Operating rules

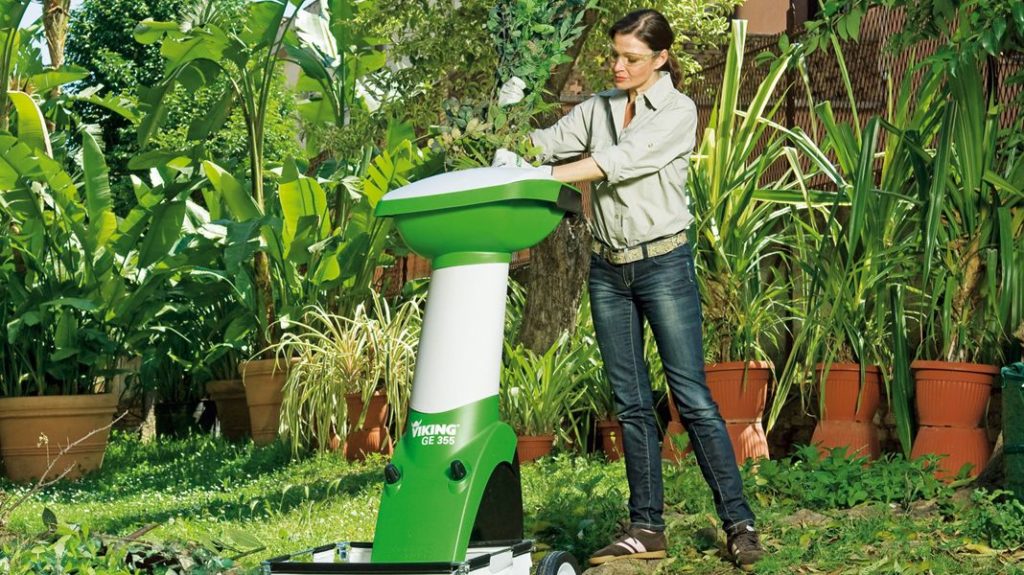

A garden shredder is a fairly simple and safe device, however, there are some nuances that should be learned before operating the equipment.

- It is imperative to work with the shredder in goggles or a mask, wear tight anti-slip gloves on your hands, and a hat or baseball cap on your head.

- Rubbish is pushed into the device strictly with a shredder and by no means by hand.

- Make sure that no pieces of metal, glass or plastic or stones fall into the hopper.

- Branches shred much better if they were wet.

- If you grind the roots, then first you should thoroughly clean them of the soil.

- If debris is stuck in the device, be sure to turn off the shredder before removing it.

- The efficiency of the garden shredder and the duration of its use largely depend on the observance of the rules for the operation of the equipment and storage. There is no need to leave the unit outdoors, store it in a dry place protected from moisture and direct UV rays.

- The unit should be periodically cleaned and inspected from time to time.

- If the shredder is broken, you should not try to repair it yourself, for this it is better to resort to the services of specialized service centers and repair shops.

Types of garden shredders

Garden shredders are divided into gasoline and electric. The difference is not only in the type of engine, but also in power: if processing of large pieces of wood is required, then a gasoline or diesel engine is preferable, and an electric crusher for branches and chips is enough for the needs of an average garden plot. Also, shredders are divided into household, semi-professional and professional.

Petrol branch shredders

The petrol engine of the wood chipper has its own advantages. Since the power of such a device is higher, then the processing of wood waste is faster. The branches can be thicker than the electric shredder can grind. An additional plus is the freedom of movement, if you wish, you can install such a unit anywhere, while moving the electric one will need a solid extension cord.

There are some difficulties when using a gasoline garden shredder. Such a mechanism should be properly operated, monitored filters, candles, and also refueled with fuel. High-tech diesel engines, in comparison with gasoline ones, can run longer in time, but they are much more expensive. The dimensions of such shredders are rather big, so they are practically not used in everyday life.

Gasoline grinders

Electric garden shredders

Unlike gasoline powered shredders, the electric shredder is smaller in weight and size. Such an apparatus is easier to move around the site. Low power is quite sufficient for gardening in the country. Branches up to 4 cm thick are easily processed, and the shredder can also handle thin vines, plant residues and grass.

