Working with an electric plane

The principle of operation with an electric plane is very simple - choose the required thickness of planing and go! When the planer moves over the surface, there is no need to put pressure on it, the weight of this electric machine is sufficient to remove chips in a given range.

I do not advise you to immediately set, for example, 2 mm, even if your model of a plane allows it, you just get an ugly front of a piece of wood. Start with 1 mm and on the second pass you will get the same result, only much more beautiful. Unless, of course, the task is to simply stupidly remove 2 millimeters of thickness, for example, to fit.

Ejection of shavings (sawdust) goes through a side hole that allows you to connect a vacuum cleaner in diameter when you work indoors, well, neglect it if you work outdoors. In some versions, it is possible to choose the side of the sawdust discharge - to the left or to the right. This feature should also be taken into account when choosing an electric planer, especially if you are left-handed - why do you need flying shavings on your clothes?

Subtleties of choice

After a place for carpentry has been arranged, the master needs to worry about the availability of all the necessary tools for woodworking. Beginners in this business sometimes have a difficult time making a choice in favor of this or that device and they buy a lot of unnecessary tools, losing sight of the most important ones, without which it will be difficult to do the job well. To avoid such mistakes, experts recommend purchasing a special set in a suitcase. It consists of the most important gadgets and is conveniently stored without taking up a lot of space.

All of them differ in price and configuration, so it is important to pay attention to the fact that the set includes the following tools. Hacksaw. It is best to give preference to models with a wide and not too long canvas.

As for the teeth, their optimal height is considered to be 5 cm. The shape of the teeth can be either in the form of an equilateral or an isosceles triangle.

It is best to give preference to models with a wide and not too long canvas. As for the teeth, their optimal height is considered to be 5 cm. The shape of the teeth can be either in the form of an equilateral or an isosceles triangle.

Hacksaw. It is best to give preference to models with a wide and not too long canvas. As for the teeth, their optimal height is considered to be 5 cm. The shape of the teeth can be either in the form of an equilateral or an isosceles triangle.

One of the main components of the carpentry set is the plane.

His choice must be taken with great responsibility, paying attention to the following indicators

- Appointment. Planers are available for shape cutting, finishing and general purpose.

- Blade quality. Serrated blades should leave neat grooves in the tree.

- Sole. You should choose a tool with a flat sole, without violating the geometry, it should also not have chips and damage.

- Lever. Her choice depends on personal preference and feelings while working with wood. The device should be easy to use and fit comfortably in the hand.

Today, among the common sets for carpenters that have received good reviews are such sets.

Intertool. It consists of such tools: a convenient square, a measuring tape (100 cm), a knife, a marking pencil and a hand saw. Thanks to the hacksaw, you can cut bars, boards, pieces of wood and small logs.To make the cut correctly, markers are used in several colors, each of which is designed for a specific wood species, and a square with right angles. Thus, this set will allow the novice carpenter to carry out the simplest work.

Before making a choice in favor of this or that tool, you should decide what kind of work they plan to perform. Novice craftsmen can get by with a minimal set, but for “experts” in joinery it is best to purchase professional sets, although they are more expensive.

See below for more details.

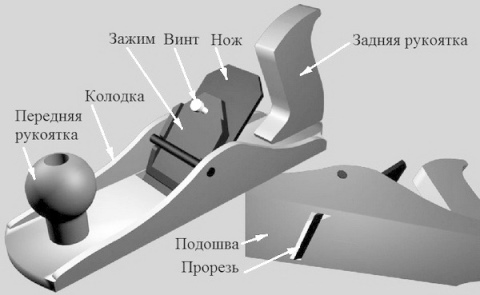

Hand planer design

A jointer is one of the variants of the plane device, characterized by a large, elongated block protruding beyond the main plane. This version of the tool is intended for fine planing (including large planes) or adjusting product fragments in a company with an auxiliary ruler.

The block is the main bearing part of which the plane consists. Already a blade is attached to it, which is commonly called a piece of iron in the environment of carpenters, as well as a wedge that fixes it in the block.

