Komatsu

The Japanese company Komatsu is a world leader in the production of various construction equipment. Wheeled and crawler excavators from this manufacturer are on the market. Mini excavators Komatsu stand out separately.

Crawler excavators are characterized by low ground pressure and high maneuverability. This advantage allows them to be used in places inaccessible to wheeled vehicles, as well as in swampy areas and on soft soils. Detailed specifications and features are presented in the table.

Table 1. Crawler excavators Komatsu

| Excavator model | Operating weight, t | Bucket capacity (SAE), m? | Engine power, (kW) | Unloading height | Flywheel power, kW / h.p. | Maximum boom reach | Excavation depth, m |

| Komatsu PC600 | 57 | 3,7 | 294 | 8,2 | 125 / 168 | 10 | 3,4 |

| Komatsu PC750 | 76 | 4,5 | 334 | 8,1 | 338/454 | 10,1 | 3,2 |

| Komatsu PC1250 | 110 | 6,5 | 479 | 8,7 | 485/651 | 12,7 | 3,5 |

| Komatsu PC1800 | 180 | 11 | 668 | 9,6 | 676/1800 | 13,1 | 3,22 |

| Komatsu PC3000 | 253 | 20 | 926 | 9,5 | 940/1260 | 13,4 | 3,9 |

| Komatsu PC4000 | 370 | 28 | 1379 | 10,3 | 1400/1875 | 15,1 | 3,9 |

| Komatsu PC5500 | 500 | 34 | 1853 | 14,4 | 1880/2520 | 16,7 | 3,0 |

| Komatsu PC8000 | 700 | 48 | 2956 | 10 | 3000/4020 | 15,7 | 3,3 |

Wheeled excavators are used in municipal services, in the repair of heating mains, water pipelines, as well as in carrying out various earthworks. The pneumatic wheel drive allows this heavy equipment to move on public roads. Their movement speed is at a height, which makes it possible to quickly move between objects. The performance of these machines allows you to cope with complex tasks under tight deadlines. The characteristics of this technique are presented in the table.

Table 2. Specifications of Komatsu Wheel Excavators

| Model | Weight, kg | Bucket capacity, m? | Engine power, kW | Digging depth, m | Overall dimensions, m |

| PW 160-7 | 16470 | 0,2-0,97 | 90 | 5,42 | 8,29/2,5/3,5 |

| PW 180-7 | 18410 | 0,38-1,13 | 107 | 5,3 | 8,9/2,5/3,995 |

| PW 200-7 | 20860 | 0,48-1,68 | 118 | 5,4 | 9,43/2,54/3,9 |

| PW-220-7 | 21650 | 0,48-1,68 | 118 | 5,4 | 9,44/2,785/3,909 |

Small-sized Komatsu equipment is in demand for urban or suburban conditions. The company offers a range of mini excavators assembled at factories in Japan and China. The weight of the models depends on the configuration and ranges from 3.7 to 6.3 tons. This technique is supported by the advantages of mini versions of excavators.

Such as:

- joystick control;

- comfortable reclining cab;

- hydraulic system CLSS;

- automatic gear shifting;

- reduced turning radius of the platform.

The outer skin contains rubber components. The characteristics of Komatsu mini equipment are shown in the table.

Table 3. Specifications of Komatsu mini-excavators

| Technical specifications | PC35MR-2 | PC50MR-2 |

| Operational weight, kg | 3580-4025 | 4765-5255 |

| Engine power, kW | 21,7 | 29,4 |

| Digging depth, mm (standard and extended stick) | 3170/3510 | 3800/4160 |

| Transport speed, km / h | 2,8-4,6 | 2,8-4,6 |

| Track width, cm | 1740 | 1960 |

Compact dimensions did not prevent the manufacturer from equipping a comfortable and functional cab for the operator. This was achieved thanks to the use of modern principles of ergonomics by designers.

Komatsu is a robust machine that can operate at different temperatures and in difficult conditions. It is distinguished by high performance, low fuel consumption, and compliance with modern environmental standards.

