4.2 Materials and construction

Woven tape and sewing thread

harness must be made of homogeneous fiber or

multifilament synthetic fibers suitable for their planned

use.

Tensile strength of synthetic fiber - not less than 0.6

N / tex.

Threads used for sewing

must be physically compatible with the fabric and the quality must be compatible with

the quality of the fabric. They must, however, be of a different color or contrasting shade.

in order to provide visual control.

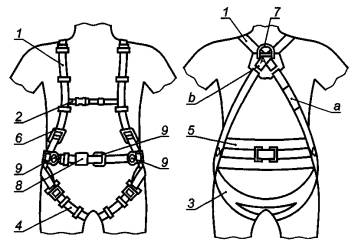

The harness must

include straps or similar elements that are placed in the pelvic area and on

shoulders (see Figures 1 and 2). The harness must be fitted to the body

by size, for which means of regulation can be provided.

The straps must not change position

and weaken on their own.

The width of the main straps should be

not less than 40 mm, and auxiliary straps - not less than 20 mm.

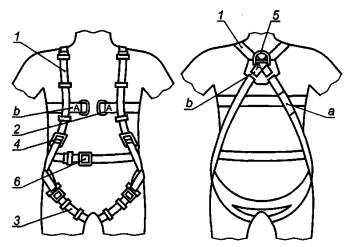

1 - shoulder strap; 2 - auxiliary strap; 3 - a belt used in a sitting position; 4 - hip belt; 5 - dorsal

support for work positioning; 6 - an adjusting element; 7 - element

fall arrest mounts; 8 - buckle; 9-piece worker mount

positioning;

a - marking, see.

section 6; b- marking with capital letter "A"

Figure 1 - Example of a full body harness with a back element

fall arrest mounts and worker mounts

positioning

1 - shoulder strap; 2 - front fastening element; 3 - hip strap (main

strap); 4 - element

regulation; 5 - dorsal attachment element; 6 - buckle

a - marking, see.

section 6; b- marking with capital letter "A"

Figure 2 - Example of a full body harness with a front

and dorsal fall arrest fittings

During static test

it should be

visually confirming that those straps that support the dummy or

put pressure on the human body, are the main straps.

Fall arrest fittings

it is allowed to place it so that when using a full body harness

they were located above the center of gravity, in front of the chest and / or behind on the back,

and / or on both shoulders of the user.

Full body harness allowed

embed in clothes. It should be possible to carry out a visual inspection of the entire

a full body harness, even if the full body harness is embedded in the garment.

All fastening buckles (i.e.

buckles other than those used for adjustment and fit) must be

designed in such a way that they can only be fastened with one

in the correct way or that all possible ways of fastening them

meet the requirements of strength and performance.

Metal fittings should

meet the requirements for corrosion protection in accordance with EN 362

(subsection 4.4).

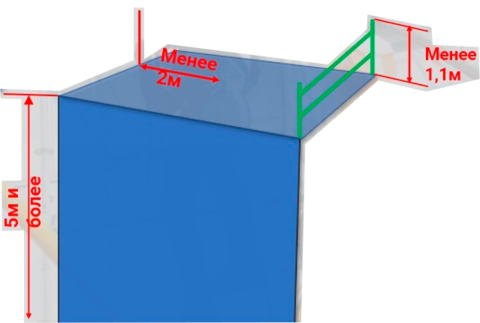

Safety harness requirements

Recall that high-altitude work includes any kind of work performed at a height of more than two meters - construction and steeplejack without support (at a height of over five meters), installation and roofing work, descent and ascent, etc. The mandatory requirements for an individual safety harness include:

- Technical requirements regulated by the standards GOST R EN 361-2008: composition of single- or multifilament synthetic materials, their tensile strength, compatibility of woven tape and sewing threads with the fabric of slings and belts.

- To visually check the integrity, the woven tapes and sewing threads that secure the connection are made in contrast to the base color of the straps.

- A safety harness is a design with the obligatory presence of straps in the hip and shoulder areas (should not be confused with a mounting belt, which does not have such structural elements).

- The harness must be able to adjust the straps according to the volume of the body - only correct and tight fixation of the system on the body will prevent serious injury in the event of an emergency.