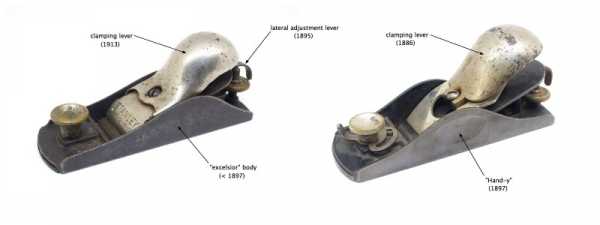

This design has existed since the days of the so-called wooden plane - which has a very long history. It is worth starting with the name of the instrument, which comes from the German word Raubank. The ancient invention was created around the first century AD, if of course you believe the finds of archaeological excavations on the territory of Pompeii. And it became widespread among the masters only at the turn of the fifteenth and sixteenth centuries. Structurally, it consisted of a wooden block with a blade fixed with a wedge.

Over the years, the device evolved into a carpenter's plane. Its differences consist in the use of more metal parts. Naturally, his block also changed the material. Of course, a wooden plane is much lighter than its counterpart, and glides very well on a wooden surface, but in practice, most basic models are quite difficult to rebuild compared to metal counterparts, which in addition are cheaper due to mass production.

Varieties of the instrument

Design

What function does this indispensable tool perform? The plane makes the thinnest cut of wood, gradually gives the details the necessary shape of excellent quality.

Mechanical hand planers consist of a wedge, a piece of iron (cutter) and a block. Electric planers are richer in details, but the main one is the motor. When rotating, the motor drum drives the knives, and they cope with all the tasks.

The word “plane” itself is of German origin (raubank) and sounds quite familiar, although it did not come from the word “cut”. However, other varieties of the instrument have a more noticeable foreign origin:

- Sherhebel is the basis for the very first, coarsest planing. It is not characterized by the usual straight shape of the piece of iron, but has a rounded blade with a width of 30–40 mm. This tool is about a third of a meter long with a comfortable handle for applying a lot of effort when working;

- Medvedka is already a relatively old instrument, it is not produced on an industrial scale. The plane is quite long, its peculiarity is for pair work. Has two handles on the sides. Planing occurs as follows: one person pulls, the other pushes;

- jointer - this tool is used for the final stage of processing a wooden part. It has a large length, allowing enough area to be cut in one motion. Has not a single but a double incisor;

- semi-jointer - by the name it is clear that it is also a shortened jointer with a double cutter;

- grinder - this type of planer is used for particularly clean planing. They clean the places near the knots, process the ends of the parts. Usually has a double blade with a chipbreaker;

- A zinubel is a special type of plane with special notches on the blade. Application - a preparatory stage for processing parts before gluing. If wooden parts are processed with this type of plane, they will be rough, and when glued, the quality of adhesion will improve;

- scraper - this type of planer is needed to scrape the workpiece. This type of work is performed before applying primers.

Working with a well-chosen planer gives a tremendous smoothness to the surface of the treated wood. If sanding with sandpaper, the result will be very different. After planing with a plane, the wood is glossy, water is not absorbed so much (and, accordingly, the wood is not destroyed so quickly), after varnishing it looks beautiful and rich. The natural pattern is especially appreciated in wood, and after such processing it is visible more clearly than after sanding.

The very work with wood adjusts the master to a peaceful mood, the resinous aroma of shavings has a beneficial effect on well-being. Working with wood is pleasant and not as harmful as with some other materials, so many carpentry is a hobby. And it is pleasant to admire the furniture, made with love by yourself.

Tool types

Planers have several classifications. If we consider their division into types, then there are tools for processing the following types:

- finishing;

- curly;

- rough or rough.

The latter are used for general purposes and are suitable for unskilled craftsmen. Finishing, in turn, implies the division of planers into several modifications.

Grinder. With this tool, the final finish of the tree is carried out. The plane perfectly copes with irregularities and defects, eliminating them from the surface, noticing even small elements left after processing with the previous tool. The design of the grinder contains two blades of increased sharpness. The knife sharpening angle does not fall below 60 degrees. A chipbreaker is also provided - a plate located above the cutting blade.

When the need arises for finishing, preference is given to the listed tools. These planers are also called flat planers.

How to use an electric plane?

