Criterias of choice

The most important criteria by which a vibratory platform is selected is its ability to reverse and the weight of the unit. To choose the right tamping tool for a summer residence, for concrete or asphalt, you must be guided by the following principles.

- To carry out landscape works for private use, units are used, the weight of which does not exceed 80 kg, and the depth of soil processing does not exceed 150 mm. If it is required to lay paving slabs, then a polyurethane mat with a damping function must be added to the equipment.

- Vibratory plates weighing 80-120 kg are used to repair the asphalt pavement or to change the landscape, as well as to lay engineering communications, while the soil processing depth will be 250 mm. Paving slabs can also be laid with these units, if a polyurethane mat is included in the package.

- To prepare the roadway for laying asphalt pavement, vibratory machines weighing 120-220 kg or super-heavy units from 250 kg are used.

An equally important parameter of choice is the vibration force of the technique. Models where this figure does not exceed 12 kN are not used for industrial purposes and for paving asphalt. For serious construction work, vibratory plates with a vibration force of at least 16-18 kN are used. If we are talking about laying paving slabs, then the vibrator with such an effort will simply trample it into the underlying ground level or break it.

As for the parameters of the vibration sole, the lower this indicator, the denser the plate will tamp the soil. Choosing the type of engine, preference should be given to the economical gasoline option. In addition, the direction of travel of the unit is also taken into account - the most convenient options have direct and reverse travel, therefore, preference is given to them.

How to make a vibrating plate with your own hands: step by step instructions

To begin with, take the metal sheet we have prepared and the grinder. At a distance of about 10 cm from the edge on both sides, we make shallow cuts (5 mm will be enough). Then, using a hammer, bend the edges approximately 30 degrees. We need bends so that the vibrating plate does not burrow into the sand during operation, but, as it were, glides over it.

Read Vibratory plate device in detail. Little secrets of big work

After that, we strengthen the sections with electric welding (do not forget to wear safety glasses). Then we take the channels and weld them across the sheet. After that, the engine will be mounted on them. On the channels, we make marks for the bolts with a marker. We weld the bolts with the base down, after which the "ears" of the engine will be installed on them. But be careful: during welding, the metal heats up quickly and may deform, this will not play into your hands in the further operation of the vibratory rammer.

And now the hour of installation of the engine itself (platform vibrator) comes. By the way, if you buy an old motor of the IV-98 type, then know that there are eccentrics inside it, by rearranging which, you can adjust the vibration force. We install our engine on bolts, fasten it with nuts and engravers.

This is followed by the most important, and therefore the most controversial point of assembling a vibrating plate with your own hands - the handle attachment. Engineers around the world are racking their brains over how to dampen vibration during operation, constantly improving their technique. But we need to make a pen ourselves and no less high quality.

There is an option for attaching the handle to car silent blocks.To the bent edge of the base, in the same way as on the channels, we weld two bolts with the bases down. Silent blocks are attached to them, and already a handle is attached to them.

other handle attachment options vibrating plates

other handle attachment options vibrating plates

Also, the handle can be simply screwed to the base of the vibrating plate with two bolts, but then it is worth putting insulation on the handle, and rubber bushings on the mounts. There is also a tip for comfortable work: you can hang a rope loop on the handle and hold on to it, then the vibration will be felt weakly.

But do not forget that a do-it-yourself vibrating plate is still a device with its own specifics. It will not be possible to get rid of vibration completely; it can only be reduced.

See All ads for the sale of vibrating plates

The weight of a do-it-yourself vibrating plate will depend on the parts from which you assemble it. But it is worth understanding the function of the product - soil compaction. Therefore, the weight should not be too small (additional weight can be welded to the base), but keep in mind that it will be difficult to handle with a very heavy vibrating plate (at least transport it). On average, 40-50 kg will be enough to compact soil 10 cm thick. To lay the foundation, the slab must be heavier and, accordingly, more powerful.

Rating of the best: 5 tested models

We selected five models of modern vibrating plates from trusted manufacturers.

CHAMPION PC9045F

Straight-forward vibratory plate equipped with a 6.5 liter four-stroke petrol engine. with. Impact force - 15 kN.

Refers to professional construction equipment.

It is used for such tasks:

- Road surface repair.

- Asphalt laying.

Key features:

- The engine is equipped with a critical oil level sensor. The sensor monitors the oil level in the engine crankcase, if there is not enough oil, the vibrating plate will not start.

- Manual starter for starting.

- The compact design allows you to work in hard-to-reach places - near poles, in a trench, next to a curb or wall, etc.