1 Creation technology

The main material for such shovels is rail steel saturated with carbon. The material is characterized by high strength and low weight, which is the best option for a working tool. Often old rails or rails that do not meet the required conditions are used for such purposes. The resulting metal is packaged, after which it is processed.

The double hardening method is often used to create rail steel shovels. It allows steel to retain a maximum percentage of carbon, which increases strength. In addition, tools made of steel containing enough carbon have high resilience, which makes them resistant to stress.

Rail steel shovel

After the preparation of the steel is completed, the process of direct production of the tool begins. It includes the following items:

-

sheet metal is cut into parts commensurate with the future blade;

-

carries out the molding of the workpiece on the press, as a result of which the tulle and the necessary bends appear on the metal workpiece;

-

bending of the already formed edges of the tulle is carried out, as a result of which an already formed shovel blade is obtained;

-

the profile of the tulle is closed by welding or stamping;

-

the cutting edge is sharpened;

-

the new production is covered with an anti-corrosion coating, which will protect the tool from rust and abrasion during operation;

-

the canvas is put on the handle.

In order to correctly bend the canvas in the area of the tulle and on the profile itself, the metal is heated to a temperature of 870-950 degrees. At such temperatures, the steel goes into a state of hot plastic deformation, which allows it to be shaped without harm to the structure and qualities of the material.

Quite often, at the same stage, the canvas is equipped with a pair of additional stiffeners. They are installed closer to the handle, in those places that give in to the greatest load during operation. This increases the strength of the tool.

Rail steel shovels

Sharpening of the cutting edge is carried out at an angle of 20 degrees. This allows you to achieve high cutting performance, while maintaining maximum strength and resistance to material wear.

When sharpening, it is important not to reduce the fineness of the material below 0.5 mm, otherwise the material will be too fragile

As a coating that counteracts corrosive processes, special paint or varnish, powdery polymer or galvanized are used. To coat the web with polymer, a static electricity system is used, which attracts the powder polymer to the web like a magnet, after which the shovel can be processed at high temperatures.

The type of shovel made of rail steel does not affect the general direction of the manufacturing process, only the specifics change. A stamp is put on the finished product, which conveys data on the production process.

1.2 Advantages of Rail Steel Shovel

Of the advantages of shovels made of rail steel, the following should be noted:

-

High strength and balanced elasticity. These qualities are ensured by a durable material and a special hardening method. Moreover, the elasticity of the metal base allows the shovel to bend slightly under load, and then return to its original position. This means that deformation does not threaten such a tool.

-

Low weight. Despite the strength and density of the material, the high carbon content makes the shovel lighter than forged steel tools. This increases working comfort.

-

Resistant to wear and corrosion. Resistance to corrosive processes is provided not only by the specifics of the material, but also by anti-corrosion coatings, which cover most of the rail steel shovels.

-

Low price indicators. Rail steel shovels on the market are slightly more expensive than forged steel and stainless steel shovels.

-

Self-sharpening during operation. Rail steel shovels, due to their structure, do not lose their sharpness even when working with hard types of soil, roots, frozen ground. And the sharpening adjustment is carried out during operation.

Description

Rail shovel from the manufacturer differs in the main advantage - durability. This factor is completely related to the basis from which the instrument is made. Rail steel contains a sufficient amount of carbon. This provides not only high strength, but also lightness. Robust modern tools don't necessarily weigh a lot.

In the course of work, rail shovels have the ability to self-sharpen. The edge of the tool cannot be damaged, even if it chops wood. Professional workers in the construction industry and ordinary summer residents have long appreciated the quality of rail steel tools, they are in great demand.

Therefore, it is offered by many manufacturers. Russian goods have acquired positive characteristics.A lot of negative qualities are attributed to foreign products, especially Chinese ones.

The quality of the product depends on the grade of steel used in production. After all, even rails are subdivided by type, which is associated with the strength of the products. For example, heat-resistant rails of the highest quality are referred to category "B", and non-heat-strengthened - to category "H". Other products are subdivided according to the method of smelting:

- M - open-hearth;

- K - converter;

- E - electric steel.

The shovels are made from the third version, which is double hardened during production. The material enhances its own strength properties, gaining additional elasticity.