Working with this tool is simple, but it has some nuances. Before use, adjust the position of the front and rear plates so that they are not skewed. This is done in the off state. The edges of the knives must be in perfect condition, otherwise you will not get a flat surface without blemishes. Even if the master already knows how to work with an electric plane, it is better to check his work on a small piece of material. Before switching on, the knives must not touch the work surface. The tool is placed on the side closer to you and begins to move forward after starting the drum.

Which electric plane is better to choose for home and summer cottages

There is no doubt that the choice of the tool is determined by the volume and intensity of the proposed work, the technical parameters of a particular model. However, the purchase can become the acquisition of a "pig in a poke" if you do not adhere to some general rules of choice.

- Only well-known and respected manufacturing companies can be fully trusted. It is best to buy equipment in company stores, from the official representatives of the manufacturer. The warranty for such products must be at least 2 years.

- At the time of purchase, check the functionality of the tool. There are cases of factory defects and equipment. All problems associated with this disappear if found at the time of purchase.

For home use, there are many models of the corresponding class. Among foreign manufacturers, such well-known brands as Makita, Bosch, Devalt, Status can be noted. Domestic manufacturers are also meeting world quality standards.Firm Interskol, Energomash, Stavr and others are gaining more and more fans not only among amateurs, but also among professionals. Moreover, the price of "our" planers is often an order of magnitude lower.

Criterias of choice

The electric planer is designed for leveling and sanding wooden surfaces. They choose it taking into account the following parameters:

- blade rotation frequency;

- depth of planing in one pass of the knife;

- processing width of the workpiece in one pass;

- engine power.

The faster the plane's knife turns, the better the surface of the wooden part is processed. The rotation speed of the knife drum must be at least 10,000 rpm, remain stable with increasing load. A good electric planer provides for the ability to adjust this parameter depending on the nature of the work being performed. Effective planing is carried out at a power of at least 350 watts. As the length of the blade increases, the resistance of the material increases, so it is better to give preference to more powerful samples.

The length of the cutters affects the planing width. Models with knife widths of 82, 102, 110 mm are often used.

The price of removable blades is low.

The depth of planing depends on how far the knives protrude from the sole surface. The higher the indicator, the more power is required for comfortable work, preventing overloads. For domestic purposes, a depth of 1.5–3 mm is sufficient.

When buying a planer, the quality of cutting elements and drive belts are also taken into account. Samples are taken with a dust collector.

The sole should have a flat surface without defects, grooves for chamfering, grooves for air exhaust.

Since working with an electric planer is fraught with risks, it is recommended to choose models with the most closed surfaces of sharp blades.

Almost all well-known brands: Skil, DeWALT, Kraftool, Rebir, Ryobi, Bosch, Zubr, Fiolent - produce budget versions of electric planers.

Industrial professional equipment is not cheap, it is advisable to buy it if regular work with increased load is planned. For infrequent use, an inexpensive household tool is suitable.

Characteristics of some samples.

Bosch PHO 2000

The electric planer is equipped with a high-performance 680 W motor. Planning depth setting is provided.

Makita KR0800

The lightweight planer is designed for planing work at home. The tool has a power of 620 watts. The width of the processed plane is 82 mm. The unit processes wood of any hardness, its derivatives: fiberboard, plywood and others. Rotation speed - 17000 rpm. Weight - 2.4 kg. The aluminum sole fits snugly to the canvas. The knife drum can be fitted with double-sided tungsten carbide blades. The model has the ability to fold, select a quarter.

Interskol R-102 / 1100EM

The plane is used in the production of shaped blanks. The unit operates at a speed of 11,000 rpm, but the quality of processing wood blanks remains at a high level. Machine weight - 3.8 kg, cutting depth is adjusted using the front handle. There is an electronic unit for soft start, speed fixing when working with increased load. Standard reversible blades 102 mm wide are installed.

Interskol 110 / 2000M

The peculiarity of the planer is the presence of an elongated base, which allows the tool to be used as a jointer. Thanks to the parallel fence with an adjustable tilt level, workpieces can be planed at different angles. The drum rotation speed is up to 15000 rpm.