- The vibrating plate is equipped with a 3.6 liter fuel tank.

- The maximum area to be compacted is 416 m2 / h.

What users say:

- Perfect for working in a confined space - where the roller will not pass, the vibratory plate will pass freely;

- Perfectly starts up in cold weather;

- Easy to move by hand (does not require much effort);

- The handle is equipped with a mechanism that reduces the transmission of vibration to the operator's hands.

DDE VP160-HK

Reversible plate vibrating plate with Honda GX200 petrol engine. Impact force - 30.5 kN.

Key features:

- High performance vibratory plate equipped with a 6 hp engine.

- The powerful engine allows you to compact the soil to a depth of 50 centimeters in 1 pass.

- Efficient transmission or extraction of torque from the engine to the eccentric (by means of a powerful 3-cam clutch).

- The vibrator rotor is equipped with reinforced steel bushings, and the motor is mounted on a sturdy mount. The vibrating plate serves for a long time and reliably.

- There are transport wheels for easy movement.

What users say:

- Large motor resource at the engine.

- High quality materials from which the device is made.

- Convenient to work with.

RedVerg RD-29155

Linear vibratory plate with a four-stroke gasoline engine. Engine power - 6.5 HP, impact force - 13 kN.

Key features:

- The RedVerg plate compactor has a solid base made of thick pressed steel plate.

- A protective cover prevents foreign objects from entering the drive belts.

- Equipped with a soft grip that dampens vibrations.

- The complete set includes a polyurethane cushion - allows you to neatly lay paving stones or paving stones.

- There is an irrigation system - an additional water tank, with which you can moisten the surface under the slab when laying asphalt.

What users say:

- Easy to manage.

- The best option in terms of price / quality ratio.

Elitech HTP 60 BVL

Gasoline vibratory plate with a reliable four-stroke engine. Power - 6.5 HP, centrifugal force - 10.5 kN.

Key features:

- The vibratory plate motor of this model is mounted on a reinforced frame.

- Works without interruption in extreme heat, as well as in frost. Full temperature range - from -10 to +40 ° C.

- The device is equipped with a shockproof cover to protect the belt transmission.

- The vibrating plate is equipped with an anti-vibration system. Reduces the negative impact of vibration on the engine and extends its life.

- There is an irrigation system with a 10 liter tank.

- Ergonomic control handle. Conveniently folds up for storage or transportation.

- The set includes transport wheels for easy movement around the site.

What users say:

- Easy to start up.

- Decent build quality.

- Among the disadvantages is that during vibration, the bolts of the transport wheels can be loosened.

CHAMPION PC5431F

Compact gasoline vibrating plate of the forward type. Equipped with a four-stroke engine, power - 2.3 HP, impact force - 8.2 kN.

Key features:

- The vibration frequency is 5140 beats per minute, the compaction depth is 200 millimeters.

- The body is made of impact-resistant plastic. Provides reliable protection of the device's actuators from impacts of crushed stone and small stones, as well as dust.

- The vibrating plate is equipped with a special damping system that absorbs vibrations well. Thanks to this system, engine parts wear less and last longer.

- There is an oil level sensor in the engine.

- Comfortable grip. It can be adjusted in height, the handle contains all the controls for the device.

What users say:

- Compact and lightweight vibratory plate, convenient to use and carry.

- Does a great job.

The principle of operation of vibrating plates

This construction tool is used for vibratory ramming of various bulk materials: sand, soil, etc. Often, vibrating plates are used in construction work, for compacting soil under a foundation or laying tiles.

Unlike large equipment, the vibrating plate can be used to work in difficult areas due to its small size. Some rammer models are reverse gear. This function allows them to be used even in narrow excavations and trenches.

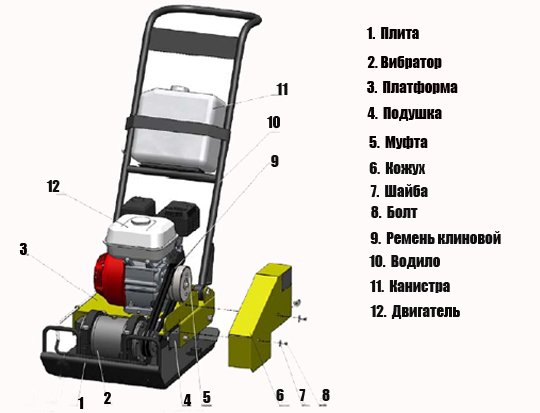

The principle of work of vibrating plates is simple. It is based on a massive platform. A vibrator is fixed on it, connected by means of a clutch and transmission to the engine.

