Varieties of hand riveters

Many craftsmen want to purchase a manual riveter. Which is better is a controversial issue, because there is a large selection of such tools on sale. Most often they are divided into 2 groups.

- Pull-out models involve pulling out the pin, due to which the aluminum rivet is expanded in the prepared hole. Such a device is quite simple to operate. Visually, it may resemble a pistol or scissors. The latter variety, known as the two-handed riveter, is considered a professional device.

- Threaded models require the use of special rivets. In the process of compressing the handles, the nut is tightened, after which it splashes, pulling the two parts together. Such a riveter is considered to be very reliable and quite expensive. Accordingly, it is practically not used in a domestic environment.

It is worth noting that both mentioned varieties can be equipped with a swivel head.

Thanks to this, it is possible to install rivets in hard-to-reach places, which is very important when performing a number of works.

Varieties of hand riveters

Many craftsmen want to purchase a manual riveter. Which is better is a controversial issue, because there is a large selection of such tools on sale. Most often they divided into 2 groups

.

- Pull-out models involve pulling out the pin, due to which the aluminum rivet is expanded in the prepared hole. Such a device is quite simple to operate. Visually, it may resemble a gun or scissors. The latter variety, known as the two-handed riveter, is considered a professional device.

- Threaded models require the use of special rivets. In the process of compressing the handles, the nut is tightened, after which it splashes, pulling the two parts together. Such a riveter is considered to be very reliable and quite expensive. Accordingly, it is practically not used in a domestic environment.

It is worth noting that both mentioned varieties can be equipped with a swivel head.

Thanks to this, it is possible to install rivets in hard-to-reach places, which is very important when performing a number of works.

As mentioned earlier, there is a large selection of manual riveters on sale, the price of which sometimes reaches 2–3 thousand rubles. To make the right choice, you need to decide on the purpose of the equipment. If you plan to frequently fix various rivets, then it is better to purchase more expensive professional equipment. Otherwise, you should give preference to the budget riveter model costing 150-500 rubles

As mentioned earlier, there is a large selection of manual riveters on sale, the price of which sometimes reaches 2–3 thousand rubles. To make the right choice, you need to decide on the purpose of the equipment. If you plan to frequently fix various rivets, then it is better to purchase more expensive professional equipment. Otherwise, you should give preference to the budget riveter model costing 150-500 rubles

.

When buying, it is worth remembering that the durability and reliability of the device largely depends on the accuracy of the master. So, even an expensive professional tool can be broken if handled carelessly.

In addition to the price of the riveter, it is worth paying attention to other factors.

Riveting material. If you plan on working with aluminum, any device will do. In the case when you need to connect steel parts, you will need more powerful equipment.

Ease of use. This is a very important factor. So, when working with fasteners that differ in diameter and material, it is worth using a two-handed riveter model

Also pay attention to the head

A rotary element is considered optimal, because it will help to perform riveting in difficult areas.

It is equally important to make sure that you have replaceable nozzles designed for different fasteners.

Among the additional functions of the riveter, it is worth noting the presence of a waste container. This is really important if you are planning to build a roof or fence in an area where small children are walking.

Operating tips

To work properly with the impact tool, you should always use only good quality rivets. Accordingly, they are the most expensive. Cheap options do not have good characteristics, and when the sleeves are tightened, their rod may break out ahead of time. As a result of this work, the rivet does not fit tightly to the hole, and the blade material does not bond well. When using the tool, you need to remove the fallen rivet shafts, as they are very sharp at the cut point and can be absorbed into the soft surface.

An overview of the Kraftool INDUSTRIE-PNEVMO 31185 z01 pneumatic riveter in the video below.

Description and scope of use

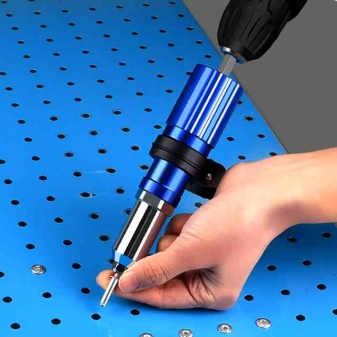

First of all, any electric riveter is a modern construction tool, the main task of which is to fasten individual parts together. Outwardly, this automatic unit is in many ways similar to the screwdriver familiar to many. At the moment, there is more than a wide range of models on the market that operate on a household power supply or rechargeable batteries.

