Types of battery cans

Having disassembled the case, you will see a number of batteries connected by metal plates. Take a photo or sketch right away. You will need to accurately recreate the entire sequence. The batteries can then be removed to determine their type and parameters. The parameters are usually indicated on the case, so there is no problem. The types are also described. In household power tools, nickel or lithium ones are used. But they can be different.

-

Nickel-cadmium, Ni-Cd. The most common earlier. A standard bank has a charge of 1.2 V, typing 10 such cans we get the usually required 12 V with a decent capacity in ampere hours. The disadvantage is the memory effect, which is expressed in the fact that the battery "remembers" the lowest charge / discharge level. Its next "maximum" will be no more than this range. So, gradually, the capacity of the battery decreases. The second drawback is the long charging time.

- Nickel metal hydride Ni-MH. Such batteries usually also have a charge of 1.2 V. They are less susceptible to the memory effect, but they charge even longer, are afraid of low temperatures, and lose capacity over time.

- Nickel metal hydride - Ni-MH. Such batteries usually also have a charge of 1.2 V. They are less susceptible to the memory effect, but they charge even longer, are afraid of low temperatures, and lose capacity over time.

- Li-ion - li-ion. Permitted when charging incomplete discharge and operation with incomplete charge. They tolerate negative temperatures better. A positive point - the standard charge of one can of 3.6 volts, a short charge time. The downside is the high price.

- Lithium polymer. They have an increased charge, do not have a "memory effect". The disadvantage is that they cannot be recovered. That is, new ones are simply thrown out and put in.

Characteristics of the battery of a screwdriver of different types

To replace cans, you need to take similar ones. With NiCd and NiMh, interchangeability is allowed. If you originally have a lithium battery, there is no alternative. It is impossible to combine NiCd, NiMh and Li-Ion, as there are different voltages, currents and charging times.

Mechanical signs of a screwdriver malfunction

It is important

Pay attention to the sound of the screwdriver during operation. If you hear any extraneous sounds, then it is worth inspecting the armature bearings or its bushings.

Types of mechanical faults that can be detected during the repair of a screwdriver:

- curved gear shaft;

- gear wear;

- wear of the bearing or bearing sleeve of the gearbox shaft;

- the pin on which the satellite is attached is broken or bent.

In the event of the above breakdowns, it's up to you whether to look for replacement parts or carry them to the workshop, but the fact that the broken parts should be replaced is not even discussed.

There is time and desire, look for spare parts on forums, a flea market, or buy a broken screwdriver of the same model for spare parts.

Repair, in this case, will be much cheaper than buying a new one, and as an option, you can only buy a "carcass", that is, the screwdriver itself without a battery and charger.

It usually costs 20-30% of the cost of the entire kit. A good option if there is no desire to repair it by hand.

How to disassemble the instrument?

First of all, you should remove the battery from the compartment so that it does not accidentally fall out or break. Release the chuck from the clamped bit or drill. Then you need to "cut in half" the body. A suitable screwdriver is used for this. Most likely, the slots in the housing fixing screws will be Phillips. Sometimes the screw holes are covered with decorative plugs, they need to be removed.

The tool you may need (ordered in descending order of need):

- Phillips screwdriver;

- pliers;

- lock washer puller;

- platypuses (for pulling out cotter pins and pins);

- socket wrench 19 ... 22 (for unscrewing the cartridge);

- small hammer;

- vice.

The screws are located along the perimeter of the entire case, there are about 10 or 15 of them in total. The length, as a rule, is the same, but there are also long ones. Set the screws from the case separately so as not to be confused with others that may still be unscrewed. After unscrewing the screws, the upper (from the side of the screws) part of the case is neatly separated.

Next, the motor and gearbox are removed in the order that is most convenient so as not to put extra effort. The motor shaft is axially separated from the gearbox.

There are two types of motors, one with a permanent magnet in a metal housing and the other with a stator winding. In the second case, when removing the rotor, the brushes fall out. This is normal, when reassembled, they are put back in their grooves and held there by the manifold.

Battery types

First of all, you need to figure out what type of battery will have to be repaired. To do this, you need to know the features of each type. The structure of these elements is similar in the models of instruments made in different countries. In disassembled form, this part represents various elements connected in series. Such a connection means that the potential of all elements is added. The total voltage across the battery contacts is the sum of all the cells.