Types of vibrating plates.

When the engine is turned on, it begins to create rotational movements, which are then converted into vibrational ones using a vibrator. In turn, vibrational movements are transmitted to the plate, and through it - to the soil or other material for ramming. Under the action of the tool, the material is compacted, the particles fill all the voids. As a result, the surface is leveled, and the embankment becomes very dense.

There are 3 main types of ramming machines, the main difference being the engine type:

- diesel;

- gasoline;

- electric.

For work in private estates and on small construction sites, electric is considered the best option. Of all types of vibratory rammers, such a tool has the lowest price. The technical characteristics are generally not worse than those of more expensive instruments.

The only drawback is the inability to work without a power source, and therefore the area of action strongly depends on the length of the cord.

Vibratory plate weight and compaction depth

The higher the weight of the equipment, the deeper the material will be able to be compacted. When choosing the weight of the equipment, they also take into account which material you will mainly have to work with.

By weight, the following types of vibrating plates are distinguished:

- up to 75 kg, light. Able to compact material to a depth of 15 cm, suitable for working with sand, fine gravel. They are used in landscaping when arranging garden paths and laying paving slabs.This technique is not suitable for asphalting, but it will definitely come in handy on the farm;

- 80-110 kg, universal. The material is rammed to a depth of 20-25 cm, used for patching the road surface, for laying paving slabs on sites, as well as for repairing roads after laying communications, in landscape work. Such a wide range of available works ensured the versatility of this type of vibrating plates;

- medium-heavy, up to 150 kg. They can ram material at a depth of 30-60 cm, are used in road and industrial construction. They do an excellent job with compaction of asphalt and backfilling of the foundation, but in no case are they suitable for laying tiles, as it can be damaged under the weight of the equipment;

- heavy, more than 150 kg. This is a professional technique that can even replace a vibratory roller. Such heavy equipment is not suitable for compacting asphalt, but is perfect for preparing the foundation for roads and for organizing the foundation.

The efficiency of the selected equipment is approximately 70% dependent on the correct choice of weight, the remaining 30% is the correct choice of vibration force.

Vibratory rammer selection

To choose a good vibratory rammer, you need to know a few rules:

- Before choosing a vibratory rammer, carefully read its technical capabilities in the instructions. Whether they are appropriate for the work you need to do.

- Once you have selected the model you want, make sure it is complete and that additional equipment such as tamper shoes, pads, etc. is included with it.

- In addition to the fact that the vibratory rammer is quite compact and this is its main advantage of working on narrow sites, technical characteristics play an important role in the choice. One of the main indicators is the size of the shoe, which determines the mobility of the equipment. The smaller the shoe or base of the rammer, the more comfortable it is to work in narrow areas.

- Its productivity depends on the number of ramming blows per minute. The more blows, the sooner the technique will cope with the compaction of the material. The gasoline rammer has the highest performance; its advantage can be attributed to the fact that it can be used at any time of the year.

- The weight and dimensions of the equipment depend on where you will use it, if for tamping ditches, it is better to choose a light maneuverable machine, and only heavy powerful equipment is suitable for trenches and drainage.

The vibratory rammer, whose price depends on what kind of drive is in the equipment, has a rather simple design. It consists of a metal frame on which the engine is mounted, there is also a vibrating mechanism, a control handle and a work sole or shoe. Maintenance of this technique does not bring much trouble, you just need to clean the air filter, change the oil in the gearbox and engine, and carry out a scheduled technical inspection. Performing all these simple manipulations will allow the technique to serve for a long time.

How much do vibrating plates cost

- Gasoline DIAM VM-60 / 5,5H will cost 27 thousand rubles. The 60 kg vibrating slab will lay the paving slabs with ease and high quality. It is also used to compact asphalt. Engine: HONDA GX-160.

- The Chinese company DIAM also offers a model VM-80 / 5.5H worth 39 thousand rubles. It is 20 kg heavier, and its productivity is almost doubled.

- The following reversible plate compactors can also be purchased on the HONDA engine: tss vp-90T (38.8 thousand rubles), STONE SFP 2200A (65 thousand rubles), STONE RP 652 (191 thousand rubles), ADA PB200Н (124 thousand rubles ) other.

- Electric vibrating plates (for example, EVP-1-055) will cost from 17 thousand rubles.

- The vibrating plate TSS-VP90E works on a three-phase electric motor. Its power is 2.2 kW. Price: 28 thousand rubles.

