How to choose the right one?

First of all, you need to decide how much the tool is generally needed. If the machine is used very rarely, it will be necessary to periodically renew the lubricant and check the general condition. The type of construction is chosen based on the specifics and nature of the proposed work. Stripping and roughing requires productive tools, and more accurate tools for clean, high-quality surfaces.

In addition, you need to decide on the technical characteristics of the tool. A lot of work will require more powerful samples, and clean and tidy procedures will require matching models. When buying, it is recommended to check with the seller the operating parameters of the tool, clarify how available consumables (loops or circles for this machine) are, how often you will have to change the brushes on the engine and service the tool. This information will help you choose the best option.

How to choose an eccentric sander

A good tool saves time and effort for the user. Each model is designed to work in certain conditions, withstands specific cyclic loads, therefore, it is necessary to choose the unit taking into account the technical parameters.

Power

The value of the parameter of the orbitals is from 165 to 1200 W. It directly affects the performance of the tool. The higher the value, the more work the master manages to do in a shorter period of time.

The most popular is the unit with an indicator of 250 - 750 watts. Their low weight ensures ease of use, and their functionality is designed to perform a wide range of grinding tasks.

The advantages of models with high power include the possibility of using coarser skins. They are chosen for rough work.

Frequency and amplitude of vibration

For 1 revolution of the eccentric, there are 2 movements of the sole from one point to another, therefore the frequency of oscillations and rotations are interrelated. The first value is 2 times higher than the second. On models with variable speed, it is from 8000 to 26000 vibrations per minute, in the absence of such a function - no more than 24000.

The value of the parameter is selected for a specific material and packing. The less abrasive the abrasive is, the finer the grinding needs to be done. Therefore, the vibration frequency must be higher. For rough work, primary processing of material, units with a low parameter level are recommended.

The amplitude of the ESM movements is 2 - 7 mm. Affects productivity, quality of grinding. The higher its value, the more roughly the material is processed, but the work goes faster.

Platform diameter

The outsole dimensions also determine the performance of the tool. The larger the area of the abrasive, the wider the processing area it covers. ESHM is produced mainly with two sizes of the diameter of the grinding "pad" - 125 and 150 mm, in rare cases there are models with indicators of 95 mm, 75 mm.

The latter are used when working with corner machines. Units with a sole size of 150 mm attract the ability to attach sandpaper, they are classified as professional tools.

Operating conditions

Orbitals are used for processing wood, plastic and metal surfaces for finishing, polishing varnish. Domestic models with a low-power engine and a limited set of useful options are used for occasional work of short duration.In a professional tool, the list of operations performed has been expanded, and the adjustment of technical parameters is provided. With its help, they carry out grinding, cleaning, polishing of various materials.

For work in conditions of increased dustiness, humidity or fire hazard, models are suitable, the passport of which indicates the presence of an increased level of protection for the tool. In the instructions, the manufacturer must describe the features of using the unit. A pneumatic ESHM would be a good option. It is used at production sites for processing ceilings and walls. The device has a minimum of dynamic units, does not require power supply from a battery or an electric drive, which ensures ease of use in any conditions.

Ergonomic

The efficiency and usability of the tool are determined not only by technical parameters, but also by a number of additional capabilities of the unit. The speed control system allows you to configure the device for processing materials of different hardness. The soft start function increases the reliability of units and parts, reduces the risk of injury to the user, and ensures comfortable operation.

The automatic brake improves the quality of work, reduces the likelihood of damage to the workpiece. The presence of a branch pipe for connecting a vacuum cleaner guarantees the best level of safety for the health of the operator and a cleanliness of the workplace. To make the fingers less tired, the ESM provides for the fixation of the start button. At the same time, in household models, the function is often triggered intermittently.

Features that guarantee ease of use also include a rubberized case, an anti-vibration system. These options provide a secure fixation of the unit in the hand at high speeds.