Bison ZR 1300 110

The electric plane is used for processing wood blanks of any hardness. Thanks to the parallel stop, you can select a quarter, with the front handle, you can adjust the depth of cut.Accidental starting is prevented by blocking, the electronic unit maintains a constant engine speed under load.

|

Model |

Power, W |

Number of revolutions, rpm |

Knife width, mm |

Planing depth, mm |

Price, rub |

|

Interskol R-82/710 |

710 |

14500 |

82 |

2 |

4450 |

|

Makita KP 0800 |

620 |

17000 |

82 |

2,5 |

7790 |

|

ZUBR ZR-950-82 |

950 |

15000 |

82 |

3 |

2950 |

|

Fiolent P3-82 |

1050 |

15000 |

82 |

3 |

4650 |

|

Bosch PHO 2000 |

550 |

19500 |

82 |

1,5 |

4689 |

Non-standard varieties of electric planers

In addition to standard models of planers, leading companies produce specific tools that meet special requirements.

It is not uncommon for mechanical devices to be added to the standard equipment set, with the help of which you can significantly expand the capabilities of the tool. For example, the well-known STATUS company equips almost all planers with additional fittings for stationary installation of the tool. They can be used not only in manual mode, but also as a planer. To do this, you need to firmly secure the plane with the sole upward, and feed the wooden blank with your hands. It is much more convenient when processing small-sized workpieces.

Stationary placement of an electric plane

Stationary placement of an electric plane

Video: do-it-yourself planer from an ordinary plane

Another know-how is related to the folding of boards. Many (almost all) planers have a groove in the form of a rectangular depression on the front platform. Such a device allows you to process the ends of the boards, but within certain limits. If you need to chamfer more than 10 mm deep. they become powerless. Therefore, a special plane is produced, which has the shape of a sole, which allows removing the corner layer up to 25–30 mm.

Folded model of an electric planer

Folded model of an electric planer

Such a tool can be used both in normal mode and, if necessary, in a special one.

To increase the level of wood processing, models with spiral knives are available. Another option is two (or one) knives, but not perpendicular to the drum axis, but at an angle. This gives good results and is mainly used in the furniture industry.

Spiral and oblique knives improve the quality of wood processing

Spiral and oblique knives improve the quality of wood processing

The original model can be considered a plane that allows you to plan curved cavities (for example, in the form of a bowl). For the most part, it serves for the masters of the artistic direction in woodworking.

Non-standard outsole shape allows you to handle curved surfaces

Non-standard outsole shape allows you to handle curved surfaces

Pioneers of wood processing

Scherhebel

The most iconic examples of hand carpentry tools are:

Scherhebel - widely used for initial work with wood that has not yet been pretreated. It was the scherhebel who appeared first from the entire line of similar tools. It is a weighty and powerful device in a steel case. Designed for primary processing, giving the workpiece the planned size and shape and deep planing with the removal of a large layer of wood.

Scherhebel does not achieve a flat, smooth surface, it is intended for a rough, surface finish! The design of the scherhebel is similar in appearance to a conventional plane, but its iron with a rounded blade is set at an angle of 45 degrees relative to the sole. In one pass, the scherhebel removes chips up to three millimeters thick, leaving deep indentations that require additional leveling in the future.

The scherhebel is equipped with an oval cutting edge, which makes it possible to plan the wood across the grain without first breaking along. The sharpening angle of the scherhebel depends on the density of the wood being processed.

Differences between the scherhebel and the plane

In essence, the scherhebel is the same plane that performs rough processing. The difference is the semicircular sharpening of the blade and its width (it is smaller). The blade protrudes two to three millimeters from the block.

Read also: DIY device for detecting hidden wiring

Jointer

Jointer. This is a hand plane equipped with a double cutter.It is intended for precise finishing, leveling of large areas under a ruler due to an extended block and for edge jointing (adjustment). A jointer block can be two or three times longer than a typical planer block. The jointer knife is equipped with a chip breaker or humpback, as well as a handle for convenience in working with the device. Can be produced with a single knife.

Difference

The main difference is in the number of blades: the jointer has two, the plane has one! Structurally, the jointer differs only in its considerable body length. It is thanks to the elongated block that the use of a jointer is effective in processing large areas.

What brands and models are better to choose

When choosing an electric planer, the brand and model of the tool are of great importance. The products of the more famous brands are in higher demand and popularity, compared to the cheap Chinese product. Despite the higher cost, branded power tools continue to be in demand due to their reliability and quality.