Even with an increase or decrease in the humidity to which the tree is exposed, the shovel itself will not lose its advantages. Shovels made of ordinary steel often deteriorate due to poor welding of the liner and blade. Due to the springy qualities of the rail products, even with an increase in pressure, there will be no resistance forces. Because of this, rail shovels are sturdy. It is allowed to use them for other purposes, for example, for chopping ice or wood.

Stalk

Today, models appear with cuttings made of metal, plastic and other materials, but wood, for good reason, is considered the best option.

Pine stands out for its low price and therefore is widely used. Low quality and fragility are the consequence of cheapness. Pine cuttings can be poorly dried and gnarled.

Acacia is much stronger and more reliable, but at the same time more expensive.

Oak is superior to acacia in quality; such a shovel handle will last more than one year. The disadvantages of oak are the high price and weight.

It is easier to use a shovel with a handle than the classic model: the hands will not slip, which means that the load on the hand will also decrease. The handle is a T-shaped or triangular attachment for the handle. Leaning on it, you can conveniently dig a trench. The triangular handle is suitable for a shovel, but when harvesting, the nozzle will be ineffective.

Device and characteristics

A standard shovel consists of the following elements: blade, shank, tulle.

Canvas

This is a working part, the shape, dimensions and parameters of which indicate the type of work for which the tool is intended.

So, for example, a conventional digging shovel has an almost flat, pointed blade with a sharpening.

And for grain tools, the working part is bent in the shape of a bucket, longer and wider.

It is used for picking up and loading bulk materials with a low specific weight.

The sharp edge of the blade is called the blade.

Its sharpness corresponds to the purpose of the shovel.

The bend at the top of the canvas is called an offensive (not every tool has).

It is on him that the foot of the foot is pressed when the canvas is introduced into a solid environment.

Shank (grip, handle)

The part of the tool by which it is held during operation.

For convenience, at the end of the handle, some models have a so-called fork or T-shaped handle.

The holder can be made of a single piece of material (monolithic), or it can consist of several tubes - knees, which, when transporting the tool, fold, like modern fishing rods.

Telescopic options are good because they allow you to adjust the length of the handle to improve the convenience of working with the tool.

Tuleyka

A detail that holds the handle firmly in contact with the blade.

It can be structurally an integral part of the web, and a separate part in the form of a sleeve.

The latter option is mainly equipped with folding models.

Canvas material

The blade of the shovel is always made light, while it must be strong enough.

The only material that meets these characteristics, but at the same time has a low cost price, is steel.

For this reason, steel products are the most common.

There is a store classification of the characteristics of this material:

- • Rail (spring) steel, similar in characteristics to that of which railroad rails are made. The tool is not subject to corrosion, strong and durable; only titanium shovels can compare with it, which, among other things, are also much lighter.

- Red-hot - used mainly for gardening and horticultural purposes.

- Polished is a great choice when working with sticky materials such as clay. Polishing the blade significantly reduces friction on its surface.

- Stainless steel - it is quite rare, it is indispensable when working with aggressive materials (cement and other solutions).

- Teflon coated or powder coated. Neither clay nor viscous soil sticks to the canvas with such a coating. Often found on "American".

Metal shovels are used for those jobs where increased tool strength is required.

Where serious loads on the canvas are not expected, but lightness is needed, for example, when clearing snow, aluminum products are used.

A cheap and at the same time quite suitable for use analogue is wooden shovels, where the canvas is made of a sheet of thick plywood.

Such a tool can be made independently, and factory modifications are used in bakeries.

Another material suitable for such purposes is plastic.

Durable plastic shovels are used both for clearing snow and for picking up various small debris.

Household scoops, by the way, are made of just this kind of plastic.

Unlike the iron versions, nothing sticks to the plastic, tk. everything glides well on its surface.

Handle material

Only two materials are used to make the cutting:

- Metal. A tube made of steel or lightweight alloy, reliable and comfortable, has a low weight. Nevertheless, it is expensive, cannot be repaired, it “freezes” your hands in the cold, has only 3 dimensions.

