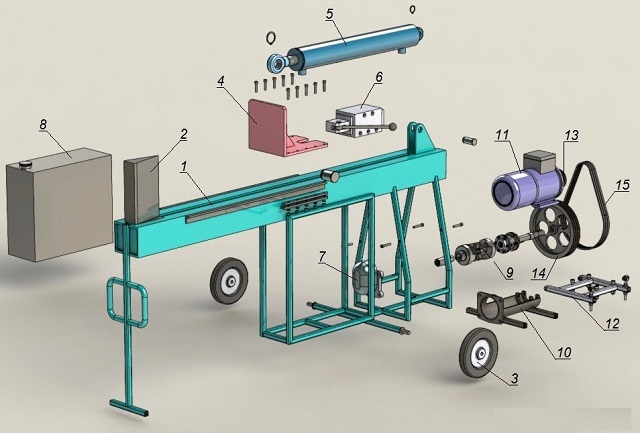

Structural elements

For work you will need:

- Metal sheet 4-5 mm thick.

- Cone (the best material for the main part of the entire mechanism is tool steel).

- Shaft.

- Pulleys (for belt transmission) or sprockets (for chain transmission).

- Belt or chain.

- Bearings with a housing.

- Electric motor.

- Wires.

- Button for turning the unit on and off (alternatively a magnetic starter can be used).

- Angles for making the bed (steel pipes are also quite suitable for this purpose).

- Bolts and nuts.

Almost all of the listed parts can be removed from old equipment. You can make the cone yourself. However, this will require certain equipment. The screw pitch must be 2: 1. Therefore, it is advisable to purchase it so that the unit works without comment.

It is recommended to use an electric motor, 220 volts. Sometimes on the farm there are wood splitters with a washing machine engine. A large unit can also be operated with a gasoline engine. The recommended shaft diameter is 25 to 30 mm.

You will also need the following tools to work:

- electric drill with drills of different sizes;

- hammer;

- welding machine;

- Bulgarian;

- tape measure, keys;

- marker.

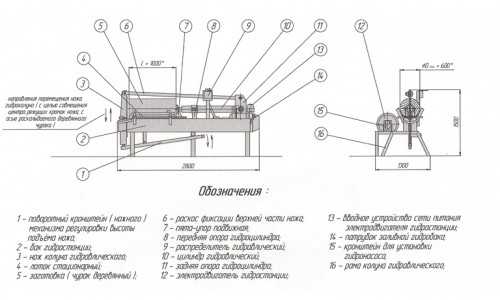

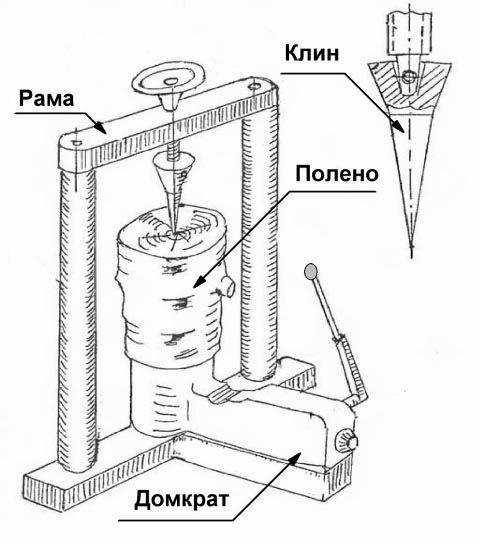

Hydraulic

It is necessary to clarify right away that such a device should only be designed by a person who has the appropriate education or at least experience in the manufacture of this type of equipment. Such a mechanism consists of a powerful frame and a hydraulic jack installed on it, a hydraulic cylinder from a tractor or a similar type of pusher.

