Peculiarities

Snow removal equipment manufactured by MTD is considered one of the highest quality and most reliable on the market today. These robust and durable snow blowers are suitable for clearing not only fresh snow that has just fallen, but also sediment that has already fallen. In addition, the units are used to clear snowdrifts up to 100 centimeters high.

The positive aspects of the operation of snow blowers from this company include the fact that they are quite easy to operate even for beginners, and the equipment is also very mobile and has increased durability. At the same time, the use of devices is possible even in the most unfavorable and severe weather conditions, which is an important factor for our compatriots. A huge plus is that both an automatic and a manual starter are provided in the design of the snow blowers, which once again proves that climatic conditions will not interfere with their work. Snow blowers are quite economical and ergonomic, and during operation they do not emit loud noise, and the vibration rate is also reduced. And according to the warranty period, the MTD unit will serve you for a long period.

Due to the fact that the component parts, and the body of the unit itself, are made of fairly strong and stable materials, the snow blower is not prone to overloads and breakdowns in the event of prolonged and intensive work. The parts themselves do not lend themselves to corrosion and deformation processes. Despite the fact that the device is manufactured and assembled using modern high-quality and complex technologies, even a beginner can quickly repair and adjust it if necessary. This is one of the main "highlights" of such units. The handles of the device have a rubberized coating, which is quite convenient when the operator is working with a snowplow.

The lineup

Let's get acquainted with the technical characteristics of some of the company's models.

MTD Smart M 56

The snow blower is self-propelled and equipped with a 2-stage cleaning system. Important indicators:

- engine power of MTD SnowThorX 55 model - 3 kW;

- cleaning in width - 0.56 m;

- capture in height - 0.41 m;

- weight - 55 kg;

- fuel tank - 1.9 l;

- power - 3600 rpm;

- wheel diameter - 10 inches;

- chute rotation angle - 180 degrees.

MTD ME 61

It is believed that a gasoline unit is intended for processing areas that have low or medium power, and this device is not suitable for large and large-scale areas due to its not too high power. The same applies to the amount of snow - with a small and moderate amount of precipitation, the car copes perfectly well, but in the case of too high snowdrifts, stale snow or icy roads, it is not the best assistant.

Technical specifications:

- engine power of the MTD SNOWTHORX 70 OHV model - 3.9 kW;

- number of speeds - 8 (6 forward and 2 backward);

- cleaning in width - 0.61 m;

- capture in height - 0.53 m;

- weight - 79 kg;

- fuel tank - 1.9 l;

- volume for work - 208 cubic centimeters;

- power - 3600 rpm;

- chute rotation angle - 180 degrees.

Also, the device is equipped with support skis, the chute is adjusted using a special lever, the type of movement is wheel

At the same time, it is important to note that the manufacturer, as well as the buyers, note the fully justified ratio of price and quality of this snow blower.

Optima ME 76

During the operation of the snow blower, the manufacturer recommends using MTD SAE 5W-30 4-stroke winter oil. This device is more powerful and capable of performing more functions than the previous model of the snow blower from MTD. Specifications:

- engine power of the MTD SNOWTHORX 90 OHV model - 7.4 kW;

- number of speeds - 8 (6 forward and 2 backward);

- cleaning in width - 0.76 m;

- capture in height - 0.53 m;

- weight - 111 kg;

- fuel tank - 4.7 UD;

- volume for work - 357 cubic centimeters;

- power - 3600 rpm;

- chute rotation angle - 200 degrees.

The turning control of the snow blower, as well as the unlocking of the wheels, is carried out by means of special triggers. The drivetrain is a friction disc and ejection control can be done quite simply using a key and handle on the operator panel. The chute can be in 4 positions, which is also controlled remotely by the joystick.

