Advantages and disadvantages of self-propelled and non-self-propelled snow blowers

Depending on the mode of movement, there are two types of snow harvesters that differ from each other in many respects.

Non-self-propelled

Non-self-propelled harvesters are manually operated, that is, they are driven by pushing force. You will also have to adjust the direction and throw distance (no more than 10 m) by yourself, turning the handle attached to the rotor. The performance of such snow removal equipment depends on the condition of the snow carpet, if it is dense and wet, you will have to exert considerable physical force to clean it.

The benefits include:

- light weight (up to 40 kg);

- rubberized lumps of metal screws, which prolongs the life of the friezes and prevents damage to smooth, fragile surfaces.

This group includes the household PATRIOT PS 301, intended for cleaning snow drifts from paths and small summer cottages.

Self-propelled

Powered by wheel or track drive. If the surface of the area that you want to clean is flat, you should give preference to tracked vehicles, and if, on the contrary, winding, and even covered with vegetation, it is better to choose a unit on wheels.

Self-propelled snow blowers have a lot of advantages:

- equipped with a separate snow capture system, which allows you to throw snow masses over a considerable distance (14-18 m) and crush even densely compressed snowdrifts using special teeth;

- have an automated speed control system;

- are started not only with a cord, but also from an electric starter powered by a side battery.

Self-propelled mechanisms differ in class. For example, PATRIOT PRO 981 ED belongs to the middle class, since according to its characteristics it is intended for daily use in small areas, but the Husqvarna ST 276EP is already a more high-class equipment designed for cleaning large areas.

Main types of devices

Snow removal products with auger construction can be manual and mechanical. Also, these devices are divided into self-propelled and non-self-propelled types. The shovels are made in the form of structures with one or two steps.

To work with a hand-held device, you must independently apply force on it. During pushing, the auger begins to rotate, due to which the snowballs are destroyed and are deflected to the side.

We suggest you familiarize yourself with: Timing of harvesting late cabbage in the middle lane

In mechanical models, a fuel or electric motor is installed, which is connected as an option. If you connect the auger shovel to the walk-behind tractor, it will be able to throw snow at a distance of 10-15 m.

Also, mechanical models can be supplemented with a fan, with the help of which the discharge is carried out. Thanks to the outlet arm, any angle can be adjusted. The rotation speed of the ventilation blades is influenced by the power of the connected motor.

The single stage shovel type has only one auger. Knives are arranged in a spiral on it. During the rotation, snow is captured, which is then crushed and diverted towards the blades. The last element of the mechanism pushes the snow through the discharge sleeve.

What to look for when choosing snow removal equipment

Before buying a unit, it is necessary to more precisely determine the choice. First, you need to calculate the expected amount of work.If you need to clean only paths and small areas (up to 4-6 hectares), then you can purchase a machine equipped with a low-power gasoline engine (up to 1-2 kW). These include PATRIOT PS 301 and Efco ARTIK 55 S.

If the territory is quite large (more than 10,000 square meters) and has complex entrances, elevation changes and vegetation, it is worth giving preference to more productive equipment, such as Caliber SNUB-11.0 / 70 E.

The second parameter of choice is the frequency of use (once a week, daily or a couple of times per season), based on it, select a tracked or wheeled, self-propelled or non-self-propelled unit with a certain power and fuel tank volume.

Pay attention also to the presence of headlights, the type of start (manual or electric). Depending on the planned budget, choose the required degree of automation and the number of speeds

Also, speaking about snow removal equipment, it is worth mentioning that you can use attachments: plows and special buckets. Initially, they were developed for garden tractors and motor-cultivators, but today there are models for cars.

How to make a wooden snow shovel with your own hands

A well-made wooden shovel can last five to six years. For its manufacture, materials will be used that are often present in the household of a person who loves tinkering.

So, to make a wooden snow shovel, you will need:

materials:

- a sheet of plywood with a size of 45 (50) x 45 (50) (for a nursery - 30 x 30) and a thickness of 6 mm,

- board 45 (50) cm long (or 30 cm, depending on the width of the shovel), 2.5 cm thick,

- a handle from an old shovel or a rail, a bar (length - 2 m, width - 4-6 cm, thickness - 2.5 cm),

- a thin metal plate or a tin strip 5-7 cm wide,

- nails, screws,

instruments:

- file or jigsaw,

- plane,

- hammer,

- pliers,

- chisel,

- sandpaper.

