the likelihood of slipping. Also, the tire is equipped with special spikes, which allows the installation to move even on an uneven surface.

But if there is too much snow on the site, the wheels may slip. Then the best solution would be to purchase a crawler-driven snow blower. Thanks to its larger surface area, this setup works well on the surface and propels the machine forward with confidence. Caterpillars will become indispensable in icy areas, slopes, etc.

Description and purpose of the professional cleaning trolley

Regardless of the type of design features, harvesting trolleys are used for:

- Dry cleaning of premises. In this case, the inventory is used to collect garbage, dirt and waste, as well as to transport tools by means of which such operations are performed.

- Wet cleaning. The trolleys are complemented by buckets in which the solution can be mixed for cleaning various surfaces and materials.

- Service maintenance. With the help of such devices, it is convenient to deliver towels, bed linen and other regularly replaced products around the premises.

> Professional trolleys are often supplemented with interchangeable units, which allow the cleaner to select the necessary attachments for himself, depending on the task at hand.

Each such cleaning equipment consists of the following elements:

- frame, which is made of metal parts;

- wheelbase;

- bucket (several buckets);

- additional details that extend the functionality of the trolley.

Depending on the field of application, the cleaning equipment is divided into 3 types:

- Uniform. The most common type of inventory. Such trolleys are mainly used for cleaning small premises. Most often, models of this type consist of a metal frame with swivel wheels on which a bucket is installed. A number of carts are complemented by a garbage bag.

- Two-bucket. Models of this type are used for cleaning large rooms. Such products simplify the work, as they allow you to perform the necessary manipulations without constantly changing the water.

- Multifunctional (universal). Models of this type, in addition to buckets, contain additional containers, nets and other devices designed to transport various items.

Professional equipment is often supplemented by means for wringing out the mop. Cleaning companies mainly buy universal models, since such equipment allows them to perform the assigned tasks without wasting time looking for the necessary tools or tools.

Cleaning technology requires an integrated approach

It is really not at all easy to comply with all the norms of winter road maintenance required by the Federal Road Agency. It is no secret that it is often the quality of the organization and conduct of events to clean roads and yards from snow that residents make a conclusion about the work of local authorities in general, reflecting their opinion later on in the ballots.

Technologically, snow removal from roads is divided into two stages. The first covers the treatment of the surface of the carriageway with anti-icing agents, as well as the subsequent shoveling of snow and sweeping of the carriageway surface with the formation of snow banks in the near-river areas. A large number of municipal vehicles are involved in the first technological stage of snow removal, despite the fact that full cleaning does not take place at this stage. This technique is called "snow removal" conventionally, since machines only move and shovel snow from the central part of the road to the shoulder or sometimes to the center of the roadway, thereby reducing the width of the roadway and impairing visibility.Instead of improving the situation on the road, they thereby increase the likelihood of an accident.

In municipal services, tractors, loaders, mini-loaders and other equipment are used to shovel snow, equipping it with snow plows and brushes, but the most effective first stage of snow removal is performed by combined road machines (KDM). As a rule, these communal machines are based on domestic chassis, and their functionality allows them to cover the entire range of work required to maintain cleanliness in settlements. Today KDM is produced by a whole group of Russian enterprises.

More than a dozen KDM models of the MD series are offered to domestic utilities by the "Kurgandormash" enterprise, and most of the models of the series have two or three modifications. Cars in the "winter-summer" operating mode are based on the chassis of GAZ, ZIL, MAZ. KamAZ, Amur. The models differ in the capacity of the sand-spreading equipment hopper, the presence of a medium brush, and various types of snow plows. The Kurgandormash sand spreaders provide for a stepless adjustment of the width of the working area within the range from 2 to 10 m, as well as the density of distribution of deicing materials (PGM) from 10 to 500 g / m2.

Combined machines of the KO series on the KAMAZ and MAZ chassis are offered by the Arzamas Municipal Engineering Plant. The machines are designed for year-round operation. In winter, they are used to clean the roadway from freshly fallen snow with the help of plow and brush equipment, and to combat icy conditions, they are equipped with sand-spreading equipment that allows covering “problem” sections of sidewalks and roads with inert materials or anti-icing agents. The design of the KDM has a tank for reagents, a body with a conveyor and a spreading disc, various types of brushes with a hydraulic drive, as well as rotary, side, high-speed and other types of dumps.

