1 Features of stainless steel and the choice of drill

Stainless steel is widely used in household and industrial applications. It is a high-quality metal alloy that is resistant to corrosion and various aggressive environments. In everyday life, this material is often used for the manufacture of plumbing fixtures, countertops, pipes, etc. In the process of repair or construction, sometimes it becomes necessary to drill a particular part made of this metal.

An important nuance when drilling stainless steels, along with the correct selection of coolants and work technology, is a high-quality drill. Many experts still prefer the time-tested and very durable cobalt versions (CO-5), which are also suitable for making holes in heat resistant metals or cast iron without the need for pre-centering.

These models were previously made on the basis of steel alloys with 5% cobalt in their composition or from high-strength steels of the R-18 type with the addition of this chemical element. Nowadays, it is difficult to find them on the building materials market, those types that corresponded to the Soviet standards of GOST - 10902-77, since they are practically not produced in an industrial volume.

Most often, the majority of domestic manufacturers simply cover the parts with a "golden" layer of cobalt, but at the same time it is contained in the workpiece to a minimum or not at all. This technology improves the sliding parameters, but does not add any strength to the rod.

On the market there are analogues of "real" cobalt versions of foreign production, the characteristics of which correspond to DIN standards - 338 or 336, and the marking contains the abbreviation HSS-C or simply NHSS. These types of drills are also made from high-strength steels with a mandatory content of at least 5% cobalt in the alloy composition (among manufacturers, it is worth noting such companies as Bosch; Ruko; Gross; Hagwert; Hilti, etc.

Their advantage is the high hardness of the material from which they are made and a specially blunt angle of sharpening of the tip, which makes them suitable for working with all types of "heavy" metals. The only drawback may be the price, which is noticeably higher than that of conventional standard drills.

Steel crowns and conical drills for stainless steel

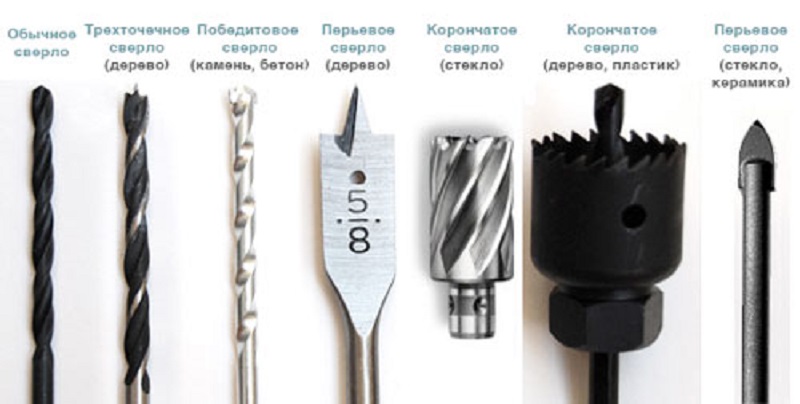

In addition to cobalt options of various diameters and strengths for stainless steel, other drills made of metal alloys of high hardness with the most sharp sharpening for dense materials, which, as a rule, are made only on one cutting side, are also used. The choice of drill and working tool depends on the grade of stainless steel, the thickness of the workpiece being processed and the selected technological process.

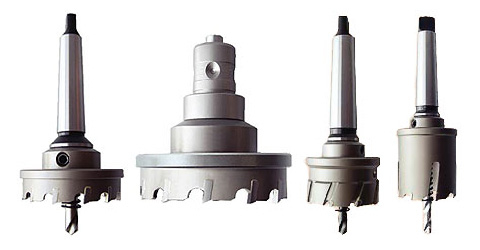

If it is necessary to make a large hole (from 14 mm in diameter and above.), Use special ring drills or crowns. They have additional clamping equipment, chuck and drill head in various sizes, which according to the tables correspond to inch and metric standards for pipe and other popular stainless steel products.

With small indicators of thickness (1-2mm), you can drill out the stainless steel with a simple steel drill, but only if its cutting part is sharpened at an angle of 120 degrees. In this case, the power tool is set to the lowest possible speed (100 rpm) in order to prevent the cutter from breaking, as well as overheating and failure of the tool itself.

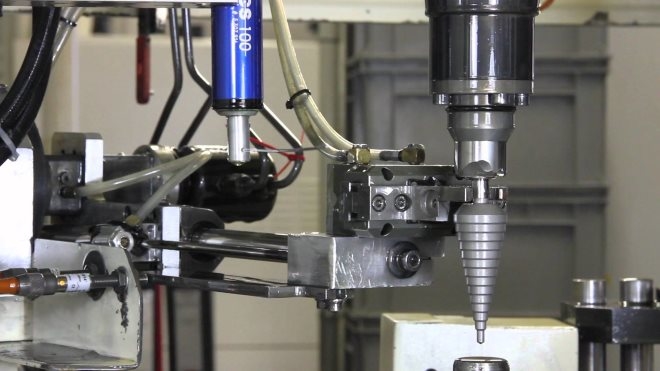

For drilling processing of sheet, food and especially thin stainless steel (less than 0.9 mm), special stepped or conical drills for metal are used. Their peculiarity lies in the fact that the working part of the part is made in the form of a spiral with annular transitions of various diameters.