As a rule, all elements have standard sizes and characteristics. Their difference lies in the capacity, the unit of which is A / h. The capacity is indicated on each typesetting element (they are also called "banks").

Battery connection diagram for a screwdriver.

"Banks" can be of various types:

- lithium-ion (Li-Ion);

- nickel metal hydride (Ni-MH);

- nickel-cadmium (Ni-Cd).

The first type has a voltage of 3.6 V, and the other 2 - 1.2 V. Each of the types has its advantages and disadvantages. The advantages of nickel-cadmium elements are as follows:

- low cost and widespread use;

- insensitive to low temperatures;

- retain their characteristics when stored in a discharged state.

The disadvantages of this type of "cans" are as follows:

- production is accompanied by the release of toxic substances, therefore they are produced in only a few countries;

- self-discharge;

- memory effect;

- low capacity;

- quickly fail due to the small number of charge / discharge cycles.

Electric circuit of the screwdriver.

Nickel-metal hydride elements have the following advantages:

- environmentally friendly production, which makes it possible to buy parts from those countries with high quality standards;

- the memory effect is poorly expressed;

- relatively high capacity;

- low self-discharge;

- a large number of charge / discharge cycles.

There are also disadvantages to nickel metal hydride parts:

- high price;

- long-term storage in a discharged state negatively affects the characteristics;

- fail quickly at low temperatures.

Lithium-ion "cans" are attractive for the following properties:

- there is no memory effect;

- very low self-discharge;

- high capacity;

- several times more charge / discharge cycles than other parts;

- fewer typesetting parts are required, which reduces the weight of the devices.

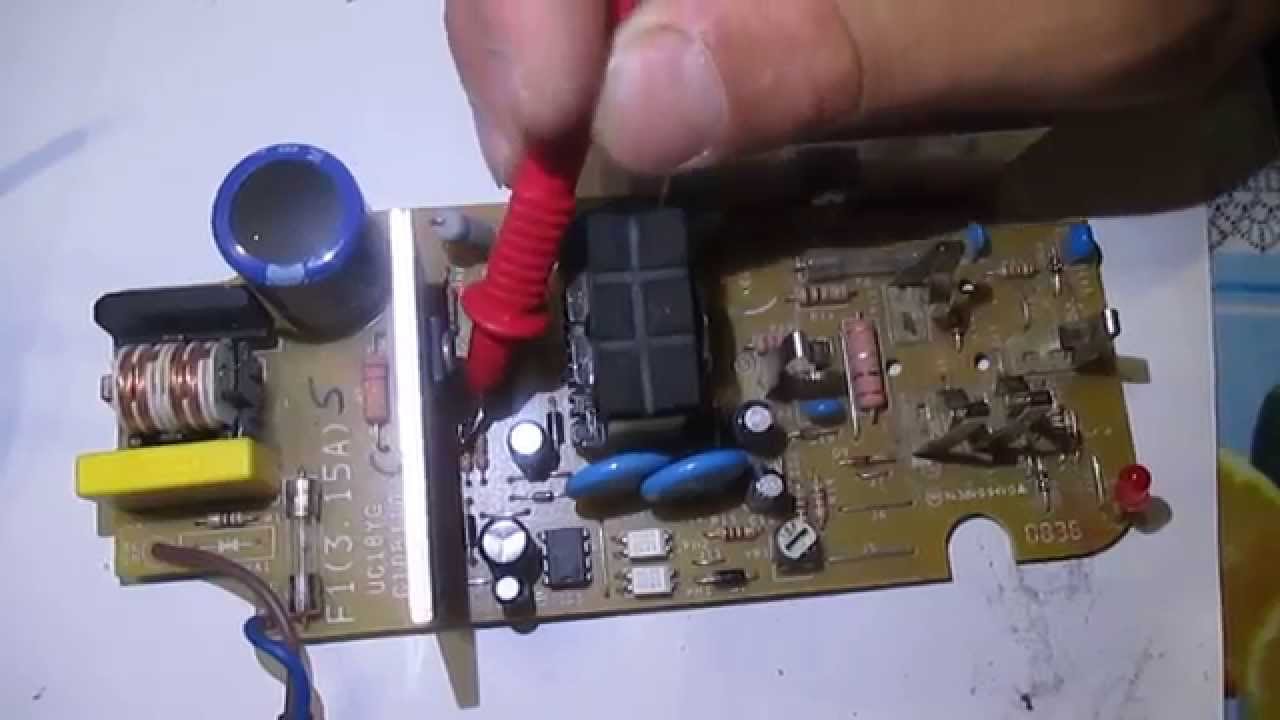

It is possible to determine a faulty battery with a multimeter, which will show which of the "cans" is faulty.

