Setting up and checking the ignition for the Neva walk-behind tractor

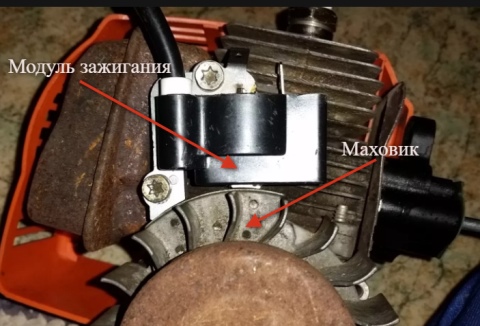

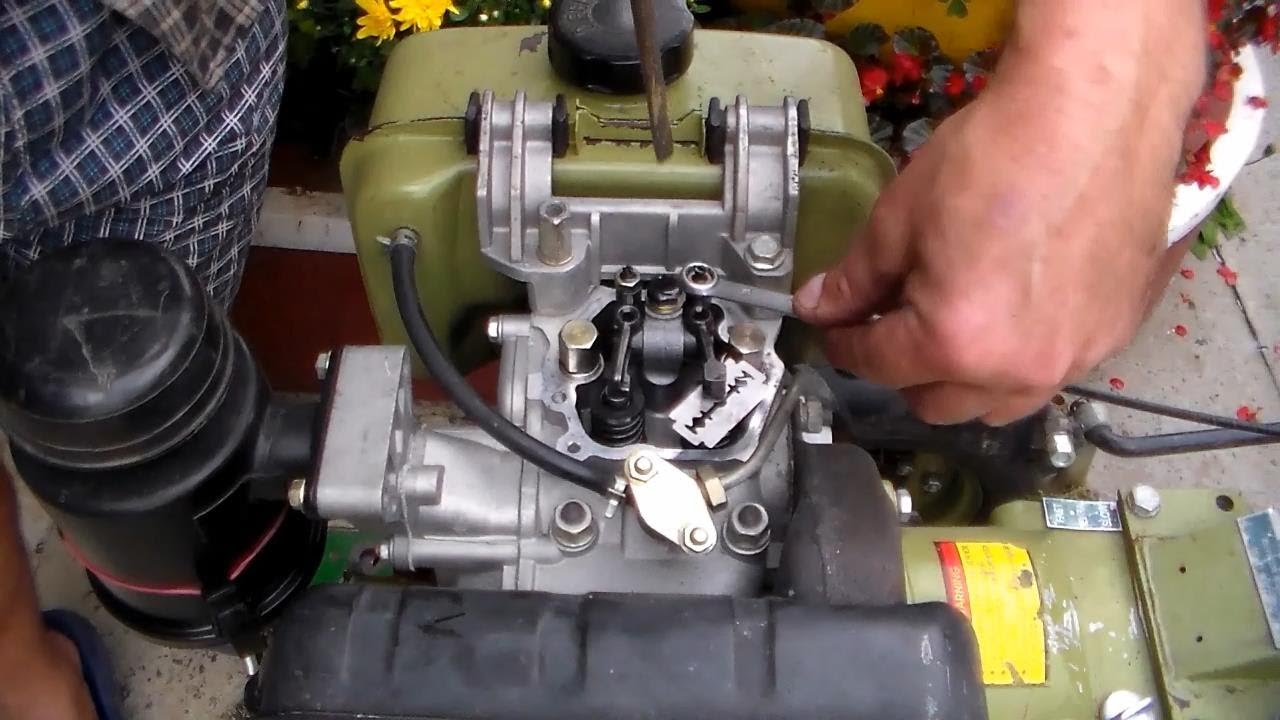

In order to correctly and quickly check the coil of Neva walk-behind tractors, you need:

- Fold A4 sheet 4 times.

- Loosen the modular fixing bolts.

- Place the paper under the pillow.

- Press it down and hold until the bolts are tightened.

- Turn the flywheel and check for spark.

Adjusting and tuning the magneto is fairly straightforward. The most common cause of a motoblock coil malfunction is a candle. Therefore, in the tool case of each owner of the cultivator, there should be sets of spare candles.

The most popular candles from well-known manufacturers are Bosch and Subaru.

Checking candles is carried out as follows. In order to check the serviceability of the candles of the coils of the MB and MB 1 walk-behind tractor, you need to follow the following instructions:

- Unscrew the candle. Wipe the electrodes.

- If there is carbon build-up, clean it.

- Set the distance between the electrodes.

- Put a tip with a high-voltage wire on the candle.

- Press against cylinder body. The electrodes should point to one side under the candle.

- Turn the crankshaft, observe the formation of a spark. If it is not there, then there is a malfunction in the candle.

Whoever owns motor-cultivators should remember that if a spark has formed, then you need to look at its brightness. If the color is intense, then the tuning and adjustment of the magneto was successful.

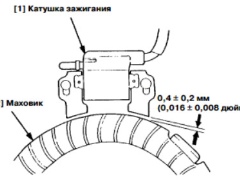

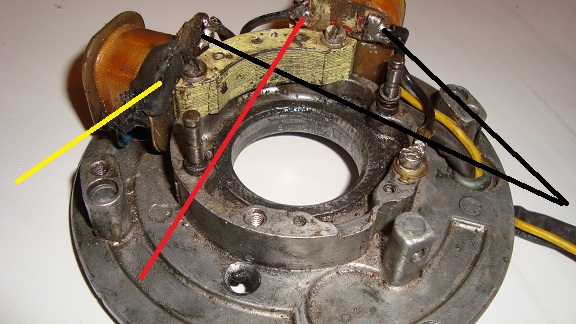

For the magneto to work well, it is important to maintain the clearance between the flywheel and stator. The distance should be between 0.1 and 0.15 mm

If the indicators do not correspond to the required ones, then it will not be difficult to configure them.