The second main element is the NSh pump, which pumps oil and creates pressure in the system. An electric motor drives the pump. The engine is not necessarily powerful, 1.1 kW and 960 rpm is enough, well, and there is what the farm has. A distributor is installed, which has bypass valves and controls the oil supply in one direction or another. All this is collected in one system and connected by oil-resistant high-pressure hoses. Hydrocounter scheme:

On the opposite side of the hydraulic pusher, a wedge-shaped knife is installed, having one, two or three blades, depending on the engine power and the volume of the hydraulic cylinder, splitting the log into two, four or six parts, respectively, getting ready firewood. An example of the work of such a press can be found here. Do-it-yourself wood splitter video:

When working on your own such machine, you must very strictly observe safety precautions and it is imperative to inspect all parts and mechanisms before starting work.

Phased assembly

Installing the motor

The optimal and final option would be a wood splitter with a 220V screw engine, although it is possible to equip a wood splitter with a gasoline engine to increase power in case of assembling a large-sized installation for splitting larger logs. If the wood splitter is planned to be assembled in small sizes, then the motor from an unnecessary washing machine is ideal. Such a motor will become economical, because it will operate from a normal voltage of 220V. Of course, such a 220V wood splitter engine is not very powerful, however, thanks to the installation of a good reducer, the power of the electrical appliance increases significantly. The most important thing when assembling a wood splitter is the correct combination of motor and gearbox. In practice, this means that installing a more compact pulley on the motor shaft and a larger pulley on the shaft with a taper will produce the most efficient results. The more the dimensions of these pulleys differ from each other, the more powerful the log splitter will be.

Attention! The correct selection of a gearbox for an electric motor is very important, because the speed of rotation of the cone should not be more than 500 rpm, and it is just possible to limit this characteristic by choosing the right gearbox and motor.

Selection of bearings

In general, you can install bearings of any type, the main thing is that they withstand the maximum possible load from the shaft. If you plan to assemble a small wood splitter, installation of a shaft with a diameter of no more than 3 cm is quite suitable. For it, you will need to select bearings whose inner diameter is equal to the outer diameter of the shaft.

Attention! The bearings must be able to withstand the maximum possible shaft loads.

The bearings are installed in a housing made of durable steel. You can choose a one-piece housing for all bearings, or you can select a housing for each bearing separately. The body can be made by any professional turner, but it is best to purchase a ready-made body, left over from old machines.

The bearings are bolted to the frame. The main requirement for the bed is strength. For this reason, these places are reinforced with metal profiles, corners or channels. The profile is fastened tightly by electric welding. The frame of the wood splitter is easy to assemble using standard metal corners or pipes.

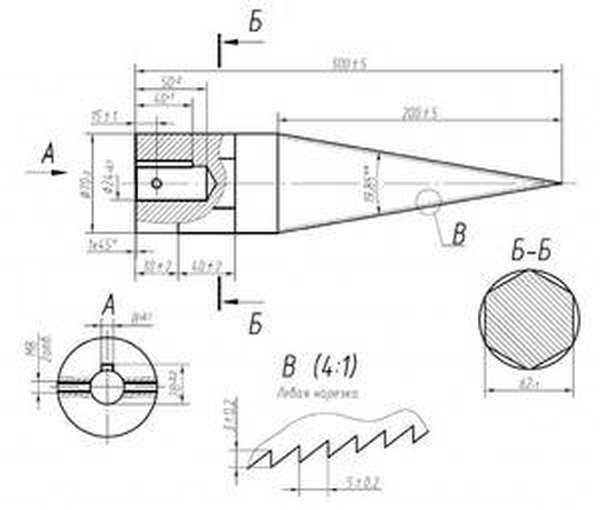

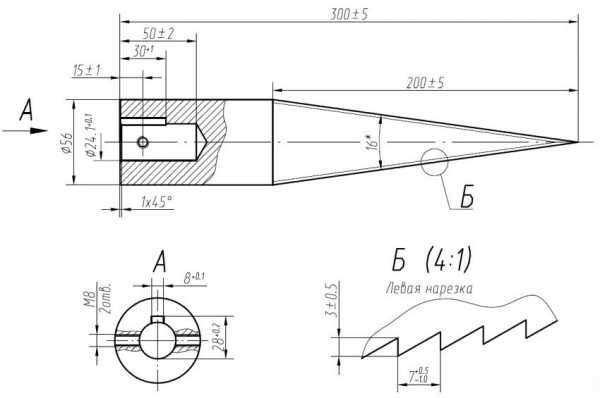

Cone selection

Now let's touch directly on the working part of the wood splitter, that is, its most important part, which is responsible for chopping wood. The material for the manufacture of the working cone must be high-strength tool steel.