The disadvantages include:

- very high price;

- since lithium decomposes, the capacity is significantly reduced after 3 years of operation.

The typesetting elements of the storage battery are enclosed in a housing. The housing has 4 pins:

- For discharge / charge 2 power contacts - "+" and "-".

- Upper control connected through a thermistor.A thermistor (or thermal sensor) protects the battery from overheating when charging. If the temperature rises too high, the charging current is limited or cut off.

- Service contact connected through a 9 kΩ resistor. It is designed to equalize the charge on all elements of complex charging stations. Such stations are used only in industrial tools and devices.

Knowing the battery design of a screwdriver is necessary to carry out repairs.

Repair of the electrical part of the tool - battery

A frequent failure of the Interskol Da-18ER screwdriver is the failure of the battery. Determining this malfunction is very simple. If you put both screwdriver batteries on charge, and one of them is charged, and the second does not, while testing the charger does not show any deviations, then the reason is in the power source itself.

It is necessary to open the battery case and remove the battery of galvanic cells from it. After that, you need to check the voltage on each bank. It should be 1.2-1.4 volts. If there is no voltage on at least one element, or it is below this value, it must be replaced. Since the banks of the storage battery are connected in series, the increased resistance of the damaged cell makes it impossible to charge the rest.

After identifying a weak point, the battery needs to be assembled and tested under load. Rechecking will help ensure that the decision is correct. The ideal solution would be to replace individual cells or the battery assembly with a new, original one. The cost of a screwdriver battery is quite high, so it is worth trying practical ways to restore the performance of "old" elements.

First of all, a damaged can must be briefly exposed to a large current. This will return it to its former tightness and stop the processes of drying and evaporation of the electrolyte.

The second option for restoring the working capacity of a faulty bank is its slight compression or slight deformation of the element body. Such actions will enable the battery to work for some more time.

If there are several used batteries in stock, then a new one can be assembled from them, selecting and soldering suitable elements. There are two things to keep in mind. The assembled battery must have a voltage of 1.5-2.5 volts higher than the nominal value, and the so-called memory effect must be eliminated on it. To do this, it is charged and discharged completely several times. In this case, you need to ensure that the screwdriver does not overheat.

Another reason for the inoperability of the battery can be a thermal switch. It is mounted on a battery of galvanic cells and connected to the control contacts. Its mission can hardly be overestimated. During charging, the sensor monitors the temperature level of the galvanic cells and, if the rated values are exceeded, interrupts the circuit, thereby protecting them from destruction. Its failure will launch irreversible processes in banks, and this will lead to their destruction.

Possible malfunctions, reasons for their occurrence and remedies

To repair a hammer drill with your own hands, you must first determine the external manifestations of malfunctions.

The puncher does not hit

If the rock drill stops hitting when switching to impact mode, but the drill rotates, it is most likely that the floating bearing is damaged. The solution to the problem is to replace it with a new one.

The second possible reason is a malfunction of the percussion mechanism. Often, during overloads, the steel firing pin splits in operation, this leads first to a weakening of the impact, and then to its complete absence. The striker must be replaced.

The third probable reason is wear or breakage of the piston group of the perforator. The liner and piston should be replaced.

The hammer drill does not spin or drill

If the chuck does not rotate when the start button is pressed, the cause can be identified by the sound beforehand. If the electric motor hums, but does not turn the chuck, most likely something is preventing the rotor from rotating inside the gearbox. What happened to the engine will have to be figured out by disassembling the mechanical part of the tool.