To set the optimal gap size, you need to remove the fan cover, loosen the stator bolts and insert a feeler gauge. Then you need to set the required indicators and tighten the nut.

Repair of ignition for motoblocks is also not difficult. Most often, magneto breakdown occurs due to a malfunction of the spark plug.

To check, you need to carefully unscrew the candle and inspect it.

If the spark plug is dry, it means that fuel is not entering the engine system. If the plug is wet, it means that the plug is constantly being filled with engine oil.

For repairs in the first case, you need to wipe the candle, with late repairs, dry the engine cylinder by running it at idle speed.

The motoblock is now a fairly widespread technique. This article describes the ignition system, how to set it up and what problems may arise during the operation of the device.

Ignition adjustment on carburetor engines

Ignition adjustment by turning the distributor

It is produced by turning the housing of the ignition distributor (distributor), the shaft of which is driven by the transmission of torque from the engine through the intermediate gears. On engines of the VAZ 2108 family, the distributor shaft is driven into rotation by directly engaging the camshaft, but this is not of fundamental importance. The most important thing is the exact coordination of the ignition system with the ICE mechanics.

Regardless of which distributor is installed - contact or non-contact (with a Hall sensor), turning its housing against the direction of rotation of the rotor increases the ignition timing. That is, to make the ignition "early", you need to determine in which direction the rotor rotates - you can remove the cover from the distributor and turn the crankshaft. Where to turn the distributor for early ignition will be clearly visible. But the required ignition timing is not always determined by the factory-set engine characteristics.Its value is also influenced by the octane number of the fuel.

This is very clearly seen when using gas equipment on a car with carburetor engines. When switching from petrol to gas for the first time, the car refuses to accelerate. To achieve normal engine operation, it is necessary not only to turn on the ignition early, but to turn the distributor as far as possible against the stroke. And vice versa, when switching back to gasoline, such an ignition timing will be unnecessary - the knock of the piston fingers caused by detonation will "tell" about it. This is due to the large difference in octane numbers between gas and gasoline. A very simple but effective way to check the timing accuracy is to test the motor in motion. When the accelerator pedal is pressed sharply in the accelerating engine, a slight short-term knock of the piston fingers should appear.

We recommend reading:

Disassembly instructions, repair tips

I just finished capitalizing the Ant's engine and decided to write a small report on the installation of the magneto. The engine had, of course, to be half charged with spare parts, don't you know who made it. I suspect that the counterfeit with which I had to spend the last two days is being produced in some garage in Rostov-on-Don, or the local hard workers are quietly doing this chukhnya at the factory. In any case, according to my information, the traders bring this muck from Rostov.

The engine that I have devoted the last two days to has already been converted to magneto. Plus, in my yard there was another "Ant", which was also altered by someone under the magneto, but the store spacer to which the magneto is attached from it at one time someone "screwed up" ... I had to buy a new spacer and the owner at the same time bought a clutch ... I don’t know why he bought it - I didn’t ask him about it. The old one was in good condition. Well, once I bought it, we'll put it on.

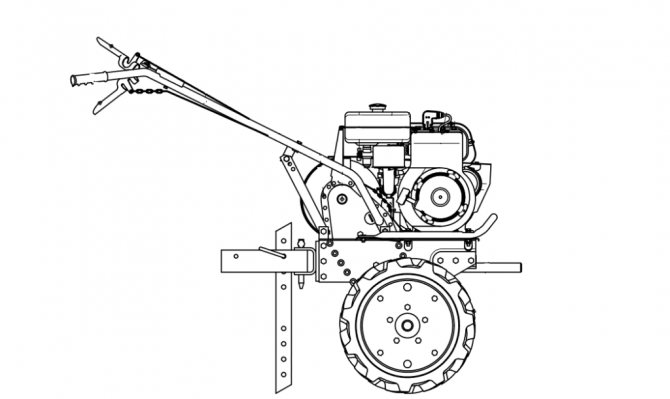

First start-up and running-in of the "Cascade" walk-behind tractor

The first start-up of the "Cascade" walk-behind tractor is as important as the subsequent correct use. The more carefully you handle the unit, the longer the equipment will serve you.

How to run for the first time:

- make sure that the walk-behind tractor is filled with gasoline and oil;

- check the build quality, the correct connection of the mechanisms;

- put the gear adjustment knob in neutral, then start the engine and, having selected the required gear, squeeze the forward travel lever;

- do not press the forward and reverse handles at the same time;

- it is also prohibited to change gears when the forward / reverse lever is in the depressed position.

Running in the "Cascade" walk-behind tractor is carried out in several stages:

- the first stage - idling without load, an average of 5 minutes in each gear;

- the second stage - work at 1/3 of the power, for 1 hour in each gear;

- the third stage - work at 2/3 of the engine power for 1 hour in each gear.

If the walk-behind tractor is not new, there is no need to run it in. During the running-in, it is forbidden to: load the walk-behind tractor at full power, carry more than the recommended (maximum allowable) weight on a cart or trailer, perform complex work such as plowing virgin lands.

Ignition device on the Agro walk-behind tractor

Auto mechanic specializing in agricultural machinery

Motoblocks have gained particular popularity over the past decade. They really do provide meaningful help to a person on a personal plot. Motoblock structures are capable of a lot - plowing a fairly large plot of land in a short time, planting and quickly harvesting crops, moving heavy loads, taking on the functions of a snowblower and much more.

Motoblocks are a mechanism that sooner or later begins to malfunction. The uncomplicated design of the unit allows you to find and fix the breakdown yourself.