Of the youngest enterprises, the Region 45 plant from Kurgan is seriously engaged in the production of CDM. The enterprise offers five models of combined machines based on the KamAZ chassis, equipped with a front blade 2.6 m wide with the ability to rotate by ± 30 ° for shoveling freshly fallen snow up to 0.2 m high.And for the final cleaning of the roadway from snow, cylindrical middle brushes are installed ∅0.55 m with a working width of 2.5 m. Moreover, the brush can change the angle of rotation relative to the longitudinal axis by 60 °. To protect the roadway from slipperiness, sand spreaders are installed on the CDMs offered by Region 45. It is no secret that the road surface covered with a snow-ice layer increases the turning radius of the vehicle and its braking distance by 3-9 times! The enterprise equips spreaders with bunkers for sand-salt mixture (PS) with a volume of 3 to 12 m3, and the bunker material is steel sheet 3 mm thick. Thanks to the original solution of the designers of the Region 45 plant, the load applied from the PSS bunker to the conveyor is evenly distributed, and this protects the conveyor chain from stretching and premature destruction, and therefore increases the service life of the sand spreader itself.

Features of operation

Snowblower at work

Snowblower at work

Compliance with the rules for the use of equipment will significantly increase its service life. The owner of a gasoline snow blower needs:

- It is good to warm up the engine before starting work so that the grease has time to spread through the gearbox. Full load immediately after starting the motor will quickly lead to wear.

- Use only low-viscosity engine oils (5W-30, 0W-30, etc.). They have the ability to spray even in frost.

- Avoid a sharp increase in the load - this must be done gradually, otherwise you can cut off the safety bolts or pins of the auger.The best working conditions for a gasoline engine are with an average snow speed of 20-25 cm.

- At the end of the snow season, the unit must be mothballed. To do this, gasoline is drained from the gas tank and carburetor, and the used oil in the engine is replaced with fresh oil (so that it does not stratify and form a sediment).

Tips for operating a snow blower

- Any newly purchased equipment, despite the presence of factory lubricant, must be additionally treated with lithol. This is especially true for snowblowers.

- If the snow blower is stored in an unheated room, it would be useful to bring it to a warm place before starting work. After warming up, it will start easier.

Before work, you need to carefully check all the fasteners of the parts.

- When working with the snow thrower, make sure that no foreign objects get into it. You need to be especially careful in the garden. Bushes and other plants can become tangled or broken by the auger.

- Heavy or wet snow cover must be removed at minimum speed.

It is better to throw snow downwind

Instructions for use

Each model of a snow blower must be supplied with instructions for use, taking into account the characteristics of a particular piece of equipment, but there are general rules that should be followed. For example, we must not forget that a snowplow is a rather dangerous machine, because a rotating auger, although it never gains great speed, is capable of catching clothes or even a person's limb, and it will be problematic to escape from its captivity without help. If this is not done immediately, the likelihood of serious injury increases significantly, because the unit has significant power. In this case, a self-propelled model, left unattended in operation, will continue to move in a straight line, which can also lead to misfortune.

Use of the machine as a whole must be carried out with great care. Suffice it to recall that the gasoline with which the snow blower is refueled tends to easily ignite and even explode, therefore it is unacceptable to refuel near open sources of fire and with the engine running.

Even a jet of snow being thrown can pose another danger - its force may be sufficient to break a window or severely damage your eyesight if it hits the eyes directly from a short distance.

Even if you do not take into account the above hazards, you still need to carefully monitor compliance with all the rules common to all equipment. So, before starting the first operation, you should definitely study the instructions so that careless handling does not contribute to the premature failure of the mechanism. Self-repair of the unit is almost always discouraged by manufacturers, and in the included form it is strictly prohibited.

Snowblower Husqvarna

High-performance snowblower, assembled in Russia from components made in China, for quick cleaning of the area around the house from snow and ice. The high-powered engine quickly removes fresh and packed snow up to 30 centimeters thick from asphalt, concrete and turf in a single pass. The two-stage grinding system transforms the packed snow and ice into small pieces up to two millimeters in size. The variator and computer control system reliably hold the machine on a slope with a steepness of up to 40 degrees.

Positive traits:

- powerful gasoline or electric engine Briggs & stratton snow;

- units of wheeled and caterpillar type are produced;

- compact size and light weight allow using the snow blower to remove ice and snow from hard-to-reach places;

- the triangular shape of the track links and tread improves traction on packed snow or ice crust;

- reliable undercarriage design;

- two-stage ice and snow crushing system;

- computerized suspension stabilizer for steep slopes;

- LED headlight to illuminate the workplace;

- heated control levers.

Negative qualities:

- simplified screw design;

- the removal of packed snow and ice at high speeds must be done at the minimum engine speed, otherwise the working body may break down.

Peculiarities

Serious snowblowers driving through winter streets and snowy highways are mostly gas powered because they are based on the vehicle's design, but don't think that all miniature snowblowers are necessarily powered by an electric battery. Even household models can be gasoline powered by a small internal combustion engine, and this design can have both advantages and disadvantages.

The first obvious advantage of a gasoline engine over an electric one is power - it directly affects performance, so a relatively small gasoline snow blower is able to clear snow from even a large area in the shortest possible time.

