Features of the taiga ax

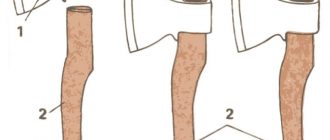

A sharp chopping tool is indispensable on a hike or on a picnic for rough work with trees and logs (Figure 1).

For these purposes, an ordinary cleaver is often used, the taiga ax has a wider application:

- In the manufacture of hunting wooden traps, for the installation of huts and the construction of elementary means for crossing water bodies.

- Butchering and harvesting animal carcasses as a means of self-defense in the event of an attack by wild animals.

- In addition to cutting firewood and trees, they can peel off the bark from logs, cut off twigs and branches, split wood along the fibers.

The correct shape of the taiga ax makes such a versatile tool, unlike a carpenter's ax, it has a number of characteristic features:

- Long handle, allowing for a wide swing, increasing the force of the blow.

- Less weight due to the cut of the upper toe, which strengthens the structure when working at low temperatures.

- There is no upper part on the head blade - it is equipped with a beard for greater product strength.

- Heated butt with a thickness of 15-17 mm, providing high strength of the head.

- Rounded blade for easy handling of a wide variety of forestry jobs.

Figure 1. A taiga ax outwardly differs in many respects from a carpentry tool

Figure 1. A taiga ax outwardly differs in many respects from a carpentry tool

The taiga tiger ax is distinguished not only by its unusual geometry, but also by a special approach to its manufacture. The hatchet is set by hand with wooden wedges and is not made on a machine. Quenching and forging are made according to the technologies of old Russian gunsmiths, and the handle is made of high-quality birch varieties. Comes with a protective leather case.

Balanced and thoughtful for solving many problems, the bear is a taiga ax with pronounced distinctive features.

Its heel is thinner than the nose and is suitable for planing, while the nose can easily chop chocks. The butt of the product serves for many years, is specially heated, which provides it with high strength. With a short length, the main weight is in the metal part - the head, which allows you to work with one hand for a long time, it is easy to cut something with two hands.

Photo of axes with your own hands

We also recommend viewing:

- How to choose a set of wrenches

- How to use the miter box

- Ratchet socket set

- How to make a pipe bender with your own hands

- Overview of modern pipe tongs

- Articulated knob

- How to make a sledgehammer with your own hands

- Types of dies for threading

- Nail gun

- How to choose a chisel

- How to choose a file

- Steel pipe cutter

- How to choose a hacksaw for metal

- How to choose a hacksaw for wood

- Hex keys

- How to choose good wire cutters

- Types of screwdrivers and their purpose

- Plumbing cable for sewer cleaning

- Types of hammers

- Which cleaver is better to choose

- How to choose a good hand planer

- Differences between pliers and pliers

- Tapping taps

- Modern side cutters

- How to choose good round nose pliers

- Instructions on how to choose and use a dry powder fire extinguisher

- How to choose an adjustable wrench

Help the site, share on social networks

Wood for the ax

Any ax consists of a holder, it is called a hatchet, and a blade. Often, wood is used to make a hatchet; it is a convenient and practical material. But not every breed is suitable for such a purpose.

An ax is a percussion tool; when working with it, colossal loads fall on the ax. For the ax holder to withstand the wood species? from which it is made? must meet certain requirements.

The wood for the ax must be solid, have high fracture strength, and withstand shock and compression. Most often, hardwood is used to make an ax. The wood for the ax must be well dried; for better drying, it is better to use special drying chambers. The drier the material, the better, this will help to avoid problems with the ax in case of moisture changes.

A very important characteristic that you should pay attention to when choosing a tree for a hatchet is the direction of the fibers. In order for the ax handle to be strong and withstand blows well, without cracking, the wood fibers must be located evenly, without interweaving

What kind of wood can I use for a hatchet?