The main types of malfunction of motoblocks:

- engine breakdown;

- failure of the ignition system;

- uneven battery performance;

- contamination of the carburetor;

- fuel supply problems.

The task of the ignition system is to generate the spark required to ignite the fuel in the combustion chamber. Failures in the system are eliminated quickly and easily if you strictly adhere to a certain scheme of actions, otherwise, you can simply harm the correct operation of the walk-behind tractor.

Installation of ignition on 402 engine

Domestic cars "Gazelle", "UAZ", "Volga" are equipped with internal combustion engines 402, which are produced by "Zavolzhsky Motor Plant", on which the ignition is important.

Operation depends on correct ignition

Automotive power units work productively if the ignition system is adjusted to 402 fuel-air mixture. Forms the composition of the fuel carburetor, which feeds the prepared mixture into the engine cylinders.

At the moment of the highest position of the pistons, the spark plugs generate a spark that ignites the fuel mixture in the combustion chamber. A mini explosion of fuel with the resulting gases presses on the pistons, turning their translational motion into a torque of the crankshaft.

The algorithm for igniting the mixture highlights one important point in the sequence of events. Will the motor work fully if the mixture is ignited at the beginning of the piston rise or when lowering. The answer is correct - it won't.

Any internal combustion engine works like a clock, provided the fuel is properly ignited. The power of the power plant increases, approaching the established standards. To do this, it is necessary to fix the correct spatial position of the distributor, which alternately closes the electrical circuit from the high voltage coil to the car candles.

Features of fuel ignition

Before installing and correctly setting the ignition order on the 402 engine, it is important to understand the design features of the distributor. An electric flow distributor without traditional metal contacts was installed on this engine.

The innovation is that a complex process is controlled together with a generator by a vacuum advance controller.

The distributor sets the order of occurrence of the spark, the sequence of ignition of the fuel in the cylinders. A mechanical slider helps to correctly "catch" the moments of the spark discharge. It mounts directly to the pulley. Has a resistor to help mix noise. The switching device disconnects the circuit in the first coil. Subsequently, it transforms the electrical impulses emanating from the node into an intermittent current in a short circuit.

We find the igniting moment in the ignition

On the 402 engine, the ignition is adjusted according to the following algorithm and order:

- The crankshaft occupies a spatial position corresponding to 5 degrees of advance ignition of the fuel mixture;

- It is easy to achieve this position by aligning the mark on the pulley with the groove on the motor block;

- A coincidence means that the power plant has marked the end of a full piston stroke.

With the distributor sensor removed, the adjustment is made as follows:

- I remove the candle from the head of the combustion chamber of the cylinder, in the order of ignition of the fuel listed under No. 1;

- Cover with a sheet of paper, turn the engine crankshaft;

- The air pushed out by the piston blows off the sheet, which indicates that it has reached a vertical maximum, from which the stroke begins;

- Then, using the keys, I set the octane corrector scale to 0.

IT'S INTERESTING: How to change a gasoline pump on Kalina

Checking for correct installation

If the order is followed without errors in the ignition of the 402 engine, then the next task will be to check the power plant while the car is moving:

- We leave on the highway and when driving 60 km / h, turn on the fourth gear. We gasp. The appearance of short knocking knocks indicates the correct ignition setting.

- Elongated detonation knocks are confirmation of the incorrect setting of the advance angle.

In this case, you should reduce it with an octane corrector, moving it to one risk. If the detonation is not heard at all, then the advancing angle of ignition of the fuel mixture should be increased. And again check the correctness of the installation by accelerating the car to 60 km / h with switching to fourth speed.

Which engine is better to put on the Cascade walk-behind tractor?

It is necessary to take into account the fact that the engines of domestic production, which were produced for this walk-behind tractor, are no longer there. So you will need to choose among the imported assortment. But it's almost impossible to find a part that is suitable in all respects. Most often, you also need to additionally purchase a set of mounts (belt, dampers, pulley, platform), since many engine models may differ in different seats or shaft diameters.

Most often, the following engines are installed on the Cascade:

- DM 68 is a good quality engine, which is recommended as one of the best options for installation on such equipment. Its main advantage is its reinforced transmission and high-quality assembly. Technical characteristics:

- power - 6 hp;

- fuel tank: 3.3 l;

- processing depth - 26 cm;

- processing width - 45/60/95 cm;

- number of gears: 2 forward, 2 reverse.

- B&S I / C is a modern engine model that is very popular among motoblock owners. This is due to its main features:

- reinforced transmission;

- increased power of 6.5 liters. with.;

- fuel tank with a volume of 3.6 liters;

- minimum noise level;

- efficient operation even at low temperatures.

- The Vanguard OHV is a powerful engine that will help you get the job done quickly and efficiently. This high level of performance is achieved thanks to its 7.5 horsepower and 4.5 liter fuel tank.

When buying an engine, pay attention to its build quality. It must meet all modern requirements, this will provide the unit with a long service life and efficiency in operation.

How to proceed if there is no spark on the walk-behind tractor?

The causes of malfunctions in the ignition system in most cases are associated with spark plugs. The spark plug is often oversaturated from too much engine oil. When it hits the part, it prevents sparks from occurring.

When the spark has disappeared, you need to act as follows:

When the spark has disappeared, you need to act as follows:

- The candle is unscrewed with a special key. The element turns and is carefully removed; the O-ring should also be unscrewed;

- If the spark plug is dry, this indicates that fuel is not being supplied to the engine cylinder;

- If the plug is too wet, it indicates an excess of engine oil. The candle is wiped, the cylinder is dried. For this purpose, the starter rope is pulled;

- If there is hard carbon on the candles, you can use gasoline and coarse sandpaper to clean it.

