Types and models

Clamps are divided into the following types:

- quick-clamping;

- G-shaped;

- F-shaped;

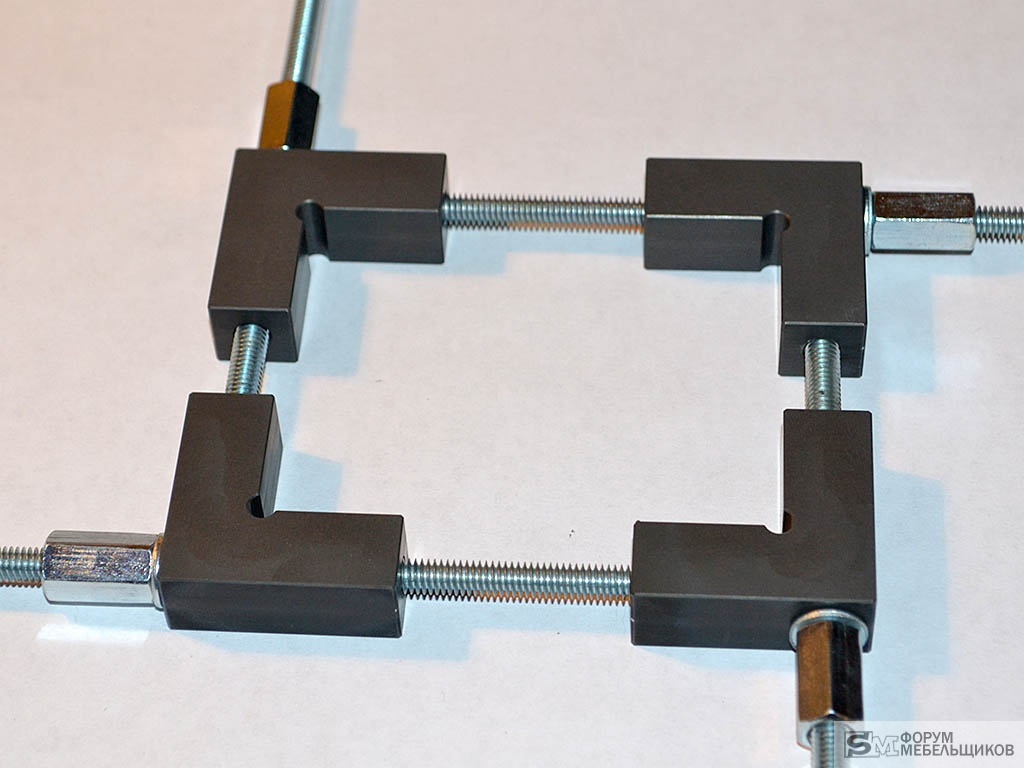

- corner;

- end;

- automatic;

- pipe;

- tape;

- spring.

A quick-clamping device is used to quickly fix parts. The tool is a lever-axial design, which reduces the stress on the user's hand while working with the clamp.

G-shaped devices are considered to be a unique type of this tool. Such a clamp is used for fastening products to any surface, and is also considered a cheap replacement for conventional vices.

F-shaped products have an adjustable clamping jaw. Therefore, this tool allows you to work with parts of different shapes.

End types of clamps are equipped with three fixing mechanisms and are used when gluing overlays on the ends of furniture modules. The device fixes securely, but is considered inconvenient. It is quite difficult to hold the clamp, adjust the screws and at the same time still hold the cover that is glued to the end of the piece of furniture.

The automatic clamp is a professional quick-clamping mechanism. The tool is one-handed. The product can be clamped with one hand. The disadvantages of the mechanism are: poor fixation of clamps and paws, made of plastic, which wears out over time.

Pipe structures are used when gluing dimensional products from which countertops or doors are made. The mechanism consists of a tube with two clamping legs. One foot is fixed with a stopper, and the other is fixed. The device allows you to glue dense parts and has a large grip. The downside of the tool is its size: the product is too long, so working with it is problematic.

The tape type clamps are not very common. It is used in the production of frames, chairs, in the assembly of wooden barrels. The fixture includes a high stiffness fabric band and a tension block.

The spring tool is equipped with a spring mechanism that creates compression. The design is similar to a large size clothespin. Such a clamp is considered an imperfect tool, because over time, the compression force of the spring weakens, as a result of which it becomes more difficult to fix the part.

An overview of the models should start with the IRWIN Quick Grip XP 600. Its main characteristics are as follows:

- metal - high quality;

- plastic elements - shockproof;

- compression force - up to 240 kg;

- clamping mechanism - two-position, stable, does not "shoot";

- the length of the fixing jaws - 96 mm;

- there is a possibility of clamping at a certain angle.

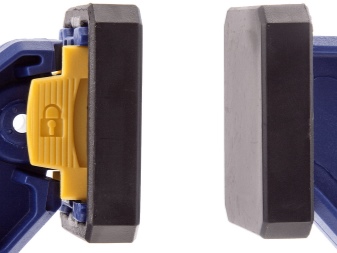

Manual clamp IRWIN T59100ECD / 38 mm. Its main characteristics:

- high quality steel;

- sponges - made of a special material so as not to spoil the part;

- smooth operation of the expanding mechanism, which ensures safe operation;

- used when gluing or compressing products with each other.

Model IRWIN T59400ECD / 100 mm. Specifications:

- a product made of durable plastic;

- comfortable handles for confident work with the structure;

- the legs have an adjustment for fixing parts of different shapes

The IRWIN T59200ECD / 50 mm model is characterized by the following features:

- used for gluing and compressing products;

- reliable and durable construction made of high quality steel;

- sponge pads do not leave marks on parts;

- Smooth expandable design for confident and safe operation.

Device and principle of operation

The quick-clamping clamp is a universal mechanism that resembles a kind of vice. The tool is used to fix metal parts during welding.Some types of devices are used when sawing or gluing wood blanks. All quick-clamping clamps differ in design, shape and dimensions.

The design of the tool looks like a metal rail. On one side of the bar there is a fixed jaw, on the other - a movable one with a trigger. The trigger is a special mechanism with two handles. The fixing of the parts takes place by clamping these handles.

The quick-release clamp has one advantage. If you turn both lips of the tool in opposite directions, you get a spacer device. Therefore, the quick-clamping clamp is considered a universal device. In the manufacture of devices, the following materials are used: metal, wood or durable plastic.

How to choose?

The main criterion for choosing a clamp is its working stroke. This parameter determines the distance between the fixing parts. The higher the value of the indicator, the more opportunities for fixing different-sized elements. The working stroke indicator varies from 20 to 350 mm.

In addition, attention must be paid to structural strength and clamping force. Metal products are distinguished by a long service life and tight fixation

When buying a plastic clamp, you need to make sure of the quality of the material. There are high-tech plastic models that can last for many years.

For a detailed description of the IRWIN QUICK GRIP XP clamps, see the following video.