MTD E 640 F

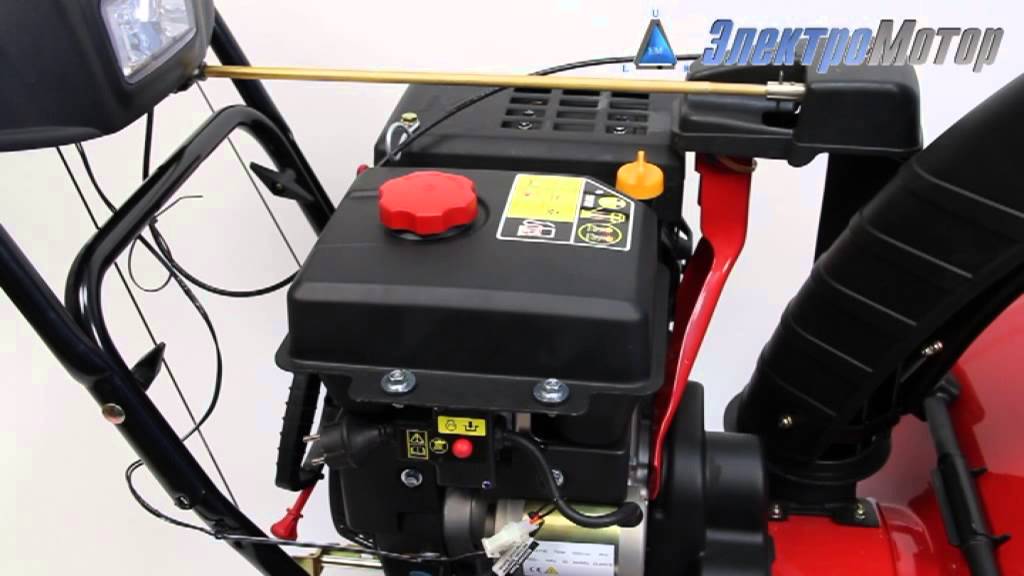

The body of the model is made in bright red. Features:

- engine power of the Briggs & Stratton model - 6.3 kW;

- number of speeds - 8 (6 forward and 2 backward);

- cleaning in width - 0.66 m;

- capture in height - 0.53 m;

- weight - 100 kg;

- wheels - 38 by 13 centimeters;

- fuel tank - 3.8 liters.

MTD Е 625

The features of this unit include the presence of a new generation auger made using a special Xtreme-Auger technology. Thanks to such a detail, the device is able to clean even snow that has been lying for quite a long time. Specific traits:

- engine power of the MTD ThorX 65 OHV model - 6.5 l / s;

- number of speeds - 8 (6 forward and 2 backward);

- cleaning in width - 0.61 m;

- capture in height - 0.53 m;

- weight - 90 kg;

- wheels - 38 by 13 cm.

It is also important to note the fact that control is carried out by means of elements located on one console. In addition, the MTD manufacturer's line includes a tracked type of snow blowers.

User manual

Snow blower Patriot

Each snow blower comes with detailed instructions upon purchase. All stages of a snow blower are clearly spelled out in it:

- The first start to prepare the motor for long-term operation;

- Preparing the device for work before each snow removal;

- Use of safety equipment and personal protection;

- Carrying out works on snow removal;

- Completion of work and preparation of the snow blower for storage (cleaning of snow and ice from the auger and other parts of the machine is carried out immediately after using the snow blower).

Important! The MTD snow blower, if used incorrectly, turns into a dangerous device, since it contains many moving parts. Moreover, they work at high speed.

To protect yourself from injury, and the device from damage, you must follow the instructions and safety rules.

Selection recommendations

MTD and other manufacturers of special equipment offer both self-propelled and operator-driven snowblowers.

Aggregates with a power drive on a wheel axle are more practical: they can work on dense snow, the rate of supply to the snow mass is selected by the operator. But such products are heavier and more massive, they can damage the decorative coating of the area to be cleaned.

Self-propelled units are produced with a two-stage snow removal system - the auger unit crushes and collects the snow mass, the rotor impeller throws it out of the working platform. In budget versions of non-self-propelled devices, only the auger works for emission.

The power rating for household and semi-professional snow throwers working in small and medium-sized areas is not critical, but it is advisable to take into account the following recommendations:

| Options |

Area of the area to be cleaned, sq. M. |

|||

|

500-600 |

600-1500 |

1500-3500 |

3500-5000 |

|

| Snow blower engine power (hp) |

5-6,5 |

8 |

10-10,5 |

13 |

| Range throw (m) |

5-6 |

7-9 |

10-12 |

10-15 |

| type of drive |

Electric motor, petrol engine |

Petrol engine |

Petrol engine |

Petrol engine |

Keep in mind that a larger throw distance setting reduces the number of passes on the job site and makes the equipment more efficient.

