Selection principles

When choosing devices for fixing workpieces, the following parameters are taken into account:

- performance of certain functions in a vice;

- fastening mechanism design;

- the material from which the sponges were made, as well as their sizes for specific parts;

- nominal pressure on the part when fastening;

- maximum screw travel when fully extended;

- the weight of the vice is selected in accordance with the dimensions of the machine's working table;

- a kind of drive mechanism.

Advantages and disadvantages

The benefits include:

- high force allows you to hold large workpieces during processing;

- the case, made of high quality steel, withstands maximum loads;

- the frame is protected from corrosion;

- with the help of a milling vise, they perform high-precision work;

- processing of soft material, without damaging it.

The disadvantages include:

- the use of pads under the sponges to prevent jamming of the part;

- vertical skew of the jaws;

- the use of a complex drive for movement.

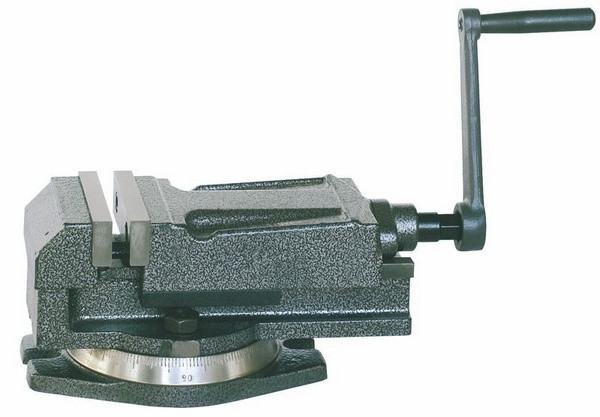

Manufacturers and cost

A rotary milling vise is made as an accessory for machine tools. Produced by domestic and foreign companies. The price range starts from 2,000 rubles and reaches 30,000 rubles.

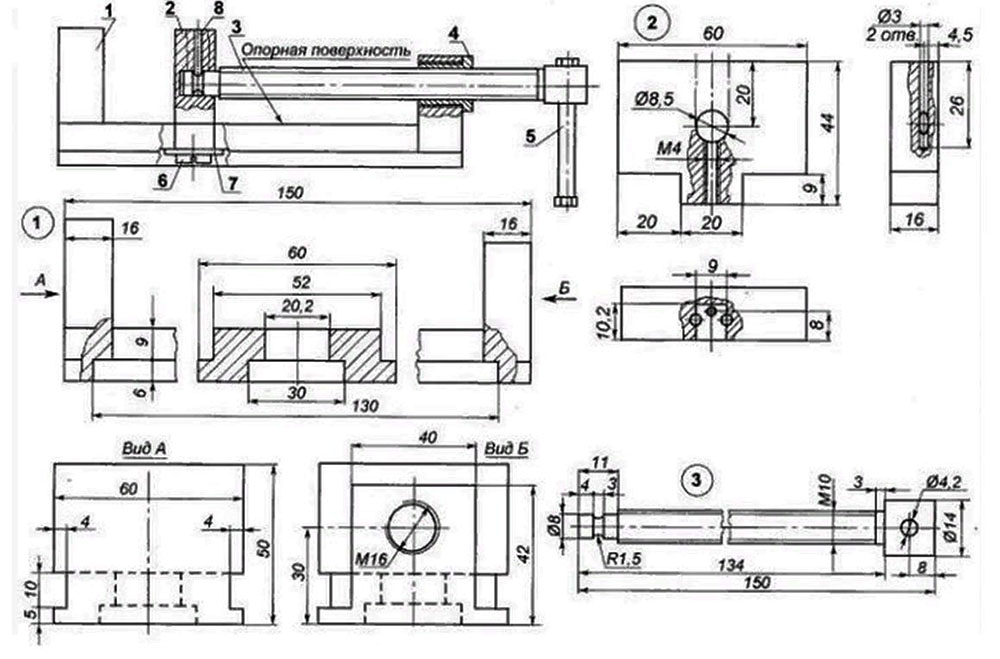

The structure of the machine vice for drilling machines

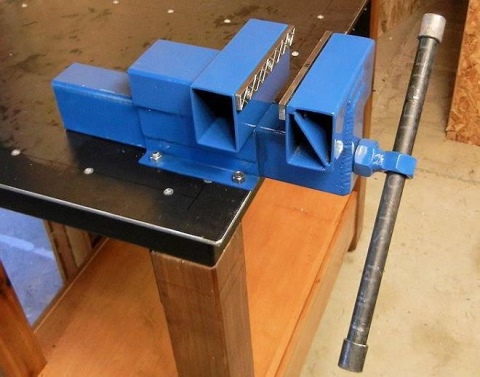

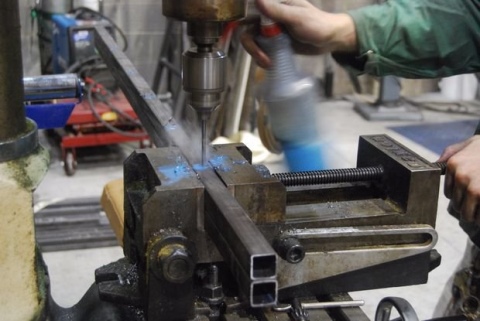

Regardless of the type of clamping device, they all have almost the same structure, as well as the same parts.

