Assortment overview

All "Zubr" drills are divided according to the type of work. Let's take a closer look at each of them.

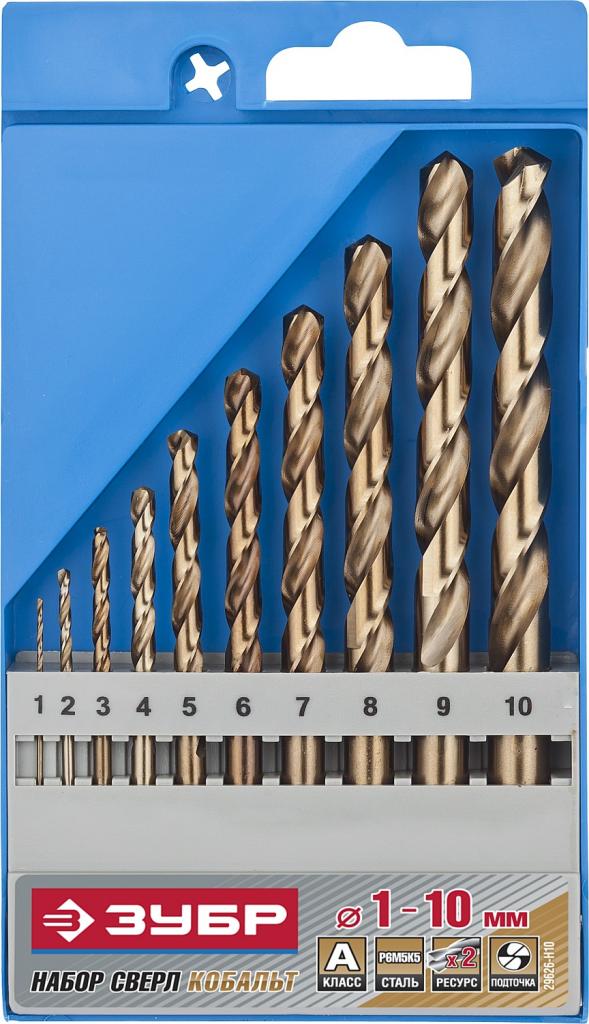

Drills for metal are presented by a Russian manufacturer in the Expert, Cobalt and Professional series. These consumables have a number of features.

- Made of high-speed steel grade P6M5 (it contains 5% cobalt) by profile grinding in accordance with GOST 10902-77. Due to this, the accuracy class is defined as "A".

- The cross-shaped sharpener allows drilling with high precision without pre-marked markings. The power of the revs is 30% higher than that of analog models.

- Sharpened at an angle of 135 ° to the bit for better centering when reaming.

- Ideal for drilling all types of steel, non-ferrous metal, gray cast iron and plastics.

