Option number 3. Another rolling jack

Homemade rolling jack

There are many examples of a rolling jack on the Internet, but in this master class the author made just such a structure from an old five-tonne.

Jack from an old five-ton

The jack, as in the previous instructions, is made of a channel. Old hockey pucks were used as stops.

The structure is welded from a channel

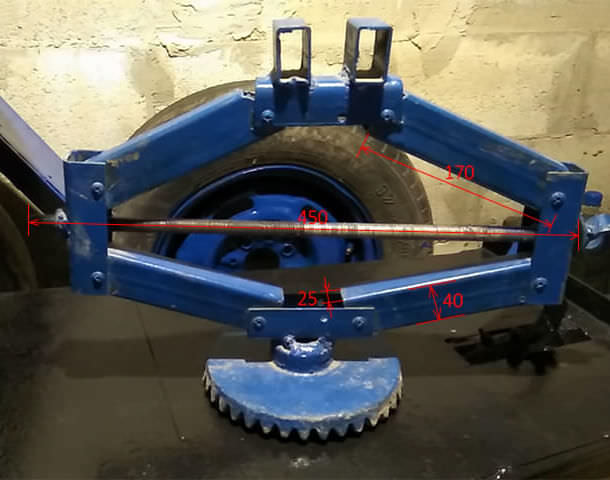

Below you can see the dimensions of this homemade jack.

Dimensions of a self-made jack Its height The length of the upper part More dimensions ... And more ... Width in the area of stops Photo of the finished structure

In addition, the author installed wheels to make the structure easier to move.

Wheels will be installed here Wheels holes Wheels make it easier to move the jack This jack is literally made of junk

As you can see, a simple hydraulic jack can be made from the most unnecessary scrap materials, literally from trash.

How to make a rolling machine

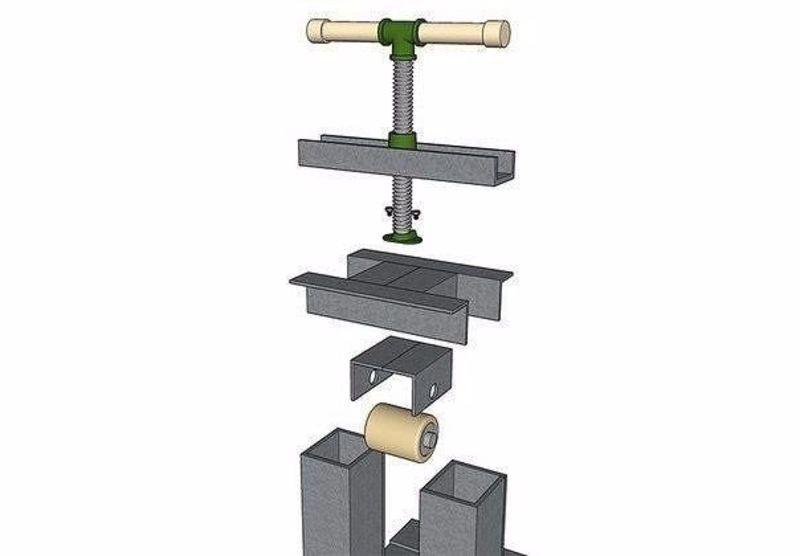

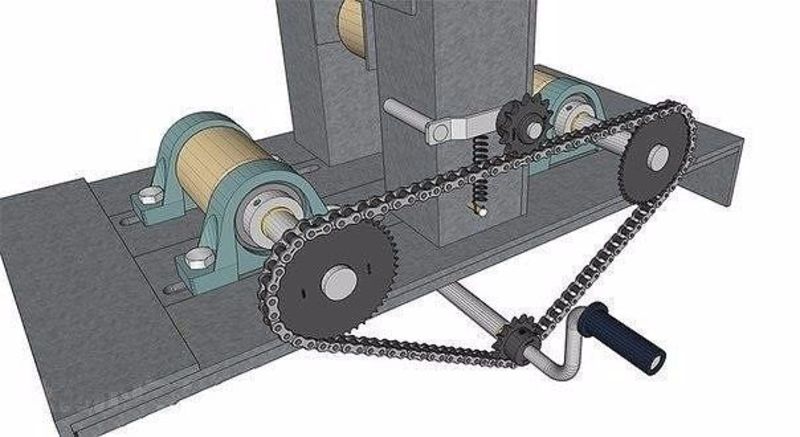

The main advantage of such a scheme is a smooth increase in the load for more precise adjustment of the bend radius. The pressure on the central roller is smoothly applied by a screw, hydraulic or rack and pinion jack. Leading can be both support and central roller.