The choice between a gasoline or electric motor depends on your preference. Units with a gas drive are more powerful and mobile, but not everyone likes noise and vibration loads, gas exhaust from such products.

Devices with an electric drive are simpler in design, lighter in weight, and free of harmful emissions.But many are rightly alarmed by the need to constantly monitor the power cable, which becomes a rather difficult task in the snow. In addition, the length of the network cable cannot be infinite and is limited to a maximum of 50-60 m.

What general characteristics MTD brand snow blowers have can be found in the review prepared for you.

From this link:

This article focuses on the Snow Fox Stiga snow blower.

The transmission of the snow blower provides from 1 to 6 modes of feeding the device to the snow massif, moving the machine to the place of work. More practical are multi-stage assemblies allowing the operator to select the most efficient parameters. The force of rotation transmitted to the augers and the impeller rotor is constant and not adjustable by the operator.

The maneuverability of the machine, the ease of its turning to a new lane ensures that one of the driving wheels is locked. Low-cost devices do not have such a function, the operator controls the maneuver due to physical force.

The discharge of the snow mass is regulated in distance and direction by a deflector. Modern devices make it possible to change its setting with a joystick from the control panel. In traditional models, the deflector is installed in the required position before the start of snow removal or lever during operation.

Additional accessories are offered: headlamp for the dark time of the day, heating unit for control handles.

Starting the unit from a battery electric starter is not provided for snow blowers. The "winter" version of the gasoline engines ensures their stable start with a manual kick-starter. Some models require the installation of a starting device from a 220 V network.

It is important! For cleaning snow drifts with minimal manual labor, the market for special equipment offers a significant range of manual snow throwers. Your choice when purchasing such a product will be optimal if you familiarize yourself with the main parameters of the unit in advance, take into account the features of the front of its use .. And the following video is devoted to the description of the MTD Smart M 61 snow blower model:

And the following video is devoted to the description of the MTD Smart M 61 snow blower model:

The cost of repairing snow blowers MTD *

The final cost of the necessary repair of the MTD snow blower largely depends on the prices of spare parts and is agreed with the customer by phone, after the diagnostics carried out by the wizard.

The cost of repairing snow blowers MTD from 500 rubles.

| Description of work on the repair of gasoline snow blowers MTD | Cost of services, rub.* |

| Carburetor adjustment | 1900-2300 rub. |

| Replacing the starter | RUB 1100 |

| Starter repair | RUB 900-1300 |

| Replacing the spark plug | RUB 100 |

| Replacing the carburetor | RUB 1,700 |

| Replacing the ignition coil | RUB 900 |

| Ignition adjustment | RUB 1100 |

| Replacing the impeller | RUB 1100 |

| Replacing the gas control cable | 1300 RUB |

| Adjusting the throttle cable | RUB 500 |

| Replacing the air filter | RUB 100 |

| Comprehensive maintenance of gasoline snow blowers MTD (work) | from 1900 rub. (from model) |

Areas of use

The machine works on a half-meter snow layer with a swath width of 61 cm, the snow mass is thrown 9-12 m. To clear a small parking lot with an area of 500 sq. M. the unit will need no more than 2 hours. The carbide teeth and sharpened edges of the drum blades mounted on the augers allow you to work on packed snow and ice.

The snow blower will lay footpaths in the snowdrifts, clean driveways to residential buildings and areas for sports and festive events, and help maintain their working condition. The petrol-powered drive is economical, ensures the independence of the product from stationary power supply systems.

Main assemblies and details

Gasoline engine installation

The power units of the MTD ThorX 70 OHV company are equipped with separate drives for the throttle and air valves, a fuel pumping system. Easy to start at low temperatures.

Single-cylinder engines operate in four-stroke mode, the valve arrangement is overhead.

The applied technical solutions for combustion of the mixture in the cylinder, start-up and control make it possible to achieve fuel economy with a low level of noise and vibration load. The unit works in Euro 3 standards.

According to the owners, it is often necessary to adjust the carburetor. In this case, there is no need to resort to the help of specialists.