- Wood. The shank has a diameter of 45 mm, it is easy to replace it in case of breakage, and it is cheap.

It is also easy to cut the tree to the desired length.

On the other hand, the handle can only be straight, and its weight is greater than that of the metal version.

Dimensions and weight

In everyday life, the following shovels are more common than others, standardized in accordance with GOST:

- Digging pointed. Width, height and thickness of the canvas - 210/285 / 1.6 mm. Weight - up to 0.98 kg.

- Solution: 240/270 / 1.6 mm. Weight - up to 1.3 kg.

- Scoop grain: 235/305 / 1.0 mm. Weight - up to 0.75 kg.

- Carbon: 340/350 / 1.6 mm. Weight - up to 1.64 kg.

- Pedigree: 325/350 / 1.5 mm. Weight - up to 1.29 kg.

- Snow removal: 330/375 / 1.0 mm. Weight - up to 1.4 kg.

What and how to make

The designs, as you have seen, are different, but the set of materials will be about the same. Their number differs, but the section and characteristics remain unchanged.

You can use a round or profiled pipe, metal rods or "parts" from the forks

Materials for making

Basically, they start with the manufacture of the frame. It is often made from a profiled pipe, the optimal section is 30 * 30 mm or so. In this case, the wall thickness is important - at least 3 mm. Some models used a corner. The shelf width is also about 30 mm, the metal thickness is at least 3 mm.

The handle can be made from the same profile pipe, you can use a round one. The wall thickness is also important. In principle, having made a retainer, you can use a wooden shovel holder. Some purchased models provide for the installation of a wooden holder.

The focus should be on the material used for the fork teeth. It must be good structural steel.

Forks are made from a bar of at least 8 mm in diameter.

What do their craftsmen make of:

- Cut off from an ordinary pitchfork, welded onto a miracle shovel.

- Straighten the suspension springs.

- Automobile springs are cut into narrow strips.

If you can find a good bar - round, square or hex - it doesn't matter, it will be much easier for you. Not a bad option, by the way, with a pitchfork

But you have to take good ones, and that is not cheap. And one more thing: calculate the dimensions of the miracle shovel so that the working forks have 8 pins. Then you will need to buy two common pitchfork jokes.

If the design is chosen with two forks - working and persistent, you can put pieces of a suitable length of a metal bar on the persistent ones. The loads are not so high here, so there should be enough strength. The diameter of the bar is 10 mm, you can use ribbed reinforcement, which is used when reinforcing the foundation.

Most companies that produce miracle shovels have a range of sizes for this product. Our people are different in build and physical fitness. For men, you can make more massive models, and for women and older people - smaller and lighter. On average, the dimensions are:

- The width of the working part is from 45 cm to 60 cm. There is no need to do more: it will be difficult to dig and the productivity will only decrease, not increase.

- The length of the pins of the working forks is 220-300 mm.

- The distance between the pins is 70-80 mm.

- The length of the handle is by height, it is more convenient if it ends in the shoulder area.

The dimensions of the miracle shovel can be selected "for yourself" - it is important to work comfortably

All other dimensions are selected depending on the design and the material used.

Working fork miracle shovel

Detail of the stop and stop forks

Full front stop design

Single-fork version with support frame at the back

Other digger sizes and different design of the stop

Easy-digger with one-piece bent handle

Do-it-yourself shovel miracle - a revolution in gardening

Keeping your own garden is a diverse activity. On the one hand, it's nice to cut fresh greens in the spring, enjoy the berries in the summer, and dig up a few bags of your own potatoes in the fall.

The other side of the coin is caring for the crop during the growth process, and the hardest work is digging up the site. Moreover, this must be done twice. Autumn and spring. Otherwise, you will have to forget about the harvest.

The classic version of the tool is a bayonet shovel. It allows you to process the soil of any complexity with high quality, but the work takes a lot of time and effort. There are walk-behind tractors, electric cultivators, in the end, you can call a tractor driver with a plow.

However, all these processes require capital investments, bringing the cost of the crop closer to the store one. Therefore, most gardeners - gardeners prefer to work with their hands. To facilitate the hard work of the summer resident, a wonderful tool was invented - the miracle of a shovel.