No skills are required to operate an electric shredder. The inconvenience can cause the need to work from the electrical network. The extension cord will have to be pulled through the entire area, therefore, it is better not to carry out work on processing parts of trees and bushes in wet weather.

Electric garden shredder mobile and lightweight

Viking GE 150

The Viking GE 150 Garden Grass and Branch Shredder is ideal for use around residential and public buildings.With its help, you can easily and quickly cut into small parts branches, roots, twigs, and the rotary knives of the unit will turn grass and leaves into mulch. The sandwich cutting system does not crush the most elastic plants and branches. The inclined funnel will provide convenient loading, for this purpose, the developers made its entrance in the form of a four-leaf. To make the work go faster, there are two entrances for sorting the material. The hopper for the chopped mass has a volume of 50 liters. A built-in safety switch prevents automatic start-up.

Advantages:

- Patented cutting technology;

- Innovative film touch switch;

- Work indicator;

- Electromechanical protective shutdown system;

- Simple controls.

Disadvantages:

- It processes rods only up to a diameter of 35 mm;

- The plastic of the case is scratched by branches and loses its appearance.

Top 5 best professional tree shredders

All professional wood chippers are equipped with 5000-7000 W petrol engines. The current models can be found in the company's product catalog.

Brands, models

The table shows the models most popular brands.

| Brand name | Model |

| Viking | GB 370 |

| GB 460 | |

| GB 460 C | |

| Stihl | GH 460 C |

| GH 370 S | |

| GH 460 | |

| Patriot | PT SB76 |

| PT SB506 | |

| PT SB76 BS | |

| PT SB100 E | |

| Champion | SC2518 |

| SC6448 | |

| MTD | Rover 464 Q |

The domestic firm "Zubr" produces inexpensive, low-noise electric grinders for giving ZIE-44-2800 with a capacity of 2800 W and a productivity of 150 kg / h. The maximum branch diameter is 44 mm.

Let's take a closer look at the TOP 5 best professional shredders of 2019.

Viking GB 460 C

The Viking GB 460 C gasoline shredder shreds branches with a diameter of 75 mm and soft debris. One branch pipe is provided for loading branches, another for leaves and grass. The powerful 4-stroke engine (9 HP) drives the Multi-Cut 450 knife chopping system.

There is a reverse system, an automatic feed function is implemented, which ensures the safe work of the operator. There is no collector, chips, recycled plant waste are poured onto the ground. The device weighs 78 kg, there are no problems with transportation, it is facilitated by a wide chassis, pneumatic tires.

Patriot PT SB76

The body is made of stainless steel. The material guarantees safe operation, long service life of the shredder. 6.5 HP Brigg & Stratton Engine with. provides a high speed of rotation of knives 3600 rpm.

The shredder grinds branches with a diameter of 76 mm and soft plant waste. Grass, leaves are loaded into the upper funnel, dried branches - into a separate receiver. The weight of the unit is 70 kg, it can be transported by car, for this there is a special mount.

Champion SC6448

The shredder is equipped with the Chinese Champion G200-2HK four-stroke gasoline engine. The engine has a power of 4800 W, a volume of 196 cm³, a large motor resource. The knife chipping system processes branches up to 50 mm thick, dry leaves, grass. The sound pressure of the SC6448 chopper is 88 dB.

The body is steel, weight 72 kg, dimensions - 62 × 83 × 125 cm. The shredder is equipped with a soft waste bin with a volume of 85 liters, a two-chamber receiver consisting of two funnels: in one raw material is loaded for grinding, in the other - for crushing.

STIHL GH 460 C

The Multi-Cut 450 chopping system is powered by the powerful PowerBuilt OHV petrol engine (5.8 kW). The unit is designed for regular processing of a large volume of branches up to 75 mm in diameter, grass, tops, leaves. The two-chamber loading system provides convenient feeding of various types of waste.

The “One Clic / One Turn” safety switch ensures safety during operation.

ROVER 464 Q

The MTD company produces reliable garden equipment that meets the requirements of environmental safety. The ROVER 464 Q has a multilevel safety system, a large grass catcher - 90 liters.