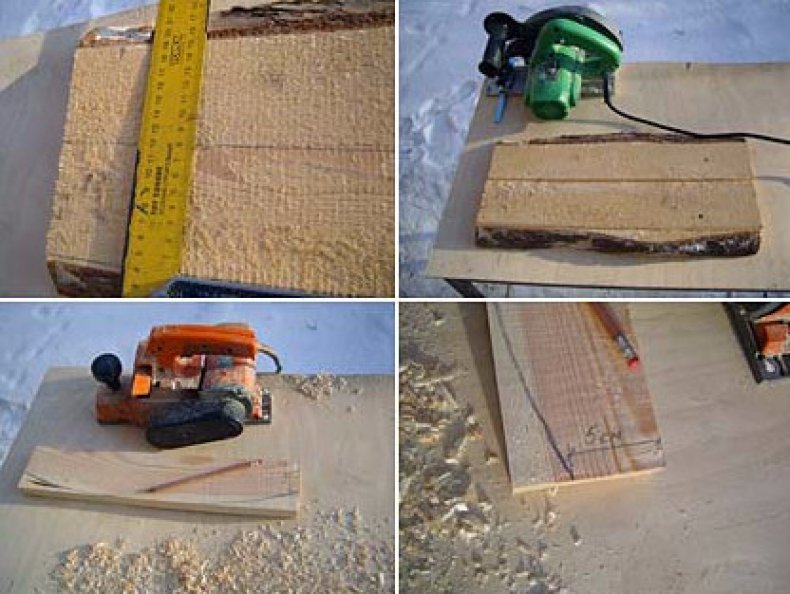

Bucket making

First, we prepare the base for fastening the plywood. We take a board and plan it with a plane from all sides to a smooth, even surface. We put the board horizontally on the workbench, its lower side should remain flat, and the upper one must be cut in an arcuate manner. Draw an arc with a pencil, in the center it should be 8 cm, at the edges - 5 cm. Saw off the excess wood. So we should get the butt of the shovel.

In the center of the end, it is necessary to mark the cut in the shape of a rectangle, where the handle of the shovel will be attached. The width of the cut should be equal to the width of the handle, and the depths of one side and the other side of the rectangle must be made different so that the holder is attached to the shovel at an angle. So, one side should be 4 cm, the other 4.5 cm. A small bevel of 0.5 mm will allow the handle to sit well, and it is convenient for you to work with the tool. The "nest" for planting the cuttings is made using a jigsaw and a chisel.

In the center of the end, it is necessary to mark the cut in the shape of a rectangle, where the handle of the shovel will be attached. The width of the cut should be equal to the width of the handle, and the depths of one side and the other side of the rectangle must be made different so that the holder is attached to the shovel at an angle. So, one side should be 4 cm, the other 4.5 cm. A small bevel of 0.5 mm will allow the handle to sit well, and it is convenient for you to work with the tool. The "nest" for planting the cuttings is made using a jigsaw and a chisel.

Next, the finished end must be connected to a plywood sheet - the working part of the shovel. This will require three nails or screws. Find the center of the plywood and the center of the butt and connect them with a nail. Then we drive nails around the edges, thus attaching the edges of the plywood and the end. The snow shovel bucket is ready.

How to make a shovel handle

If you decide not to use a commercially available shovel handle and also make her own hands, then you will need a board or rail 2 m long (for the nursery - we select according to the child's height) and 2.5 cm wide.

The advantage of this method is that you can make it any shape - rectangular or round. The board or rail used to make the holder must be free of knots.

The finished shank is attached to the plywood. To do this, you need to calculate the place of its attachment using a tape measure. The entry points for the nails should be marked on the back of the plywood sheet.

Be careful, as incorrect markings can cause the holder to sit uncomfortably and make it difficult to work with the shovel.

Varieties of snow shovels

These designs differ according to the following criteria:

- the material from which the canvas is made;

- holder type;

- dimensions and shape.

