What do you need?

Depending on the purpose, intensity of use and use at home, it is necessary to select the size of the blanks before the process of making a simple carpentry vice. Therefore, the key question remains open. To assemble a functional tool with your own hands, you will need a number of materials:

- wire;

- self-tapping screws;

- metal studs (2 pcs.);

- nuts (4 pcs.);

- plywood sheet;

- die with a holder for threading.

In addition, you need to prepare the tool:

- square;

- fountain pen or pencil;

- hacksaw;

- electric drill;

- sandpaper;

- PVA glue or its equivalent;

- drills of different diameters.

Before starting the manufacture of a bench vice, it is advisable to draw a sketch (ideally a drawing), with the stated dimensions in order to simplify the assembly steps and eliminate typical errors. A visual drawing should be clear so that in the process of work there are no doubts about the correctness of the actions.

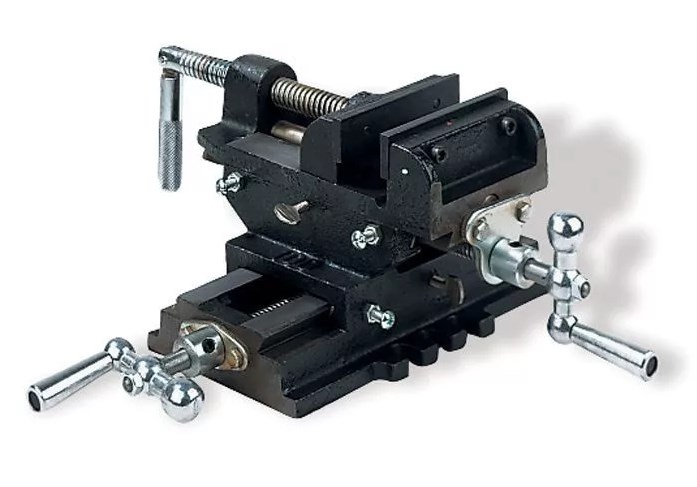

Model overview

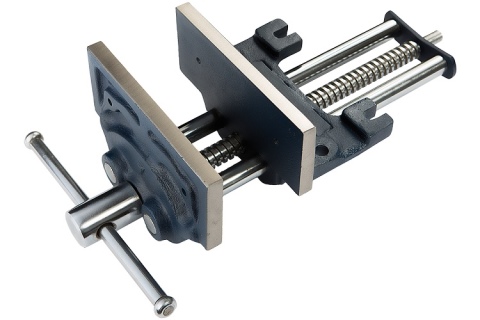

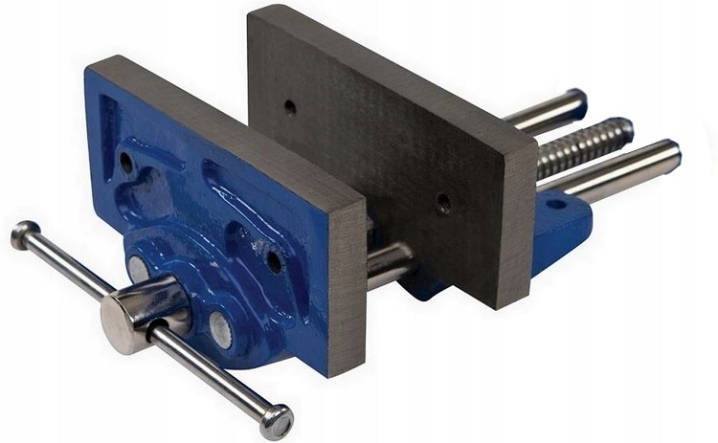

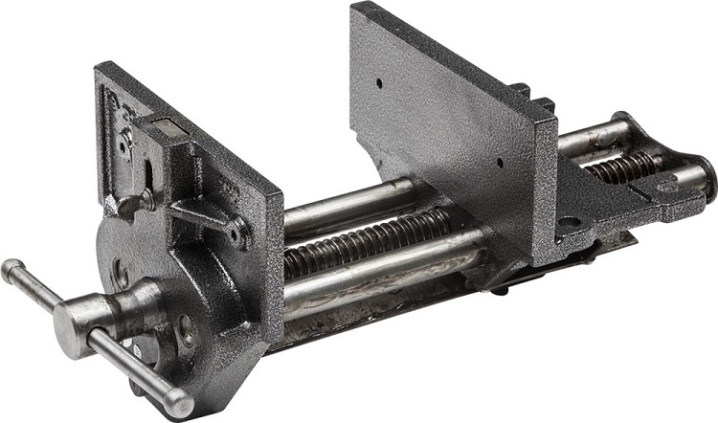

Opens the list of joinery models Groz workbench vice WWV-150. Specifications:

- the device is completely made of ductile iron, which will ensure reliability and maximum service life;