Belt sander manufacturers

Buying a good tool is not easy, as the market is filled with models from different companies. In order for the device to serve for a long time, when choosing, you need to take into account the quality of materials and assembly. Reliability, ease of use of the unit can be determined by the reputation of the manufacturer. The best belt grinders are produced by the following companies:

- Bort Global Ltd. Is an international company for the production of construction equipment, power tools. The assembly of goods is carried out in factories in China. The quality of the models is confirmed by a three-year warranty. Users appreciate them for their ergonomics, modern design, and innovative developments. Products are chosen not only by ordinary users, but also by professionals in the field of construction and repair.

- Hammer Werkzeug GmbH is a German company that produces electrical tools, gardening and measuring equipment. Quality control is carried out in 2 directions - manual checking together with automatic testing, customer feedback. Only those models that comply with ISO standards are launched into serial production.

- Hyundai is a South Korean holding company that operates in the automotive, metallurgy, and chemical industries. It also produces consumer electronics, power, garden equipment, and power tools. The peculiarity of the latter lies in the use of the original engines of the company, which ensures reliable, stable operation. They are designed for the middle price segment.

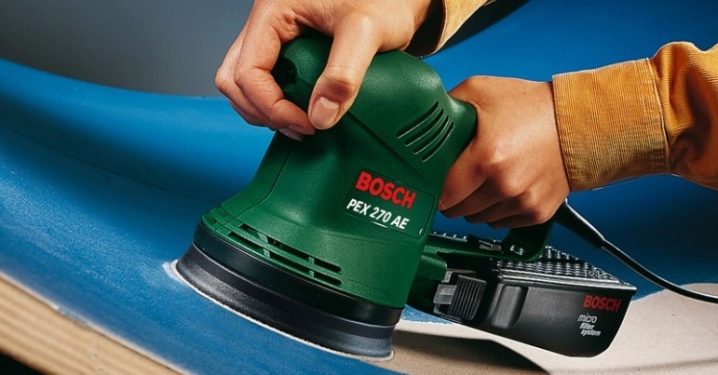

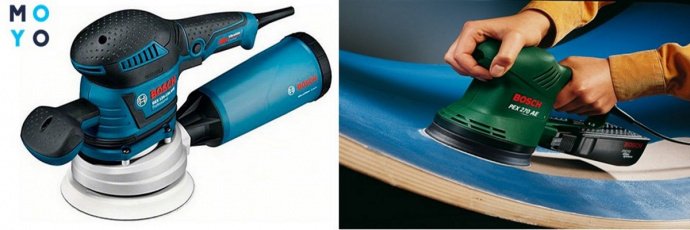

- Bosch - a German group of companies is a reliable supplier of stationary, electric tools, household appliances, auto parts. The company has always been famous for the quality of goods, which allowed it to occupy top positions in the ratings of manufacturers of functional, reliable devices.

- Caliber is a Russian company that produces garden and construction tools, welding and compression equipment. The low price of products is due to the lack of additional frills, bells and whistles. The manufacturer puts the main emphasis on a wide range of proven models that are designed for regular use in everyday life.

- Makita Corporation is a Japanese company supplying professional construction tools to the market. The range includes over 1000 types of models for efficient processing of any materials. Users appreciate the quality, reliability of the motors, the strength of the housings, and the ability to work under extreme loads.

- Interskol is a Russian company engaged in the production, sale and maintenance of power tools, small-scale mechanization equipment. The success of the company is due to a large assortment, affordable price of products, a wide network of service centers. Products are characterized by the lowest warranty return rates in their class.

- Black + Decker is an American manufacturer of construction and garden tools. The assortment includes models that will help in solving any issues related to home improvement, summer cottages.

- Sturm is a Russian group of companies producing petrol, electric and hand tools. The product catalog includes all types of equipment that a consumer needs to work in the house, garden or in the country. Models are assembled at the best factories in China. The development of devices is carried out in cooperation with Japanese and European specialists. This takes into account the operating conditions of Russia.

What abrasive to use for a grinder

Wheel, tape and other consumables for the sander are usually supplied in the kit

When buying, it makes sense to pay attention to this - after all, then all this will have to be bought

In stores and markets, prices for abrasives for grinders vary greatly. In some cases, cheapness automatically means unacceptable quality. In some - the price is unreasonably high

When choosing, you should pay attention to the hardness of the abrasive - the higher it is in the price category acceptable for you, the better

The grain size is selected according to the result that you plan to get. The higher the number in the marking, the smaller the grain, the finer the work, the smoother the grinding, up to polishing, can be done.