Such manipulations can be performed on a diesel walk-behind tractor and on gasoline models.

It is important to carry out all actions as carefully as possible without damaging the part.

How to set the ignition on a walk-behind tractor - we study in detail

If, in order to start the walk-behind tractor, you need to pull the starter cable for a very long time, or you notice that the engine of the unit starts up with some delay, then most likely you will need to adjust the ignition system of your agricultural machine. The operating instructions for the unit will help you do this correctly. If it is not there, then the ignition adjustment should be carried out in the following order:

- The first step is to put the elbow on the spark plug. Its body should be reliably pressed against the cylinder head, while turning the part in the direction opposite to the hole in the cylinder head;

- Then you need to turn the crankshaft. To do this, you can pull the starter rope several times.As a result of pulling the cable, you should see a blue spark jumping between the electrodes;

- If the spark does not appear, you will need to check the clearance between the flywheel magnetic shoe and the stator. Ideally, it should be 0.1–0.15 mm. To adjust the gap, a special template should be installed between both parts, and the stator and magneto screws should be turned until both elements are close to each other at the required distance. The video will help you to get acquainted with the procedure for setting up the ignition system of the walk-behind tractor in more detail.

The installation of the ignition of the walk-behind tractor made in this way takes no more than 20 minutes of time. Having completed this simple procedure in a timely manner, you will protect the other mechanisms of the walk-behind tractor from increased load and excessive wear.

Missing spark: how to fix the problem

For ignition in the ignition system, all elements must be in good working order. The most common problem is the lack of a spark. Among the various options, there are two most common - carbon deposits have formed, or the candle is not working properly.

There may be several reasons why there is no spark

There may be several reasons why there is no spark

The first step is to unscrew the candle. After that, it is required to inspect it, including the lateral and central type electrodes. If there is carbon deposits, then, in addition to cleaning, it is necessary to check the entire fuel system of the walk-behind tractor. It is also a common mistake to use the wrong fuel and oil, which leads to soot and spark plug filling.

Among the fuels for gasoline engines, both 92 and 80 gasoline can be used. The main point is to use a high quality and suitable oil.

A number of motoblocks are not picky about oils, but for all-season work it is worth using seasonal oil. For example, for summer it is recommended mineral type 4ТD STANDARD SAE 30, and for winter - 4ТD ULTRA SAE 5W-30.

A spark plug for a walk-behind tractor should also be included in the category of high-quality and recommended for this model. Information on the most suitable options can be found in the instruction manual.

Step-by-step option in the absence of a spark:

- unscrew and clean;

- for complete cleaning, heating is used, after which all carbon deposits from the dried fuel are scraped off;

- the tip is put on the upper part of the candle;

- the candle is brought to the motor body, taking into account the distance to the electrode of 1 mm;

- the second hand is required to start the motor.

If a spark does not appear, then it will be necessary to adjust the distance between the side and center type electrodes. The thin blade should fit snugly between them. If you need to move the electrode, you will need to gently knock on the back side until mixing. After that, the candle is also checked.

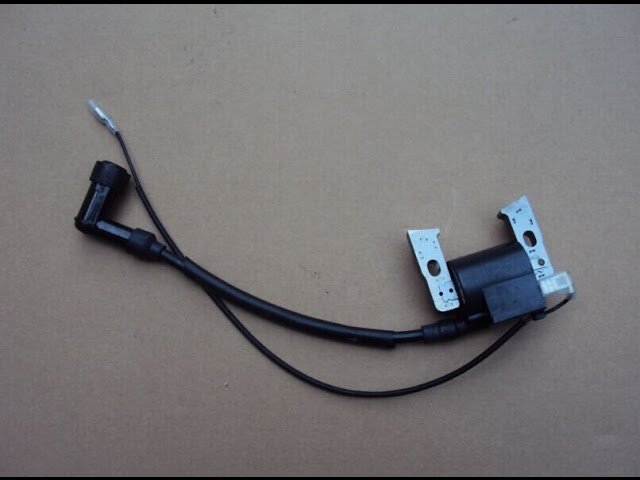

If the spark plug is serviceable, then the absence of a spark may be due to the ignition coil on the walk-behind tractor, magneto, or faulty wiring.

It is required to take into account that it is the candle that is initially checked, after which the rest of the mechanisms and elements of the system are examined and adjusted. Also, for any checks on the performance of the walk-behind tractor or setting the ignition, only stable and serviceable candles are used.