- polished surface, which is responsible for smooth running during processing;

- steel guide pins ensure the parallel precision of the workpiece;

- the width of the fixing legs is 15 cm for a secure clamping of the product;

- for fixing wooden plates, the tool is equipped with threaded holes, which protects the tool itself and the workpieces used;

- working stroke - 115 mm.

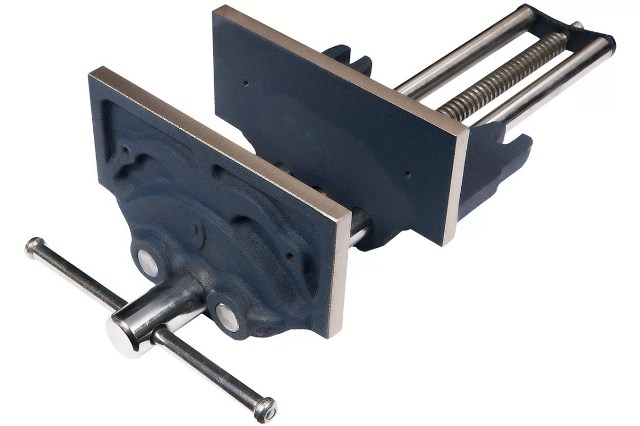

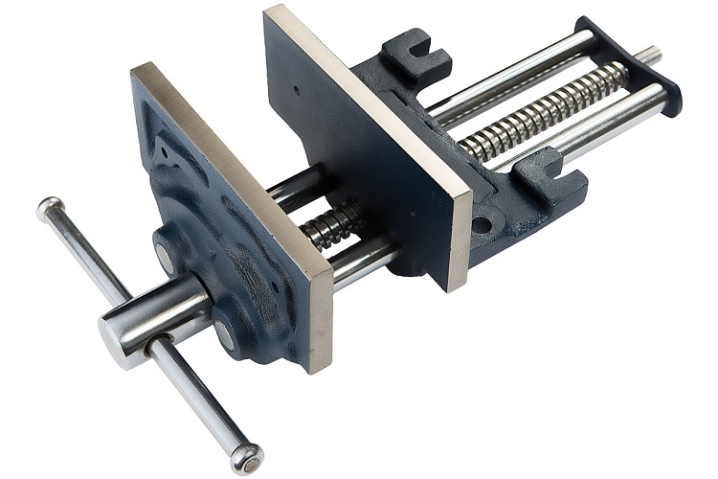

Vice American manufacturer Wilton WWV-175 65017EU. Peculiarities:

- clamping feet consumption - 70 mm;

- distance between legs - 210 mm;

- the tool is used for processing large parts;

- smooth surface of the legs eliminates deformation of the workpieces;

- the undercarriage has two guides and a clamping screw;

- frame structure with special holes for fastening to the surface;

- smooth running during work.

The disadvantage of the model is the lack of a rotary mechanism.

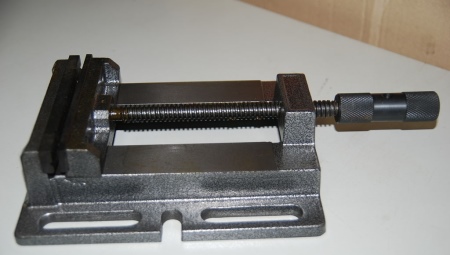

Vice "Zubr Expert 32731/175". Features of the model:

- fast and reliable fixation;

- clamping screw with trapezoidal thread, which indicates the strength and durability of the mechanism;

- smooth rectilinear course of two guides;

- the possibility of fastening to the workbench using hardware;

- the legs are equipped with special holes for replacing the linings;

- legs width - 175 mm;

- lack of backlash.