A liquid-fueled snow blower grinds snow much more efficiently and is able to throw it up to a distance of 10-12 meters, which is very convenient if you need to clear not a narrow path, but a wide road. At the same time, more expensive models are often equipped not with wheels, but with caterpillars - this is hardly useful on a personal plot, but it will be very useful for cleaning a skating rink or on a hillside. Needless to say, a gasoline snow blower does not have the slightest connection to an outlet, and its use is possible absolutely in any conditions, including far from civilization - provided that there are enough gasoline reserves.

However, one cannot fail to note some of the shortcomings that force a certain circle of consumers to make a choice in favor of electrical engineering. A truly powerful gasoline-powered unit will weigh quite a lot, and the tracked version is also huge in size, so it is quite problematic to transport or use the non-self-propelled version in some situations. Prices for equipment with a gasoline engine are also much higher than for cars with electric traction. Finally, any gasoline engine is always inferior to an electric one in terms of noise and gaseous emissions, therefore, in a small area near the house, many may consider the use of such technology an inappropriate solution.

Self-propelled models

A self-propelled snow blower moves independently using fuel supplied to the engine. It doesn't need to be pushed. The machine is equipped with a drive. Therefore, even people who are unable to lift weights can use it.

This option is better suited for large areas. These machines are powerful, capable of removing packed, wet or icy snow. Such models, due to their power, are capable of throwing snow over a decent distance (up to eighteen meters). This prevents blockages.

The self-propelled snow blower has several speeds. This allows you to change the pace of cleaning and adjust the time allotted for this process.

But at the same time, the car has a lot of weight. This means that it can slip or fail.

Features of snow removal in the city

Despite approximately the same amount of snowfall, winter road maintenance in the city differs from the maintenance of country roads. High, uneven hourly intensity of urban traffic, a non-uniform flow dictate increased requirements for the organization of this type of work. The technology of cleaning on country roads allows you to throw snow onto roadsides or slopes.In cities, this technology can be used mainly on circuit roads, and even then only on sections with a suitable cross-section.

A significant difference from out-of-town highways is also associated with the limited width of the streets and the presence of so-called "red lines" - conditional boundaries in which the street lies, most often these are the walls of buildings. The high population density in the city also affects, which requires timely cleaning of pedestrian zones and public transport stops. It is not possible to store or throw snow outside the roadway due to the presence there of lawns, sidewalks, bike paths and similar structural elements of the streets.

The technology of winter maintenance of urban roads provides for a significantly higher consumption of chemical deicing materials in comparison with suburban areas. In the city, the fallout of even a small amount of snow requires mandatory prevention of its compaction through the use of reagents. In suburban conditions, snow is removed mainly reagent-free or with a minimum amount.

Thus, snow removal of city roads is based on the technological sequence of the use of mechanization means using chemical reagents, which, falling into the snow, form solutions. The solutions are distributed in the snow mass over the surface of the snow crystals and create a film that contributes to an increase in the mobility and movement of these crystals under the influence of external forces. Such a mixture of reagent and snow, being in a free-flowing state, for a long time does not compact under the action of the wheels of vehicles, does not freeze, easily moves apart, provides contact between the wheel and the coating and remains mobile, which ensures the efficient operation of snowblowers for several hours.

Work on the winter maintenance of the road network in the city is carried out on large areas, under various weather and climatic conditions, is very laborious and must be carried out within the specified time frame, and in some cases - in an emergency. These features determine and determine the complexity of the organization of work with the need for a wide and targeted use of mechanization means, consistent performance of technological operations while observing time parameters.

In order to speed up the treatment with reagents and remove the snow mass from the surface of the pavement, high-performance road equipment is used with the appropriate characteristics in terms of the power of the base machines, the width of the working area, the maximum speed of movement, while ensuring the proper quality of cleaning the road surface. As a rule, all models of modern road equipment for winter road maintenance are equipped with both solid and liquid deicing agents and plow and brush equipment.

Which will fit

Detergents differ by category. Before buying, you should clarify whether the chemicals are suitable for the type of flooring and the type of scrubber.

5 types of cleaning chemicals:

- For wet cleaning. After washing with such a means, the flooring acquires a glossy shine, an anti-slip effect is noticeable. Detergents of this type do not leave streaks. Recommended for use on demanding natural stone surfaces.

- Universal. Will overcome any stains on various surfaces. Produced in liquid form, it belongs to low-foam products.

- Alkaline. The composition includes concentrated hydroxides of alkali and alkaline earth metals. It is used for cleaning stubborn stains and stubborn stains from polymer and polyurethane coatings.

- Medium alkaline. For removing rust, cement or deposits. Highly active detergent removes mild stains from floor coverings.

- Weakly alkaline.Suitable for daily cleaning, as well as removing fresh greasy or oily stains of soot, soot, carbon deposits.

High-quality detergents take care not only of floor coverings, but also of floor cleaning equipment. In the process of creating household chemicals, all the subtleties of the equipment used were taken into account - the tool will not harm expensive cars.