- The fixation of the straps must be absolutely reliable with the exclusion of the possibility of arbitrary loosening.

- The width of the base straps should be at least 4 cm, and the auxiliary ones - at least 2 cm: this will prevent the straps from cutting into the muscle tissue in the event of an abrupt stop during a high-altitude fall.

- The harness should be made of a material that can withstand a weight much greater than the weight of a person, while the structure itself should not be heavy - often polyamide is used as such a material.

- Convenience and ease of use of a leash, a properly fitted size will allow a person to easily prepare for work and navigate, if necessary, in a difficult situation.

Only the exact fulfillment of these requirements will be able to ensure high-quality, optimal in terms of time and labor costs, and, possibly, save human life.

Species overview

The types of safety systems are divided into stationary and individual. Personal fall arrest systems are self-supporting and are designed to distribute the dynamic force resulting from a fall from a height.

Stationary systems are anchor devices and anchor lines of various modifications. With their help, the user can move horizontally, vertically or work with an inclined surface. A complete stationary system covers the entire working area, while the lengths of anchor lines are up to 12 m. Unlike mobile systems, stationary structures are fixed in their permanent place.

Chest harness

Made of a wide waist belt to which 2 shoulder straps are attached. The use of a chest harness alone without the use of leg straps creates the possibility of injury, since with a long suspension that occurs during a fall, it presses heavily on the chest area, thereby provoking fatal suffocation. For this reason, a split chest strap without a leg strap is not used.

There are different types of chest straps.

- Eight-shaped - the chest harness is made in the form of the number "8". There is a possibility of adjustment to the required size using buckles, but there are also non-adjustable models in a ready-made size design.

- In the form of a T-shirt - made of a girth along the chest line, to which 2 shoulder straps are attached. This is a common harness option, as it can be adjusted to any size, and in addition, it has additional loops for equipment.

Waist arbor

Convenient and practical model, which has many forms of execution.

- Belt - waist circumference with a sling attached to the lining fabric. Provides grip and reliability during a fall, which depends on the number of retaining buckles. The location of the buckles can be symmetrical (right and left) or asymmetric (1 buckle). The symmetrical version is most convenient for adjusting the size.

- Leg loops - they can be without the possibility of regulation according to the size of the leg or adjustable with the help of power buckles.

- Power loop - this element of a stitched sling connects the leg loops with the belt, and also serves as a means for connecting belay devices.

- Power buckles - used to adjust and fix the belts. Fixation comes with a counter-flow used for long-term performance of work, and there is also a Doubleback option, which allows you to quickly tighten all fastening elements to your size.

- Unloading loops - they are made of plastic or sewn slings. They are needed for hanging additional equipment, they are not used for insurance.

The harness is considered to be a simple and easy-to-use harness.

Combined

The design is a combination of top and bottom straps. It is considered the most reliable and is used for difficult mountaineering and rock climbing. Often this type is positioned as a five-point attachment system that reliably holds even children, providing maximum safety conditions.

Chapter 2 Practical part

2.1.2 Which fall arrest devices should I use?

Relief typeRope type in the case of a “classic” belay, only a half-time or a “glass” with an additional carabiner can be effectively used to delay a fall in the absence of intermediate points. In the case of belay through the body, the presence of a carabiner at the central point of the station makes it possible to use other types of brakes.2.1.3 Presence of intermediate pointsIn the presence of a large number of intermediate points, especially if they are located in a zigzag, the friction effect leads to an increase in the load on the last point, a decrease in the difference between the methods of belaying and, in part, between the braking devices.on unreliable terrain (ice, broken rocks, etc.), the use of two half-ropes alternating at points is justified by a decrease in the load at the last point.

in the case of a “classic” belay, only a half-time or a “glass” with an additional carabiner can be effectively used to delay a fall in the absence of intermediate points. In the case of belay through the body, the presence of a carabiner at the central point of the station makes it possible to use other types of brakes.2.1.3 Presence of intermediate pointsIn the presence of a large number of intermediate points, especially if they are located in a zigzag, the friction effect leads to an increase in the load on the last point, a decrease in the difference between the methods of belaying and, in part, between the braking devices.on unreliable terrain (ice, broken rocks, etc.), the use of two half-ropes alternating at points is justified by a decrease in the load at the last point.