Auger drive and reducer

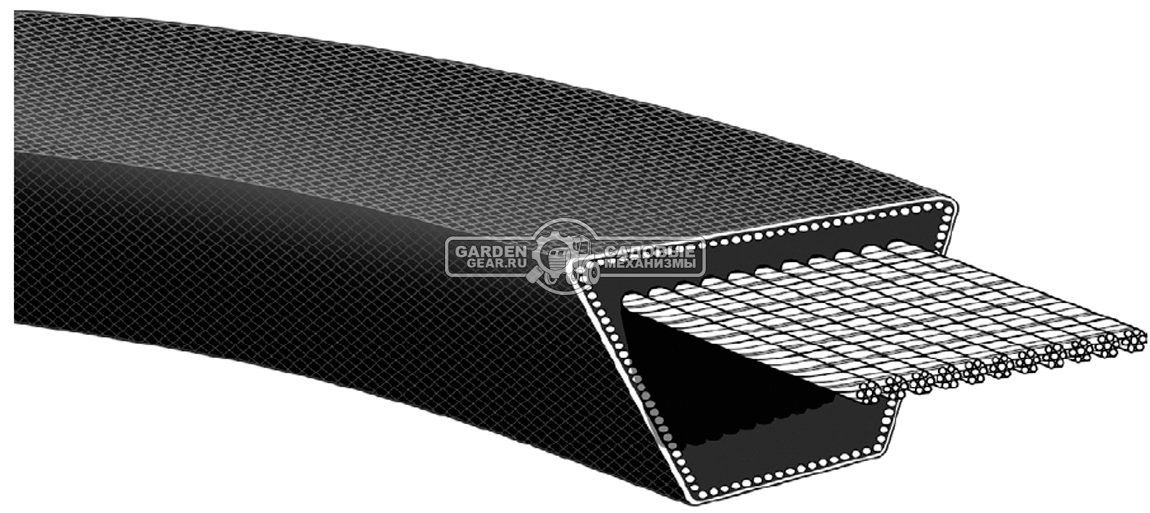

Rotation from the engine is transmitted by V-belt transmission through a pulley on the motor shaft to the pulley of the shaft of the ejection impeller and the reducer of the auger assembly. The role of the clutch is played by the tension roller - when the belt is loosened, the rotation of the impeller and augers stops.

The end of the shaft is installed in the bearing assembly, the opposite side is in the auger gearbox. The rotor impeller is attached to the shaft with shear bolts that protect the mechanism from emergency loads.

The reducer of the screw assembly transmits the counter-rotating force to the pair of screws in the bucket device. Reducer housing made of silumin alloy, gears made of soft metal. The unit is non-separable, in the event of a breakdown it changes completely. The auger shafts are mounted, respectively, in the cages of the gearbox and in the bearing assemblies of the bucket device.

Running gear

Self-movement of the snow blower is ensured by the Disc-o-Matic friction transmission. A tension belt from a pulley on the motor shaft rotates a friction disc, against which a metal friction wheel with a rubber ring is pressed at right angles along the rim.

Depending on the distance of the point of contact between the disc and the wheel from the axis of the first, the rotation speed of the wheel shaft changes, which, through a gear drive, transmits torque to the axis of the driving wheels.

The wheel along the diameter of the disc moves the slider, controlled by the speed change lever on the control panel.

It is important! Models MTD 61 series have 5-6 speeds forward and 2 reverse. Stop the machine before changing modes.