If the engine does not hum when turned on, it is more likely that the engine has broken down. Having opened the lid of the device, it is necessary to determine what exactly led to this phenomenon. This can be an open circuit in the power supply, a breakdown of the start button, or a short circuit in the windings of the coils. With the help of a tester, the specific cause is determined and the appropriate repair is made.

The drill does not hold in the chuck and flies out

Punch rig incontinence can occur during long-term use. A drill or chisel inserted into the chuck does not hold and flies out during operation. Not only is it impossible to continue chiselling with such a tool, it is also very dangerous - a flying chisel can cause injury.

The reason for the incontinence of the tooling lies in the wear or breakage of the chuck. The cartridge must be disassembled and the problem identified. Perhaps the balls were deformed, a depletion appeared on the restraining ring, or the fixing spring sagged. Usually, after replacing the damaged part, the chuck will start functioning normally again.

Video: why drills fly out of a hammer drill

Brushes sparkle

Sparking of brushes is a fairly common phenomenon when working with a tool in dusty conditions. As a rule, sparking is a consequence of the depletion of the material of the brushes themselves. Replacing the latter with new ones will help to correct the situation, sparks will no longer fly out.

If not, the cause must be sought in the stator or rotor windings. It is possible that the large amount of dust entering the engine has abraded the protective varnish covering the copper conductors. And this entails a short circuit. The presence of turn-to-turn closure is checked by electrical devices (multimeter).

Resistance measurement between lamellas is carried out with a multimeter

In addition, it should be borne in mind that dust can adhere to the lubricant of the bearing located next to the manifold. To prevent this, the collector is degreased with a swab dipped in alcohol or solvent.

The hammer drill gets very hot

If the rock drill becomes excessively hot during operation, this is a clear sign of a malfunction of the electric motor. First of all, to prevent overheating, it is necessary to observe the operating mode of the device:

- pause at regular intervals;

- after exertion, allow the tool to idle.

When drilling, it is recommended to use a periodic mode: apply maximum power for no more than 1 minute, then turn on idle for 3-4 seconds.

If the temperature of the case does not decrease, then you need to revise the electric motor. Having felt the characteristic smell from under the casing of the tool, you must immediately stop working and disconnect the device from the network. It can only be disassembled after it has cooled completely.

The hammer drill does not hold a chuck

Sometimes there is a situation when a cartridge flies off on a working perforator along with the equipment. This is due to the wear of the holder of the chuck body at the end of the trunnion sleeve, which is a retaining ring. If it breaks, the fixation is broken and during the push, the rubber boot flies off, followed by the spring and balls.

Normal operation of the chuck can be restored by installing a new retaining ring. This is done quickly and does not require any additional devices other than the usual screwdriver.

Views

Today, cordless screwdrivers are equipped with three types of batteries: nickel-cadmium, lithium-ion and nickel-metal hydride models.

Nickel Cadmium (Ni-Cd)

They are the oldest and most widespread type of battery known to mankind for the last 100 years. The models are characterized by high capacity and low price. Their cost is almost 3 times lower than that of modern metal-hydride and lithium-ion samples.

The batteries (banks) that make up the common unit have a nominal voltage of 1.2 volts, and the total voltage can reach 24 V.

The advantages of this type include a long service life and high thermal stability of batteries, which allows them to be used at temperatures up to +40 degrees. The devices are designed for a thousand discharge / charge cycles and can be operated in active mode for at least 8 years.

The main disadvantage of nickel-cadmium samples is the presence of a "memory effect", due to which it is not recommended to charge the battery until it is completely discharged. Otherwise, due to frequent and short recharging, the plates in the batteries begin to deteriorate and the battery quickly fails.

Another significant drawback of nickel-cadmium models is the problem of disposal of used batteries.

This entailed a ban on their use in many European countries, where strict control has been established to maintain the cleanliness of the surrounding space.

Nickel Metal Hydride (Ni-MH)

They are more advanced, in comparison with nickel-cadmium, battery option and have high performance.

The batteries are lightweight and small in size, which makes it much easier to work with a screwdriver. The toxicity of such batteries is much lower than that of the previous model, and although the "memory effect" is present, it is rather weakly expressed.

In addition, the batteries are characterized by a high capacity, a durable case and are able to withstand more than one and a half thousand charge-discharge cycles.