The Super Digging Shovel is a symbiosis of a pitchfork and a sled. Sharp teeth quite easily pierce the ground, with the help of a lever in the form of a long handle, a large butt of the earth rises and loosened against the second part of the forks, which are on the surface.

Of course, the device can be bought in a store, or you can make a miracle shovel from scrap materials with your own hands.

Do-it-yourself blade for a walk-behind tractor, drawings, video

Many owners of agricultural machinery are interested in whether it is difficult to make a blade for a walk-behind tractor with their own hands, because a homemade shovel is no worse than a purchased one, and besides, there is an excellent opportunity to save money.

If you use improvised materials, a sheet of steel, an old barrel, a gas cylinder, a pipe and elbows of a suitable size, then the price will drop dramatically.

We offer several different ideas with drawings that will help you make universal equipment with your own hands.

Shovel from a barrel to a walk-behind tractor

Do not rush to throw out the 200 liter barrel, which takes up space in the garage, make an assistant out of it - a shovel-blade, which will help out in various situations. We offer several diagrams and drawings that will help you create this attachment:

After a detailed study of the drawings, prepare all the necessary equipment and materials. To work you will need:

- tin sheets, at least 3 mm thick. The dimensions of the sheets must be 85 x 22 x 45 cm;

- 1 metal stand - a steel pipe is suitable for this;

- 4 stiffening ribs, about 4 mm thick;

- a strip of steel long enough to cover the blade. The thickness of the strip must be at least 5 mm;

- 2 lugs for fastening the blade rod;

- a set of washers and nuts;

- square pipe, with a cross section of 4 × 4 cm and a length of 1 m;

- a set of drills with a diameter of 5–6 and 8–9 mm;

- a flat piece of rubber;

- 2 rods, 52 cm long each;

- 1 sheet of steel, 10–12 mm thick with dimensions 60 x 60 cm;

- welding machine;

- grinder with discs for cutting steel;

- hammer drill or electric drill.

These photos, diagrams and drawings will help give a second life to an old unnecessary gas cylinder:

Homemade blade-shovel made of sheet steel

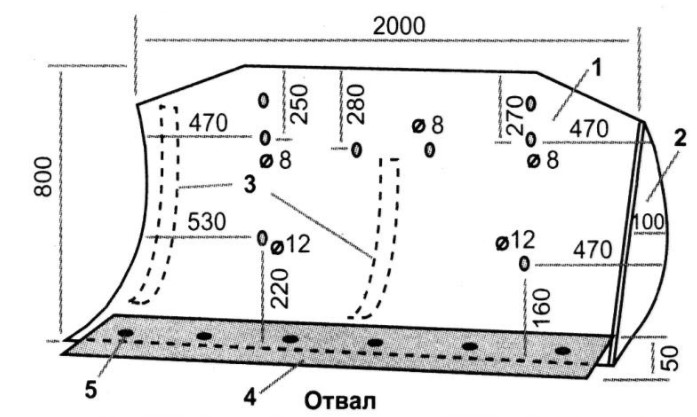

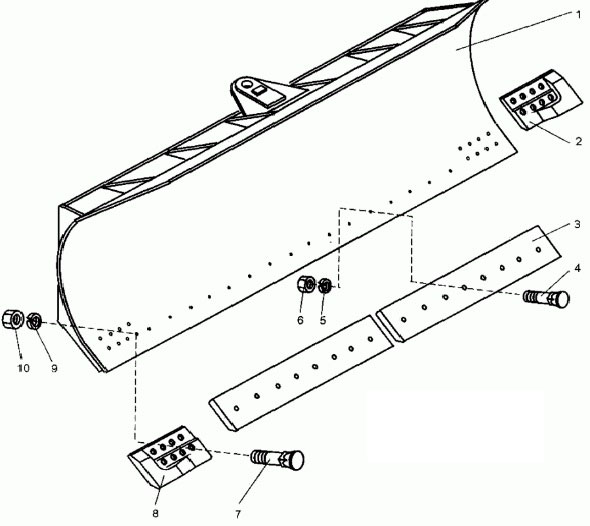

If you have sheets of steel or tin with a thickness of 2-3 mm on your farm, then you can make an excellent blade-shovel from this material. We propose to study the diagrams and drawings, where all the required dimensions are indicated.