Of the most famous brands that are constantly in demand among the consumer, both for the home workshop and for professional use, the following brands can be called:

- Bosch from the German manufacturer, the Robert Bosch GmbH group of companies, which has production facilities around the world;

- Makita, owned by the Japanese corporation of the same name, which is famous for high-quality professional power tools;

- De Walt and Black & Dekker, both produced by the same Stanley Black & Decker, Inc. from USA;

- Hitachi from Japan;

- Interskol from a Russian manufacturer;

- Sparky, a brand from Germany, whose products are manufactured in German factories and in Bulgaria.

When choosing an electric planer, you should pay attention to the country in which it was assembled. Products of original origin have the best quality, reliability and durability.

Unfortunately, in the modern market, you can find Chinese fakes under well-known trademarks of not only Western companies, but also Russian ones. These models even have Russian names "Grad" or "Zubr", which often confuses the buyer. Immediately it is worth deciding, so as not to run into a cheap fake, that it is better not to consider an electric plane worth up to 3 thousand rubles as an option for a purchase.

Of the most popular models, the following can be distinguished.

Bosch GHO 15–82, with a planing width of 82 mm, which belongs to the category of professional tools, but has a low weight (2.5 kg) and is designed for finishing work. With such a plane, you can choose a groove up to 9 mm, and with the help of the accessories included in the kit, you can transform a hand tool into a convenient planer. According to customer reviews, it is good for large volumes of work. But it is recommended to buy only an original German device or a European-assembled product.

Electric planer for finishing works

Makita KP 0810 C, equipped with a soft start system. providing a clean cut start. This tool has a high productivity, given the optimal ratio of time and area for roughing. According to the reviews of users of electric planers of this model, it removes chamfers and produces a quarter sample.

Equipped with side rip fence and soft start system

Bosch GHO 40–82 C 0.601.59A.760 has a comfortable ergonomic design of high-quality assembly. The presence of electronics allows for a smooth start and a clean surface finish when planing hardwood boards. Not very suitable for processing timber and large volumes of work, due to the presence of only one blade on the drum, which will have to be changed frequently. But the machine is suitable for home use. Blades change quickly and easily. The set of the tool includes 10 interchangeable knives, together with the key required for replacement, they are fixed directly to the body of the electric planer. According to customer reviews, this model is very easy to use.

Tool for working hardwood

De Walt D 26500 K. This model is ideal for working on any wood surface, including hardwoods. Quarter and chamfering functions are available. The tool makes little noise during operation.It can be used to process boards and bars that are not too wide. The device has an electronic soft start system, and can also be transformed into a machine.

Designed for large volumes of work with any type of wood

Interskol R-102 / 1100EM is an inexpensive but functional and convenient electric plane with a wide sole (102 mm), designed for processing wide beams and boards with an uneven surface. It has the function of sampling a quarter up to 15 mm, and is suitable for large volumes of work. The model is interesting for the presence of a smooth start, adjusting the speed of rotation of the knife drum and a system for maintaining a certain number of revolutions under load. Such a tool is ideal for home and summer cottages, and has a lot of positive feedback from consumers.

Types of hand planers

The typical design of this carpentry device has many varieties. Even a classic professional hand planer with standard dimensions can be classified according to design features.

- Single plane. Suitable for leveling the surface, thanks to the design of a single straight knife blade. The cutting edges have the smallest radius of curvature, therefore they do not leave marks on the surface.

- Double plane. Convenient in that it is equipped with a chipbreaker, which ensures clean planing. Therefore, the tool is indispensable for the final processing of the product.

With the development of the craft, the types of planers have acquired many modifications, each of which meets a certain number of tasks.

- Jointer. This is a hand tool for finishing a product. It differs from a planer with a long block with a double or single knife, which allows for high-quality leveling of the surface.

- Scherhebel - a narrow plane designed for recesses, outwardly similar to the classic model. But the scherhebel is more massive and differs in a small in width, rounded blade, which, when working, is located at an angle of 45 ° to the surface. This feature allows the tree to be planed along and across the grain, leaving deep hollows. The main value of this device is in roughing the product and removing the rough top layer of wood.