The disadvantages of nickel-metal-hydride models include low frost resistance, which does not allow them to be used in conditions of negative temperatures, fast self-discharge and not very long service life, in comparison with nickel-cadmium samples.

Lithium Ion (Li-Ion)

Batteries were developed in the 90s of the last century and are the most modern accumulator devices. In terms of many technical indicators, they noticeably outperform the two previous types and are unpretentious and reliable devices.

The devices are designed for 3 thousand charge / discharge cycles, and their service life reaches 5 years. The advantages of this type include the absence of self-discharge, which allows you not to charge the device after long-term storage and immediately start working, as well as high capacity, light weight and compact dimensions.

The accumulators have no "memory effect" at all, which is why they can be charged at any discharge level without fear of power loss. In addition, the devices charge quickly and are free of toxic substances.

Along with many advantages, lithium-ion devices also have weaknesses. These include high cost, lower service life and low impact resistance compared to nickel-cadmium models. So, with strong mechanical impact or falling from a great height, the battery may explode.

However, in the latest models, some technological flaws have been eliminated, so the device has become less explosive. So, a controller for heating and battery charge level was installed, which made it possible to completely exclude an explosion from overheating.

Another drawback of lithium-ion models is the fact that their service life does not depend on the intensity of use of the screwdriver and the cycles it has worked out, as is the case with nickel-cadmium devices, but solely on the age of the battery.So, after 5-6 years, even new models will already be inoperative, despite the fact that they have never been used. Therefore, the purchase of lithium-ion batteries is only reasonable in cases where regular use of a screwdriver is expected.

How to repair a screwdriver gearbox

The tool reducer consists of a body in which its working elements are located. For example:

Depending on the manufacturer and model of the device, its internal elements can be made of metal or plastic. The first option ensures their long service life and tool reliability.

Disassemble the gearbox

The housing of household models of the screwdriver is made of plastic, and of professional models - of alloy steel. After dismantling the metal plate, we get access to the inner part of the gearbox: teeth and gear shift ring. If the crown has no defects, it is enough to clean it from dirt and lubricate it.

Now it's time to start examining the outer rim, the inner part of which is equipped with teeth along the perimeter. The efficiency of the gearbox depends on their condition. If the teeth are worn out, it is not possible to replace them with new ones. But there is a way out of the situation.

Drill holes in the gear housing

First you need to take the smallest drill bit and drill 4 holes in the gearbox housing with it.

It is important to pay attention to the fact that the holes should be located in the very center of the tooth.

Screw in bolts instead of new teeth

In place of the worn out teeth, bolts of suitable diameter can be installed. Each bolt is carefully screwed into a pre-drilled hole in the body.

Use a drill

The bolt heads installed do not have the required geometric shape. In order to correct the situation, you can use a drill. With its help, we carefully trim the heads and legs of the bolts, giving them the necessary shape.

When working with a drill, it is important to perform short and smooth movements. Otherwise, the possibility of overheating of the plastic housing of the gearbox is not excluded, which will lead to its melting

Assemble the reducer

Before proceeding with the assembly of the gearbox, experts recommend checking the correct installation of new teeth. To do this, take a natfil and clean the surface of each erased tooth of the gearbox with it. If this is not done, the crown may not sit tightly in the groove of the body or it will scroll.

Then a metal crown is inserted into the body. If it does not scroll and sits tightly, then all operations were performed correctly and you can continue to assemble the gearbox. In this case, do not forget about the obligatory lubrication of all working elements of the gearbox.

How to convert a battery for lithium-ion batteries?

Often, owners of screwdrivers powered by nickel-cadmium batteries want to adjust the battery for lithium-ion batteries. Such popularity of the latter is quite understandable. They have many advantages over other options. These include:

- the ability to lighten the weight of the tool (it is more convenient to work with it if lithium-ion batteries are installed);

- it is possible to eliminate the notorious memory effect, because it simply does not exist in lithium-ion cells;

- when using such batteries, charging will occur several times faster.

In addition, it is necessary to take into account the fact that with a certain assembly scheme of the device it is possible to multiply the charge capacity several times, which means that the operating period of the screwdriver from a single charge will significantly increase. The positive aspects are, of course, obvious. But we must bear in mind that there are certain drawbacks in adapting technology for lithium-ion batteries.