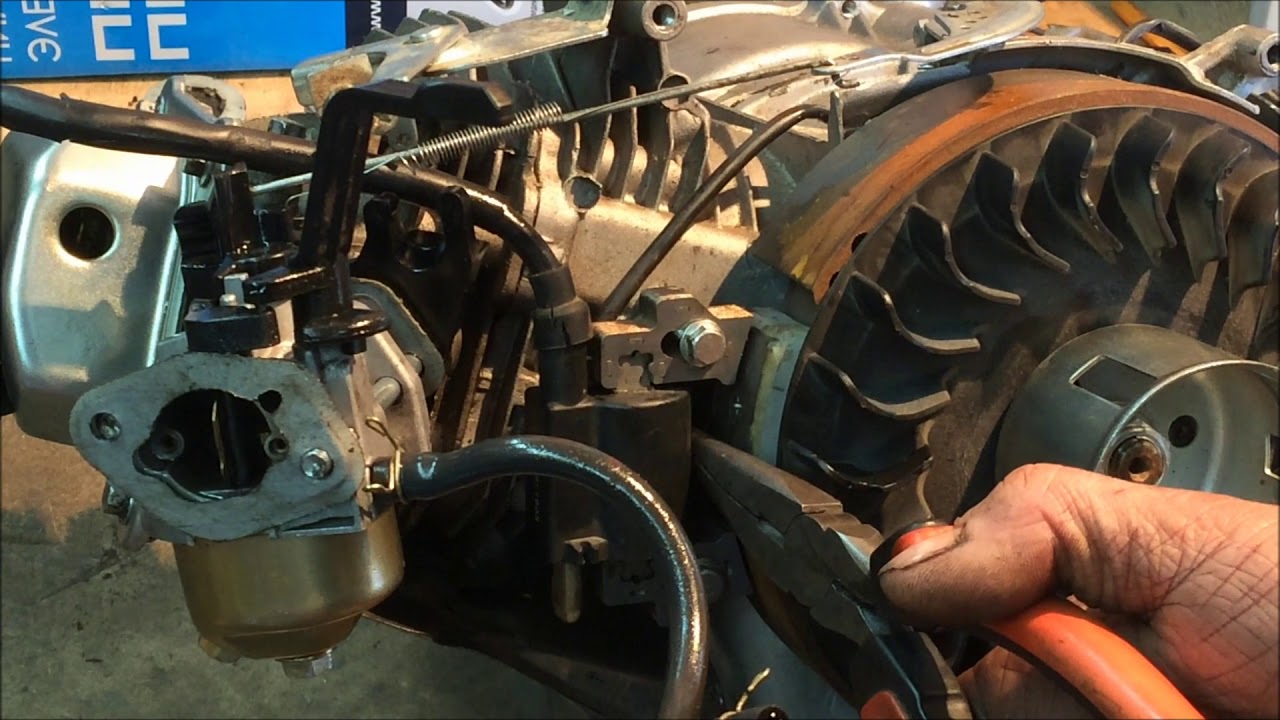

Walk-behind tractor device, engine diagram

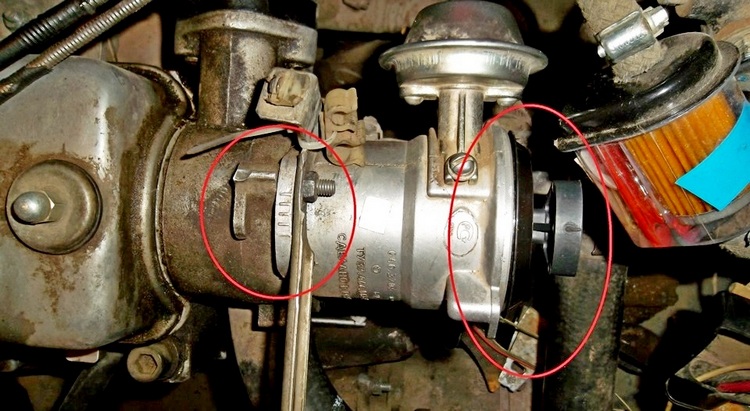

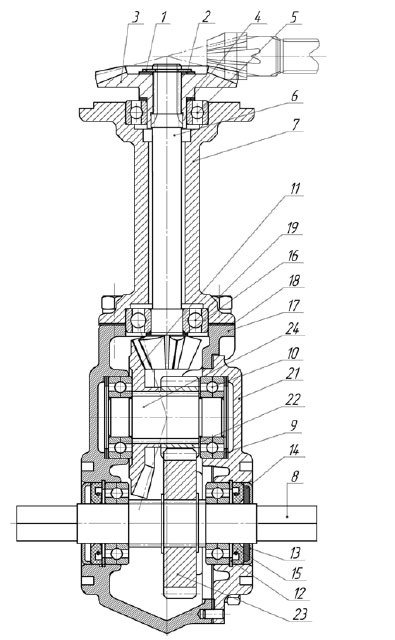

The carburetor device of the "Cascade" walk-behind tractor is shown in Figure 2.

Adjustment (adjustment) of the carburetor of the "Cascade" walk-behind tractor is carried out according to the standard scheme:

- the engine should warm up;

- further, the position of the throttle valve is changed using the adjusting screw;

- after that, the idle speed is reduced to a minimum, the operator must achieve a uniform engine sound;

- then the maximum and minimum engine speed is adjusted three to four times until the sound is even and stable at the selected position of the damper.