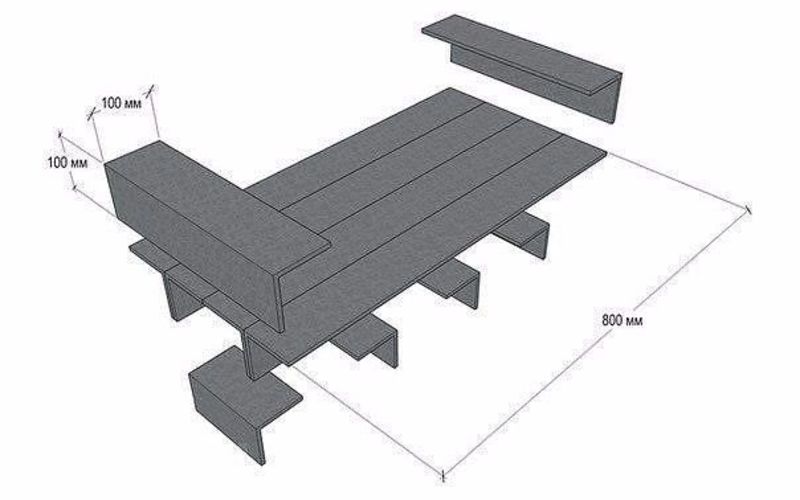

A reliable platform is welded from metal profiles, on which attachments for the bed can be provided immediately. A frame is welded to the platform - the supporting structure for the central roller and the jack. Choose a jack with the smoothest possible stroke.

If the pipe bend is regulated by the position of the extreme rollers (and the central one is the leading one), then the supporting structure can be made of wood. However, some of the parts will still be made of metal:

- roller axles;

- stock;

- fasteners;

- a handle for scrolling the rollers.

Further, support rollers are installed on the platform, the drive mechanism is brought in. In some cases, an adjustable distance between the stops is provided: through grooves are drilled in the base, the clamps are tightly pressed with bolts and washers.

Recommendations

Nowadays, it is advisable to make homemade jacks of a complex type with your own hands only in those cases when enough material and old devices have gathered in the garage for this, which will ensure their almost free creation. The sliding version of the hoist can be built without hydraulics - using a pneumatic jack.

You should also not forget about such an important negative side of the rolling lifting device, as its significant dimensions. This product is more of a garage type, and not for transportation in the trunk. However, for those mechanics who are seriously involved in car repairs, such a lifting unit is an indispensable assistant in their work.

How to make a rolling jack with your own hands, see below.

Drive variations

Mechanical. The movement of the handle is used for lifting. Jacks of this type are physically demanding, but their design is compact. Recommended when the need for use is rare.

Hydraulic. The rise takes place with the help working fluid pressure... It is similar to the previous type, but the physical costs are much less. Recommended if frequent use is expected.

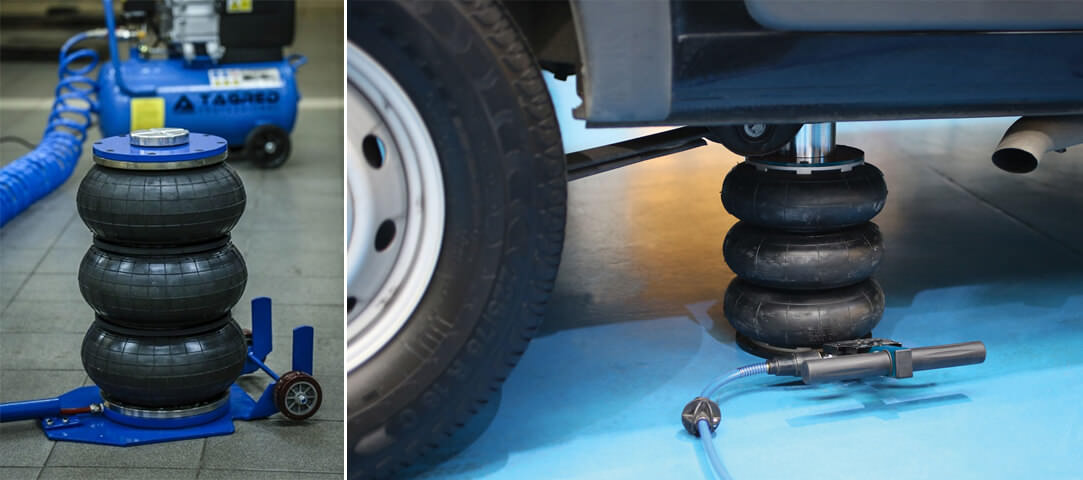

Pneumatic. The lift is carried out using the energy of compressed gas.Gas from high-pressure cylinders is fed into a special chamber, where, expanding, it raises the car.