The cutting and shredding system consists of 12 threshing knives and 2 cutting knives. They are powered by a 7.5 liter B&S 1100 SERIES OHV gasoline engine. with. working volume 250 cm³. There are two bunkers. The branches are loaded into the main one, their maximum diameter is 75 mm, the additional one is placed on the ground, it works like a vacuum cleaner. Soft waste is raked to it.

The mobile unit with a powerful petrol engine handles large volumes of hard and soft plant debris.Turns it into mulch, compost material, decorative chips.

About the Bosch garden shredder - how it works, the best models

All About Garden Shredders - Branches & Grass Shredders

Makita UD2500 - parameters and description of the chipper for the garden

Vacuum cleaners for cleaning leaves in the garden - description, varieties

All about the garden shredder Bison - the principle of operation, how to use

How to make a chopper of grass and branches for a summer residence with your own hands

Varieties, description

Depending on the power, mechanism and engine, chippers can work with different materials, which makes it possible to divide all shredders conditionally into three groups.

- The simplest process foliage and grass. These are inexpensive units that can be useful even in a small garden, as they grind soft plant debris into porridge for composting. Their body is made of plastic, and the cutting parts are made of inexpensive metal. They do a good job with their function, but if a branch or something solid gets along with the grass, the shredder may break. Therefore, you need to be careful when working.

- There are shredders for shredding wood. They have a sturdy frame with an alloy steel cutting mechanism that can handle even hard rocks. Such models crush cut branches, tree bark. This equipment is used when pruning trees, uprooting bushes. They process branches of various thicknesses, but this equipment is not used to grind stumps or trunks - professional equipment is needed here.

- As a third option, the natural choice is to buy a multi-purpose shredder. It works with both soft material and hard debris.

According to the engine type, garden shredders for grass and branches are divided into:

- gasoline;

- electrical.

Devices assembled on the basis of an electric motor are distinguished by lightness and mobility, and those with an engine running on gasoline are more overall, but also more productive.

By the type of grinding there are:

- milling;

- screw

Let's consider all types in more detail.

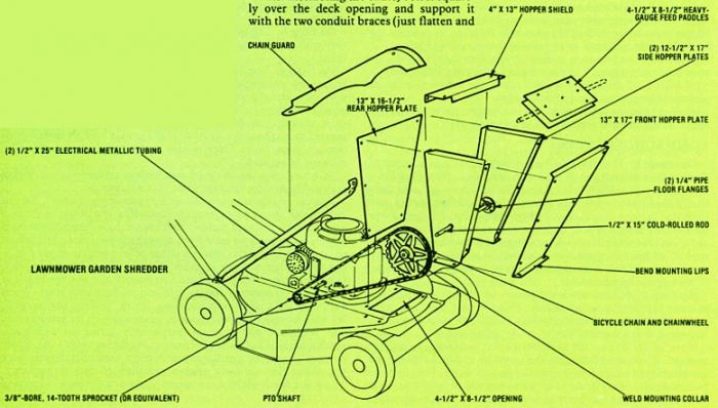

Manual

Rice. 1. Drawing of a manual grass chopper.

This is the simplest grass chopper that you can make with your own hands. It is a mechanical device similar to a meat grinder. Bunches of grass are fed into the receiver, and at the exit it is cut with a pruner. The use of this type of equipment is possible only for processing grass or leaves - even thin branches cannot be chopped with this knife.

Petrol

Such a motor, installed on the unit, allows it to be used in the field, where there is no possibility of connecting to the AC mains. Installing a gasoline engine on the shredder provides it with high power as well as good productivity. Gasoline powered shredders are versatile, but also quite costly to maintain. They are heavy and make a lot of noise.

Electric

For domestic use, the most often chosen garden shredder with an electric drive. It is a compact and lightweight unit. It is easy to operate and works almost silently. Electric shredders are inexpensive. They are environmentally friendly and easy to operate. With a number of advantages, electrical appliances are not without disadvantages:

- Dependence on an alternating current source;

- Low power;

- Power surges can damage equipment.

Shredders have a variety of shredding systems. The simplest devices are equipped with a forestry mechanism - they process grass and foliage. In them, the fishing line is attached to a drum, which gives it a high speed - this is how the shredding of soft material occurs.

If a branch enters the shredded mass, the line may break, which becomes a significant disadvantage of such a system.