The most popular types of wood used for the hatchet

- ash. Of all the possible types of wood used for the manufacture of an ax holder, ash is the most ideal for all requirements and has practically no drawbacks. Ash is very close to oak in its mechanical characteristics. Ash wood is solid, durable, has a high density, which allows it to withstand high impact loads. Despite this, ash is not so expensive, such wood is available and you can find it in any hardware store;

- jatoba. An exotic breed that has won many fans in our country. Jatoba wood has high strength and hardness indicators, which surpass those of oak wood. At the same time, this tree has a very beautiful structure and color, and products made of it have a high decorative value. Such wood is processed easily, it is not demanding in maintenance. It costs a lot, given its foreign origin, but you don't need a lot of it to make an ax;

- beech. The beech wood for the ax has a high hardness and is characterized by durability. Despite its high hardness, beech does not cause difficulties in processing, does not crack. But such wood absorbs water very strongly, which negatively affects the operation of the ax;

- oak. Oak tree is the standard of reliability and durability. Indeed, such wood has high hardness, resistance to any stress, as well as moisture, fungi and pests.

It looks nice and expensive, of course this is not so important when making an ax handle, but still. But oak has a lot of weight and, together with its high hardness, creates a strong recoil in the hand when working with an ax;

- Birch. This kind of wood for a hatchet is not the best option. It dries for a very long time and is problematic, has a high hygroscopicity and is prone to decay. The hardness of birch can be called low. But more than half of the axes on sale are equipped with a birch ax. Why? The answer is simple - the low cost of the material and the ease of working with it. With the help of proper processing, the properties of such a material can be significantly improved and such wood is quite suitable for small household axes;

- maple. Also one of the most popular types of wood for making a hatchet. Maple is durable, resilient, easy to handle. In addition to good mechanical properties, maple also has a beautiful color and a soft texture.

Irina Zheleznyak, editorial staff of the Internet edition “AtmWood. Wood Industrial Bulletin "

How useful was the information for you?

How to choose the right wood for the handle

Curiously, not all tree species are suitable for making a hatchet. It is recommended to use only hardwood, previously dried in special chambers or cured in a dry place. Failure to comply with these requirements will lead to the fact that in the process of use the handle will dry out and it will be very problematic to securely fasten the blade to the handle.

Craftsmen use several types of wood to make wooden handles, each of which has its own advantages and disadvantages. Let's try to figure out which wood will make the best handle for an ax.

Birch

This is a come and take feedstock, but the availability of the material does not guarantee high quality. To make a high quality birch hatchet, the wood will have to dry for 10-12 months. Even then, the material remains sensitive to the humid environment.

Maple

Also available and common material with a limited area of application. In particular, maple sticks are not suitable for making quality tools for a carpenter or lumberjack. However, the wood has a beautiful texture, so it is ideal for decorative and souvenir wood products.

Hickory

This unusual name hides an American nut that grows in Canadian forests. For the manufacture of an ax handle, this is the best option, successfully combining indicators of strength, elasticity and durability. However, only American and Canadian loggers can truly appreciate these benefits.

Jatoba

This is a species of wood, unique in its properties, which is used for the manufacture of sports equipment and furniture. Jatoba is easy to process and has a presentable appearance. At the same time, in terms of strength, such an array is not inferior to oak, so the handles for an ax made of it are very reliable.

Ash

Among the listed options, ash is considered the optimal balance of availability and quality. At the same time, the wood has an interesting texture, therefore, after appropriate processing, the wooden handle will have a presentable appearance without loss of strength and elasticity.

Wood product

A wooden hatchet cannot be compared with the work of an iron

, but sometimes you really need it. Due to its low weight, it is easy to take on a hike for cutting simple branches, and it can also be used as a weapon for training or at home.

How to create this product? The hatchet and head can be made separately or as a whole structure. The material is selected strong, dry, without fibers. It is worth taking oak or maple.

Hunting ax

The hunting tool must have perfect grip balance

The hunting tool must have perfect grip balance

to execute the correct punches. It is best to use an all-metal device, because the likelihood that the hatchet will fall apart when cutting a carcass or when cutting the bones of an animal will decrease. If there is no chance to forge such a product, you can make it yourself from the blade and axes made of wood.

Then you need to temper the iron

Then you need to temper the iron

... To create a hatchet, a special birch, mountain ash or elm tree is used. To find out the correct length of the handle, you need to take it by one end, while the particle with the attachment for the product should touch the ankle. When pushing the blade onto a part, its end must be wedged for better fixation. After that, the cut is made obliquely and the wedge is placed.