This means that this part can only be bought, because even the most experienced turner cannot make the highest quality cone in accordance with all requirements. This can only be done by the manufacturer. The most important point when choosing a cone is to accurately select its size, focusing on the size of the logs to be split. How to choose the right cone depending on the size of the wood? With a diameter of 7 cm, the split will reach a depth of 45 cm, with 8 cm - 55 cm, and with 10 cm - 75 cm, respectively.

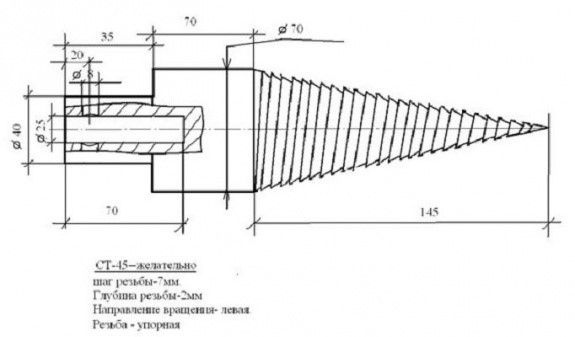

The diagram above shows the dimensions of the cone screw. It is also important in which direction the threading should be carried out. She should be left. In practice, this means that when the cone is screwed into the log, it should pull it towards itself. Thus, the left-hand thread serves an important function, making the work of the entire wood splitter easier. Thanks to the thread, the workpiece makes translational movements when the cone rotates. This factor is very important for low-power wood splitters, which are based on a motor powered by a voltage of 220V, because such devices do not have a supply unit. This work is done by hand. And thanks to the left-hand thread, there is no need to press on the logs, thus creating pressure and speeding up the cutting process

This is why it is important not to be mistaken with threading.

Types of cones

When choosing a cone for a wood splitter, it is important to decide on its design. There are two types of cones: with a shank and with a bore

How to make a taper with a shank? On the side of the shaft, to which the cone itself will subsequently be attached, you need to drill a hole for the shank, and then insert it there and securely fix it with a locking screw, screwing it from the end of the shaft. If there is more need for the second version with a bore, then a shaft must be inserted into it, and then secured with two locking bolts. Below is a photo showing the second option.