- Diesel vibrating plates cost from 39 thousand rubles (Masalta MS-90-1).94 kg machine on a four-stroke Kipor engine with a capacity of 4.2 hp. moves at a speed of 0.4 m / s.

- AMMANN AVP1240 Y will cost almost 101 thousand rubles. Its 5 liter Yanmar diesel engine allows it to operate from a vibration force of 12 kN and a power of 3.8 kW.

- SOVTE CNP-25 (average price - 55,000 rubles), Masterpac, Masalta (the minimum price for a model weighing 51 kg is 24,000 rubles, the maximum price for a model weighing 83 kg is 40,150 rubles). One of the most expensive for today, as well as one of the heaviest and most powerful - the SHATAL RP6012 vibrating plate (weight 400 kg). The price for it is 389,500 rubles.

Comparison with a vibratory plate

The hand tool, with which you can ram bulk soils, does not only consist of a vibratory rammer. In addition to this device, there is also a vibrating plate. In some cases, it copes better with the assigned task, since the area of its tamping sole is twice as large as that of a vibro-leg.

In appearance, the vibrating plate has a base-platform on which the vibration unit, a motor, a general structural frame and a control system panel are based. With the help of this device, loose substances are tamped in small areas. Some models of vibrating plates have a water reservoir in their design, which wets the rammed surface, improving the density of free-flowing fractions. The ramming depth of the vibratory plate is less than that of the vibro-foot, and is 30-50 cm, but due to the larger area of the working sole, the productivity of the vibratory plate is much higher.

Vibratory rammer and vibratory plate have common applications for soil compaction. But there are also differences between these devices. Structurally, the vibrating plate is designed so that vibration appears in it due to a special mechanism - an eccentric, fixed in the ramming plate. The mechanism is powered by the engine, and the vibrations are transmitted to the plate. The manual vibratory rammer is arranged differently, since the energy generated from the motor is converted into push-and-forward movements. The connecting rod piston pushes the vibration sole, and at this time, an impact is created in relation to the ground. The impact force of a vibratory rammer is much greater than that of a vibratory plate, but the processed area is less.

Despite the fact that both hand tools are designed for ramming, their purpose is also different from each other. The vibratory rammer is not used on clay soils and is not used for paving asphalt, while the vibratory plate is suitable for these tasks.

Instructions: vibratory plate and criteria for its selection

The most important parameter for choosing a vibrating plate is its weight. In this matter, there is a clear classification that should be studied carefully and in detail:

- For landscaping works, laying paths from small soils up to 15 cm thick, for laying paving slabs, completing sidewalks with damping polyurethane mats, it is advisable to use light models weighing up to 75 kg.

- For landscaping, patching of asphalt road surfaces, repair of road surfaces after laying utility lines, for work on a soil layer of no more than 25 cm, a vibrating plate is used, which is recommended to buy with a weight of 75 to 90 kg.

- For ramming the foundations of roads under construction, compaction of backfilling of trenches around the perimeter of the foundation, for repairing asphalt pavements, work on soil with a layer thickness of 25 to 60 cm, medium-heavy vibrating plates are used - from 90 to 140 kg, or heavy - from 140 kg. To perform work on compaction of asphalt, the weight is selected in a range not exceeding 100 kg.

The next selection criterion is vibration force. This parameter determines the degree of compaction of the coating. If the choice is between two plates with the same weight, and the priority is the highest packing density of the surface to be developed, then your choice should be stopped on the one that has a higher vibration force.For models from the group of lightweight mechanisms, this figure does not exceed 10 kN, they are not suitable for asphalt paving. For laying paving slabs, models with a weight of 75 to 90 kg and a vibration force of 18-20 kN are optimal. If these indicators are higher, the vibrating plate will not lay the tiles, but will trample it into the ground more than necessary or even break it.

The size of the working surface has already been mentioned above - the smaller this indicator, the greater the seal gives the mechanism. Choosing among models with the same engine power, vibration force and weight, it is advisable to opt for the machine that has a smaller working surface.

The next selection criterion is the type of engine according to the type of gasoline consumed. Models with different power sources have the same indicators in other criteria, therefore, the type of fuel does not affect the type of work performed. But each of the three types of engines has its own advantages and disadvantages:

- Vibratory plates with a gasoline engine are considered the most convenient and profitable option. The mechanism itself has a relatively low price, while the gasoline engine demonstrates a high power rating and low noise level. The price for these models is relatively low, while they work in any conditions, since they do not require a constant source of electrical power.