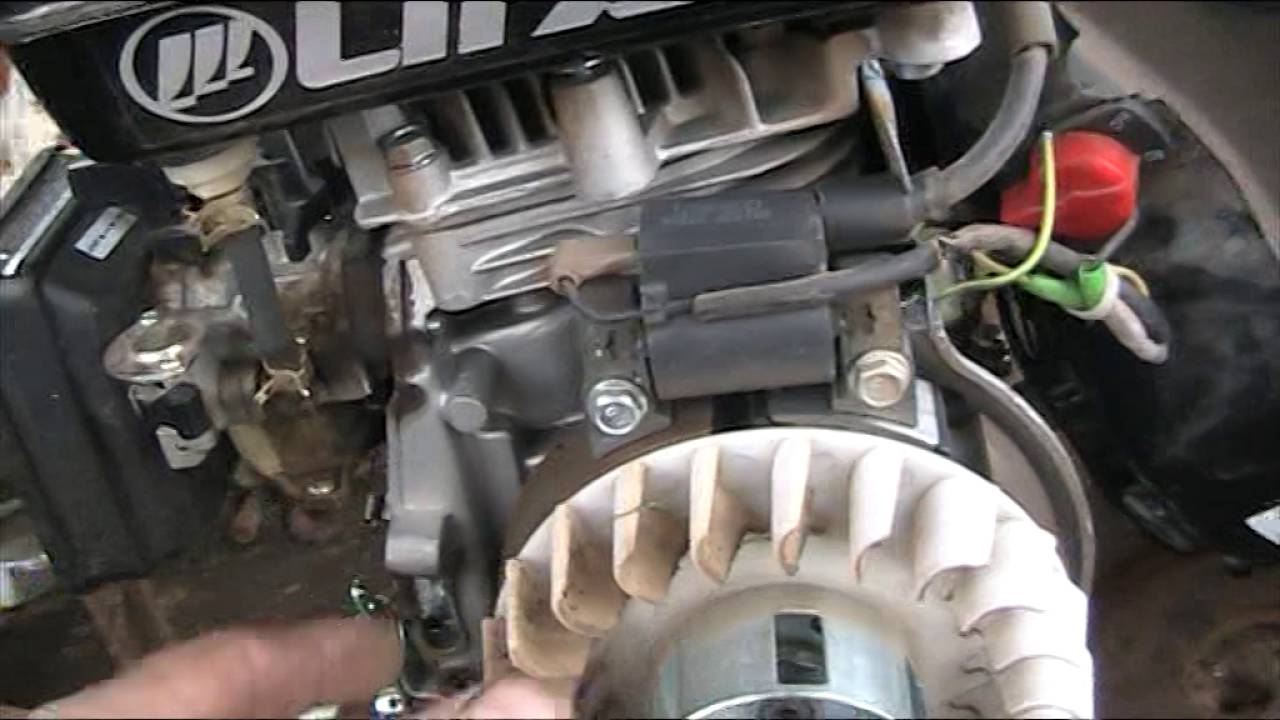

Ignition of the "Cascade" walk-behind tractor

Sometimes the problem of starting and functioning of the walk-behind tractor lies in the ignition itself.The ignition adjustment of the "Cascade" walk-behind tractor is carried out based on the type of engine. An operating manual is given for each engine, therefore it must be studied in detail.

- The engine starting mechanism - starter - is designed to spin up the crankshaft.

- The electronic ignition system ensures uninterrupted spark formation at the spark plug.

Basic recommendations for the adjustment / operation of the ignition of the "Cascade" walk-behind tractor:

- use these types of spark plugs BP6ES, BPR6ES (NGK) or NHSPLDF, so you can avoid the appearance of carbon deposits;

- carry out maintenance of the spark arrester every 100 operating hours (cleaning from soot on a mesh filter);

- the idle speed for the engines of the "Cascade" walk-behind tractor is 1700 (+ -150) revolutions per minute.

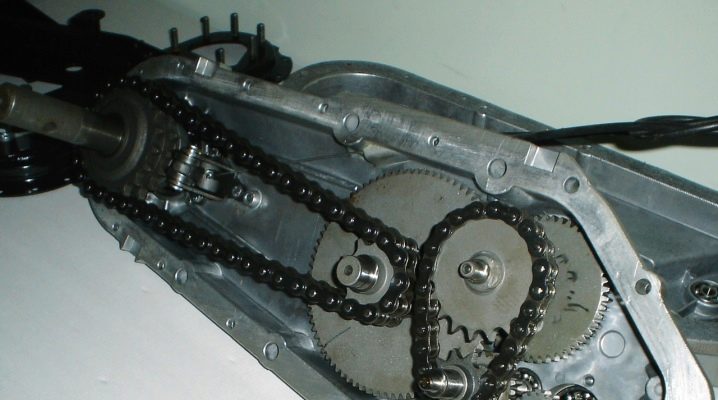

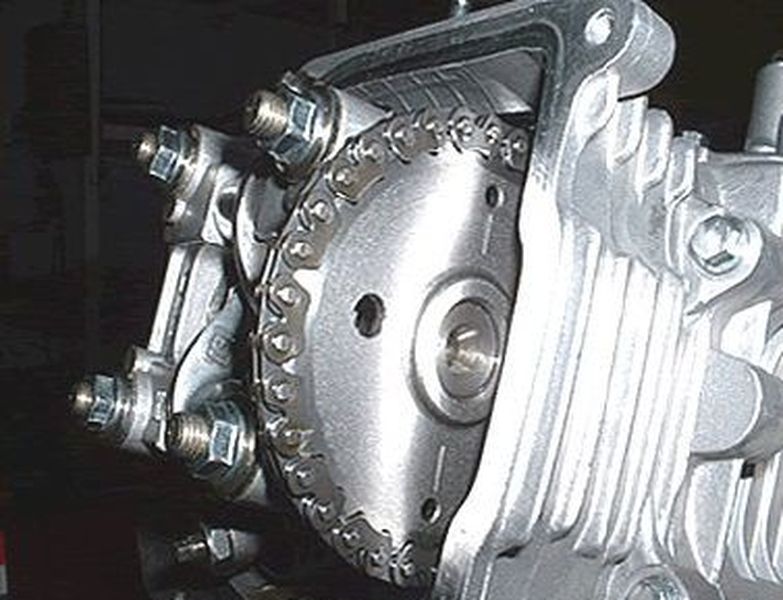

Reducer of the motor-block "Cascade"

Mechanical gearbox, chain. The clutch and manual transmission are the basic components of the transmission and are often housed in a special block.

The output shaft of the reinforced gearbox is located on bearings with a significant diameter, which steadily react to mechanical damage and the negative impact of various kinds of vibrations.

Figure 3. Scheme of the "Cascade" gearbox

Oil seals (cuffs) of the motor-block "Cascade"

Oil seals seal the engine, protect against engine oil leakage and are installed in special places in the rotating parts of the engine. The oil seal is installed on the shaft and with its working edge tightly fits the working surface of the shaft. The oil seal can be replaced by yourself.