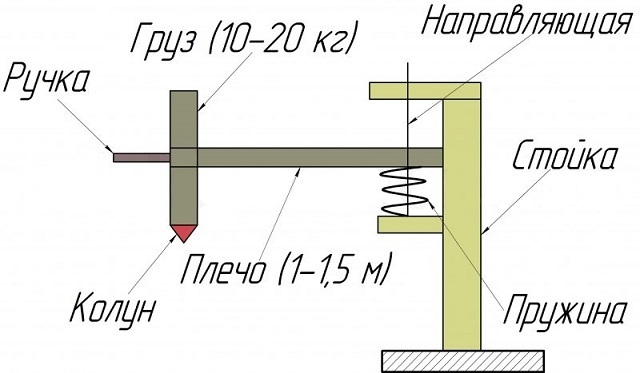

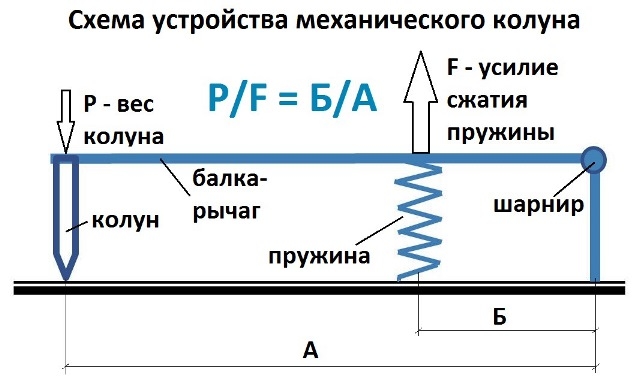

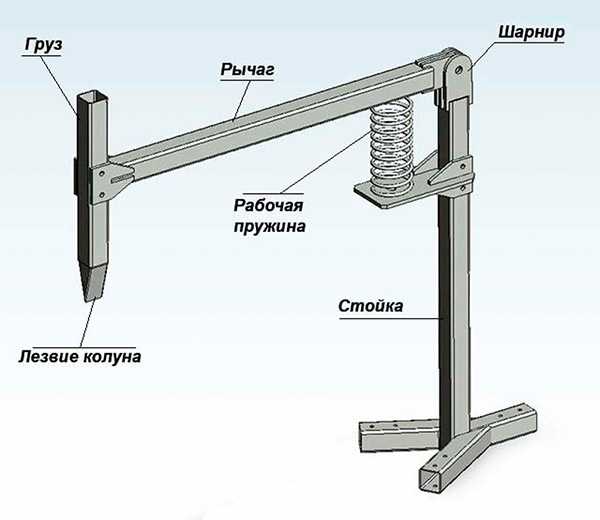

The simplest mechanical wood splitter

The unit is very similar, both in appearance and in principle of operation, with a well crane. The difference is that a cleaver with handles is attached instead of a bucket.Racks with a crossbar are connected using hinges, the disadvantage is that the connection will often have to be lubricated.

The principle of operation of the wood splitter is simple - the chock is placed on a stand, the lever is jerked down, the cleaver, under the action of force and gravity, picks up speed and splits the log. The process is repeated, getting thinner and thinner logs.

The design has some disadvantages. First, to stop the cleaver after he splits the log, you have to make an effort. Secondly, the device is rather bulky - a long lever is required to reduce the applied force.

Despite the disadvantages, such a device greatly simplifies the process of splitting firewood. In order for it to work as it should, it is required to weight the cola with a blank welded to it, or a pipe filled with concrete.

Do-it-yourself wood splitter

At home, it is quite possible to make both the simplest cone and hydraulic wood splitters with your own hands.

Home Installation Benefits

Such installations, as a rule, are inferior to factory devices in terms of power and appearance. However, for small volumes of home production, they are perfect. The advantages of home mechanisms are as follows:

- they are much cheaper than professional machines;

- collecting them is easy from the most common materials;

- since the assembly is carried out independently, you can take into account all the features of the mechanism that are needed exactly for you, for your needs;

- By collecting such a product by hand, you will gain valuable experience that can be useful in other household chores.

Mechanism requirements

Basically, any wood splitters (both self-made and factory-made) must meet a set of minimum requirements:

- Engine power not less than 2kW

- All stationary and moving parts are made of solid steel.

- The minimum distance from the floor to the cone is 80-90 cm.

- In domestic conditions, the number of revolutions per minute is sufficient 400-500.

- Dimensions are selected approximately, in the standard version they are approximately equal to 85 * 40 * 65 cm (respectively, length, width and height).

Making a screw wood splitter: step by step instructions and video

The simplest version of a wood splitter that you can do yourself is a screw one.

The device can easily split chocks of almost any diameter, which is clearly shown in the video.

To make it, you need a minimum of tools and materials:

- steel bed (base, to which all installation elements will be attached);

- engine, the power of which is selected according to individual needs;

- shaft;

- reduction gear;

- threaded cone nozzle (its drawing is presented below)

A schematic drawing of the device is shown below.

The sequence of actions will be as follows:

- First of all, it is necessary to choose the right power unit - it can be an electric motor from another mechanism with a developed power of 2-3 kW. You can use not only electrical units, but also a gasoline engine (for example, from a walk-behind tractor) with a capacity of 7 horsepower or more.

Further, it is very important to decide on the choice of the cone, since it is this element that will split the chocks.

Video review, which describes in detail the purpose of the part

| cone type | 1,1 | 1,2 | 1,3 |

| tilt degree | 15 | 18 | |

| length, mm | 220 | 250 | |

| diameter, mm | 75 | 85 | 100 |

| splitting depth, mm | 500 | 600 | 700 |

- Next, you need to correctly assemble the bearing assembly - for this, a shaft with bearing supports is purchased. It is installed on a firm, level surface. The distance is chosen arbitrarily, usually the shaft rises above the table by no more than 10 cm.