Stalk

Although not as significant a parameter as the previous one, but still of considerable importance

And above all, what is important is what the stalk consists of. Three options are possible here

Wood

The most common option, since it combines two positive features at once: acceptable cost and quality. In addition, the wood does not freeze hands when working in cold weather. The wooden part can be cut to the required length, and in case of breakdown, it can be easily replaced with a new one.

Of the minuses - considerable weight. It is worth noting that the tree is subject to natural deterioration: it cracks, dries up, molds. However, most of these problems arise from improper storage.

Cheap cuttings are made from pine, but they are distinguished by low operational properties, such a handle has to be changed to a new one pretty soon. More expensive products are equipped with birch and acacia handles. Cuttings from larch, oak and ash are considered to be the leaders in strength.

From whatever species the handle is cut, it is important that the wood is well polished and that there are no chips, cracks or knot marks on its surface. Otherwise, there is a risk that under heavy load, the handle will simply break.

In some cases, the wood is coated with varnish or paint. This allows you to protect it from decay, but complicates the selection process: there is a risk that low-quality material is hidden under the coating layer.

Metal

The shank is made of aluminum or steel. It is a hollow tube, which can be of a special shape, not just straight, like a wooden handle.

These tools are quite reliable. At the same time, aluminum is also distinguished by its low weight. But such devices "cool" hands in the cold, are more expensive than wooden ones and have a limited range (only three sizes in length). In addition, the handles cannot be replaced and in the event of a breakdown, you will have to buy a new shovel. And the price for them, as they say, “bites”.

Carbon fiber

Composite material with excellent performance characteristics: strong, non-breaking, lightweight. But unfortunately, the cost of such a tool is unlikely to please you.

Plastic

It stands out for two advantages: low weight and low cost. This is where the advantages end, because the technical characteristics of such handles are far from brilliant: they do not withstand the slightest serious load, they can crack from impact - in general, fragile and short-lived.

It is necessary to carefully consider the selection of the cutting parameters. The standard length is 120 cm, but it is advisable to select the equipment for your height: the shovel should be 10 cm below your shoulder. The ideal cutting diameter is 40 mm. Larger or smaller sizes can lead to quick fatigue.

In addition to simple straight handles, there are other types. Shortened versions are used for small operations. They are also suitable for adolescents and those who, for health reasons, are not able to handle large objects. They have less functionality, but they are much lighter and more compact.

Curved are used mainly for American shovels.In telescopic models, the handle folds and spreads like a vacuum cleaner pipe. This solution makes it possible to easily adjust the length of the tool to your height. In addition, they are easy to store and transport.

Special-purpose shovels

The listed five types of shovels are the basis that provides 100% of human needs in gardening and construction. However, there are many options created for extreme and military conditions, as well as for a specific function.

Military shovels. There are two types - infantry (MPL-50, BPL-110) and sapper (MSL-50, BSL-110). The sapper is also used as a weapon.

Tourist shovels. These are combined folding products that combine a shovel, bayonet, saw, ax and other tools. Folding or telescopic design. The price of a decent tourist shovel is about $ 100. e. Cheap counterparts are unreliable due to savings in material, but cost from 15–20 USD. e.

Superlope from China on video

Other special shovels. In this category - scoops of cleaners, wooden shovels of bakers, four-meter shovels of steelmakers, pick-up scrapers and a whole armada of home-made devices for different needs.

DIY winter shovel on video

Handle selection

In the old days, only wooden cuttings were offered to the target contingent to assemble the heroine of the theme.

Now the instrumental segment has expanded and the traditional woodland has been pushed aside:

- Aluminum - makes the work item lightweight, durable and rustproof;

- CFRP - its handles are not as strong as aluminum, but they are also lightweight and resistant to corrosion;

- Plastic - makes the structure lighter and cheaper, but does not cope well with the loads;

- Steel - significantly makes the device heavier, but makes it durable.