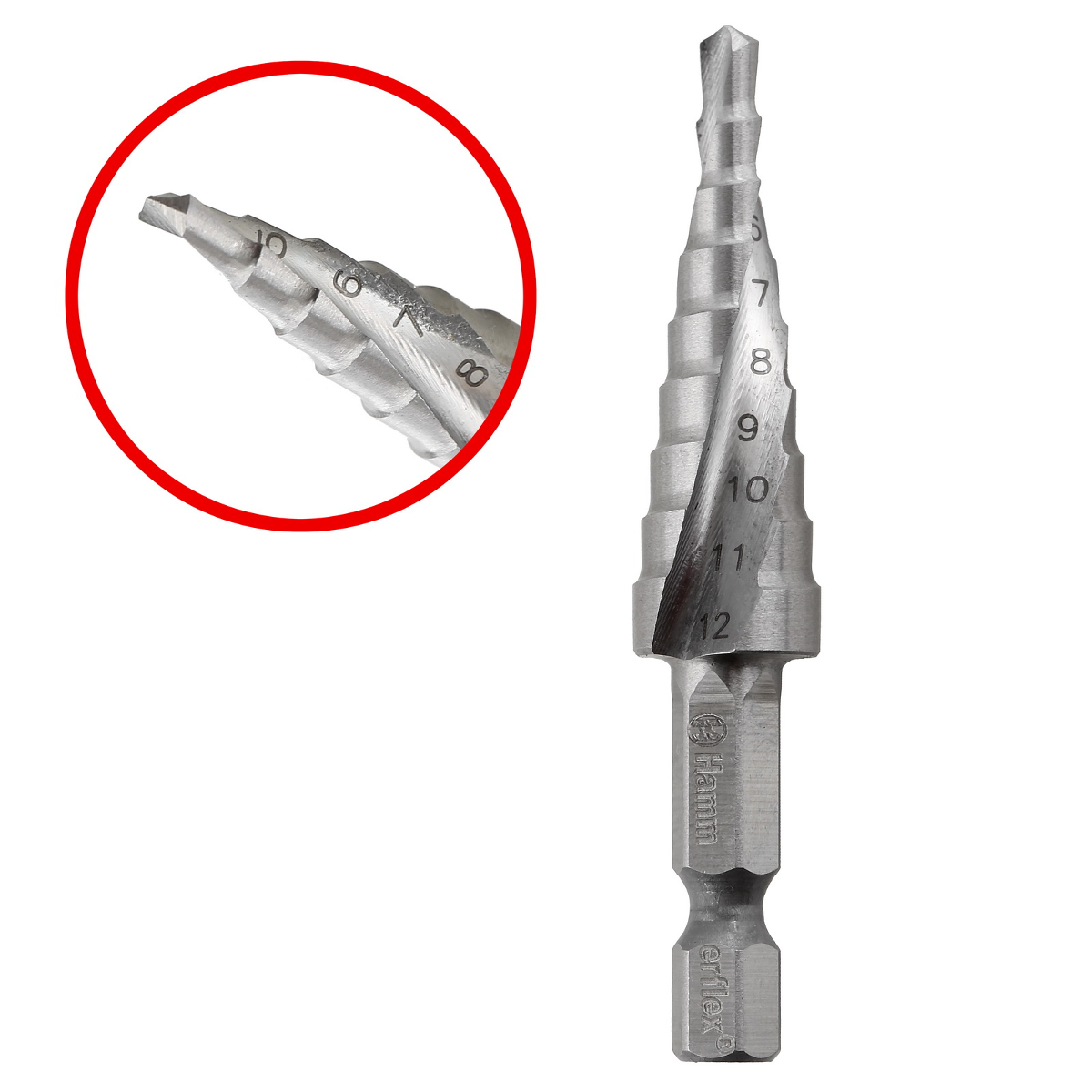

The Cobalt series is represented by a step drill. It is considered a class "A1", made according to technical characteristics corresponding to GOST 10902-77, from special high-speed steel R6M5K5 (it contains 5% cobalt).

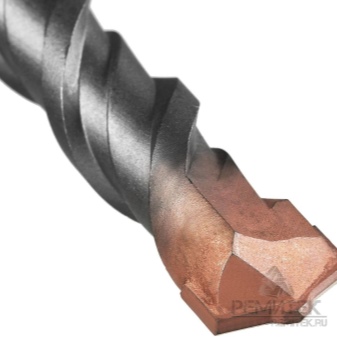

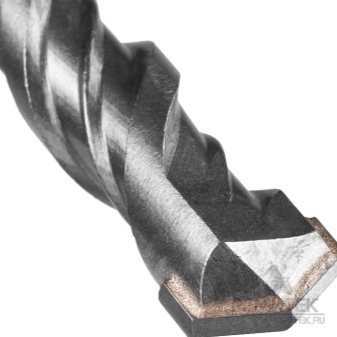

Drills for concrete (drills) are represented by the series "Professional" and "Master". Reinforced drill, with a special soldered tip, which is made of solid carbide in the shape of the letter W. For optimal performance, the drill is equipped with four notches between the working surfaces. This prevents the drill from heating up, at the same time it perfectly removes dust from the concrete surface.

Pay attention to the shank - it can be cylindrical or hex. The latter option is much more reliable, since it will not be able to scroll in the chuck of an electric drill.

The appearance of scoring or curved edges is unacceptable on the storm.