The replacement process is very simple:

- the cutters are removed from the shaft and cleaned of dirt and dust, then the cover fixing bolts are removed, the cover itself is removed.

- After that, the worn out gland is removed, a new one is put in its place, and a sealant is applied to the connector.

- Sizes of oil seals "Cascade": 42/28/7 (shaft 30 mm).

- The gearbox bearing of the "Cascade" walk-behind tractor has dimensions 941/20 (26 * 20 * 14 mm).

- Clutch of the motor-block "Cascade" of dry type. The clutch mechanism works by tensioning the V-belt transmission belts.

Belts of the "Cascade" walk-behind tractor - tension, dimensions, tension rollers

The Cascade unit has two types of belts: forward and reverse. Forward belt type: А-1180 or А-1213 GOST 1284; type of reverse belts: А-1400. The "A" value is 13 mm. The diameter of the tension rollers: outer - 92 mm, inner - 12 mm.

Today, motoblocks are perhaps one of the most popular agricultural techniques, which have found their application both in farming and in summer cottages. These units, without much difficulty, will process any soil with high quality in a fairly short time. Everyone knows that it is common for any technique to fail. This also applies to motoblocks. Now we will analyze several cases of breakdowns of the Cascade walk-behind tractor and give short instructions for eliminating them.

Read also How much propolis do you need for half a liter of vodka

Description

Motoblocks "Cascade" have established themselves as reliable assistants to the farmer. They are productive, durable machines capable of working with a full range of attachments, performing the functions of a cultivator, plowing machine, mower, snow sweeper and many others.

Timely maintenance of the walk-behind tractor is also important. For "Cascade", the maintenance schedule is the same as for any other household walk-behind tractor:

- scheduled maintenance: once a season, at the end of seasonal work and before their start (at the beginning and at the end of spring, at the beginning and at the end of summer, etc.);

- regular mini-technical inspection - every day upon completion of work and turning off the walk-behind tractor, as well as an external examination in order to identify damage, paint chips, etc.;

- winter storage - it is allocated in a separate category of maintenance, since it provides for the discharge of all fuels and lubricants and storage of the walk-behind tractor in a room with a positive temperature, upon completion of the winter "conservation", the unit is refueled with fuel and lubricants;

- annual engine prophylaxis (identification of malfunctions, their elimination, maximum extension of the service life of the engine and other key components of the unit).

Next, we will consider the basic rules and requirements for fuels and lubricants, the process of starting and running in the "Cascade" walk-behind tractor, as well as the most common malfunctions of these devices.

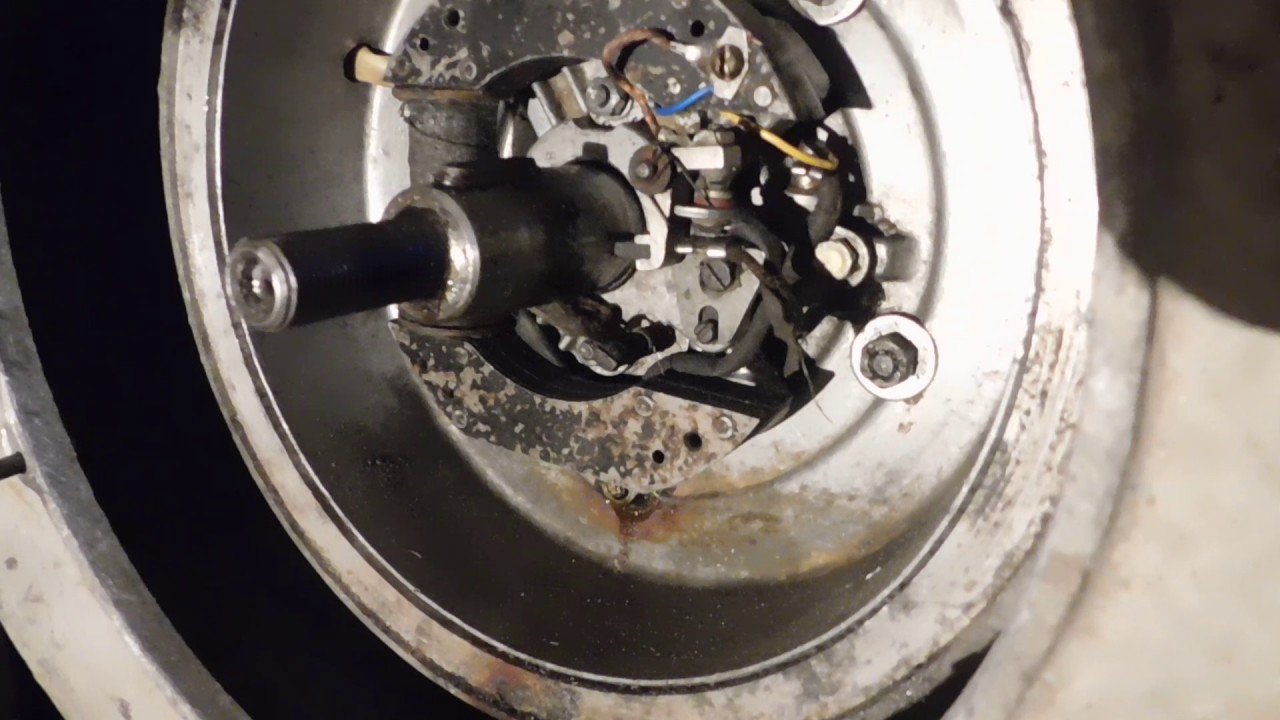

Checking the ignition coil

Before you check the ignition coil of your unit for possible problems, you need to understand exactly how it looks in a broken state. The farmer should have a visual inspection first. Often, breakdowns are caused by cracks, dents or similar mechanical damage on this spare part. If there are no such problems, the coil is intact, without visible defects, it will be necessary to make some additional checks of this element.

