Features of Hex Shank

Drills with a hex shank are similar in purpose to drills with a round holder. They can make holes in any material, be it metal, wood or building elements. The shank of the original shape in the form of a hexagon only expands the possibilities of using drilling equipment. What are the features of this form of an element:

- The drill can be mounted in a standard chuck of a conventional electric drill. This is due to the fact that the clamping jaws of the chuck just capture such a shank through one face, thereby preventing displacement of the axial center.

- The accessories are convenient to use with any screwdriver with a hexagonal holder. On one of the edges of the drill there is a special groove for additional fixing of the equipment in the holder using a ball.

- The holder has dimensions equal to 33.32 mm in length, and 6.3 mm in thickness between opposite edges. These are the default settings for almost all curly and flat bits.

- On the edge there is a drill number stamped or painted.

- The hexagonal shape gives another advantage - the drills in it do not rotate during drilling operations. But this can also be a disadvantage if the rig gets jammed: it will simply burst.

- One of the negative features of the hex shank is a strong runout at high speeds during operation, due to the fact that such a holder does not have a rigid attachment to the drill with a power tool.

- The positive aspect of this design is the ability to quickly change the drilling equipment, which can be done in a matter of seconds.

Characteristic

Hex shank drills are a versatile auxiliary tool that is not only used for drilling a variety of materials, but also perfectly matches a large number of different drills, and is also used in conjunction with screwdrivers and hammer drills. These drills are metal products with a hexagonal tip (shank). Easy to use - if necessary, they can be easily and quickly removed from the mount.

The product is attached to the drill with a chuck. The latter firmly squeezes it, not allowing the product to escape. Some hammer drills are equipped with holders instead of chucks, where the hex drill can be firmly fixed, unlike the model, for example, with a round shank.

Other important advantages of using such "hexagons" can be noted.

- Products are easily and firmly attached to conventional electric drills.

- They can be used together with screwdrivers (only if the latter have a hexagonal holder).

- The presence of holders of the same size for all hex drills, regardless of their length, diameter, thickness. Tool holder length 33.32 mm, width 6.3 mm between parallel sides. The standard sizes help to firmly attach them to a variety of devices.

- The ability to quickly replace one product with another hexagonal one.

Other features of such a hexagonal product include increased runout when operating at high speeds. The reason is the lack of a rigid attachment of the drill and power tool. And you also need to know that drills with a hexagonal holder cannot ensure the accuracy of drilling.

Purpose of drills with a hex shank

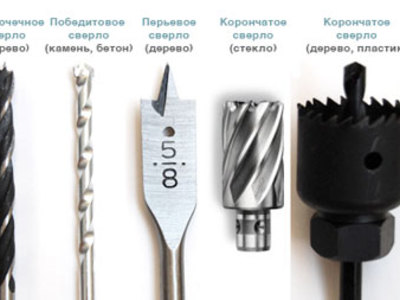

- Drill metal surfaces. The equipment easily handles steel and non-ferrous metals.It is convenient to use such equipment during the installation of metal profiles for drywall, to assemble structures from a profile pipe, to mount fences from a similar material.

- Get holes in wood material. For example, all operations on the construction of roofing battens, interfloor cake, installation of guide bars under clapboard cladding or other finishing material are not complete without drilling.

- Work on ceramic tiles. Cutters with pobedit soldering and a hex shank are excellent for drilling ceramics, plaster and bricks for installing polymer dowels in these holes.

- Drill any polymer materials. Can work with acrylic sheets, PE, PP material and other plastics.