This allows you to accurately determine during drilling which hole was made in size at a certain stage of work. In such cases (with a very small thickness), these types are able to replace a whole set of parts for stainless steel, including round crowns and conventional drills with various types of sharpening.

Which drill is best to use

- Any instrument in which cobalt is present. The higher the percentage of this component, the better. Cobalt products differ from ordinary ones in a yellowish tint. Do not confuse cobalt alloy with the application of this metal only to the outer part of the drill by electroplating. In the latter case, it will not be possible to drill the stainless steel.

- An expensive specialized tool. These victorious drills can drill stainless steel, not just concrete. They have a certain angle of sharpening.

- For thin stainless steel, you can use a feather-shaped ceramic tile drill. This is not the best option, but it will help you drill through the workpiece one time.

Application of cobalt drill

Of the old Soviet stainless steel drills, the most suitable tool will be the P6M5K5 brand. This type of tooling contains up to 5% cobalt in the alloy composition. Due to this element, the tool acquires high strength, and the heating temperature can reach 135 degrees Celsius, which does not entail material destruction. Products of this quality can only be found in markets where old Soviet equipment is sold, and even then not always. An alternative to the domestically produced cobalt drill is a foreign analogue under the brand name HSS-Co.

Stainless steel drilling tricks

As you can see from the article, the process of drilling stainless steel is quite laborious and requires certain skills and training.

We have prepared some useful tips on how to drill stainless steel:

- The metal shavings during drilling should be long and come out in uniform sections, while small dark shavings indicate that the rotation speed is not selected correctly, and the cutting edges of the drill are overheated.

- If there is no prepared lubricant on hand, you can use ordinary vegetable or olive oil, and pork fat or lard is also perfect.

- For working with thin sheet stainless steel, you can use a special drill bit for porcelain stoneware.

- The drilling process should preferably be carried out at a low frequency of rotation of the cutting tool, and if the drill does not have the function of regulating the rotation, perform drilling by short-term switching on and off for 2-3 seconds.

- If you do not have a cobalt drill, you can use a 135-degree victorious tool.

- Before starting the drilling process, the workpiece should be screwed on to make it easier to center the drill.

- When drilling a workpiece of increased thickness, it is possible to preheat the processing site using a gas torch; during cooling, the heating can be periodically repeated.

- When processing thin stainless steel parts (up to 1 millimeter), you can use a high-quality feather drill for wood, as experience shows, the holes are even and with accurate dimensions.

What are they?

According to the materials from which the drills are made, several classes of products are distinguished.

- Tool steel drills with an edge reinforced with a high hardness plate. The main difference is low cost.

- Metal drills with cobalt additives or pure cobalt.Best suited for drilling in hard metal alloys, as they tolerate high temperatures and heavy workloads.

- Titanium tools are similar in strength to cobalt ones. Perfect for working with a variety of steels and alloys. They can keep the original sharpening for a long time.

- HSS drills perform well their functions and are distinguished by an acceptable cost. However, it should be borne in mind that sharpening quickly leaves them. Especially if operating temperatures have been exceeded.

When choosing drills, it is also important to consider that there are various models that differ in their shape. The classic type is considered to be stepped drills that have a cylindrical shape.

They are used most often for drilling holes in metal sheets. As a rule, for their manufacture, steel with the HSS marking is used, which has increased strength and durability.

The classic type is considered to be step drills that have a cylindrical shape. They are used most often for drilling holes in metal sheets. As a rule, for their manufacture, steel with the HSS marking is used, which has increased strength and durability.

Drills are also divided by color, since it allows you to determine what quality they are, of what they consist.

- Gray - means that metal drills have not been treated in any way. These tools are often disposable.

- A black color is obtained if the metal has been treated with steam at a high temperature. This gives the products increased strength, allows them to cope well with cyclic heating and cooling, and also retains their original sharpening for a long time.

- Dark golden drills are tempered (normalized), which increases their strength by reducing internal stresses. These tools are suitable for drilling in very strong metals and carbide alloys.

- The bright gold color indicates the addition of titanium to the metal. Such drills are fully consistent with their high price and do an excellent job even with very difficult tasks.

By the length of the drill, it is customary to divide into 3 types.

- Drills with a length of 56 to 254 mm are called long. Their diameter is usually between 1 and 20 mm.

- Elongated can be from 0.3 to 20 mm in diameter. Moreover, their minimum length is 19 mm, and the maximum is 205 mm.

- The length of short tools varies from 20-131 mm, and the diameter is completely similar to the diameter of the elongated ones.

1 Drilling in stainless steel - choosing a lubricant

Many home craftsmen, accustomed to doing everything in everyday life with their own hands, are very surprised when they cannot drill a hole in the "stainless steel" using a conventional drill. Such steel differs from other metals in high toughness, so the drill heats up almost immediately as soon as a person begins to process a product made of a stainless alloy.

This means that the operation can be successful only if you take care of high-quality cooling of the drilling tool.