2.1.4 What type of rope to use?

in the case of using two half-ropes, in the general case, it is more expedient to use them as a double rope, snapping them into one carabiner; only in situations where the priority is to reduce the load on the belay points and the rope goes in a zigzag, it is better to alternate the points, working in the double rope technique

2.2 Which belay technique to use?

If the belay points are not very reliable, (as often happens on firn, broken rocks, etc.), techniques that involve raising the belayer are preferable, since there is less load in the belay chain. Too much lifting can be reduced by reducing the station lock triangle, while taking into account the effectiveness of load distribution to the belay points.

Acting on solid rocks with reliable hooks (sleeves, “bolts”, etc.), techniques that do not cause the belayer to be lifted are preferable, as they are safer for the belayer and allow to limit the pickling of the rope. In this case, the classic belay can be used in both parallel and sequential blocking of station points.

Why is this needed?

The question may arise, why are separate child restraint systems needed when the car has seat belts for everyone? However, in fact, the safety systems in the car bodies are designed for persons with a height of more than 150 cm. Therefore, in emergency situations, the belt compresses the throat of people below this mark, which leads to injury even in minor collisions. The most dangerous situation is when the child is transported on his knees. If a collision occurs, then his weight will increase several tens of times, and his body will cause serious damage to an adult.

There are several restraint systems for people under 12 years of age. In addition to car seats, the simplest of them is also used - the domestic "FEST". It costs several times cheaper than car seats and at the same time meets all the requirements of the law.

The design of the child restraint system is clearly visible in the photo.

III. Risk factors and safety measures in special cases.

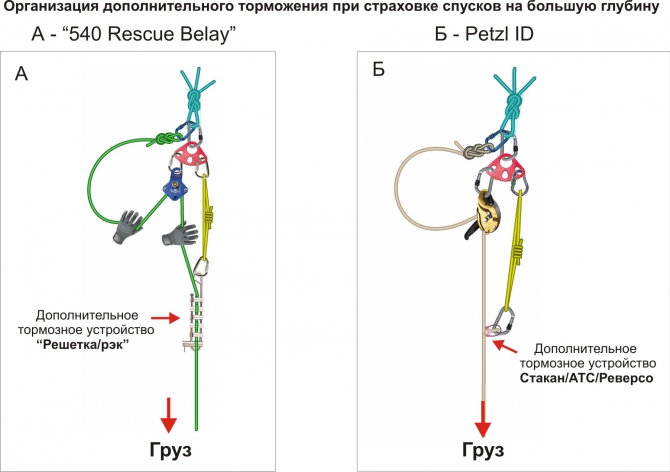

1. Risk factors when descending to great depths.

1.1.1.2.1.3. 1.4.1.5. Recommendations to mitigate the risks associated with descent to deeper depths:Do not use descents to great depths unless absolutely necessary. 1.5.1. Rice. 4

Rice. 4

2. Special cases in which it is dangerous to use a double rope.

2.1.2.2.2.3. Twisting two ropes can lead to the following dangerous consequences:2.4. Measures to reduce the risk of rope twisting.3. Organization of a descent / ascent system at one station. failure of a single station will mean a failure of the entire system as a whole and can lead to serious consequences and / or death of the victim and accompanying persons, as well as rescuers working at the station.

Safety harness check

Checking the fitness of a full body harness includes:

Visual inspection - checking in accordance with the instructions for the presence of all elements, integrity, correct assembly, absence of mechanical damage and traces of repair.

Belt Check - Check for cuts, scuffs, loose fibers, paint or oil marks, heat damage, or damage from stopping a fall. The flexibility of all belts is also checked, which should be the same along the entire length. The tapes are also checked for foci of discoloration, which indicates thermal, chemical or ultraviolet exposure. A sign of the use of the harness in stopping a fall is the presence of focal lamination, which should also be absent. The width of the tape should be the same along its entire length. And it is also very important to carefully check the joints of the bands with size adjustment buckles and connecting rings.

Seam Check - Check for damage such as cuts, scuffs, burns. The tightness of the seam and the integrity of the threads are checked, the wear of which cannot be more than 30% of the original diameter, as well as the presence of a knocked-out thread at the end of the seam, which should not exceed more than two punctures.