- Devices with diesel engines did not receive the same popularity as gasoline ones. With constant work with a vibrating plate, the owner saves on fuel, but the initial price of the mechanism itself is much higher than models with a gasoline engine. The profitability of this purchase can be determined individually, based on the scope of the proposed work. Another significant disadvantage of diesel vibrating plates is a high noise level during operation.

- Electric vibrating plates have a narrow range of applications, since it is determined by the length of the electric cord. It is worth refusing to purchase this type of device if it is supposed to work outside the area of access to electrical networks. A significant plus of these models is their relatively low price. Having exactly the same performance, a vibrating plate with a gasoline or diesel engine costs an order of magnitude more expensive than an electric one.

The last criterion by which they make a choice is reversible machines or those with a straight course. The reversible plate compactor has a reverse gear, this is its significant advantage over the models with a straight swing, which need to be turned frequently. This inconvenience increases the time to complete the work and the physical costs of them. Reversible models are indispensable when performing work on planes with a small area - trenches, pits, foundations of low-rise buildings.

Private use

Homemade vibrating plate is most often used on the site, during the construction of gazebos, arrangement of paths and summer playgrounds

However, we should not forget that it is a homemade tool, with which it is also important to follow safety rules.

A homemade vibratory grinder will be more beneficial if its owner uses the following tips:

So that vibration is not transmitted to the hands and thus does not tire the user while working with the device, it is worth attaching two loops of dense rope to the handle, which can be held in the process.

A home-made construction weighing 60 kg is capable of perfectly compacting the soil surface by 10 cm.This is quite enough for laying paving slabs or landscaping. But for use in construction, it is necessary to increase the weight of the structure so that it is more than 80 kg.

Irrigation system simplifies the ramming process

For this, the working surface in front of the device must be well moistened with water.

When the device is ready for use, it is very important to check the tightness of each element and fastening.There should be no broken elements, fragile or defective.

Before full use, you can conduct small tests to ensure the reliability and quality of the completed unit. It is necessary to store the tool in a clean, dry place so that it will serve without complaints for more than a dozen years

It is important to check, tune and adjust the instrument from time to time. If a gasoline engine was used in the vibrating plate, then its care should be more careful, it is periodically necessary to change the oil and filters, check the candles

Experts recommend changing the lubricant after 25 hours of vibratory plate operation.

Working with a vibratory rammer

Vibrating rammer is not a complicated technique, but there are still some nuances when working with it:

- Before starting operation, you need to carefully read about safety when working with a vibratory rammer. Check if all parts are securely in place.

- The lubrication condition of the rammer mechanism must be checked every time you are going to work. To determine the oil level, you need to tilt the technique back a little, if you see oil through the sighting hole, then it is enough for work. If the oil is not visible or it is at the bottom, then it needs to be added. A machine that uses a solid lubricant must also be lubricated periodically.

- The environmentally friendly gasoline rammer uses lead-free fuel that is mixed with oil in a 50: 1 ratio. In conventional technology, gasoline is used with the addition of oil in a ratio of 25: 1.

- Before starting work, you need to add gasoline; during operation, it is not recommended to do this so that fuel does not get on hot parts. Also, no smoking is required during this period.

- Every day you need to check if there is dust in the air filter. They are the first cause of all equipment breakdowns. If you work on a construction site or in an area where there is a lot of dust, then the air filter should be cleaned several times a day. And it is forbidden to disconnect the filter and work without it.

- You also need to check if oil is leaking from the bellows, if so, then it is necessary to tighten the clamps, and if this does not help, then the bellows is damaged and it is worth changing.

- For electric rammers, you need to check the condition of the cable before work, if there are problems, they need to be eliminated or the cable replaced.

Conclusion

Have you ever worked as a vibrating plate?

There was a case!

Manufacturers of construction and road construction equipment are constantly improving their equipment.

The devices are becoming more efficient and productive, and this gives a number of advantages:

- Saves work time.

- Reduces maintenance and repair costs (equipment is more durable).

Remember, it is quite easy to make a mistake when choosing, and the point here is not at all about knowing the technical characteristics. Everything is much simpler - there are conscientious manufacturers, and there are not very good ones. Therefore, when choosing a vibratory plate, consult with a specialist - so you can be sure that you are choosing really high-quality and proven equipment.

- Pumping station for summer cottages. How to choose? Model overview

- How to choose a generator for a summer residence. Main criteria and an overview of the best models

- Inverter welding machines. Model rating, how to choose

- Petrol self-propelled lawn mower. How to choose, rating of the best