Important to remember! When using belt sanders, several approaches are usually taken. At the same time, they start with coarse sandpaper, gradually moving to fine

Therefore, it is possible that for the same product you will need several consumables of different grain sizes.

You can be smart when choosing an abrasive for the size of the machine. For example, a circle for an eccentric, if you have not found a suitable ready-made one for yourself, can be cut from a regular roll. It is quite possible to put a larger disc on an orbital machine - but not less! - size. As for belt sanders, you must take a specially made "endless belt" (abrasive tape glued into a ring)

Don't try to glue it yourself! It makes sense to pay attention to such a parameter as automatic centering of the abrasive belt. If there is such a function in the tool, you can put sandpaper narrower than the sole on it.

No. 9 - "Interskol" EShM-125 / 270E

Price: 2735 rubles. On the next line of the rating is an inexpensive eccentric sander from the Russian manufacturer "Interskol" EShM-125 / 270E. This is a kind of quintessence of the grinding machine. There are no additional features on it, except that the simplest one in the form of speed control is just bare functionality.

Power "Interskol" EShM-125 / 270E - 270 W, this provides a maximum speed of 12000 rpm, which is enough to effectively perform a direct grinding task. Fastening the sheet with Velcro. There is a built-in dust collector for dust and waste. For its extremely low price, Interskol EShM-125 / 270E can be considered just an excellent device.

"Interskol" EShM-125 / 270E

Description

Grinding machines represent a separate category of power tools that are in demand when processing surfaces of a wide variety of materials.They are indispensable for roughing as well as sanding and interact with substrates such as solid wood, glass, natural stone, as well as plastic and metal.

Belt grinders are considered one of the most popular types of grinders. Such installations are used for continuous grinding of very large surfaces. Due to the high efficiency and power characteristics with the help of such a tool, it is possible to successfully clean rather rough bases, in particular, non-planed boards, compacted plastics and rusted metal products, but such devices are unsuitable for polishing.

Belt sanders have rather large dimensions, they are equipped with a weighted lower platform, along which sandpaper of varying grain size moves. During work, the operator makes almost no effort, his only task is to maintain a uniform movement of the machine over the surface to be treated. A delay in one place is highly undesirable, since this may create a depression that will ruin the entire surface.

The package includes two additional handles, so that the tool can work in a wide variety of conditions. The problem of cleaning dust generated during work can be solved in two main ways - either it is collected in a special dust collector located on the body of the machine, or a powerful vacuum cleaner is connected to the installation, which quickly removes all the flying out sawdust as they are formed.

In addition to the traditional mode of operation, LShM is often used together with a specialized frame. It is necessary to protect the workpieces being processed from all kinds of damage. In addition, a stand is often mounted that holds the tool in a static position. Such a device is a kind of rigid vice. They fix the machine upside down so that the sandpaper is placed vertically or with the paper facing up. In this position, the sander can be used to sharpen dull cutting tools, as well as skates and golf clubs.

The best polishers up to 1000 watts

These polishing machines are designed for domestic use. They are capable of continuous operation for up to half an hour, have a fairly compact size and modest dimensions, and the disc diameter of such models is no more than 240 mm. In this category, the team of the Expert's Choice project reviewed four nominees who entered the TOP thanks to the buyers.

Bison ZPM-240

Compact, but at the same time powerful enough polishing machine is also suitable for finishing work on wood, metal or polymer materials. The power consumption of the model is 140 watts, which allows you to maintain a sufficiently high speed, with a maximum amount of 3200 rpm. The amplitude of the eccentric stroke is 3 mm, and the diameter of the working circle is 240 mm, therefore the force pressure on the processing zone is reduced. The tool is powered from the mains, the length of the mains cable allows you to move away from the outlet up to 2.5 meters, and the start-up occurs by pressing the corresponding button on the body.

Dignity

- Power button lock;

- Additional handle;

- Long warranty period;

- Low price.

disadvantages

- Turnovers are not regulated;

- The sole is not removable.