In cheap devices, a knife, rotary grinding system is installed.For all its simplicity, it has a high efficiency, copes well with both soft material and thin branches. This is a system of discs with radially arranged knives rotating at a given speed.

Milling

Most often, such a system is installed on gasoline devices. It is a gear, cast from high-strength steel, equipped with sharpened teeth of a certain configuration. The incoming raw materials are tightened by the cutter and grinded with it. The mechanism crushes thick branches up to 7 centimeters in diameter. The equipment does not need close monitoring, as a rule, they have protective mechanisms that can protect the engine from overloading. The disadvantages of the milling mechanism are its high cost, as well as the inability to use it for processing soft vegetable waste.

Auger

This type of grinding is more like the principle of a meat grinder - a screw with sharpened edges is installed inside, which grinds the material falling on it. It can be located inside the device strictly vertically or at a slight angle. It is used to crush dry or freshly cut branches, turning them into sawdust.

The augers do not process grass as it tends to wrap around the screw.

Scope of the garden shredder: what is it for

Spring and autumn are the time to work in the garden. In spring, fruit and flowering trees and shrubs are pruned. In the fall, it is required to prepare the garden for winter: remove dry grass, faded parts of plants, fallen leaves and cut branches of flowers and shrubs preparing for shelter. In both seasons, debris is generated from branches and roots, and for those who have their own plot of land, cleanliness in the garden matters.

Sometimes it is required to free a large area from unnecessary trees

Electric or gasoline garden shredders solve the problem of eliminating unnecessary branches by turning them into small residues. This shredded waste can be added to compost or removed in bags from the site.

A good grower helper - electric shredder

Bosch AXT 25 D

The brainchild of the famous concern fully justifies the reputation of the manufacturer. The chipper is equipped with an optimized drum cutting system, therefore it has a capacity of 175 kg / h and a cutting capacity of 40 mm. Thanks to the automatic tightening mechanism, it works quickly and efficiently. Recycled materials enter a spacious 53 liter container. The Bosch AXT 25 D is equipped with a removable hopper and takes up 30% less space during storage. Only 67 cm tall.

Advantages:

- Closed cutting mechanism;

- Removable funnel;

- Optimized roll design;

- Safety function;

- Practical pusher;

- Low noise.

Disadvantages:

Not found.

If the grass catcher is not installed correctly, the chopper will not start. In general, this device has positive reviews.

It is interesting: Crown for metal - types, sizes, methods of application

Device and technical characteristics

Modern industry offers a wide range of various types of grinders, which differ in their dimensions, technical and operational features, however, they all work according to the same scheme. Any shredder has a solid body made of metal or polymers, most often it is mounted on a frame equipped with a wheel drive. This makes it much easier to move the unit around the garden area.

The effective operation of such installations is due to the action of a power drive or an electric motor, a little less often - a gasoline internal combustion engine. In this case, the drive acts on the chopping mechanism by means of a power traction. At the very top of the device, as a rule, a loading container is placed, usually it is in the form of a funnel, due to which the plant residues are fed to the grinding more evenly.The recycled mass either goes back to the receiving tank, or, depending on the model, goes into a special bag or is simply discharged to the ground. Some modifications of the branch shredders are supplemented with spreaders, so that the processed products can be evenly distributed over the entire cultivated area.

Let us dwell separately on the structure of the power plant. As a rule, shredders are equipped with an electric drive or, as we have already mentioned, with internal combustion motors. Each of these varieties has both advantages and disadvantages. The electric drive is usually installed on small-sized units with low or medium power parameters, less than 2.5 kW. They can process crop residues in moderation. Due to their low weight, such devices can easily move around the site to the main work site, without creating any problems for their operators.

However, such devices are tied to an AC network, therefore, if it is necessary to process a large area, you need to use a very long cable, which is often not very convenient, and if there is no connection point, then it is completely impossible. In addition, for safety reasons, there are some operating restrictions due to weather conditions. Units with a gasoline engine are devoid of this drawback; they can work in any weather, including rain, hail and even snow. In addition, they can be used in places where there is no electric current. It should be noted that such models can do quite difficult work, for example, grind large plant residues, even the trunks of small trees.