It is important to take into account both. Consider what disadvantages you can face with such work:

- lithium-ion power components are more expensive than other options;

- you will need to constantly maintain a certain degree of charge of such a battery (from 2.7 to 4.2 V), and for this you need to insert the charge and discharge controller board into the battery box;

- lithium-ion power parts are more impressive in size than their counterparts have, so it is not always convenient and problem-free to place them in the screwdriver body (often you have to resort to various tricks here);

- if you have to work in an environment of low temperatures, it is better not to use such a tool (lithium-ion batteries are "afraid" of cold weather).

If, considering all the pros and cons, you still decide to replace the nickel-cadmium batteries with lithium-ion, then you should carry out the following procedures.

- First, you need to determine the number of lithium-ion sources.

- You will also need to choose a suitable controller board for 4 batteries.

- Disassemble the battery case. Remove the nickel-cadmium cans from it. Do everything carefully so as not to break important details.

- Cut the entire chain with pliers or side cutters. Do not touch only the upper parts with the contacts necessary for connecting to the screwdriver.

- It is permissible to remove the thermistor, because after that the controller board will "observe" the overheating of the batteries.

- Then you can proceed to assembling a chain of lithium-ion batteries. Attach them consistently. Next, attach the controller board based on the diagram. Pay attention to polarity.

- Now place the prepared structure in the battery case. Lithium-ion batteries should be placed horizontally.

- Now you can safely close the battery with a lid. Fix the battery on the horizontally laid out batteries with the contacts on the old battery.

Repair of the mechanical part of the tool - self-clamping chuck

Another area requiring attention is the screwdriver chuck. This is not to say that it often fails, but breakdowns do occur. At this point, the main task is to dismantle the cartridge.

At first glance, it is difficult to get close to him, but in reality everything is simple:

- with a Phillips screwdriver clockwise, since the left-hand thread, you need to unscrew the locking screw of the chuck;

- insert the hexagon wrench # 8-# 10 into the chuck with the short side and strike sharply on the long side of the wrench in a counterclockwise direction.

If, for some reason, the screw cannot be unscrewed, an anti-corrosion liquid is pre-poured into the cartridge. Then the procedure is repeated. If this does not help, disassemble the screwdriver and remove the gearbox. Then, using a 198 pipe wrench, hold the spindle and unscrew the chuck.

The chuck is completely changed because the jaws and flare nut can only be picked up from a similar chuck. You need to buy spare parts for a quick-release device, having a screwdriver and an old chuck in stock.

After reading the presented article, a craftsman will be able to repair a simple Interskol screwdriver, and he will not have to spend extra money in service centers.

The most "popular" home craftsman tools is a screwdriver. However, just like any product, it breaks down. What to do here? In some types of work, an electric drill can save the situation, but only in some. Take the tool to the service center and do not wait for it to be repaired. However, this will take time not money that will have to be paid for repairing the instrument. Alas, you, not the third option is available - repairing the Makita screwdriver, additionally not so difficult.

It is necessary to consider the main symptoms of screwdriver malfunctions, not how they can be eliminated on their own.

General recommendations before testing the battery

Immediately before checking the battery, it is necessary to clearly determine what type of battery the battery belongs to. Depending on this type, and the approach may be different.For example, the most common nickel-cadmium batteries are highly sensitive to operating conditions. Infrequent or irregular full recharges will significantly reduce the capacity of the battery and the battery will not fully utilize its resources. We will consider the types of batteries in more detail below.

It is also recommended to fully charge the battery before checking. This will allow you to make more accurate conclusions about the performance of the device. It has been proven that the most accurate readings are taken under load. And a full charge is a very suitable type of load.

Before testing, it is necessary to minimize the influence of the "memory effect" on the device. Since this effect appears in batteries in case of improper use, in order to eliminate it, it is necessary to use the battery several times in accordance with all the rules.

It is enough to carry out the charge / discharge cycles 3 times to significantly reduce the effect of the effect. For a faster discharge, it is best to use an incandescent lamp, which, together with a multimeter, will need to be connected to the battery.

