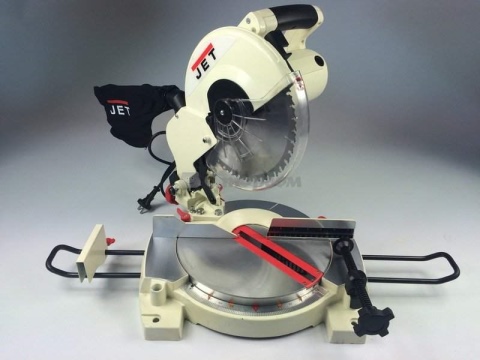

JET JSMS-12L

JET tool JSMS-12L from a Swiss developer, with high power and speed. The laser marker is equipped with a fine adjustment screw that allows you to adjust the beam line to the desired parameters. The fixation of the rotation of the working table is carried out with the help of a latch-stopper, which makes it possible to quickly and accurately install. The cutting depth adjustment function allows you to machine complex parts in the manufacture of furniture or joinery. The tool is equipped with worktable extensions for working with long workpieces, a clamp for fixing parts.

| Specifications | Meaning |

|---|---|

| Power, W | 1800 |

| Number of revolutions, rpm | 3800 |

| Disc diameter, cm | 30,5 |

| Maximum cutting depth, mm | 105 |

| Maximum cutting width, mm | 305 |

| Weight, kg | 22,5 |

| Features and Capabilities |

|

| Head tilt left - right, deg. | 45 / 0 |

| Rotation of the desktop to the left / right, degrees | 45 / 45 |

| Additional options |

|

| Developer / Manufacturing Location | Switzerland / Taiwan |

| price, rub. | 23940 |

Watch a short video overview of the tool characteristics:

DeWALT DW717XPS

This miter saw is considered to be the best for ripping purposes, although it does a great job with rip saws as well. It is efficient for both light and difficult jobs thanks to its powerful 1675 W motor. However, even under high load, the motor does not heat up and lasts long enough, according to reviews. An interesting model makes it possible to control the working line thanks to the shadow from the disc. The XPS system, which is responsible for this, does not require adjustments and guarantees the accuracy of placing the material in the right place, as well as good surface visibility.

Advantages:

- Disc with 60 teeth;

- The key for him is in the set;

- Roomy dust collector;

- Saws at an angle of 90 degrees to a depth of 15.2 cm;

- Cutting element diameter - 25 cm;

- Stability on the surface;

- Idling parameters - 4000 rpm.

Disadvantages:

Weight 23 kg.

Operation and maintenance

Since the end plate is a cutting tool, certain safety rules must be followed when working with it. First, you need to prepare the workplace, excluding the placement of foreign objects. Protective gloves and goggles should also be worn. Before starting the engine, you need to make sure that the disk is working properly. If there are cracks or deformations on its surface, then the element should be replaced with a new one.

During the rotation of the disc, do not touch it with your hands. Any contact with part of the disc can cause serious injury.

When ripping, it is recommended to use stops and special rectangular guides. If the disc is slipping or is jammed, the equipment must be disconnected from the power source as soon as possible. You must first fix the problems, and then continue cutting. To avoid jamming, fit the saw blade with a seat that matches the product model. It is forbidden to cut the material if there are nails in it.

Compliance with the rules for servicing the device also plays a huge role. The tool cord must be protected from oil and water. It must not be allowed to overheat and tighten. The protective cover must be stored under the conditions specified in the manufacturer's instructions. It is forbidden to code or tie it up. Periodically, the saw needs to be diagnosed.In case of any malfunctions, it is necessary to send it to the service center for repair.

How to choose a good miter saw, see the video below.