The use of such a tool in the framework of installation work allows you to significantly reduce time costs and simplify the entire assembly process. It is also worth noting that, unlike manual riveters, their electrified counterparts do not require significant physical effort. When starting the device, uniform pressure is created on the shank of the rivet without any jerks. This contributes to the fact that the sleeve is tightened as smoothly as possible until the rod is biting off.

One of the key advantages of electrical models is, of course, the high quality of the connection created. At the same time, in the presence of physical strength and a certain practical experience, similar results can be achieved with the help of a manual (mechanical) riveter. However, the automated tool is designed to facilitate the riveting process. This is most important in confined spaces.

It should be noted that relatively recently, the described tool has a worthy competitor. We are talking about special rivet bits for screwdrivers and drills.

In fairness, it should be borne in mind that a specialized power tool still has one significant advantage. The fact is that these devices are equipped with containers for rivet shanks to be pulled out, which do not have to be removed manually. This in itself significantly increases the productivity and speed of installation.

It is important that the specified waste does not fall on the floor of the workshop. However, despite the indisputable advantages, not all models are equipped with such containers.

Electric rivets are used wherever rivets of various types are fasteners. Most often, we will talk about the assembly of structures and their individual elements, the parts of which are made of sheet materials. By the way, it can be not only metal structural elements. Today, this type of tool has found application not only in construction, but also in the furniture industry and the automotive industry.

Technique of use

Those who have already encountered a riveter know that using this tool is quite simple. The main thing is to remember the principle of work. Initially, everything should start with the preparation of the processed material. This procedure is carried out as follows:

- The metal surface is carefully leveled so that both workpieces fit well together (you can use a hammer).

- At this stage, both parts must be placed on a special wooden blank and secured well.

- Use a marker to mark points where small holes for rivets will be drilled. It is worth considering that this point must be performed with maximum accuracy so that in the future all the holes coincide.

- Using a conventional drill, holes are drilled for rivets. Be sure to consider the size of the drill and rivets. For example, if the hole diameter is 4.8 mm, then you need to take a 5 mm drill.

- At this stage, it is imperative to check that the fixing skirt fits snugly against the metal workpiece.

It is important to remember that the length of the rivets must correspond to the thickness of the fastened parts and the load that will ultimately act on them. Compact rivets are designed for metal sheets that will not be loaded

All further manipulations must comply with the scheme:

- It is necessary to correctly install the thin end of the rivet in the sharpener so that the nozzle sits in place.

- The rivet head is positioned exactly in the hole on the part. It is worth considering that the rivet should protrude slightly, no more than 12 mm.

- On the top of the part, you need to put on a rivet, which should be located perpendicular to the base.

- Now it remains to make a strong hold. If, after this procedure, the rivet leg does not fall off, then you need to make several powerful attacks.

In order for the result of the work done to differ not only in quality, but also in durability, it is necessary to carry out a broach with a lever system. In this case, it is better to choose a mounting wire made of steel. Due to the strong pressure, peculiar overlays are formed at the edges, which will provide reliable adhesion. If the metal workpiece will be subjected to heavy loads, several rivets should be placed along the joint. All wire pieces must be removed from the tool. A slotted screwdriver is best suited for this.

Principle of operation

How to use a riveter is perhaps the most important question that interests the master. In order to create a reliable connection, during its execution, you must adhere to the following algorithm of actions:

- Surface preparation.

- Marking and hole drilling.

- Installation of fasteners.

At the first stage, it is necessary to align the surfaces well so that the most tight contact between the parts can be ensured.

When starting to drill holes, make sure that they are located strictly in one line. For the proper performance of this operation, it is recommended that the surfaces be placed on a flat surface, for example, a piece of wood, to which they should be fixed. After that, they proceed to drawing the locations of future holes. Next, they begin to make holes, making sure that on each part they are located exactly in the designated places.

An important task is to ensure that the hole size matches the required parameters. To do this, it is recommended to take a drill with a slightly larger diameter.

For example, if you are creating a 3.8 mm hole, you should use a 4 mm drill.

When the holes are ready, be sure to "try on" the prepared fasteners. If everything is done correctly, then the rivet head will tightly adjoin the surface in the area of the hole edge and completely cover it.