An integral part are the clamping jaws - these are plates made of very strong metal, to which the workpiece directly adjoins. Slots are applied to the front of the plate, which help to avoid slipping of the part clamped in the vice.

However, not all jaws are chamfered; when working with soft materials such as wood or plastic, the plates must be smooth so as not to damage the surface of the workpiece.

Therefore, many manufacturers include several removable clamping jaws, chamfered, smooth or serrated, in the machine vise set. The peculiarity of the pressure plates is that one part always remains stationary, the other, on the contrary, moves to the first with the help of mechanical action on it. The workpiece is clamped between these two jaws.

The thickness of the screw and the pitch of the thread depend on the required clamping force of the vice, and the length on the size of the workpiece being processed. For easy operation, manufacturers often use a hydraulic mechanism, in which the screw rotation handle acts on the bolt through several gears assembled in a closed box and filled with hydraulic oil.

This allows less effort on the lever to move the pressure bars. As for the base of the vise, when the machine vise is manufactured at the factory, the platform for them is a plate cast from a solid metal with slots for fastening bolts, without welding seams.

This design is strong and durable due to monolithic production. But it should be remembered that handicraft clamping mechanisms have a rather long service life. Especially if they are made of high-quality thick-walled metal, as well as with welded joints.

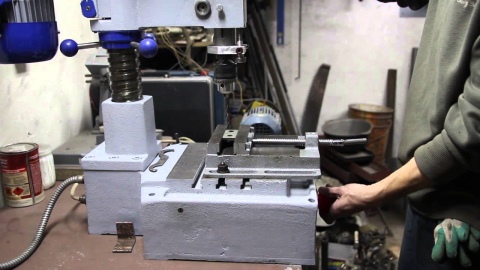

Drilling machine vice from BISON

Types of vice

There are the following machine vices for drilling machines:

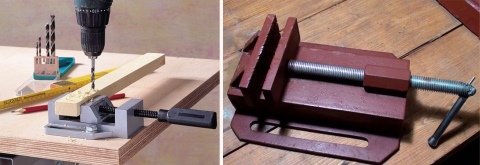

- The simplest clamping mechanisms for holding the workpiece in the machine work only in one plane. Often such a vice is made of cast iron alloys or made of metal. A vice is used with a relatively small size of the drilling machine itself, since there is no need to fix large parts and move them along the axes.

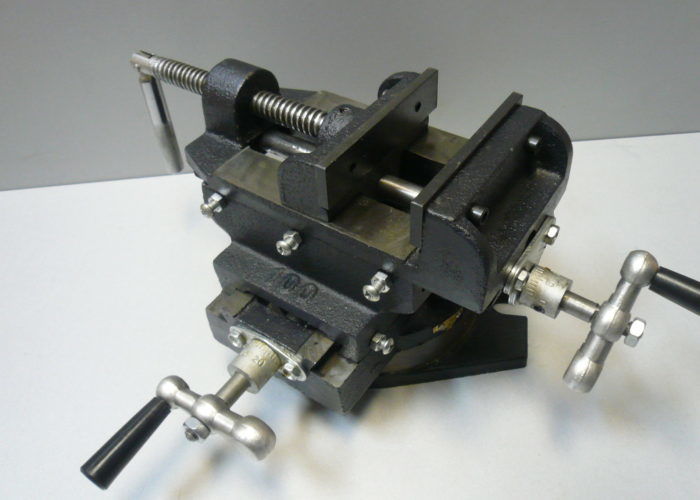

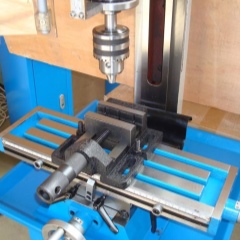

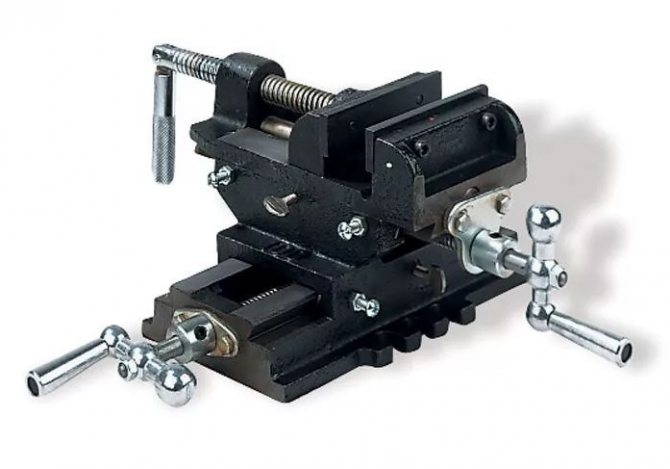

- Cross vise is a complex mechanism that makes it possible to work with materials in various planes, and they are also called coordinate vices. This clamping mechanism rotates 360 degrees, the worker does not need to unclamp the part when drilling holes in different places on the same plane. In this case, you just need to turn the second clamping mechanism and move the object without removing it from the vice. The cross vise is also good in that the workpiece rotates not only around its axis, but also shifts a few centimeters to the side;

- Three-axis machine vise - the advantage of such clamping devices is the ability to rotate and move the workpiece not only horizontally, but also to choose the angle of inclination of the part. Often, for convenience, a digital scale is printed on the rotary ring to allow precise adjustment of the drilling direction. Adjustment of the turning elements is carried out using the handle.