Triton SJA100E stand vise. Specifications:

- equipment mobility;

- the ability of fastening dimensional workpieces;

- the clamping mechanism is equipped with a foot drive;

- manual spreading of the legs;

- the ability to work without attachment to a workbench or to any other surfaces;

- large working stroke;

- the width of the legs - 178 mm;

- folding legs;

- the tool is equipped with a swivel mechanism.

The disadvantage of vices is their high cost.

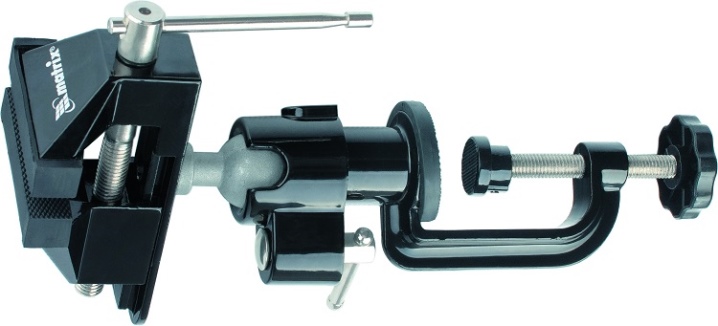

German vise Matrix 18508. Features:

- the presence of a fastening clamp that provides attachment to any surface;

- adjustment of the desired angle of inclination when processing a part;

- rubber pads on the fixing legs;

- replaceable nozzle in the form of a clamping clamp for fastening the workpiece;

- legs width - 70 mm;

- foot consumption - 50 mm;

- working stroke - 55 mm;

- the presence of a rotation function;

This model is considered versatile and multifunctional.

Manufacturing instruction

When the blanks and tools are prepared, and the dimensional drawings are at hand, the first step is to make jaws for a simple vice. Here you should select plywood, timber and cut out the parts according to the selected length and width.Take a square, fountain pen, or pencil and mark the holes. The workpieces are better secured for increased comfort and safety. Clamps can be used.

At the next stage, it is necessary to drill 2 holes, and in the plywood separately - along the edges of the ends - drill an additional 6 holes. They are designed for self-tapping screws. And in order to then drown the caps into the material, it is necessary to slightly ream the finished holes with a larger diameter drill.

To make homemade handles, you need a pair of ring crowns. One is small and the other is medium. Attach the fixtures to the tree and mark the diameters with a pencil. Then, using a special nozzle, set the crowns and cut the blanks along the marks with an electric drill. Then take sandpaper and remove any burrs from the sharp edges.

Create small indentations in large diameter parts. For this purpose, you can use a chisel drill. Drive a nut into both blanks and screw in threaded studs into them. Insert a piece of wire into the pre-drilled holes in each stud, which will serve as a stopper. The resulting two circles now need to be glued using pre-prepared PVA glue, and for better reliability, reinforced with two self-tapping screws. This completes the manufacture of handles.

Let's consider how to make another model of a vice for carpentry work. You will need the same tools, and add a metal corner and a plumbing tee of the required size to the materials.

Such a vice is mounted as follows.

- Cut a piece of the corner of the required size.

- Drill a hole in the center for the lead screw, and at the edges - another hole with a smaller diameter.

- Cut the workpiece out of the prepared corner. Clean sharp edges with burrs.

- Take a stud with a pre-cut thread and a nut at one end.

- Use a plumbing tee - screw it onto the end of the stud with a nut through the central hole of the prepared metal workpiece.

- Next, you need to equip the workpiece with guides that are inserted into the holes along the edges. On the other side of the workpiece, screw in a nut and tighten tightly.

- Take two nuts, a metal strip and assemble the lead screw guide.

- It is advisable to fix the resulting structure on the trimming of a thick board.