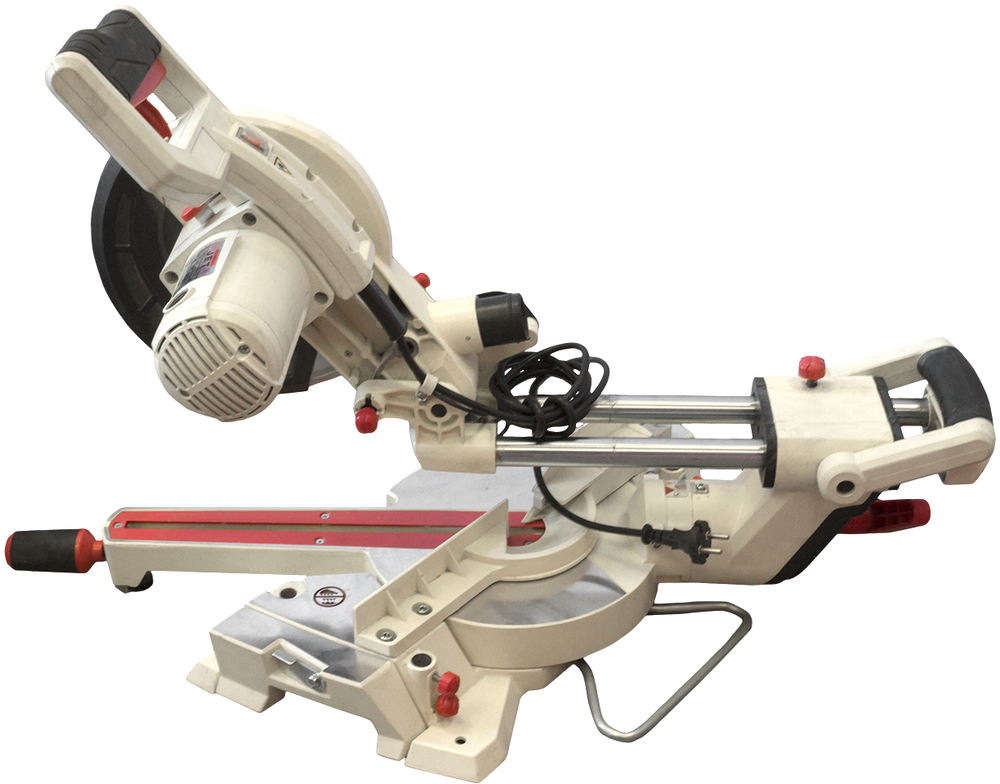

Best feed miter saws

The standard design allows high-quality performance of basic functions with relatively little movement of the disc along the workpiece. The limitation is due to the principle of operation of the pendulum unit. Typical models are not intended for creating longitudinal grooves, sawing large workpieces. The problem is solved with a special addition - "broach". Built-in rails increase the allowable width from 60-140 mm to 290 mm or more.

1. Makita LS1040F

A manufacturer with extensive experience in specialized activities knows the real needs of the user. The collected information helps to take into account the peculiarities of individual technological operations in order to improve the parameters of the equipment. This miter saw from Makita confirms the benefits of a professional approach when developing new models. The increased motor power prevents overloading when cutting hard workpieces. Smooth start-up extends the life of the saw and prevents breakage if not handled properly. The sophisticated dust extraction system is equipped with a large bag, so frequent cleaning breaks are not required. In low light conditions, the operator can use a bright lamp. The flexible drive allows you to install it in a convenient place. To work with large products, retractable support elements are used.

Pros:

- high-quality equipment at an affordable price;

- smooth start;

- the motor is protected by double insulation;

- ease of replacement of brushes;

- easy adjustment of the angle of inclination;

- backlight;

- metal durable protective casing;

- high-quality universal wheel as standard.

Minuses:

the screw retainer performs its functions qualitatively, but this method of securing the workpieces is associated with a certain amount of time.

2. Metabo KGS 216 M

With the use of the built-in mechanism, the working unit moves in the horizontal direction, which allows increasing the cut up to 305 mm. With the help of a special stop, grooves can be created quickly and accurately. When machining large workpieces, the widely spaced support elements help the Metabo KGS 216 M to maintain a stable position. The large, funnel-shaped intake opening facilitates the removal of generated sawdust. An economical LED luminaire provides uniform illumination of the work area. Users note the good visibility of the controls and the applied markup. The thick, durable handle makes the saw easy to carry.

Pros:

- one of the best miter saws with a broach rating in terms of the sum of technical parameters and cost;

- the ability to cut large workpieces;

- high cutting accuracy;

- blocking of the saw head is provided;

- excellent equipment;

- detailed instructions with recommendations for operation and configuration;

- efficient sawdust removal system;

- power supply of the laser marker and backlight from the 220 V network;

- light weight.