The most popular materials from which these devices are made are iron, aluminum, plastic and wood.Wooden options can be made with your own hands at home. They are also the cheapest of all models on the market. But they also have disadvantages such as:

- due to the constant exposure to moisture, the tree begins to rot, therefore, these representatives of shovels need constant drying;

- wooden shovels are not very durable and are not equipped with high sides.

Aluminum options are heavy and expensive, but they can last much longer. These shovels are not afraid of moisture. Many country house owners recommend purchasing plastic shovels. They are lightweight and endowed with high strength at a low price. On the negative side, it can be noted that plastic options are not durable and break with slight impacts. Standard plastic shovels are vulnerable when working in temperatures below -25ºC. However, for a little overpayment, you can buy a composite plastic instrument.

Self-production

Factory auger shovels are quite expensive, so to save money, you can make the device yourself. If you use an electric motor, then the device will depend on the power source, and this is rather inconvenient. It is best to use a gasoline engine.

The procedure for making a shovel with your own hands:

- For the auger, you need to take a pipe with a cross section of 20 mm. Trunnions are welded along the edges and bearings are put on. If it is decided to use a belt drive, then you need to fix the pulley on the trunnion. In the case of a chain drive, a bicycle sprocket must be used. To obtain the blades, several plates of sheet steel should be welded in the center of the pipe (at least 2 mm thick). Circular knife rings can be cut from old car tires.

- It is advisable to weld the frame from the corners, but bolted connections can also be used. We must not forget to provide a place for installing the engine.

- Now you need to take a sheet of steel 50 cm wide and bend a bucket, the diameter of which will be 30 cm.For the knives, on each side, you should leave 1.5 cm, that is, their diameter will be 28 cm. Thick sheets of plywood are attached to the sides, in which holes need to be cut in the center. Through them, the hub will be fastened. The snow throwing sleeve is installed in the middle of the body. You need to make a hole with a diameter of 16 cm.

- An asterisk is installed on the engine.

- The shaft is inserted into the hubs, after which the bucket is mounted on the frame.

- The engine is fixed.

- For the chassis, you can use skis or wheels.

- The control handle is being installed. It can be made from a curved P-shaped pipe.

- Now you can make the first launch.

Tags: snow, cleaning, Miracle shovel, auger

About the author: admin4ik

«Previous post

Choosing inventory for cleaning the yard

When it becomes necessary to remove snow near the house, it is important to take into account the features of the upcoming work:

It can be a thin layer of a freshly fallen layer, deep, caked snow, or one that has already turned into ice.

What matters is exactly which surfaces need to be cleaned. We can talk about a path, a lawn, the roof of a house or garage, the surface of a personal car.

Where are the cleaning plans planned: only on the paths or you need to remove the snow over the entire area of the yard .. Important! Depending on what kind of cleaning method is used, this work can sometimes require significant physical effort.

Important! Depending on what kind of cleaning method is used, this work can sometimes require significant physical effort. Various methods can be used to clear snow:

Various methods can be used to clear snow:

- Snow shovels. Usually, with their help, snow is thrown aside for a short distance.They are suitable for cleaning narrow or small areas. Otherwise, working in this way takes a lot of time and effort.

- Scraper or snow scraper. They resemble a very wide shovel. With its help, the snow is pushed in front of you until you reach the right place. Suitable for cleaning the yard, but it is difficult to clear dense snow and it is impossible to break the ice.

- The engines use a vertical blade. Usually used in the same way as scrapers, but have several different designs to increase their efficiency.

-

Ice axes are designed to break ice or clear dense, packed snow from a hard surface (for example, from asphalt). They are ineffective for clearing loose and medium density snow.

- Special scrapers are also used. They look like an ice ax, but they use a thin metal plate instead of an ax.

- When clearing snow from, for example, the roof of a private house or garage, using a conventional mop can be effective.

- If you need to free the car from snow, it is convenient to use special plastic brushes or shovels. They will help remove snow and prevent damage to the vehicle.

