How to care

In order for the armbands to retain their protective functions and to be able to ensure the safety of a specialist, they must be properly looked after.

It is periodically necessary to clean products from industrial pollution. Canvas oversleeves should be washed at a water temperature of no more than + 40 ° C and dried thoroughly so that no moisture remains. Models from various leather variations: suede, split leather must be cleaned, it is not recommended to wash.

Storage is carried out in a dry place, it is necessary to exclude exposure to direct sunlight and interaction with chemically active substances.

Top brands

Due to the fact that overalls for welding are important in production processes, a large number of domestic and foreign companies are engaged in the manufacture of such a robe. Consider the ranking of the best brands:

- the trade mark "Avangard-Spetsodezhda" is engaged in the manufacture of not only clothing and footwear, but also additional accessories for welders;

- the company "Vostok-Service" offers consumers a wide variety of robes for welders, also the range of the company includes protective equipment for the head and hands;

- the main activity of the Ivspetsposhiv company is the production of suits for welders, while the assortment also includes footwear, protective equipment and additional accessories;

- Technoavia is a company that manufactures and sells clothing, footwear, hats and protective equipment for welders;

- "Shaturskaya sewing manufactory" specializes in the production of professional clothing;

- ESAB is a global leader in the niche of production of workwear for welders;

- the Belarusian company "Alexander Sokolov" offers consumers a large number of specialized clothing for welders and gas cutters.

Elements of a set of overalls for a welder

Welders' clothing consists not only of a suit, there are a number of parts that are not intended for other professions, for example, an apron or glasses with light filters. The welder's clothing includes knee pads and sleeves, gloves and a hat, as well as boots, thanks to which the clothing can protect the employee from harmful effects and prevent burns and other damage to the skin and eyes.

Elements of a set of overalls for a welder.

Elements of a set of overalls for a welder.

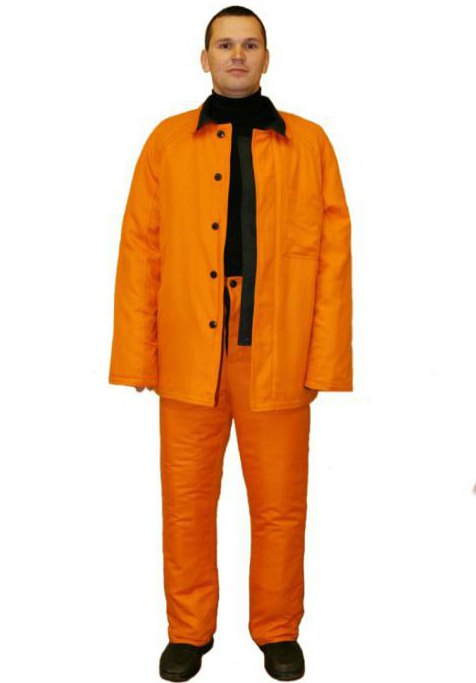

Jacket and Pants

In order for the welder's jacket to protect the worker from flying splashes and drops of metal, it must have closed pockets, straps, a special close-fitting collar and adjustable cuffs. The portwest welder's jacket has all these features, plus it:

- can be washed several times without losing its fire retardant properties;

- reliable and durable;

- has a modern appearance;

- lightweight, ergonomic.

Various fabrics are used in the production of clothing for welding: from tarpaulin and cloth to leather and combined.

No less thoroughly you need to approach the selection of trousers. They are sold together or separately, and are sewn with straps like overalls

When choosing such clothes, be sure to pay attention to the quality of tailoring, accessories, the presence of linings and pockets.

Work gloves

The welder's hands are most exposed to high temperatures, and therefore gloves for welding must be selected carefully, they must be strong, wear-resistant, fireproof, durable. Mittens are:

- Two-fingered - similar to ordinary ones, the thumb is separated from the rest.

- Three-fingered - apart from the thumb, the index finger is also separated, which is more convenient when using tools.

- Five-toed - each finger is separated from the rest.

Mittens are made of various materials, have insulation in winter versions, and can be of different colors.

Shoes

The selection of boots or boots should be approached responsibly. All fasteners must be closed with special flaps. The outsole uses nitrile rubber that can withstand temperatures up to 300 ° C

If oversized equipment is used, you need to pay attention to whether the shoes have a metal toe. The method of attaching the sole to the upper is considered equally important, the most reliable is the molded one.

A cap

Helmets with a shield or special masks are considered a hat for welders. Under them, a comforter is put on, which should tightly fit the head and neck of the worker.

Apron

Another important part of the welder's work clothes is the apron. Most often it is used when working at the welding table.

The aprons are made from different materials and also provide additional protection to the front of the welding garment.

Armbands and knee pads

Sleeves and knee pads are important additional protection. The first differ in the fabric and thickness of the product.

Fixation on the hands can be carried out by means of Velcro, buttons, elastic bands, buttons or thumb loops.

Knee pads provide additional comfort if you need to lean on your knees, while protecting you from electric shock or contact with hot elements. They are fastened with straps, which makes their size universal.

Welding mask.

Welding mask.

Spectacles with filters or mask

When welding, the face and eyes of the welder are protected by masks, they are:

- in the form of a simple shield;

- folding;

- with lifting light filter;

- with filter and air supply.

Points differ:

- the presence of a dimming filter;

- filters in the form of rising frames;

- tight fit.

Filters, in turn, can be in the form of dark glass or chameleon glass. The latter has the property of automatically dimming with a flash of a light arc.

Industrial fire retardant welder hats

Some performers prefer to make their own headgear rather than buying a ready-made protective device. Homemade and purchased hats have their own advantages and disadvantages, which we will discuss next.

Advantages of industrially manufactured hats:

- appropriate quality of materials and accessories;

- high quality tailoring;

- a large selection of hats from various manufacturers, different shapes and configurations.

Disadvantages of purchased hats (except for the need for financial costs and prices) were not identified

It is important to point out that some models are not of high quality. Unscrupulous manufacturers can save on materials and accessories

Therefore, it is necessary to purchase protective devices and accessories only from trusted manufacturers and sellers.

Advantages of hand-made hats:

- the opportunity to create something on your own, to show imagination and skill;

- you can sew a headdress of the desired size, from the necessary materials; such an accessory will fit a particular performer in size and fit.

Disadvantages of self-produced hats:

- a handmade headdress may not meet all necessary safety standards and regulations;

- you need to spend time on the selection of materials, as well as on the process of cutting and sewing.