Checking metal elements - checking the adjusting, fasteners for serviceability and for the absence of any deformation, cracks, corrosion. All metal elements are checked for corrosion in places where they are stitched with the tape.

Species overview

Safety belts come in several varieties. According to GOST, the following classification is used:

- frameless;

- strap;

- with shock absorber;

- without shock absorber.

Strapless safety harness (restraint harness)

This is the simplest type of safety harness (1st class of protection). Consists of a safety (assembly) strap and a fixing halyard or catcher for fastening to the supports. Another name is a holding leash; in everyday life, such a leash is simply called a mounting belt.

The restraint harness is suitable for working on a relatively safe surface where you can rest your feet and there is no danger of falling (eg scaffolding, roof). The length of the halyard is adjusted to prevent the technician from leaving the safe area and to get too close to the edge from which to fall.

But at the very fall, the mounting belt, unlike a full safety harness, does not guarantee safety:

- due to a strong jerk, the spine can be injured, especially the lower back;

- the belt will not provide a normal body position during a jerk, fall - there is a high risk of toppling upside down;

- with a very strong jerk, a person can slip out of the belt.

Therefore, the regulations prohibit the use of beltless belts where there is a risk of falling, or the specialist must be unsupported (suspended).

Harness harness (harness)

This is a safety system of the 2nd, higher class of reliability, consisting of an assembly strap and a special system of straps, rods, fasteners. The straps are fixed to the mounting strap at the attachment points on the chest and back assemblies. That is, the assembly belt does not act here autonomously, but as an element of a more complex system. Such a system is called a safety harness (not to be confused with a restraining harness) or in everyday life - just a harness.

Leash straps are:

- shoulder;

- thigh;

- joint;

- saddle.

The fastening of the straps should be as reliable as possible, capable of withstanding high breaking loads, the width of the supporting straps cannot be thinner than 4 cm, and the total weight of the leash should not be more than 3 kg.

The design of the safety harness allows you to fix it to the support at several points - from 1 to 5. The most reliable type of construction is a five-point one.

Therefore, it can be used when performing hazardous work, including on unsupported structures.

With shock absorber

A shock absorber is a device built-in or attached to a mounting strap (usually in the form of a special elastic band) that reduces the force of a jerk in case of a fall (according to the standard to a value of less than 6000 N) in order to prevent the risk of injury. At the same time, for effective absorption of the jerk, there must be a "reserve" in the height of the free flight of at least 3 meters.

Without shock absorber

Slings that are used in conjunction with a belt are selected depending on the conditions and load: they can be made of synthetic tape, rope, rope or steel cable, chain.

How to navigate structures and high-rise objects

Scaffolding andmobile work platforms must be made in accordance with the manufacturer's documentation or individual design.

Forests should be planted on stable and delineated land with a slope that allows rainwater drainage. The number and location of scaffold anchorages and the size of the anchorage force must be indicated in the scaffold design or in the manufacturer's documentation.

Scaffolding and mobile work platforms must:

- have a bridge with a sufficient working surface for people performing robots, as well as for storing tools and the required amount of materials;

- have a stable structure adapted to transfer loads;

- have protective railings and communication rails.

The persons involved in the assembly and dismantling of scaffolding and mobile work platforms must have the required qualifications. The assembly, operation and dismantling of scaffolding and mobile work platforms according to the following criteria are prohibited:

- if lighting is not provided at night to ensure good visibility;

- during thick fog, precipitation, snow and frost;

- during a storm or wind with a speed exceeding 10 m / s.

Important! The use of scaffolding is permissible after it has been accepted by the building manager or an authorized person. Acceptance of scaffolds is confirmed by an entry in the construction log or in the technical act of acceptance

To move on other building structures at a height, you must apply:

- self-belay;

- employee insurance from below;

- organization of the safety system.

The belayer must create an independent anchoring device with a dynamic rope braking system.

Self-belay

Safety harness test

Like any PPE, a harness must be operated in strict accordance with GOSTs. This applies to regular use and the frequency of scheduled inspections. Before testing the joint venture, you need to study the instructions attached to it from the manufacturer. It describes the procedure for preparing, checking, using the product.