For flat planing

The processing of flat surfaces, such as bars or boards of the correct geometric shape, must be carried out with high precision. Deviation from straightness entails a change in the overall dimensions of the product. For this type of processing, devices with characteristic design features are provided.

- Half-dough. Unlike a typical jointer, it has a smaller sole and cutter. This allows you to process both large and small products with a straight and even surface, while achieving high accuracy rates.

- Tsinubel. It is intended for imparting roughness, which is necessary for better adhesion of products when attached with glue. The device is equipped with a serrated blade, which can be used to chip even twisted wood and the ends of workpieces.

For curly planing

Shaped wood processing is a whole art

To create unique specimens with a profile section, it is important to use first-class timber - straight-layered, with a minimum number of knots. However, no less important is the use of varieties of special-purpose carpentry planers.

- Kalevka is a type of plane designed for curly processing of products. Has a multi-level sole and special edges on the knife. It is used in the manufacture of cornices, baguettes and doorways.

- Tongue and groove. It is used to sample grooves, tongue-and-groove joints or holes in boards connected by a tongue-and-groove system. It consists of a guide and anchoring blocks held in place by screws.

- Primer. Suitable for cleaning trapezoidal grooves along wood grain.

- The quarters and grooves are selected with a zenzubel, and then they are cleaned. The knives of this tool resemble blades, and there is a special hole in the body for the exit of chips.

- The falzgebel is used for crimping and stripping quarters and has a stepped sole.

- The humpback has a convex form of the sole, therefore it is convenient for processing semicircular, concave or cylindrical surfaces.

Types of planing tools

Planing tools are of different types. For a home craftsman, it is enough to have a plane with which you can perform all the usual work on cleaning surfaces (the design of such a plane is shown in the figure below). The plane can be either wooden or more modern, metal. The planers currently in production are easy to adjust and quite sturdy - just what the hobbyist carpenter needs.

A standard plane has a length of 20 to 25 cm. Planer knives are single and double. The double knife is characterized by the presence of a strip designed for breaking the removed shavings. The cover also prevents too thick chips from being removed from the wood surface. A useful addition to such a planer can be a universal plane, which does not use a long knife with a straight cutting edge, but a narrow blade that resembles a razor blade. Such blades are replaced if they have served their life.

For small surfaces, as well as the side edges of parts, a small - about 15 cm in size - a planer for cleaning the end sides is best suited (it also uses replaceable blades).

Those who decide to seriously engage in woodwork will need other planing tools - a scherhebel, a jointer or a falzgebel.

The small butt-clearing planer, equipped with replaceable blades, can also be used as a falzgebel: the cutting edge of the blade crosses the sole of the planer from edge to edge.

Three typical wooden planing tools (from left to right): the falzgebel, the double knife (with chip breaker) and the single knife.

Regulation

Every time before starting work, check that the knife is installed correctly. Its cutting edge should barely protrude outward and at the same time be strictly parallel to the sole of the planer.

To determine how the knife is adjusted, the tool is raised with the sole upward at eye level. The cutting edge of the knife should protrude above the sole by an average of 0.5 mm. In the scherhebel, which is intended for the initial rough planing, the protrusion of the cutting edge is noticeably larger - up to 1 mm.

It is very easy to adjust the position of the knife in modern planers. It is necessary to sequentially turn to the right and left the large and small adjusting screws, which are located behind the knife platform, until the cutting edge is in the desired position. This position is then fixed with a centering lever and a guide screw on the upper pressure plate.

With a new tool, the knife position is usually already adjusted. However, after prolonged use, the setting may become slightly out of place. Therefore, if you take up the plane after a long break, check first that everything is in order.

You should not immediately start processing parts with a newly adjusted plane, first try it on an unnecessary section of the board.

This is how the professionals check whether the knife is installed correctly: the sole of the planer should be at eye level.

Electric plane malfunctions and repairs

Malfunctions are inherent in any technique. And despite the fact that an electric plane is a relatively simple device, it should be repaired by a person who is well versed not only in mechanics, but also in electrical engineering. In addition, repair requires tools, sometimes non-standard ones.Many manufacturers insure their products against unauthorized entry with the help of special slots on the threaded fasteners and other little "tricks". Therefore, if the instrument is under warranty, the best solution would be to contact a service center. They will also help with post-warranty service.