- In everyday life, a kind of chemical snowplow is also used. The most popular is to sprinkle with kitchen salt or sand. In the first case, an aggressive chemical environment is created that acts on the soil layer and on shoes. In the second, pollution occurs, which then will have to be removed. For this purpose, there are special chemicals on the market that combine the effectiveness of the application with complete harmlessness.

- Freshly fallen snow can be removed with a broom.

Scraper selection options

Retail outlets offer a variety of snow scrapers, among which it is difficult to choose a convenient tool. Snow removal equipment has the following differences:

- the size;

- material for making the handle and working surface;

- mass of the tool;

- the shape of the working surface, handle;

- the presence of additional devices that simplify the cleaning of large amounts of snow.

Usually, when buying a scraper, a person is guided by his financial capabilities, which is extremely wrong. The price is of great importance, but the amount of work to be done must also be taken into account.

First, scrapers are hand tools. Choose the size of the inventory according to their physical capabilities. The lighter and more comfortable the scraper is, the less fatigue you feel from removing snow.

Advice! Plastic scrapers are ideal for women and teenagers. The equipment is lightweight and does not adhere to snow.

If you focus on lightness and long service life, they prefer inventory made of aluminum or composite alloys.

Secondly, cleaning will be easier if the person does not bend over too much to scoop up the snow. The scraper handle is selected according to its height. It is optimal to purchase a tool with a height-adjustable handle. Each family member will be able to operate the scraper, adjusting the handle for themselves.

Buckets of snow shovels and scrapers are made of plastic, composite alloys, plywood, aluminum, galvanized. The cuttings are usually wood or thin-walled aluminum tube. The handle material only affects the usability of the scraper. The bucket is selected taking into account the surface on which snow removal is supposed to be. In order not to damage the paving slabs or other type of decorative coating, cleaning is carried out with a plastic or wooden scraper. On the ground or old asphalt, it is better to paddle with an aluminum or galvanized bucket. A plastic and wooden shovel will work, but they should have a steel blade at the edge to protect the blade from abrasion.

Advice! For convenient storage in a shed, it is preferable to purchase snow removal equipment with a removable handle.

Snow shovels are available with different bucket widths, and it varies on average from 25 to 80 cm.If a large amount of work is expected, it is better to purchase equipment with an increased bucket size, for example, a scraper-drag. The tool can even be operated by two people. For easy movement, choose a model equipped with casters or small wheels.

Description

Forte QI-JY-50 is called an advanced shovel. It consists of a bucket with an internal auger and a plastic-coated metal handle. And now - in more detail about each part.

The bucket is located at the bottom of the machine. There is a side wall on the left side, but not on the right. This design is due to the fact that the snow is transported to the right.

This part of the shovel is made of durable plastic, reinforced with stiffening ribs on the back side, which extend the service life. The lower edge is protected by a metal edging, which also has a protective function. If the snow blower hits a stone, obstacle or other obstacle, it will not crack.

The screw is a metal rod with a solid helical surface along the longitudinal axis. It is located at the bottom of the bucket. The shoveling snow moves along it to the edge of the path.

Varieties of inventory

The choice of auger tools is quite large. But choosing a shovel with a blade for a personal plot should be taken slowly, having studied all the pros and cons of the models available for sale. Shovels with a screw device used for gardening are of the following varieties:

- one-stage modifications clean the snow masses using a periodically rotating auger mechanism;

- two-stage tools - capture the snow with an auger, break it, and then eject it thanks to a specially built-in tray. In this case, the ejection is due to the action of the rotor.

In addition, this inventory is:

- manual - it can be made at home. The tool is effective for clearing snow in small areas. But in this case, a lot of physical effort is required from a person, which reduces the pace and effectiveness of work;

- mechanical - this type of tool is more difficult to make on your own, but it is more convenient and easy to use. This type of inventory has a drawback - it is difficult for them to remove tall snowdrifts, in addition, its mobility is limited due to the length of the power cable. For those who do not have physical strength, this type of instrument is suitable.

In addition to these classifications, a shovel is:

- self-propelled. These attachments are equipped with an engine and a special tracked device. They are easy to operate with handles. The equipment is powerful, dense and allows you to throw snow far away;

- non-self-propelled. It moves only with the help of a person's physical strength.