Minuses:

there is no soft start.

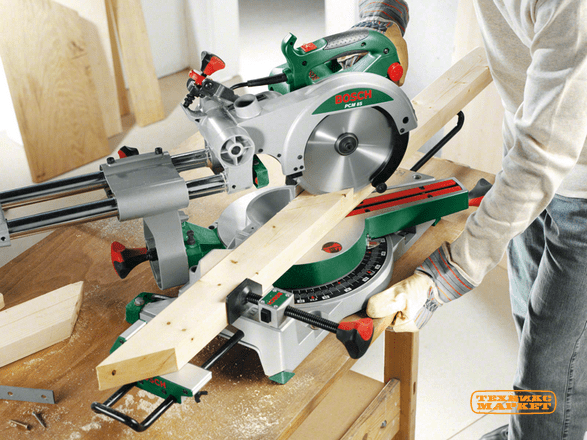

3. BOSCH PCM 8 S

This saw model is equipped with original fittings that create a wide support area for comfortable work. The miter saw is equipped with a high-quality feed mechanism that ensures smooth movement of the blade when cutting wide workpieces. The bright laser marker helps you complete complex work steps without errors. The design is designed with improved electrical insulation, so a high level of safety is ensured even without connecting the ground loop. A special button blocks the arbitrary movement of the main unit.

Pros:

- the most reliable manufacturer, flawless assembly;

- clear instructions, simple handling;

- cut - up to 220 mm in width;

- high cutting accuracy;

- stop for creating a groove;

- high quality assembly and components;

- lightweight construction (11.4 kg assembly);

- improved electrical insulation characteristics.

Minuses:

small storage bag for collecting sawdust.

How to choose?

Today the construction market is represented by a huge assortment of miter saws, which differ not only in design, but also in technical performance. Therefore, it is difficult to make the right choice in favor of a particular model. Experts recommend to study its capabilities before purchasing a tool, as well as to determine the scope of planned work. If the equipment will be used only for domestic purposes or rarely, then the simplest modification, equipped with the usual type of functions, will do. For frequent and high-quality cutting of parts from various materials, you will need a professional saw, a versatile option that has a wide range of possibilities.

In addition, when choosing such a device, it is important to pay attention to several important parameters.

Security.

It is better to give preference to a tool in the design of which there is an option of blocking against accidental starting and a protective cover. Such products are much more expensive, but they completely eliminate injury when cutting.

-

Dimensions and weight.

The saw must be ergonomic and mobile. This will ensure a comfortable working experience. Small and lightweight saws are well suited for cutting workpieces at height. Despite their size, they have high productivity and are in no way inferior to large end machines. Professional modifications are always available in size, since they have more power. -

Depth and width of the cut.

For high-quality processing of workpieces, you should choose devices with a disc diameter of at least 20 cm. Moreover, the larger it is, the more convenient it will be to work with the equipment. -

Manufacturing material of the bed and the working unit.

The service life of the saw depends on this. The right decision is considered to be the purchase of devices, the main parts of which are made of durable metal. -

The number of revolutions and power.

Powerful saws are suitable for fast work, as they have a higher number of revolutions of the blade. For simple modifications, the power is equal to 1.6 kW, it is enough to carry out various works. Professional saws have a capacity of over 1.8 kW, but they require good electrical wiring.

-

Duration of operation.

Household tools are inferior in terms of use to professional ones. -

Manufacturer.

Despite the fact that the equipment of different brands may have the same technical characteristics, they differ significantly from each other. This is due to the fact that manufacturers use various materials and assembly technologies in the manufacture of tools. -

Price.

Low-cost options for products are usually designed for processing soft wood species. The more expensive models are equipped with universal blades that allow you to cut hard wood, metal or plastic. Therefore, it is recommended to buy inexpensive saws as training equipment and for simple work when installing fences or building houses.

It is also important to choose the right saw blades. These elements can differ in the bore, outer diameter and shape of the teeth.

The inner diameter and seat are usually 3 cm, while the outer diameter can vary from 21 to 30 mm. In addition, the discs are matched to the power of the motor. Large discs are not recommended for powerful models, since during processing, an inaccurate cut may result.