If everything is done correctly, then after a few full cycles the battery will be able to restore its capacity and can again be used in a screwdriver. If the operation did not help, then the problem was different.

Nickel cadmium battery

The most common type of battery. They charge quickly enough and have a good volume. They are distinguished by their durability and resistance to external influences. The average number of charge / discharge cycles can reach 3500. When using accelerated chargers, the battery does not wear out faster and can last for a long time. Separately, it is worth noting the cheapness of such batteries and the ability to operate at temperatures below zero.

But there are also disadvantages, the main one of which is the so-called "memory effect". Batteries are quite toxic in the event of a malfunction and have a high self-discharge rate. Due to toxicity, manufacturers are now trying to rapidly reduce the percentage of such devices.

To prolong the life of such a battery, it is recommended to completely discharge it before recharging.

Li-ion battery

A much more expensive analogue, which, however, has a number of undeniable advantages. These batteries are used in leading-edge screwdrivers from well-known brands.

These batteries have a large capacity and a much lower percentage of charge loss due to self-discharge. However, such batteries are strictly not recommended to be overheated and left completely discharged for a long time. This can lead to degradation of the crystals and damage to the battery. If overheated, there is a risk of explosion of such a device.

Like the first type, the lithium-ion battery is capable of functioning in cold weather.

Device and principle of operation

Device

Device

The gearbox is a complex mechanical transmission unit through which the axis of the motor-power unit transmits torque to the chuck.

Two or three gear stages are installed in the gearbox.

The construction of the unit of the "household" two-mode screwdriver includes:

- The plastic body is a small drum that is attached to the cartridge. The body itself is fixed motionlessly, and the chuck shaft is inserted into a clamp on one of the transfer plates;

- 2 or 3 transfer plates (carrier) - a round metal plate, on one side of each there are 3 protrusions for small gears. On the other hand, one of them has a clamp for the chuck shaft, and the other (or 2 others) has one more so-called. A "planetary" gear that rotates three small cogwheels;

- 6 or 9 small cogwheels (three each: they can be of the same or different thickness) are the so-called "satellite" gears, which are installed and rotate freely on the projections of the transfer plates.With their teeth, they interact with the sun gear located between them and with the ring gear, which is located on the inner surface of the housing;

- ring gear - a metal ring with teeth on the inside and small protrusions on one of the rings on the outside. On these projections and ball-bearings, it fits on the inner surface of the housing.

The parts are lubricated, assembled in series and installed inside the ring gear, which lies inside the housing drum (it has a seal with grooves for ball bearings and gear protrusions). After that, the surface of the open satellites is closed with a metal washer, in the center of which there is a hole, into which the engine shaft enters with another gear fixed to it.

During the operation of the screwdriver, the gear wheel on the engine shaft rotates the upper satellites, and they, rotating around their axis and, along the ring gear, respectively, transmit the movement to the next carrier. Depending on the number of plates and small gears, the rotation speed will decrease proportionally.

Useful Tips

So that a new battery from a screwdriver (of any company) does not lose its capacity, the first few times it will need to be charged for 10-12 hours. During the operation of the screwdriver, it is advisable to use the battery until it is completely discharged. After that, hurry up to immediately connect it to the charger and leave it there until it is fully charged.

None of the firmware options will be effective when it comes to a nickel-cadmium battery in which the electrolyte has boiled. Capacity is inevitably lost in these parts.

When buying a new component of the power supply for the battery, it is very important to ensure that the level of its capacity and dimensional indicators correspond to the native elements of the screwdriver. Otherwise, it will be very problematic to install them, or maybe completely impossible.

If, when repairing the battery of a screwdriver, you resort to using a soldering iron, then you should keep in mind that you need to work with it as quickly as possible. This rule is due to the fact that holding this device for a long time can lead to destructive overheating of the battery parts. Act quickly but carefully.

If you decide to repair the battery of the tool on your own, then you should act carefully and accurately. try not to make mistakes so as not to harm the device even more. Remove and install individual components carefully so as not to damage other important parts. If you doubt your skills and abilities, then it is better to entrust the battery repair to experienced specialists, or buy a new battery and simply install it in a screwdriver. In this case, it will be very easy to change this part.

For information on how to properly repair a battery for a screwdriver with your own hands, see the next video.