Here we will restrict ourselves to the simplest and most necessary recommendations.

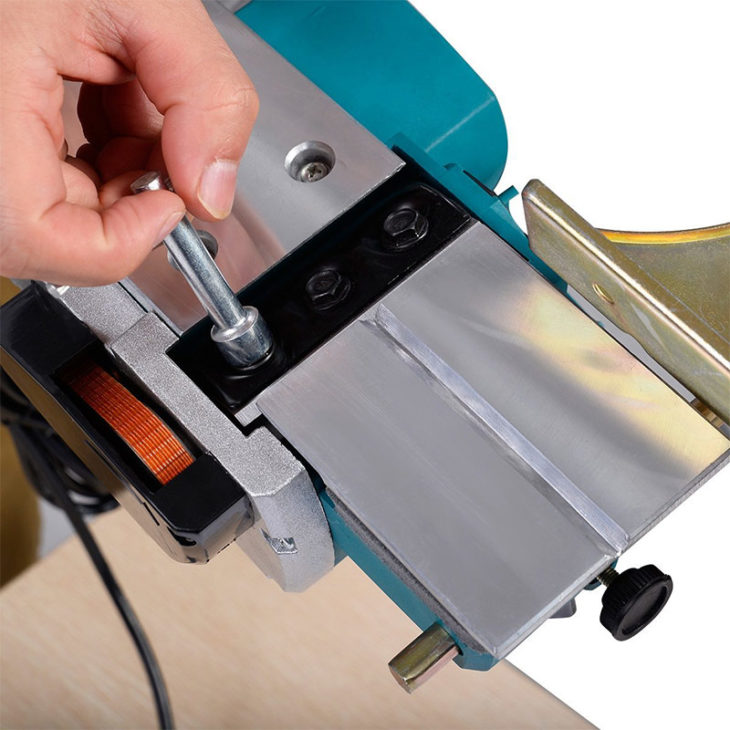

How to change knives

As a rule, there are no big problems with this operation. If the operation of the planer took place without gross violations, replacing the knives is a matter of 5 minutes. For this you need:

- disconnect the tool from the network;

- turn the knife shaft to a position where the knife mounting bolts are accessible;

- loosen the bolts until the jaws of the clips freely "release" the blade;

- carefully remove the used knife, avoiding contact of the sharp edge with the skin of the hand;

- insert a new knife in its place and clamp it with the locking mechanism, tightening the bolts with little effort.

Video: replacing knives in an electric plane

Setting up the knives

If old knives are replaced with new ones, no adjustments are required. It's just that the new blades should plunge evenly into the fastening groove, resting their bottom end against the bottom of the groove.

Knife fixing screws are located on the knife drum

Knife fixing screws are located on the knife drum

If, however, the sharpened knives are replaced, the position of the blade must be additionally checked. The fact is that during sharpening, a change in the geometric shape that is not visible to the eye can occur. This can affect the overall balance of the shaft (vibration) and affect the machining quality. To avoid such troubles, it is necessary to align both parts of the sole in the same plane and, using a metal ruler, set the edge of the blade strictly in the shape of the platform. After that, it remains only to fix the knife in this position.

How to set them up: video

Replacing the transfer belt

The operation is standard and it is best to refer the reader to the instruction manual - there it is described in detail, taking into account the design features of each model.

Video: how to install a new belt on an electric plane

In general, the procedure for replacing a belt looks like this:

- Disconnect the instrument from the mains.

- Remove part of the protective cover located above the belt.

- Loosen the belt tension with a special screw.

- Replace and reassemble the tool in reverse order.

The knife locking mechanism will allow you to correctly maintain the sharpening angle

The knife locking mechanism will allow you to correctly maintain the sharpening angle

The electric plane is a high-speed tool equipped with sharp metal knives. When working with him, you should carefully consider the observance of safety measures and personal safety measures. It is unacceptable to operate a knowingly faulty tool, especially if there are signs of mechanical damage to the protective casing or the attachment of knives. Carelessness leads to accidents or injuries while working. Before using the device, it is recommended that you familiarize yourself with the instruction manual of the tool, as well as its technical characteristics.