The larger the outer diameter, the more teeth it has, which reduces the load on them. Such diameters last longer. Discs with few teeth are typically used for rip cuts

When choosing discs for a saw, you need to pay attention to their markings, which are written on the surface.It indicates the direction of rotation of the cutting element, maximum rotation speed and compatibility with a particular model of the device.

Makita LS1216

When buying a powerful, durable and multifunctional miter saw, you can safely stop on this model from the Japanese manufacturer Makita. Professional trimming cuts metal, plastic and wood perfectly when fitted with the appropriate saw blade. Cutting height / width 107/363 mm, which significantly expands the range of available jobs. Users call this saw "a tool without drawbacks" and there are many reasons for this: with impeccable assembly quality and all working elements, the trimmer has the highest angle setting accuracy. Also, the model is equipped with a soft start system, which is very appropriate for a powerful 1.65 kW engine. This is undoubtedly the best model of a miter saw in its class, the tool will cope not only with carpentry, but also with precision carpentry - with the production of stairs, the manufacture of decorative trims for doors.

Advantages:

- easy setting of any cutting angle

- long broach

- high power

- starting current limitation

- long service life

- the presence of double guides increases the accuracy and rigidity

- small size

Disadvantages:

the disadvantages include only weight (26 kg), but with its characteristics this is justified

Outcome

Our quick overview will showcase the features of popular models for hobbyists and professionals to help you choose the best miter saw. The tool of decent quality is easy to maintain and operate, and even an inexperienced beginner will master the principle of its operation. Saws from the best manufacturers of cross-cut saws combine high worthy assembly and a wide range of available jobs

When choosing a reliable miter saw for home or work, we recommend paying attention to the products of such miter manufacturers: Makita, Metabo, Interskol, Bison, Jet. All models considered in the rating showed high quality in work and functionality

When performing carpentry work, it is often necessary to cut the workpieces at the selected angle, observing a high degree of accuracy. This can only be done using a special device - a miter saw with a broach. This attachment is easy to use and allows for fast diagonal cuts.

What is a miter saw

The purpose of the miter saw is clear already from its name - facing (in other words, transverse cutting) of long parts: platbands, baseboards, fillets, moldings, etc. A master unfamiliar with a miter saw will probably be surprised - all of the listed parts are perfectly cut with a circular saw, and if you need to cut cleanly and at a certain angle, you can use a hacksaw and a miter box. So it is - it is the hacksaw and the miter box that is designed to replace the miter saw, for which it is sometimes called the "electric miter box".

Anyone who has ever had to connect platbands and skirting boards "in a mustache" knows that this is not as simple as it might seem at first glance. Without the proper skill, even with a miter box, making a perfect 45-degree cut is not easy. And if the part is not flat, but of a complex shape? If it is a wide outer platband or a decorative element and it simply does not fit into any miter box? And what if the joint angle is not straight and you need to cut not at 45 degrees, but, say, at 57 degrees? And if you also need to cut at an angle to the vertical? A hacksaw on a swivel bed will not help here either.

So it turns out at the junction an ugly gap, which has to be covered with putty and masked with a color scheme in the color of the details.

But with a miter saw, such problems cannot arise, and any craftsman who has tried this tool will never return to a miter box and a hacksaw.Moreover, now on sale there are not only expensive professional models, but budget household ones, which are not much more expensive than an ordinary circular saw, and at the same time are capable of providing a previously unattainable quality of connection "in a mustache" of parts of any shape.

Interesting: Manual brush cutter - tool selection criteria

Choosing a Miter Saw Blade

The quality of the cut depends on the characteristics of the miter saw and the cutting part. Saw blades are distinguished:

- by the shape of the teeth;

- along the outer diameter;

- along the mounting hole.

The bore or inner diameter of the disc is usually 3 cm. The outer diameter can be 21, 25 or 30 mm. This indicator is indicated in the characteristics of the tool and on the face of the disc.

When choosing the parameters of the cutting product, you should pay attention to the engine for which a specific standard size of the disc is selected. Large discs are impractical for powerful engines.

As a result, you can get a poor-quality and sloppy cut.