A video of the assembled bearing assembly can be

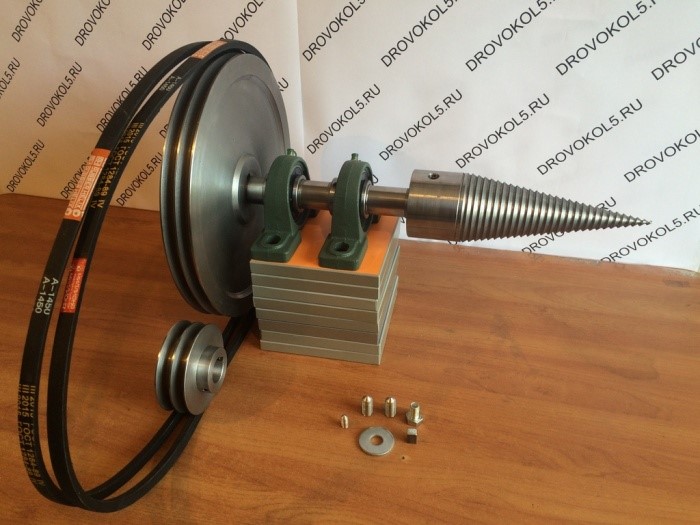

In a complete set, the installation looks like this.

Finally, the rig is fixed to a table covered with a steel plate. The cone is directed to the workpieces to be processed, the belt goes under the table and is mounted with a power unit.

How to properly work with a screw log splitter

Before you start working with the device, you need to run it at idle to make sure that all the elements work without failures and the engine is gaining the required power.

When working with a screw log splitter, you need to follow a few simple rules:

- The chock is brought to the mechanism in an upright position.

- The height of the working surface of the table must first be adjusted to the desired level. If necessary, put a board.

- The chock is brought up in a state pressed against the surface (it is incorrect to work on weight).

- If the chock is large, then the bark can prevent the splitting - it can be chopped off beforehand (especially for birch birch bark).

- If there are knots in the chock, it has an uneven internal structure, it is better to start splitting from the place where the internal layers of the tree are arranged easier.

DIY hydraulic log splitter: step-by-step instructions and video

Unlike the screw, the hydraulic wood splitter works fully in automatic mode, and the human's task is only to monitor the progress of the operation and correct the lumps in time, if necessary.

In this case, the block moves not due to human strength, but by a hydraulic mechanism. It can be connected to the tractor power plant or other power source.

Chainsaw wood splitter

The easiest way to use the saw as a wood splitter is to install a special attachment. They are sold for specific models and pair with the device without any problems.

To work with such a nozzle, you do not need a table or any device to hold the logs. You can just hold them with your foot. The process of working with the nozzle is shown in the video.

If this option does not suit you, you can make a homemade machine.

To do this, the chainsaw in the usual configuration is installed on a prepared wooden frame.

The entire device and canvas are secured.

A rigid frame made of PVC pipes and metal allows you to hold the product in place, despite strong vibrations during operation.

A rigid frame made of PVC pipes and metal allows you to hold the product in place, despite strong vibrations during operation.

However, it should be understood that this is more a device for sawing timber, boards, logs along the length than for splitting them into logs, which is clearly visible in the final part of the roller.

Safety engineering

For safe work with a homemade device, the following rules must be observed:

- The process of harvesting wood must be carried out in closed clothing, gloves and goggles so as not to be injured by chips flying off the workpiece.

- The workpiece must be firmly located in the chute and not displaced when moving.

- When the piston moves, it is forbidden to reach out to the knives and correct the shifted workpiece.

- Any manipulations with the workpiece are performed after turning off the unit and completely stopping all of its components.

- Work on the repair or replacement of the wood splitter units is carried out by disconnecting the electric motor from the mains supply.

Wood splitters make it much easier to harvest large amounts of firewood, saving time and effort. However, there is no need to purchase sophisticated expensive equipment to provide a fireplace or bath with wood. It is much more pleasant and healthier to use a regular ax.