Augers and rotor impeller

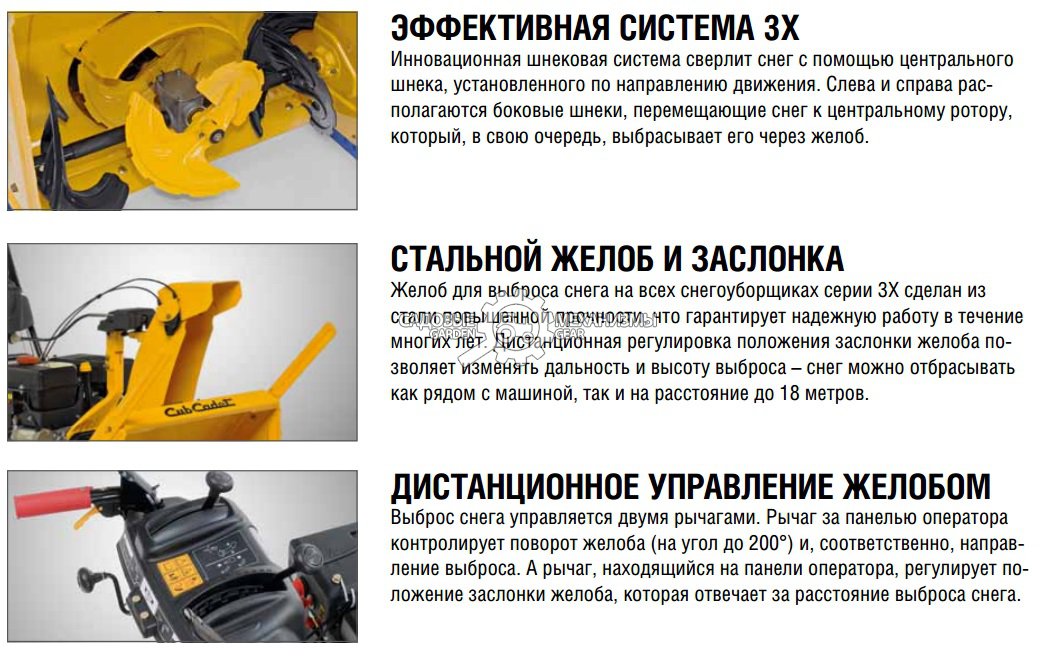

The snow mass is raked in by two counter-rotating augers (first stage), and thrown through the outlet chute by a rotor impeller (second stage).

Metal screw device with Xtreme-Auger technology - destruction of snow and ice is carried out by two cruciform augers rotating on their own axes.

The auger assemblies are attached to the shaft with special shear bolts, which are destroyed when the auger is blocked.

The impeller is plastic or metal with 3–6 blades, fixed on the shaft with shear bolts.

Bucket device

The augers are mounted in a metal snow grab bucket, the geometrical parameters of which form the width and height of the strip of snow to be removed during the passage.

On the sides of the bucket, plastic skis are attached, with the help of which the gap of the lower edge of the bucket to the ground is set.

The manufacturer recommends keeping the bucket-to-surface distance within 10 mm.

At the point of contact of the bucket with the mass of snow, along its lower edge, a scoring knife (plate) is installed. Double acting skis and knife plate are spare parts that require regular replacement or rewiring.

Wheels

The diameter of the wheels, depending on the model, is 33–38 mm and the width of the Snow Hog tubeless tire is 10–13 mm. The tire tread is deep, X-shaped and provides a stable ride on soft snow and ice.

Outlet chute (deflector)

Snow deflector made of frost-resistant plastic, allows rotation up to 180 degrees. The parameters of the direction and distance of removal of the snow mass are set by the operator using the lever handle.

Design features

On a self-propelled platform with a driving wheel axle, a gas engine is installed, the rotation force from which is transmitted to the auger snow collection device located in the bucket on the front of the machine.

The snow mass is fed to a rotor impeller rotating at high speed, which throws it in the direction determined by the installation of the outlet chute. Part of the power plant's energy is transmitted through the transmission unit to rotate the travel wheels.

You can familiarize yourself with the characteristics of the MTD ME 76 snow blower model in our next article.

We bring to your attention an overview of the German brand snow thrower - Hooter.

SunGarden SW-M Attachment Brush for MTD Snow Blowers

This accessory is intended for better cleaning of areas with even terrain. It is available for mounting on the most popular MTD models of the E, YM, DEM and SWE series. The brush is installed in place of the intake bucket, and the snow blower power take-off shaft is used to connect it.

The bristles of the brush are made of unique nylon, thanks to which they withstand intensive use in almost all weather conditions. The body of the device is assembled from high-quality and corrosion-resistant steel.

Attachment brush options include:

- working width - 90 cm;

- diameter - 32 cm;

- possible range of turning to the right / left - 25 ⁰;

- the maximum permissible speed is 2.5–5 km / h.

The attachment is started by the snow thrower clutch handle. The brush device has support wheels that prevent the snow thrower from leaning forward.