Tile drill series "Professional", "Master". Tile - the material is quite brittle and requires careful handling. Drills for glass and ceramic tiles are distinguished by clean drilling without chips. Sizes - from 0.4 to 1.0 cm, looks like a rod with a sharpened crown. The bit contains a titanium-tungsten alloy due to the high hardness of these metals.

Drill on porcelain stoneware series "Professional", "Master". To drill through porcelain stoneware, you need a drill with a diamond tube head. This will not harm the tile and will make it easy to make a hole, and exactly where you want.

Wood drill - Expert series. The most popular and best-selling type of drill.

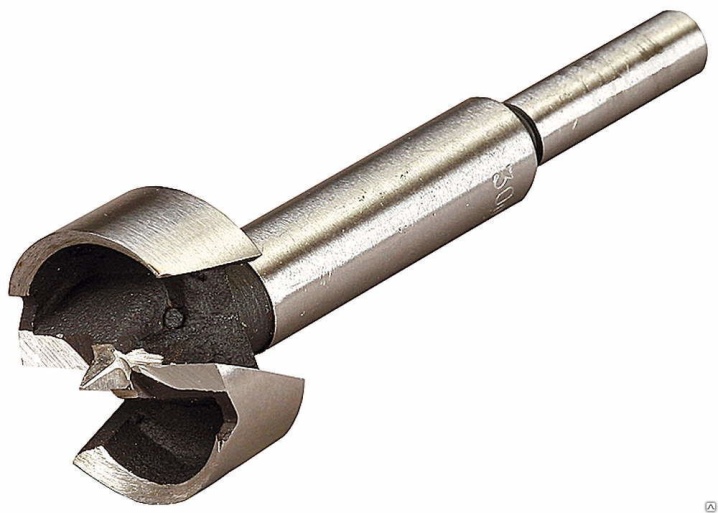

The Forstner drill is used to drill through holes in various woods, chipboard, plywood sheets and others related to wood-based materials. Made of robust tool steel, equipped with a centering point, two sharpened edges and side cutters.

How to choose?

When choosing a consumable for metal, you need to pay attention to the cutting edges, ideally they are located at an angle of 10-45 ° relative to the axis. It is also necessary to carefully treat the metal from which it is made - it is best if it is high-speed or alloy steel.

For concrete or brickwork, choose bit-tipped drills or modern drill models made from modified tungsten-cobalt alloys.

Depending on the nature of the work, you can choose one of the main types of drills.

- Twist drill. Scope of application - drilling holes, small in diameter, but quite deep.

- Drill bit. Scope of application - drilling a blind hole with a diameter of 1.0 cm and more in wood.

- Cylindrical drill. Scope of application - drilling large holes from 2.6 cm.

When choosing a drill, you need to carefully examine it.A high-quality consumable will be free of chipped spots, dents, scratches and other imperfections. The cutting edges are sharpened over the entire length of the blade, evenly colored. Sharpening without distortion, even.

When purchasing drills, you also need to pay attention to the manufacturer, trusting those brands that have managed to recommend their products in the construction market, for example, the Zubr company. The products of this brand are in the middle price segment and are of fairly high quality.

For information on how to choose a drill, see the next video.

Description

All drills are a special nozzle for making holes, the main differences of which are diameter, length, material of manufacture, working purpose and method of sharpening the edge of the drill. The surfaces for work are in the form of a spiral, between them there are two longitudinal grooves, with the help of which chips are removed during drilling.

Consumable tools from the Zubr trademark are favorably distinguished by their budgetary cost and good quality.

The drill with a taper shank is inserted without adapters or bits directly into the machine or power tool. A drill with a cylinder or hex shank needs special chucks.

The size of the drill must be selected in accordance with the thickness of the material intended for the work, or with the width of the self-tapping screw, bolt or anchor, under which the hole is drilled. In addition to size, the nature of the job in which you want to use the drill also matters. After all, if you take a drill for wood that can drill through metal, nothing terrible will happen, but if on the contrary, you can not only break the drill, but in the worst case, an electric drill or screwdriver will fail.