The difference between machine vice and locksmith

Depending on the specifics of use, devices for fixing parts are machine or locksmith. What are their constructive and functional differences:

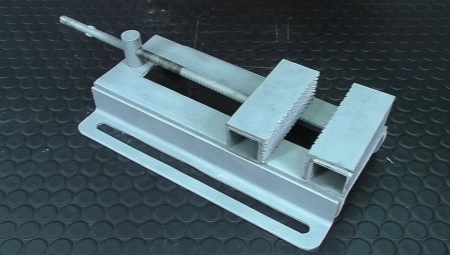

- Machine vice, as the name implies, are used for processing products on drilling, milling, turning and other machines. They can be mounted on a turntable of the equipment, which provides the choice of a convenient angle for fixing the part. The design of this vise is optimal for secure installation on the machine: the flat bottom part has long side slots for bolting to the surface. Replaceable jaw pads of the device often have V-shaped slots, which improve the vertical and horizontal fixation of cylindrical workpieces.

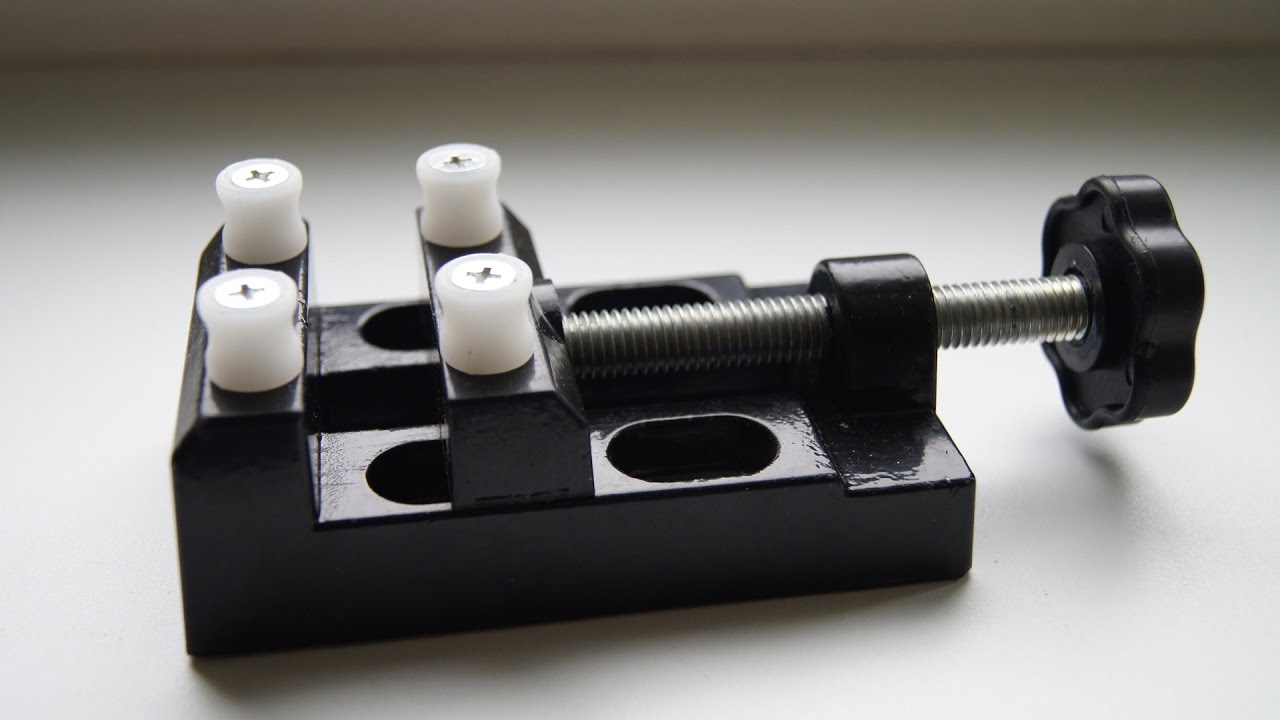

- Locksmith vices for home and production are relevant when processing parts with a hand or electric tool and are installed on a workbench. The device is attached to the surface with a pair of bolts through the holes in the base. Locksmith vices do not need to be as rigid and stable as machine vices, so they are suitable for working with softer materials such as wood or plastic.

Peculiarities

First of all, you need to find out what jewelry vise is in general, how they differ from vices used in other industries. In a vise for jewelry, various parts are clamped (fixed) in order to facilitate manipulation with them. Professionals call this tool "shrabkugel". The literal translation is "ball vise".

A heavy ball is placed on the stand. Small vise is placed on this ball. Their lips can be changed as needed. Sometimes, instead of one tool block, a mount for replaceable devices is installed. Small vices can also be inserted into it. It is common to find simply reduced copies of the locksmith's tool, but its functionality is in doubt.

Shrabkugel, also known as a ballnogel, is capable of spinning in an arbitrarily chosen direction. Therefore, the workpiece will be placed in the most convenient way for jewelers. The diameter of the ball at the base is usually 60-120 mm. However, there are also some models with a support ball of 140 mm diameter.

Species overview

To date, all hand vices produced in the territory of the Russian Federation are produced in accordance with GOST 28241-89. The classification of the tool is made according to two criteria: the design and the tool fixation system.

As for the design of the models, the standard assumes the presence of three types of fixtures: hinged, spring and conical mount models. So, hinged samples consist of two spring-loaded cheeks on a hinge and a transverse clamp, while in spring models the hinge is replaced by a spring. In a conical vise, the ends of the jaws are driven by a rotating cone.

Jewelry hand-held vise with a transverse or end clamp, which can be made not only of metal, but also of wood and even of nylon, stands apart. The latter have a special wedge and outwardly resemble linen clamps.

Another criterion for the classification of manual vices is the clamping system. On this basis, two variants of models are distinguished: lever and with jaws.

With levers

These models are very similar to the snap pliers and consist of two jaws and two levers. Lever samples are very convenient to use and are highly popular with DIYers.

With sponges

Such models consist of steel jaws, a handle and a bridge with a screw. The fixation of the part is carried out by rotating the handle, while the cone on the back side enters between the shanks of the lips and causes them to be compressed.

Separately, mention should be made of the manual vise-pliers and vise-clamps.Compared to classic vices, they have a more complex design and higher cost. So, if the usual manual vise can be purchased for 300-500 rubles, then the vice-pincers and vice-clamps will cost from 800 to 3000 rubles and more. Such models are distinguished by good fixation and wider possibilities.