In the reviews on the Bison, users indicate that in order to adjust the speed, it is necessary to additionally purchase a dimmer, which will provide a smooth adjustment of the rotation. The kit also includes two attachments for applying polish and for polishing itself.

Status XPA 15-150CE

Sufficiently lightweight and compact polishing machine with a working disc diameter of 150 mm. The minimum number of rotations of the disk reaches 2000 rpm, and the power is 900 W, which makes the model economical in terms of energy consumption and does not overheat the surface during operation.The maximum speed can reach 4200 rpm, however, at this rate, users need to take a break so as not to overload the machine. The tool does a good job of removing thin layers of dirt, paint or varnish from wood or metal surfaces. The ergonomic, comfortable handle provides a tenacious grip, and the start button has a lock for secure fixation in the working position.

Dignity

- Constant vibration frequency support;

- Dust cover;

- The disc is perforated to protect against overheating;

- No vibration.

disadvantages

- Noisy;

- Quick start of work.

The set includes two more handles, a polishing sponge, a wrench and spare brushes. The Status can also be used without additional levers, or both can be used at the same time, which is highly appreciated by many experts.

Diold MP-0.5

Orbital grinder Diold has small dimensions and good build quality. It is capable of speeds up to 13,000 rpm, which, with low power (500 W) and forced cooling, proves the excellent operational parameters of the tool. Also, this model provides a dust removal system, you can even connect a vacuum cleaner to it, which ensures almost absolute cleanliness of the dust collector. The attachments are fastened with Velcro, the disc diameter is 150 mm, and the electronic speed control allows you to set the desired pressure on the working surface.

Dignity

- RFI protection;

- Double insulation;

- Start button lock;

- Motor overheating protection.

disadvantages

- Short cable;

- Does not maintain constant speed under load.

Diold buyers praise for its endurance, lack of overheating and ease of use. Its ergonomic rubberized grip provides a grip and comfortable use.

Bosch GPO 950

The Bosch polishing machine can be operated in an upright position, it is powered from the mains and is also capable of withstanding significant loads. The power consumption is only 950 W. and the maximum rotational speed of the disk reaches 2000 rpm. Smooth, electronic speed control and stabilization system allow you to accurately solve any task for polishing and sanding wood, metal or polymer. Also, this model provides an option for a soft start, which ensures a decrease in the load on the engine, even with intensive work.

Dignity

- Easy access to brushes;

- Inrush current limitation;

- Two-position handle;

- Low weight.

disadvantages

- High price;

- Small warranty period.

Makita BO3711

Main characteristics:

- Power - 190 W

- Platform stroke size - 2 mm

- Oscillation frequency - 11000 rpm

- Working surface - 93 × 185 mm

- Grinder attachment - clamp

- Weight - 1.6 kg

Body and ergonomics. This vibratory sander has a lightweight plastic body and a heavy metal base that protrudes slightly beyond the base. It has an elongated grip with embossed rubber inserts that allows you to grip with both hands. It will be comfortable for both right-handers and left-handers. The tool weight of 1.6 kg does not cause fatigue during prolonged work.

Design features. The machine is equipped with two spring clips for fixing a sanding cloth measuring 93x230 mm.

On the back there is a canvas dust bag with a zip for easy emptying. Instead, you can connect a vacuum cleaner. The length of the power cord is 2 meters, which may not always be sufficient.

Functionality and capabilities. The electric motor of the tool develops a good power of 190 watts. It is enough for continuous operation with a vibration frequency of up to 11,000 movements per minute with an amplitude of 2 mm. The speed is regulated by a small wheel located in the recess of the handle, which protects against accidental misalignment of settings.With a long operating cycle, the wide start key can be fixed in the pressed position.

Equipment. In addition to the machine, the standard kit includes a sheet of sanding paper, a dust collector and a plate for perforating the sanding paper, with which you can easily make technological holes that exactly match the holes on the sole.

Pros of Makita BO3711

- Quality materials and excellent build.

- Convenient design for one-handed and two-handed operation.

- Adjustable vibration speed.

- Effective dust extraction.

- Wide release key with lock.

- Inexpensive consumables.

- Soft vibration and low noise level.

Cons of Makita BO3711

- The machine is more suited for finishing than coarse sanding.

- Short and stiff cord.