- Lastly, the clamping jaws are cut from plywood, and the knob is cut from a wooden handle.

Now the structure needs to be assembled and tested.

To make a carpentry vice, you will need ordinary tools, wooden blanks, corners, bolts, nuts, which are sold in the assortment on the construction market. In order to follow the procedure and not make a mistake, the assembly stages of the future product must be indicated in the figure. Now we can draw the final conclusion - making a carpentry vice with your own hands is within the power of every man.

How to make a carpentry vice with your own hands, see below.

Do-it-yourself carpentry vice for a workbench

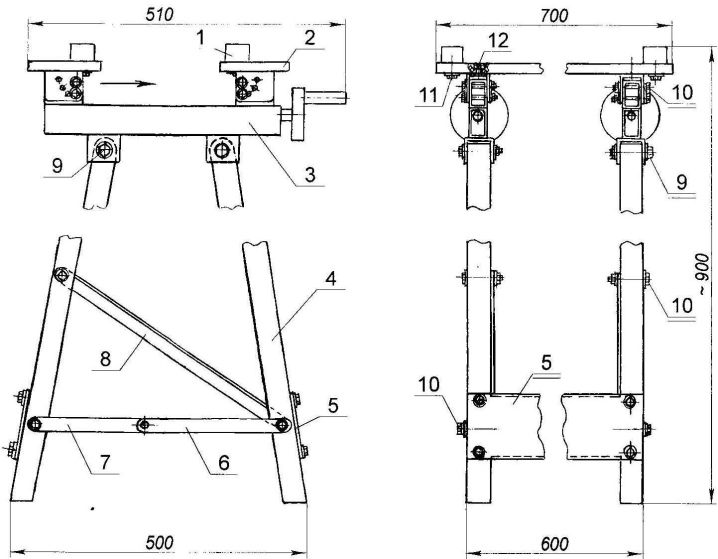

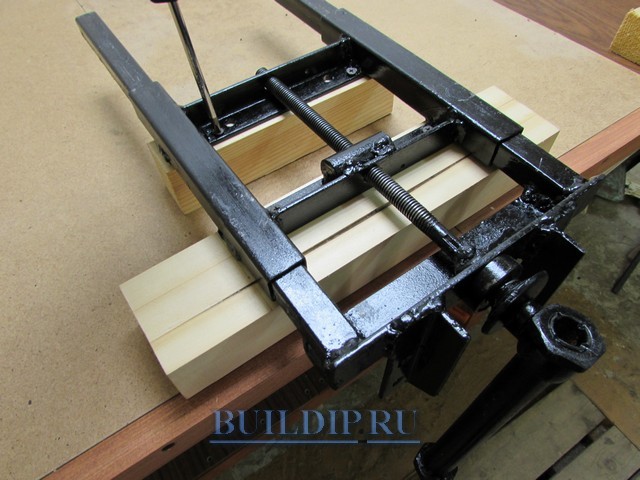

Cut the parts with a grinder and make grooves at the ends of the corners to fit the size of a square profile pipe. Select the correct washers and bushings for the clamping unit, the inner diameter of which must match the gauge of the threaded rod.

Fix the ties with clamps and weld them to one profile pipe.

Install the second guide strictly parallel to the first and weld the parts.

Attention: even if you are a non-professional welder, you will have to try and make welds that provide sufficient structural rigidity. Grind the top surface with a sanding disc, removing all protrusions

Grind the top surface with a sanding disc, removing all protrusions.

Insert the movable guides, align their ends and press the brace corner against them. Secure the parts with welding.

Install the vertical corners and weld them.

Drill the screw holes in the middle of the corners.When marking their location, keep in mind that the rod must lie in the screed of the moving part so that the thrust washer can rotate.

Secure the travel nut by welding. Assemble the clamping unit: first weld to the shaft of the wrench sleeve.

Now install the movable bush and weld the thrust washer. To maintain the gap, insert a strip of thin sheet metal under the corner.

Take care of the crank. If you use a half-inch pipe for it, then the nuts at the ends can be welded or fastened to the threads and then pounded.