The question is, what is the best holder if they all have their pros and cons? Typically the handles listed are sold with tapered ends.

For this reason, these models must be selected based on the complexity of the soil and the general work plan. It is not worth saving either on the cutting part or on the handle.

For different uses, you can limit yourself to a wooden handle. It is maintainable and affordable. It is made from different species - pine, ash, birch, aspen.

Worst pine, best aspen or ash, moderate birch

Also, when choosing a wooden shank, you need to pay attention to the knots. Because of them, the array quickly breaks down

The handles are also telescopic so that they can be folded. But this feature is not so useful when a lot of work is at stake. In addition, frequent loads wear down the folding mechanism.

Purpose of the tool

A shovel is a device that allows you to perform certain types of work in various areas of life. With this tool, you can quickly and easily dig, clear and transfer land and other materials. In our age of development of modern technologies, builders, janitors, firefighters, military men, metallurgists and people of other professions still cannot do without a shovel.

Using a bayonet tool, you can perform a number of excavation and agricultural work, a sapper shovel is included in the shooter's outfit and is used as a cold weapon, a large sapper is an important component of a set of army vehicles, a snow plow is used to clean the roadway and pedestrian sidewalk, a garden shovel will help to carry out work on own personal plot, loading is used at vegetable warehouses on a par with solid wood, a garbage scoop is designed for garbage collection, a bread scoop will help plant and remove products from the oven. The gardener will need several types of tools.

If you plan on working on soft ground, a steel shovel with a birch or plastic shank is suitable. It is lightweight and makes digging fun. For soil with dense turf, it is rational to use a universal bayonet garden shovel with a titanium blade.The earth will not stick to it, and subject to regular sharpening, the product will last for many years. For tough rocky soil, it is better to buy a shovel made of durable steel with powerful teeth and a multi-layer plastic handle. It will withstand any digging load with flying colors

The gardener will need several types of tools. If you plan on working with soft ground, a steel shovel with a birch or plastic shank is suitable. It is lightweight and makes digging fun. For soil with dense turf, it is rational to use a universal bayonet garden shovel with a titanium blade. The earth will not stick to it, and subject to regular sharpening, the product will last for many years. For tough rocky soil, it is better to buy a shovel made of durable steel with powerful teeth and a multi-layer plastic handle. It will withstand any digging workload with flying colors.

Types of smart tools

Before buying a miracle shovel, you should carefully study the varieties of this tool on the market. The choice must be made, taking into account the nature of the work for which the device is being purchased, the available budget and reviews about the manufacturer.

Among the popular models of smart shovels are:

- Excavator. These attachments are equipped with sharp teeth that easily enter the ground, making digging and loosening of the garden easier. The depth of tillage is influenced by the length of the selected cutting and, of course, the efforts of the gardener. On sale you can find models with forks from 5 to 8 teeth.

- Mole. The bayonet depth of this shovel is at least 25 cm. This hole is optimal for planting vegetable crops. The tool is produced with steel and reinforced forged teeth of different widths.

- Archimedes' shovel - popular with gardeners due to the presence of a small foot lever, pressing with the foot on which provides soil cultivation without much effort.

- Plowman. This shovel is designed on the principle of a lever system. The lever ensures the passage of the movable teeth through the fixed ones fixed on the frame. Thus, there is a thorough loosening of the soil, without raising and turning over the clod of earth by the gardener.

- Tornado is an improved version of the previous model. This tool is lighter and features durable powder coated teeth. It is good for uprooting weeds. But he does not cope efficiently enough with loosening the compacted soil.

- Kozma is a budget model of a shovel for digging and loosening the earth without turning the layer and digging out root crops. It is also convenient for cutting grass. The tool has an additional metal bar to support the foot during work.

- Gaidamakha is a miracle pitchfork for loosening the soil of Ukrainian origin. They increase the productivity of digging a vegetable garden by 5 times. The absence of wooden parts significantly extends the life of the tool.

The work will be easier on pre-moistened soil. But you should be aware that this tool is not suitable for processing virgin, soddy, stony and highly clayey soil.