It's great if the wedge is created from the same material as the hatchet. It can be put on glue, and if the inner part of the butt is loosened, the problem will be quickly solved if the device is soaked in water. Do not use a metal wedge, because it will begin to rust and damage the wood.

Do-it-yourself hatchet

Drawings are primarily required to create this product.

This is a very important device and not difficult to make. In order to make it, you will need:

- Wood blank.

- Knife.

- Joiner's and locksmith tools.

- Cutting device.

- Pencil.

- File.

- Hammer.

The creation process itself will be performed in a specific order:

- A template is created on paper. The hatchet of the finished device is placed on the cardboard and outlined with a simple pencil. Cut out.

- A bar is made from dried wood.The particle of the workpiece on which the ax part will be placed must exceed the dimensions of the metal eye by two or three mm.

- The contours of the template are transferred to a wood blank. The front should leave a margin of ten mm, and in the back - ninety mm.

- Cuts are made transversely along the upper and lower parts of a bar of wood, the depth of which does not reach the selected contours of the hatchet by a couple of mm.

- The fitting attachment of a metal part is performed by hitting a mallet. If all goes well, do a cleaning.

- An almost finished base is grinded everywhere with a blade. They try to smooth out the corners and transitions with a file. At the end, all are sanded with sandpaper.

- Using a small hammer, knife and chisel, the workpiece is finished to the required shape. A knife is put in place of the saw cut and slowly knocked out with a hammer. That's all, the hatchet is done.

“Give me back my stone ax” - probably, there is no person in our country who would not hear this song. Yes, the first axes were made of stone. But this time has passed many thousands of years ago, and now high-quality wood and steel are used for the manufacture of this product.

During the development of civilization, many varieties of this tool appeared (construction, throwing, etc.), which still has not lost its relevance. Moreover, on the market you can find many varieties of this product, which are designed to solve certain problems, for example, that a hunter or tourist faces.

Care rules

If you want the ax to serve for a long time, you should take proper care of it. Tool breakage not only degrades the quality of work, but also creates a danger for those who use it.

It is very important to ensure that the ax was well planted on a hatchet. In the event that the handle is broken, it is better to replace it with a new one.

It is important to protect the ax from rust during the rainy season. To do this, it is enough to apply ordinary machine oil to the metal parts.

If it was not possible to protect the product, then the tool can be cleaned of rust quickly and easily using special products that are sold in household stores. It is advisable to store the ax in a case, which is often sold immediately complete with it.

For sharpening axes a round sharpener is best suited, which is desirable to moisten. When sharpening, hold the implement by the butt and the middle of the handle. The sharpening stone must always rotate towards the blade. With a large number of burrs, the cutting edge is leveled with a file. Axes cannot be sharpened with an electric grinder.

For information on how to choose the right ax, see the next video.

A little about sizes and shapes

Each master made an ax with his own hands, focusing on his height and the specifics of the application. It's no secret that a tool designed for chopping wood will be slightly different from a similar product designed for cutting down trees. At the same time, a small carpenter's hatchet for small carpentry work will be the exact opposite of the two categories listed above.

Despite this, a professional ax with a wooden handle always consists of three main parts:

- working part made of metal with a sharpened front part;

- a hatchet - a handle made of wood;

- wedge - a spacer that connects parts of the structure together.

When self-manufacturing, special attention is paid to the metal part, otherwise the tool simply will not cope with its main function. It takes into account not only the shape and material, but also the aspect ratio and sharpening angle.

Modern axes are usually made from medium alloy tool steel that has been heat treated and quenched.

The shape of the blade is selected depending on the application.For example, products intended for woodcutters are often used for chopping tree trunks and removing large branches. Such work requires a great depth of penetration, so the shape of the ax must be wedge-shaped. The cleavers used to chop wood are similar in shape, but have thicker cheeks and a sharper sharpening angle.

The length and size of the ax is directly related to the impact loads. If a significant impact force is required, the handle is made elongated to provide more swing. Here the dimensions are 700-900 mm. The length of the handles of axes for felling (carpentry tools) usually does not exceed 500 mm, a good cleaver is attached to the shaft of about 800 mm.

The shape of the hatchet should provide a comfortable grip, therefore, the middle part is always made curved, the seat and the shank have thickenings. The seat angle of the blade usually varies between 70-90 degrees.