The advantage of this type is that there is no physical cost for lifting.

How to make a pneumatic jack at home: description

To make a pneumatic lift with your own hands at home, you must first acquire an air cushion and two bolts. The airbag is the main working part that is sold in the market or in specialized stores. It is also recommended to give preference to an ordinary rubber cylinder, which is located on the air suspension of any vehicle.

Important!

It is advisable to use a container from a truck, since its strength allows it to withstand strong pressure and significantly increase the lifting moment. But these cylinders are distinguished by their high height, due to which it is not always possible to substitute such a device under a car with a small ground clearance .. To make a pillow and a valve, you need to prepare two bolts in advance

The pillow should be fitted with a factory threaded hole where the high pressure tubing is screwed in. This tube must be replaced with a bolt of the same diameter, and then pick up another one that will act as the top cover. Products must be drilled in such a way that a cavity is formed during their connection.

To make the pillow and valve, you need to prepare two bolts in advance. The pillow should be fitted with a factory threaded hole where the high pressure tubing is screwed in. This tube must be replaced with a bolt of the same diameter, and then pick up another one that will act as the top cover. The products must be drilled out in such a way that a cavity is formed in the process of joining them.

The location of the pillows in the pneumatic jack

The location of the pillows in the pneumatic jack

A strong inflation nipple and a ball from the bearing must be placed in the upper bolt. The final stage is welding the structure and screwing it into the hole in the pillow.

Manufacturing of a "rolling" jack

The name "rolling" jack received because of the external resemblance to a cart. Despite the simplicity of the design, it is used for lifting trucks.

It is easiest to make a rolling jack with your own hands, based on a bottle-type mechanism, the pickup height of which is 23 cm.For work, you will need channels of 10 and 12 mm. A stand is made of 12 mm, and a base and a lever for lifting from 10 mm.

When the jack is working, several working rods are used. The main part of the unit is the piston. The task of lifting the load is performed by a hydraulic cylinder acting on the lever.

The rollers used in a household washing machine are mounted on the front. During the assembly process, a car bump cup is used, and a 20 mm bar is used for the braces.

The operating principle of a rolling jack is similar to that of a bottle jack, but unlike the latter, the working cylinder is placed in a horizontal plane.

When the mechanism is operating, the piston is not directly connected to the pick-up, but moves under the car when the lever is lifted.

The unit is operated by lever movement and lowered by turning the valve screw. To lower the load, the handle is put on the valve screw and when it rotates, the pressure in the cylinder decreases.

Peculiarities

Without exception, all rack jacks work according to the same principle. When the ratchet mechanism interacts with the rail, the jack body begins to rise, and with it the pushed object rises.

In this case, rack jacks are of two types: mechanical and electronic. It is clear that electronic models are much more convenient, since the direct participation of the owner is minimized.However, at the same time, they are also quite expensive, and assembling such a device at home is a very difficult task that requires you to know not only mechanics, but also electronics.

Mechanical rack and pinion jacks, in turn, are divided into two more subspecies: gear and lever. The housing in the lever jack is lifted by pressing the lever, and in the gear jack - thanks to the handle with gears.

Even the simplest rack and pinion jack models can lift up to 8 tons, which is enough for a car. And there are also more advanced models (for construction work) that can lift weights from 10 to 20 tons.

The main disadvantage of rack and pinion jacks is their size. All the same simple models weigh about 40 kilograms, and the weight of building models can reach up to a centner.

Those who decide to make a rack jack with their own hands should take into account several important nuances.

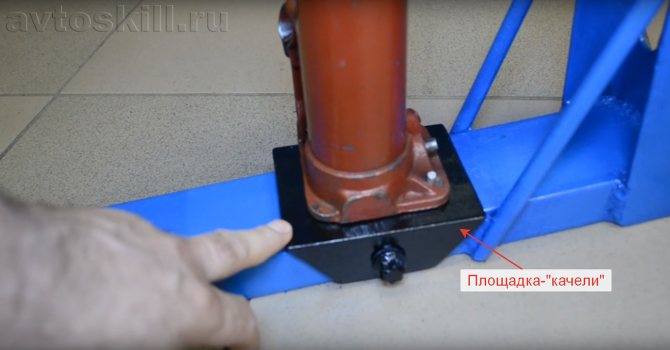

One of the main parts of a rack and pinion jack is its support platform.

It is she who affects the stability of the entire structure, which is very important, given that we are talking about lifting loads weighing several tons.

Another necessary element is the bracket. When making and using it, it is imperative to take into account the lifting height.

The lower the grab goes, the better

Low lift systems can lift loads even from the ground.

In fact, making a jack with your own hands is not so difficult. If you have at least minimal experience, you can probably do it without outside help.