Make mounting holes and remove scale and rust from surfaces.

Cover the joinery vice with primer and paint.

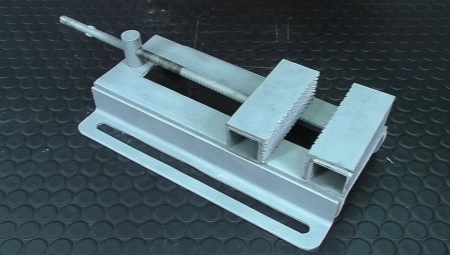

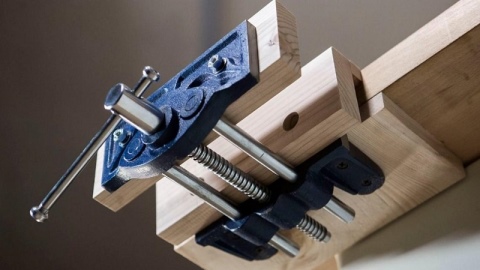

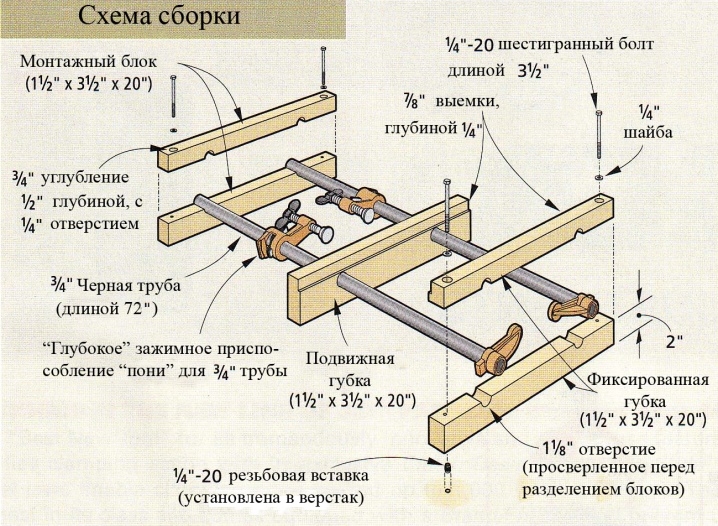

Start making wood joinery vices.

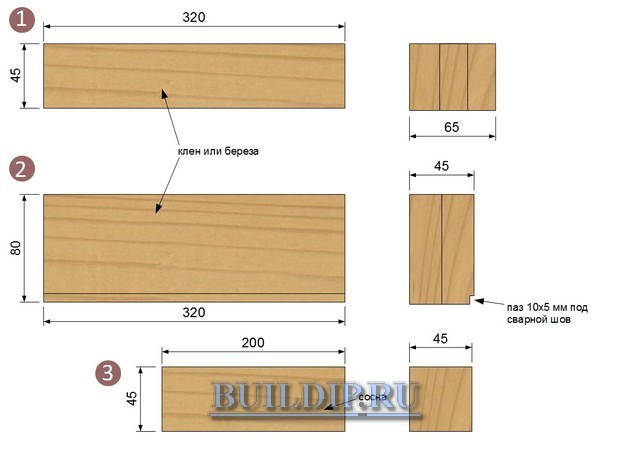

Drawing of the wooden parts of the joinery vice: 1 - small fixed sponge; 2 - large movable sponge; 3 - support bar.

Prepare planed strips with a thickness of 22 mm from hard wood: make an allowance for the length of 15–20 mm, for the width of 3–4 mm, and for the blanks of the movable jaw, instead of 80 mm, take 85 mm. Saw off the support block immediately to size from pine.

Glue the two pieces together.

After the glue dries, cut the parts to a length of 320 mm.

Sharpen the fixed jaw to the finished size and sand the front side. Fasten the wooden parts at the corners with screws through the auxiliary holes.

Place the vise on the workbench, aligning the fixed jaw with the end of the worktop. Secure with clamps and mark the drilling points.

After removing the fiberboard from the workbench lid, drill the holes for the mounting bolts.