Operation manual

The instructions are included with every snow blower that comes off the assembly line of the factory. The purpose of the manual is to familiarize the owner of the equipment with the device of the snow blower, its maintenance, methods of work, namely:

- The device of the MTD snow thrower.

- Safety measures during the work and maintenance of the snow blower.

- Features of the specific model MTD snow blower.

- Preparation for work, start-up, running-in.

- Maintenance of the MTD snow blower.

- Trouble-shooting.

Let's briefly touch on the important points:

Commissioning

- Assembling the MTD snow thrower.

- Refueling.

- Filling engine oil into the engine crankcase.

- Connecting the I / O wire to the spark plug.

- Checking the pressure in the wheels (if the snow thrower is wheeled).

- Starting the snow thrower.

- Checking the operation of the auger, idling, gear shifting, engine brakes.

Running in

The run-in lasts about 8 hours, during this time it is forbidden to use the MTD snowplow at full capacity. At the end of the running-in, it is necessary to change the engine oil in the engine crankcase.

MTD Snow Blower Maintenance

- Plug maintenance / replacement (change every 100 hours).

- Changing the engine oil (immediately after running in and every 25-50 hours).

- Cleaning the snowblower.

- Lubrication of mechanisms.

- Adjustment work.

- Auger maintenance.

- Tire pressure monitoring.

- Tightening fasteners.

Malfunctions of snow blowers "MTD"

The gasoline engine does not start:

- there is no fuel in the tank;

- out of oil in the crankcase;

- poor quality of technical fluids;

- clogged fuel lines;

- primer does not pump fuel;

- lost carburetor settings;

- the ignition system does not work;

- the candle is out of order;

- the high-voltage wire is cut off;

- the piston group is worn out;

- wrong flap position, etc.

Selection Tips

When choosing a self-propelled snow thrower, there are some important rules to follow. So, first of all, you will have to decide on what size and area you plan to process with the purchased equipment. Obviously, the smaller the site, the less power of the unit is needed, respectively, the less money you will have to spend on the purchase.

Not only the size is important, but also the relief of the site.Be sure to carefully read the instructions for use and the technical specifications of any MTD device you purchase to make sure it can be used on a particular type of terrain.

The unit should only be purchased directly from the dealer or from certified retail outlets. Before buying, ask for a demonstration of the fact that the device is functional, also inquire about the warranty periods

Do not forget to check the kit of the device, it is important that it includes all the declared parts and spare parts.

Snow thrower MTD 611 D - machine features

This mid-power semi-professional model is popular with users due to its versatility, good performance and high quality factory assembly. A proprietary 4-stroke German engine is embedded in the standard basis of the machine, whose device allows the operator to independently adjust the position of the throttle and choke valves. The manufacturer has foreseen the possibility of a smoother start of a cold engine by equipping the machine with a pump for pre-pumping fuel.

The snow blower auger is equipped with welded-on pointed metal tines, which make it easy to crush the compressed snow. The mechanism is completed with a serviceable gearbox, placed in a reinforced cast housing.

The performance parameters of MTD brand snow blower include;

- power / torque of the standard internal combustion engine - 5.5 liters. sec. / 5500 rpm;

- working speeds - 5 forward / 2 back;

- factory wheels diameter - 30 cm;

- noise level - 98 dB.

Among the design features of this German brand snow blower, the ease in daily operation and self-maintenance stands out. The device of the model provides free access to the main frequently replaced parts, which makes it more convenient to repair important working parts with your own hands.

User manual

In order for your snowblower to serve for quite a long time, you should pay attention to the rules for its use:

check the oil level before operation (4-stroke oil should be used, it should be changed every 5-8 hours of operation);

bolts, nuts and screws must be tightly tightened;

the spark plug must be replaced after every 100 hours of operation or at least once a season;

pay attention to the correct installation of the springs;

do not forget about regular lubrication for the gearbox;

check the draft adjustment;

correctly carry out the order of starting and gear shifting;

after use, let the engine run a little more so that the snow and ice crust on the engine disappears;

When preparing for storage, run the engine for just a couple of minutes to prevent freezing of the auger.

In the next video, you will find an overview of the MTD ME 66 snow blower.