What factors should be considered when choosing funds?

Within the framework of the tools available for drilling, several of the most common types can be distinguished:

- cylindrical;

- end;

- keyed.

Making the right decision in favor of the right type is only possible if the buyer has an idea of what he plans to use this device for. In addition to the drilling depth, you need to know about the material that will have to be processed.

At the stage of choosing solid carbide drills for metal, the following parameters deserve the greatest attention:

- strength;

- quality of performance;

- brand and country of origin;

- the material used for the manufacture;

- price;

- reliability.

The best solution would be if the buyer opts for drills from trusted manufacturers. By acting in this way, it can be ensured that there are no forced interruptions during drilling, and that the poor quality of the finished products will be ruled out.

Drills for stone materials

For drilling in brick, concrete, natural or artificial stone, conventional metal drills are not suitable. They become dull instantly. The drill or drill for stone materials must have a carbide tip.

The very operation of drilling concrete, brick or stone also has its own peculiarities. In addition to the rotational movement, the drill or drill inserted into the perforator also carries out a shock-translational movement. That is, the stone, in fact, is not cut, but crushed.

The drill or hammer drill bit can have a regular cylindrical or a special standardized SDS shank (SDS-top, SDS-max or SDS-plus). Its advantage is that the insertion and removal of the drill from the chuck is carried out without a key and very quickly, in one motion.

Small and medium-sized holes in brick and concrete are drilled with a drill or a drill with a carbide tip. The tool is in the form of a screw.

If a large hole is required to be drilled, then use a bit with carbide teeth or diamond dusting. Drilling can be wet (with cooling water supply) and dry. At the end of the drilling, a core remains inside the crown - a cylindrical piece of cut material.

Carbide inserts soldered to a drill or drill have different hardness. For drilling granite, drills with high hardness pobedit plates are used. Medium or soft Pobedita grades are suitable for working with concrete or brick.

Now let's take a look at each drill quality indicator in order.

The color that the surface of a drill has for metal is a parameter by which one can judge the quality of the presented tool, but perhaps this is one of the most questionable ways to determine the quality of a tool. A snag in gray and black drills.

Drills with a predominance of gray

There is a point of view that gray drills are the cheapest and unsuitable even for a one-time job. Not having any improvements, special processing. It is not true. For example, drills that have undergone oxide treatment may well be gray. Therefore, when choosing a drill, do not trust the tales and do not run past gray drills - they can be quite suitable for the job.

Black predominates

It is believed that black drills are better than gray ones. And more expensive. This is neither true nor certain. Yes, there are drills that turn black from steam or something else, but in general - black drills can also be of poor quality. Don't blindly trust such schemes.

Drill shade gold

These are tools that have undergone the vacation procedure.Tempering means heating just below the limit, and then gradually cooling in air to ambient temperature. The tempering allows you to remove the internal stresses of the drill material and improve its strength.

Intense golden color

These drills are considered to be the best supreme tools, and needless to say, they are expensive. Actually, the shade of the drill is acquired by adding titanium to the composition. This material reduces the friction of the drill on the surface, which greatly increases its survivability.

When choosing a drill of one type or another, keep in mind how long you expect it to last and what quality of holes you expect.

The more often and more intensively you drill metal, the more expensive drills will be suitable for the job. As we already said, it is better to buy one expensive drill than to use the 10 cheapest for professional work. There will be little pleasure from the work, the drilling itself will take more time and effort.

Buying a cheap tool saves money, but they have to be changed more often, moreover, they are more suitable for one-time or infrequent work with medium effort and malleable metal.

Tool design

Each of the types of cutters for metal for a drill described above is distinguished by its design features. End mills have a wide variety from this point of view, however, tools of other categories are also produced with cutting teeth of various shapes and designs.

These are the main structural elements of a cutter for metal, due to the characteristics of which its ability to process metal products is ensured. According to the configuration of the cutting teeth, the cutters can be pointed and reared. Mills, the teeth of which are formed by flat front and rear surfaces (pointed), have one big drawback: their regrinding is performed along the back surface, which leads to a change in the geometric parameters of the tooth. For this reason, spiked cutters cannot frequently undergo this procedure.

On the left are coarse-tooth cutters for coarse cutting of soft metals. Right-hand cutters with a fine cut for fine deburring of hard metal surfaces

For cutters of the undercut type, only the front surface of the cutting teeth is flat, along which regrinding is performed. Thanks to this design feature, cutters of this type can be resharpened repeatedly without worrying about the fact that their geometric parameters will change in the process of performing such a procedure.

Solid and assembled tools

The metal cutters used to complete the electric drill can be produced in one piece or in a prefabricated version. In the first case, they are made from one metal blank. Accordingly, their body and cutting part are made of steel of the same grade. This approach to the manufacture of cutters allows you to reduce their cost, but affects their performance.

Ball or spherical heads can be attached to the rods of these cutters.

The body of the assembled cutter is made of inexpensive steel grades, and carbide inserts are used as cutting elements, which are fixed to the body by soldering. Despite the fact that the cost of prefabricated cutters is higher than that of solid cutters, their purchase is a justified step in many situations, since they have a longer operational life and allow you to perform machining with higher productivity and accuracy.