In short, the general test rules are as follows:

- before each use, the joint venture must be carefully inspected for damage or loosening of the nodes;

- when putting on, you need to make sure that the belt is at the waist, leg, shoulder straps - in their places;

- the dorsal point should be adjusted, the shoulder straps should be tightened;

- further, the shoulder straps must be connected to the belt using buckles and carabiners.

After that, you can carry out strength tests, observing the conditions established by the manufacturer, that is, in the recommended temperature regime, away from chemically active substances, piercing-cutting objects.The product is tested for static, dynamic loads on special stands using a steel dummy that imitates a person.

The storage of the joint venture is carried out according to the rules: in a dry room, protected from direct sunlight. Do not store equipment near heating devices, flammable or chemically aggressive substances. After cleaning, only natural drying of the product is possible.

It is important to remember that in case of any damage or weakening of the structure, the harness cannot be used, and at the end of the warranty period, the equipment should be taken out of service and destroyed. Similar standards apply to the operation and storage of mounting straps, but the test details are different

Once every 6 months, the belts must be tested for a static load of 4,000N

Similar standards apply to the operation and storage of the mounting straps, but the test details are different. Once every 6 months, the belts should be tested for a static load of 4,000N.

This is done in two ways:

- the belt for work at height is fastened with a buckle on a rigid cylindrical beam, and a load is suspended from the ring on the waist belt for 5 minutes giving a load of 4000 N;

- after fastening the belt to the beam, the ring on the lumbar safety belt is connected to the winch, which develops a load of 4000 N for 5 minutes.

If, after testing, the metal parts are not deformed, fabrics and threads are not torn, no other defects appear, then the test of the safety harness is considered successful.

Whatever the level of professionalism of the person using the harness, before using the harness directly, you should study the manufacturer's instructions, thoroughly inspect the equipment, check the characteristics, and conduct practical tests.

The frequency of the scheduled inspection of the safety harness is regulated by the requirements of GOST, before each use, it must undergo a visual inspection. In the presence of damaged areas, incompatibility of nodes and structural elements, the potential for self-unlocking of any of the buckles, the use of a safety harness is prohibited.

Each piece of the harness must be accompanied by instructions that determine the procedure for preparing, checking and using the harness. The general rules are as follows:

Before use, the harness is put on: the belt is located at the waist, leg loops and shoulder straps - on the corresponding parts of the body. The dorsal position is adjusted and the shoulder strap is tightened. Shoulder straps are attached to the belt with buckles and carabiners

The testing of the harness is carried out under the conditions specified by the manufacturer: it is important to observe the recommended temperature conditions and to exclude the possibility of damage to individual units and elements by chemically aggressive substances and piercing-cutting objects

The storage of safety equipment is carried out in dry rooms protected from direct sunlight, with air that is non-aggressive in composition and without obvious dust contamination. During storage, it is necessary to exclude the presence of tethers near heating devices, flammable and chemically aggressive substances (gasoline, kerosene, acids, etc.

Types by area of use

The choice of safety equipment depends on the type of work performed and the user's activity. According to the scope of application, protective equipment is divided into several types.

Systems for climbers are convenient and comfortable, they can be suspended for a long time. It is made of a waist belt with a wide base and adjustable leg straps. It is not uncommon for users to add gear loops to such a system.

How to care?

In order not to shorten the life of the fall arrest system, it requires regular maintenance after use.It is allowed to wash equipment using laundry soap, it is better to clean it from dirt by hand. After washing, the structure must be dried, but not on the battery. Materials made from polymers must not be cleaned with organic solvents or other chemicals.

Before each use, the protective system must be carefully checked for its integrity, and metal parts must be inspected for deformation or breakage. If defects are found, the equipment is not subject to use.

See the next video on how to choose the right belay system.

The main conclusions on the third part of the article:

There is no single universal “recipe” for organizing insurance during rescue operations in the mountains. The choice of the method of organizing the descent / ascent and the technique of belaying depends on a combination of many factors.All of the above recommendations refer primarily to potentially hazardous conditions and are not absolute. These guidelines are guidelines for decision making, not laws.In each specific situation, rescuers need to make a decision on the choice of tactics and technique of insurance independently, taking into account the specifics of the conditions in which rescue operations take place. To be continued:

155

Login or register to leave a comment