To cool the device used for drilling holes in the "stainless steel", a special lubricant composition consisting of sulfur and machine oil is usually used. Sulfur can be used both colloidal and special for fumigation. In hardware stores, the latter is sold precisely under the name "for fumigation" (sometimes it can be called "sulfur color"). It is usually allowed to be used without any additional preparation. If you have purchased large fractions of sulfur, you should first grind it thoroughly and only then mix it with machine oil.

Drilling holes in stainless steel structures will be many times more effective when using a cooling compound based on fatty acids and all the same sulfur. These acids do not need to be bought anywhere, make them yourself.To do this, take the cheapest laundry soap, grind it up, and then pour the resulting mixture into hot water. Hydrochloric technical acid is added to this composition and they wait until the fatty acids we need begin to float to the surface.

As soon as the acids rise up, it is necessary to pour cold water into the container where the operation is performed (you do not need to feel sorry for it, the more you pour, the better). As a result, the fatty acids will begin to solidify, and they can be removed from the surface of the liquid without the slightest difficulty. The sounding process of isolation of the required compounds (soap in hot water - cooling - removal of acids) can be repeated several times (3-5).

Mixing of fatty compounds with colloidal or "fumigating" sulfur is carried out in compliance with the ratio of six to one. That is, six parts of acids must be added to one part of sulfur. Professionals assure that it will not be difficult to drill a "stainless steel" of any thickness with such a cooling compound (if, of course, you follow other recommendations, which we will discuss below).

3 Rules and tips for drilling at home

In order for the hole to be smooth and of high quality, several simple rules are used that allow you to perform work on stainless steel with high quality, namely:

When drilling parts that are located in a horizontal plane, the drill is pushed through a rubber washer or another material of suitable size and properties (for example, a plastic plug), which, in turn, is filled with a cooling compound and installed directly above the place of the required cut. Or, the area is additionally sprayed with universal metal products in the form of aerosols.

For vertical surfaces, a paraffin bead can be installed, which is a good lubricant. To facilitate work in any plane, experts recommend making preliminary markings (axial risks) or a special template with already marked contours.

Regardless of the type of part, thickness and other parameters, a household power tool or machine is adjusted using adjustments to the minimum feed in revolutions (100-450 rpm). This will allow you to drill evenly and accurately. The indicator of a correctly selected speed is the long and uniform metal chips that arise during operation.

When the thickness of the steel product is more than 7 millimeters, the procedure is performed in several technological runs. First, a small-diameter preliminary hole is made with a suitable drill (for example, 4-5mm), and then it is carefully drilled to the required parameters. This allows you to get the most even and neat edges, which is especially important when working with food or sanitary stainless pipes.

Drilling stainless steel at home is not difficult if you have theoretical and practical ideas about it and choose reliable power tools and a set of quality drills. Do not forget about the constant cooling of the metal, safety precautions and technological breaks.

Selection rules

If a cobalt tool is purchased in order to drill only a few holes with it, then you can opt for more economical options. For frequent and intensive use, it is advisable to choose more expensive products from trusted manufacturers that can last a long time without losing their original characteristics.

The highest quality and most reliable cobalt drills include tools that were produced by enterprises of the former Soviet Union. It becomes more and more difficult to acquire such drills, which can be recognized by the P6M5K5 marking, every year.Specialists, who are often faced with the need to drill stainless steel, are well aware of the quality characteristics of such a tool and will never miss the opportunity to buy it.

Drill from alloy R6M5K5 - time-tested quality

If we talk about cobalt drills from modern manufacturers, then the most high-quality and reliable of them are the tools produced under the Bosch and Ruco trademarks.

When choosing such tools, you must first of all pay attention to their marking, by which you can determine how much cobalt is contained in the chemical composition of the material of manufacture. So, the marking P6M5K5 or HSSCo5 (according to the foreign classification DIN 338R), applied to the shank, indicates that the drill material contains 5% cobalt

It should be borne in mind that in the material for the manufacture of tools belonging to the cobalt category, this element must contain at least 4%.

Cobalt drill marking

To create a high-quality hole, it is important not only to choose the right cobalt tool, but also to know how to drill stainless steel with it. To improve the accuracy of such a technological operation, as well as to reduce the wear rate of the used cobalt drill, it should be drilled with it at low speeds.

In addition, it must be borne in mind that such a drill does not need frequent cooling during use. Moreover, if you subject a cobalt drill to frequent cooling, it will deteriorate much faster.

Sink drilling

Often the question arises about how to drill a hole in a stainless steel sink

It is important to understand that the sink must first be dismantled so as not to damage the plumbing elements and the bedside table. Then the sink must be placed on a flat horizontal surface.

Next, the place of the future hole is marked and its punching is performed. If the hole is intended for installing the mixer and has a large diameter, then it is better to use a conical step drill, since the metal of the sink body is thin-walled.

If you doubt how to drill a stainless steel with a drill, then there are no big features from the technology described above. The main thing is to use a suitable drill and ensure it is well centered. Use a drill with adjustable speed, set the torque to a position close to maximum. A hand drill can assist in making holes up to 10 to 12 millimeters in diameter.