Make indentations in the countertop under the caps with a feather drill.

Fasten the vise with bolts at least 10 mm in diameter.

Sharpen the movable jaw in thickness and cut a groove for the weld.

Place the sponge in a vise and mark its exact height.

Remove excess wood with a plane and put the part back in place.

Apply the finishing compound to the wood elements, lubricate the rubbing parts of the clamping unit and the running nut.

The considered design of the joinery vice is both simple and reliable. Make this clamping device for your home workshop.

How is a vice for carpentry work

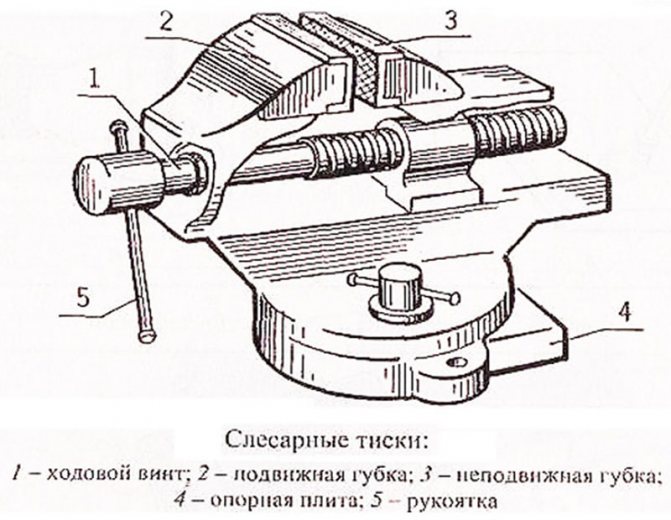

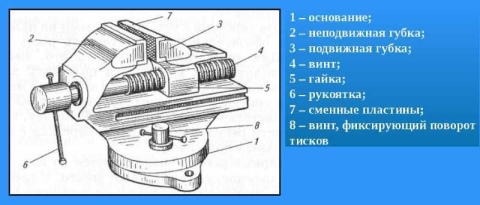

The vise for joinery consists of the following elements:

- support, which is at the same time a fixed clamping jaw;

- movable clamping jaw;

- two metal guides along which the movable jaw moves;

- a lead screw that moves the movable jaw;

- a knob, due to which rotation is imparted to the lead screw.

The main parts of the vice for the joinery workbench

The fixed support of the carpentry vise is securely fixed to the surface of the workbench using long screws or bolted fasteners. In many serial models, it is possible to use replaceable pads for the movable and fixed jaws. Such pads, which increase the versatility of the joinery vice, can be made of metal and polymeric materials.

Since bench vices are often used to handle large pieces of wood, many models are designed with a spring mechanism to facilitate handling. Such a mechanism, which can also be installed on a homemade carpenter's vice, provides a preliminary clamping of the part (it is finally fixed with a lead screw). If this mechanism is absent in the design of the bench vice, then the carpenter will have to hold the wooden blank for a long time before the movable clamping jaw is brought to it.

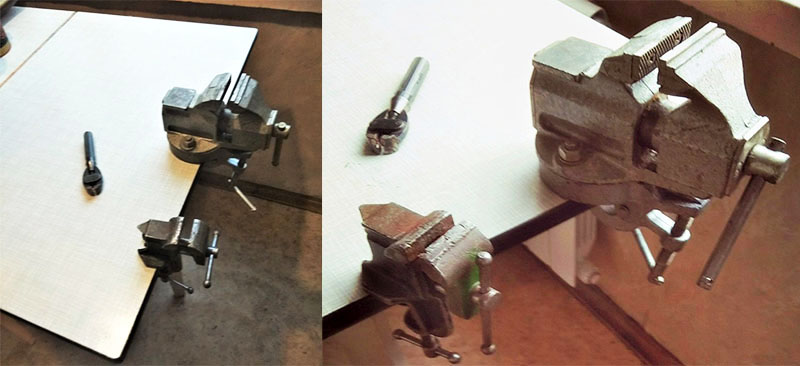

Homemade jaw clip retainer