Model overview

The most common protective gloves of this kind are Kevlar models. It is worth mentioning what this material is - Kevlar. It is a special tough fiber that is cut resistant, although it looks like wool or regular fabric. This material is also used as inserts in some tracksuits.

The cheapest Kevlar gloves cost from 250 to 400 rubles on average in a regular building supermarket. As a rule, each of the gloves will fit either hand. Models with woven steel threads have received not very good reviews - the latter are knocked out and can slightly scratch the skin. They are resistant to various cutting objects - metal sheets and glass fragments. They are distinguished by a short wrist.

Other anti-cut Kevlar models, the price of which starts from 350 rubles and ends with 500 rubles, differ in a longer wrist. The main feature is that you can do smaller work in them (for example, twist self-tapping screws). The material of these models is denser and has a finer weave.

Another interesting option is SuperFabric gloves. They are ordinary woven gloves that are not cut with a knife, with an orange polyester coating on the inner working surface of the palm and fingers. The coating has a characteristic pattern. The main feature of the model is high resistance to punctures from syringe needles. The model and material developer is HerArmor.

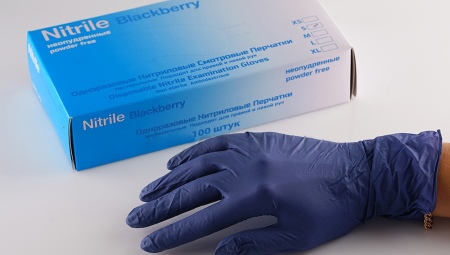

Among other similar gloves, the following models can be noted: products with a double nitrile coating, models with split handhelds, with a PVC coating.

DIN EN 407 - Protective gloves against high temperatures

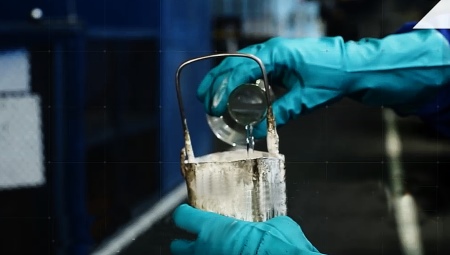

The European standard DIN EN 407 regulates the minimum requirements and special test methods for protective gloves with regard to thermal risks. Protective gloves certified to this standard protect a person from contact heat, heat radiation and molten metal splash.

However, this does not apply to the use of heat resistant gloves in firefighting or welding. Heat resistant gloves are designed for the following functions in accordance with DIN EN 407:

- low flammability or flame spread

- low heat transfer (protective effect against radiant, convective and contact heat)

- high temperature resistance

Protective gloves are classified and tested according to DIN EN 407 according to the following criteria:

Ignition protection:

the protective glove is exposed to a gas flame for 15 seconds. The measurement is then carried out until the glove material starts to burn / smolder. (Maximum efficiency level 4 = afterburn time 2 seconds, self-smoldering time 5 seconds)

Contact heat protection:

Measurement of the temperature (from 100 ° C to 500 ° C) against which the glove provides protection for 15 seconds, without heating the inside of the glove to more than 10 ° C. (Maximum performance level 4 = + 500 ° C)

Convective heat protection:

measuring how long the glove material can hold the temperature inside the glove above 24 ° C. (Maximum performance level 4)

Radiation protection:

the protective glove is exposed to heat radiation. Time is measured until a certain amount of heat has penetrated the inside of the glove. (Maximum efficiency level 4 = at least 150 seconds)

Molten metal splash protection:

measuring the number of drops of molten metal to raise the temperature between the glove material and the skin by 40 ° C. (Maximum efficiency level 4 = more than 35 drops)

Molten metal protection:

measuring the amount of molten metal pellets to damage the PVC synthetic leather (attached to the inside of the glove). (Maximum efficiency level 4 = 200 grams)

In accordance with the test according to DIN EN 407, the protective gloves are classified according to the level of effectiveness in relation to each of the individual thermal hazards (numbers 1 to 4, with 4 being the best)

It is important that the glove should not come into contact with an open flame unless it meets performance level 3 in the fire test.

How to choose and use?

It seems that there is nothing easier than putting on gloves and starting to use them. However, the process of choosing such products is not entirely straightforward. There are several characteristics for this, which we describe below.

Manufacturing material. There are now several fairly well-known synthetic materials that provide durability to products. You can stop your choice on any of them. Quite often, steel or other threads are also woven into the main material for making gloves. They add extra strength.

Purpose of application

It is important to immediately understand for yourself whether the gloves are only anti-cut or also heat-resistant. It is also important to distinguish between construction gloves and kitchen models.

Typically, heat-resistant gloves for household use will withstand temperatures up to 100 degrees Celsius.

Length. For work with a large number of small cutting parts, it is better to choose longer gloves for protecting hands.

The number of washes. An unusual but relatively important factor in product selection. The fewer washes allowed by the manufacturer, the faster the gloves will wear out and will sit poorly on your hands.

Manufacturer. Of course, the best, in comparison with domestic or Chinese production, is American or European. However, not all jobs require high quality, high density gloves. The main thing in this matter is the price suitable for the buyer.

In conclusion, I would like to note that when buying such gloves, you need to remember that the products should not only feel breathable, but also maintain the sensitivity of the fingers and the entire palm, without hindering movements.

Review of Kevlar anti-cut gloves in the video.