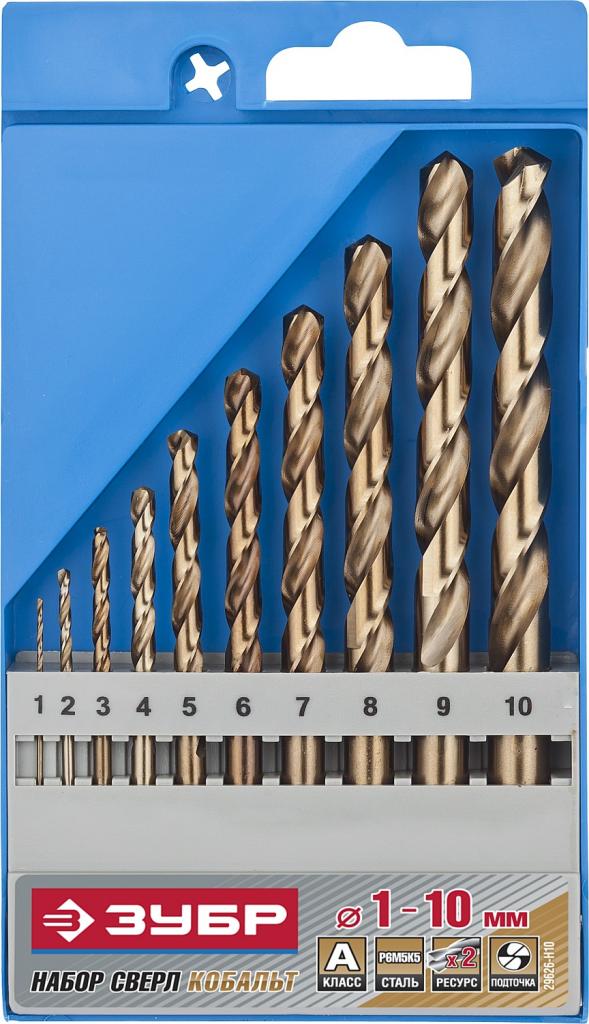

The best drill bit sets for metal

Knowing thoroughly all the nuances of the types of this tool, materials of manufacture, design and type, we propose to consider the rating of drills for metal, which will show the best models that have proven themselves well among users. The TOP is compiled both according to the characteristics of the product and taking into account customer reviews.

Extreme2 29 Pcs. DeWALT DT 7926

A set from an American manufacturer, manufactured at a manufacturing facility in Germany. Contains 29 units at once with a diameter from 1 to 13 mm.In addition to solid values of 1, 2, 3 mm, there are intermediate values of 1.5, 2.5 mm, etc., which covers all the needs when working with metal and creating various holes. The cylindrical shank has three edges to improve chuck holding.

Watch product video

+ Pros Extreme2 29 pcs. DeWALT DT 7926

- Convenient three-section case with signatures for each drill.

- Fast start drilling.

- Long retention of sharpening.

- The markings are above the working area, so you can always read which diameter is indicated.

- Cons Extreme2 29 pcs. DeWALT DT 7926

- You need to carefully examine the drills when buying - sometimes you come across used ones.

- Some drills are marked HHS, although the box says HHS-G.

- Thin diameters get very hot during operation - some even redden.

- A complex sharpening that is difficult to fix yourself.

Output. It is an excellent choice for professional use with regular drilling in stainless steel.

AEG HSS-R (19 pcs; 2-10 mm)

A relatively inexpensive set of 19 units with a diameter of 2 to 10 mm. The steel is steam treated, so the drills are black.

Watch product video

+ Pros of HSS-R (19 pcs; 2-10 mm) AEG

- Convenient case with signed labels and sturdy seating for each element.

- They even drill Soviet steel.

- Sharpening is good despite frequent use.

- The box has a second lockable compartment for small items.

- Cons HSS-R (19 pcs; 2-10 mm) AEG

- The 10 mm diameter has a large angle of attack, so pre-drilling with a smaller drill is required, otherwise you can waste time or spoil the tooling.

- You can't put too much pressure on them and take the drill to the side, because they break off.

- There is no 11-13 mm diameter for inserting locks and other similar works.

Output. This is the best choice for home use so you don't have to buy these sets every year. It will last a long time and the tips will not have to be sharpened often.

Metabo (1-13mm; HSS-G)

Products of a German manufacturer, containing 25 pieces in a set. Differs in a metal case and convenient extraction of drills. Produced with the use of grinding, which increases the strength of the edge.

Watch product video

+ Pros of Metabo (1-13 mm; HSS-G)

- All required diameters from 1 to 13 mm.

- Intermediate values of 1.4, 2.5, 3.5, 4.5 mm help create precise holes without backlash.

- The iron case will not break if accidentally dropped.

- The edge does not overheat.

- No beating when rotating.

- Cons of Metabo (1-13 mm; HSS-G)

- They drill slowly.

- Weak fastening on the case.

- Sometimes the cutting edge still breaks off, but re-sharpening helps to restore performance.

Output. A good choice for construction and housework. Such a set will last for many years, so it will be a profitable investment.

Bosch Robust Line 10 pcs. (1-10 mm; HSS-CO)

Decent set from a German manufacturer. High-speed steel with the addition of cobalt was used in the manufacture, which makes them the most durable in the rating.

Watch product video

+ Pros Bosch Robust Line 10 pcs. (1-10 mm; HSS-CO)

- Suitable for drilling all types of metals.

- Very long service life.

- Sharp factory sharpening.

- The drill from the set with a diameter of 7 mm will quickly pass the channel with a thickness of 12 mm and the disc from the circular saw - tested by users.

- It looks like new after 100 holes have been made.

- Cons Bosch Robust Line 10 pcs. (1-10 mm; HSS-CO)

- There are no intermediate values.

- Only 10 units per set.

- It is not possible to drill holes over 10 mm in diameter.

- The manufacturer recommended a special lubricant for working with these drills, which is difficult to find on the market.

Output. It is the best choice for professional work with frequent drilling of stainless steel with a tensile strength of 1200 N / mm2.