At the final stage, rivets are installed, adhering to the following order:

- First, the cylindrical body of the rivet must be placed in the drilled hole of the elements to be joined.

- With the help of a riveter, you need to grab the rod passing through the whole body, and it must be fixed with the lips or the riveting head of the tool directly at the base of the cylinder head.

- Exerting the necessary force on the rod, it must be pulled through the rivet body, simultaneously expanding it with a cap and deforming the end of the cylinder. As a result, you should have the opposite wide part of the rivet on the inside of the connected elements.

- Having selected the necessary force for the riveter, the parts are securely connected, after which you will only have to break off the protruding parts of the elongated rod.

In most cases, when using a manual riveter, you have to press the lever several times to achieve the desired result. After connecting the elements, the head of the rivet body will be located on one side of it, and the flattened end of the cylinder, looking like a group of petals, will be located on the other side.

Description and principle of operation

The pneumatic riveter is a special tool whose function is to install blind rivets and rivets. The tool is highly durable and vibration-resistant. The result of his work can be compared to spot welding. It is widely used in professional activities and in everyday life. To work with this tool, it is necessary to attach the materials to be fastened to each other and drill a through hole in the right place.

First, we select a sleeve of the required size for the riveter so that it matches the circumference of the rivet rod, then insert it into the tool and secure it with a wrench. We set the rivet with a rod close to the surface so that the tip completely enters the hole. We inspect so that on the other side the head looks out at least 1 cm. Slowly press on the riveter until it comes into full contact with the head and remove the lever several times until the leg is formed.

How to choose a quality tool

Now on the market there is a huge selection of manual riveters. Before buying, you should immediately decide on the main purpose of the tool and the ability to work with it. When it is very often necessary to rivet parts together, then it is worth buying an expensive professional tool. For simple homework, you should choose a model in the middle price range.

Do not forget the fact that the reliability and durability of the riveter depends on the skill level of the worker. Even a high-quality professional pistol breaks down if used poorly.

In addition to the cost of the tool, it is necessary to take into account other features.

- Rivet material. When you need to fasten aluminum parts, you can buy any tool. If you plan to work with steel, then you should give preference to a high-quality professional riveter.

- Convenience of work. This can be called the most important criterion. When working with fasteners that differ in material and size, it is necessary to use a two-handed type of tool. Additionally, you need to consider the head. A pivoting design can be considered ideal. This helps to hold items together in hard-to-reach places. Another important point is the availability of several replaceable nozzles, which are made for various types of fasteners.

Another useful function of this tool is considered to be the presence of a special container for metal waste. It is very important when you need to build a roof or fence in a place where small children can be.

How to use a riveter?

So that the use of such a tool does not cause difficulties, you must first prepare all the details. They are carefully applied and marked. After that, it is worth putting on protective gloves and making a hole that will exceed the rivet diameter by 2 mm

So that the use of such a tool does not cause difficulties, you must first prepare all the details. They are carefully applied and marked. After that, it is worth putting on protective gloves and making a hole that will exceed the rivet diameter by 2 mm

... All movements must be accurate and fluid. If you want to mask the rivet, flare.

The fasteners themselves are carefully inserted into the tool, and the cap is placed in the prepared through hole.After that, it is necessary to put on the working head of the riveting machine and press the handle. Thanks to this simple movement, the parts will be firmly connected.

Competent operation of the riveter presupposes following simple guidelines

.

Rivet size must be carefully selected. Otherwise, the connection may not be strong enough. If the size was not chosen correctly, then one compression of the handles is not enough to fix it.

To install the fasteners, the rivet head must first be pressed down and only then the handle must be pressed.

Various materials can be used to create rivets, including stainless steel, aluminum and steel

For a really strong connection, it is important to choose rivets and parts from the same material.

When working with the tool, it is imperative to use protective gloves and goggles.

It is important to study the instructions in advance to help avoid major mistakes.

The riveter should be carefully examined. If any of its elements turns out to be inoperative, it is worth contacting a master who professionally repairs tools.

Thanks to the development of modern technology, riveting has become a simple activity that takes a little time

... This is facilitated by the use of a rivet. It is a handy hand tool that makes it easy to fix metal elements.

- Scope of the tool

- Difficulties in working with a riveter

A special joining gun can be useful for joining parts, but not everyone knows how to use the riveter correctly, and what safety recommendations are there.

A riveter is required for joining parts.