To do this, you need to know how to disassemble a walk-behind tractor and, at the same time, study in parallel ways to troubleshoot problems and their causes. The test is to change the resistance values of the coil.

This is interesting: why there is no spark at the Cascade walk-behind tractor.

This technique is not the most popular today, since not every farmer has information about what the optimal parameter of the winding resistance should be on the existing unit. Another difficulty in checking may be due to the fact that the resistance indicator includes semiconductor elements used to generate the required high-voltage pulse. Against the background of such a situation, when trying to ring the coil of a motor cultivator through a high-voltage or negative wire, a person will receive a too high resistance indicator, if before that there is no break in the circuit.

Another way to check ignition system parts is to use a spark plug. To do this, turn it out and attach it to the cylinder. Next, you need to pull the starter cable and see if a spark is formed between the contacts. At the same time, the master must understand that such a technique will not allow to determine exactly which of the elements is the cause of the breakdown.

This is due to the fact that during the test, the spark plug is under the influence of some pressure, due to which the flywheel is able to rotate faster than usual. Each of the above methods is advisable to use only in cases where the farmer does not have the opportunity to contact a highly qualified specialist. To do this, a person must have skills in working with electricity, as otherwise there is a risk of electric shock.

How to set the ignition on a walk-behind tractor?

The following signs will prompt you to urgently adjust the gap in the ignition system:

- the need for frequent unsuccessful pulling of the starter cord;

- late reaction of the walk-behind tractor engine to manipulations with the starter;

- complete lack of starting the internal combustion engine of the agricultural unit.

Each of these faults indicates that the operator must install the ignition of the walk-behind tractor used on the farm. The correct procedure for this can be found in the operating instructions for the existing equipment. However, the operator's manual is not always at hand. In this case, the gap between the built-in ignition module and the flywheel can be set in the following sequence:

- First, the operator must cover the candle with a special square;

- Then its body will need to be pressed against the head of the standard internal combustion engine cylinder;

- Next, the candle must be turned in the opposite direction from the hole provided in the end of the chrome-plated cylinder;

- After that, it is necessary to carefully turn the crankshaft of the engine of the walk-behind tractor - for this it is enough to pull the cord of the starting mechanism;

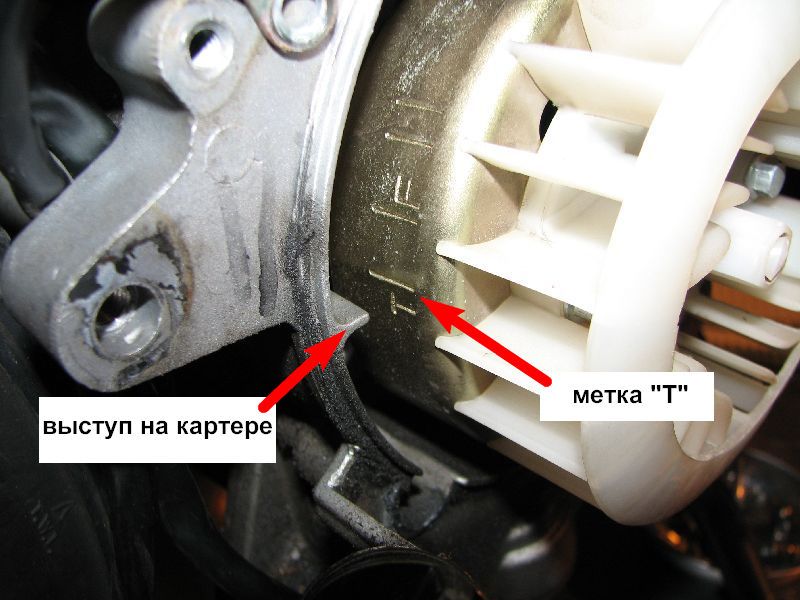

- As a result of the actions performed, a bright blue spark should slip between the built-in electrodes.If this does not happen, then it is necessary to check the distance between the magneto and the starter of the walk-behind tractor - it should be from 0.1 to 0.15 mm. If these requirements do not meet these requirements, the gap between the elements will need to be adjusted.

Many experienced users adjust the ignition of a household walk-behind tractor by ear. Both contact and non-contact magneto are suitable for this. To configure the system yourself, you must:

- Start the engine and slightly loosen the standard distributor;

- Slowly turn the breaker in each of the possible directions;

- Achieve the maximum speed of the factory engine and quickly secure the structure;

- Listen and find the moment at which a spark instantly appears;

- Turning the breaker, wait for a clear clicking sound;

- Fix the standard distributor fasteners.

In some cases, a stroboscope will help to correctly adjust the available gap.

To configure you need:

- Warm up the power unit of the walk-behind tractor;

- Connect the device to the power supply network of the agricultural unit;

- Install the sound sensor on the high-voltage wire connected to one of the cylinders of the standard internal combustion engine;

- Carefully remove the vacuum tube and plug it with any available means;

- See where the strobe light will be directed - it should "look" towards the standard pulley;

- Start the engine and leave it idling;

- Scroll the distributor;

- Once the marks on the built-in pulley align with the mark on the cover of the device being used, turn the nut of the factory breaker all the way.

Each of these methods is suitable for adjustment on both a gasoline and a diesel walk-behind tractor. The main thing in the self-tuning process is not to remove the coil and other elements of the ignition system - this can lead to a malfunction of the entire unit.