The saw blade must be selected based on the power of the tool

Helpful advice! For high-quality and durable operation of the disc, the proportionality of its size and thickness must be observed. Otherwise, frequent breakdowns of the part are inevitable.

The larger the value of the outer diameter, the more teeth are located on it, and, therefore, the less the load on each of them. This suggests that larger drives have a longer service life. Discs with a small number of teeth are advisable to use for longitudinal cuts, with a maximum - for transverse. On the surface of any disc, its markings, maximum rotation speed, direction of rotation and compatibility with the tool are indicated.

Wood Miter Saw Blade Teeth Design

The quality of processing of products is influenced by the size, sharpening, geometry and material of manufacture of the teeth of the disk. The smaller the size of the teeth, the better and more accurate the cut is.

This is especially important for laminate flooring and lacquered or painted wood. For coarse cutting, discs with a small number of large teeth can be used.

They are used for cutting plywood and softwood.

The saw blade contains recommendations for its use.

For processing plastics and composites, it is better to choose discs with trapezoidal teeth or with "triple chip" brazing. For hard woods, it is advisable to use products with tungsten carbide or cobalt alloy carbide teeth. For cutting chipboard, plywood and veneer, ATV-brazed discs are preferable.

Helpful advice! To obtain a high quality cut in wood products of valuable species, you should use combined discs, where several beveled teeth alternate with one cleaned one.

The geometry of the teeth indicates the nature of the cut. Depending on this, discs are distinguished for longitudinal, transverse cuts or for finishing and neat processing. Some discs for long-term use have thin notches and smooth lines, which compensate for thermal deformation of the wheel and reduce the noise level during tool operation. The surface of the teeth should be smooth, without jagging, and the edge should be sharp enough. The discs are made of heat-treated steel with composite overlays.

Saw wheels for cutting must be selected based on the thickness and type of material

Power and speed

When choosing a saw, you should pay attention to its power and the frequency of rotation of the cutting part of the tool. These parameters are closely related.

The higher the power of the device, the higher the rpm of the dusty disc.

The service life of more powerful devices is slightly longer than that of analogs with a lower indicator. The standard power value is 1.6 kW. This value is sufficient for any kind of task.However, many modern models have a power of 1.8 kW. But this directly increases the weight of the unit and complicates the work with the tool. In addition, powerful models require proper wiring so that when the saw is in operation, there are no short circuits and there are no power outages.

The number of revolutions that the blade makes affects the quality of the cut. The larger this value, the neater and cleaner it will turn out. Modern models have a built-in function for adjusting the number of revolutions, which is convenient for processing a particular type of material.

The service life of professional models of miter saws is slightly longer than that of household devices

How to choose a miter saw

Choosing a miter saw is a tricky task

In order not to be mistaken, pay attention to the following points:

- Power. The choice of this parameter depends on the tasks assigned to the instrument. For home use, a saw with a power of 1000-1500 W is quite enough. If the equipment is purchased for daily constant work, you will need a power of 2000-2500 watts.

- Maximum disc diameter. It is also selected taking into account the assigned tasks. The more, the, respectively, the larger the dimensions and power. Therefore, models with large discs are more expensive, as is the case with grinders.

- Angular speed of rotation. Varies between 3200-6000 rpm. The higher the speed, the better the cut quality. Inexpensive models have a low speed - up to 4000 rpm.

- Engine's type. The asynchronous motor works almost silently and has exceptional durability, but its disadvantage is its low power and large dimensions. A brushed motor can be powerful, but it requires maintenance and is quite loud. The best quality are brushless motors, which contain the advantages of both of the above types of motors. However, they have another disadvantage - a high price.

- The presence of a laser. A must if you need a precision cut-off tool.

- Possibility of autonomous work. If you have to work in an environment where power outlets are not available, you should purchase a battery-powered miter saw.

- Case and build quality. The plastic case is not the most reliable, it is better if it is aluminum. The body parts must fit well together.

- Reviews. If you have chosen the saw that is optimal for yourself, make sure that users leave good reviews about it online. Otherwise, it is better to refuse it.

Some useful features of miter saws have become a trend in recent years, which include automatic shutdown in case of blade jam, soft start and the ability to adjust the speed.