Possible problems and how to fix them

What breakdowns can occur and how to repair the circulation pump with your own hands? Let's figure it out.

The pump hums and the impeller does not rotate

Possible reasons:

- Foreign object in the impeller chamber.

- Prolonged downtime of the apparatus led to oxidation of the rotor shaft.

- The power supply to the device terminals is interrupted.

In the first case, you can eliminate the malfunctions by carefully removing the device and untwisting the housing in the impeller area. If there is a foreign object, remove it and turn the shaft by hand. To avoid re-entry of foreign bodies, a filter should be installed on the nozzle.

The circulating pump hums even if the power supply fails. First check the voltage with a tester. If the cable is damaged or broken, it should be replaced. If the cable is in order, look at the voltage at the terminals. The infinity icon on the tester indicates a short circuit. A lower voltage means a broken winding. In both cases, it is necessary to replace the terminals.

The pump does not work at all

The pump does not work when there is no mains voltage. The tester checks the voltage, as well as the correct connection of the device to the power supply.

Circulation pump shaft

If there is a fuse in the pump, there is a risk that it will burn out from power surges. If this happens, replace the fuse. It is advisable to install a reliable stabilizer.

The pump turns on, but stops after a couple of minutes

The reasons may be:

- Limescale between moving parts of the appliance.

- Incorrect connection of the pump in the area of the terminals.

The pump can be turned on, but also stopped immediately if there is scale. Remove limescale and lubricate the joints between stator and rotor.

In the second case, check the tightness of the fuse on the device. It is removed and all clamps are cleaned. All wires must be correctly connected in the terminal box.

Pump makes noise when turned on

If the pump is noisy, this could indicate the presence of air in the system. It is necessary to bleed the air from the pipes, mount a unit in the upper part of the circuit so that the air is released automatically.

The pump can also make noise due to wear on the impeller bearing. It is required to disassemble the body of the device, and, if necessary, replace the bearing.

The pump vibrates and makes noise

If the activation of the pump is accompanied by vibration and noise, then the reason is insufficient head in a closed loop. You can solve it by adding water to the pipes or increasing the pressure at the pump inlet.

Weak pressure

With a low pressure or when the pump almost does not pump the coolant, check the direction of rotation of the impeller in the body of the apparatus. If the impeller rotates incorrectly, then you made a mistake when connecting the pump to the terminals in phases, if you use a three-phase network.

A decrease in head may result from the high viscosity of the coolant. At the same time, the impeller experiences increased resistance and does not work well, not at full strength. It is necessary to check the mesh filter and clean it. It is also advisable to check the cross-section of the pipes of the holes. After that, you will need to adjust the correct parameters of the pump.

The equipment does not turn on

The pump will not turn on if there is a power problem. It is necessary to check the phases and fuses. If they are in order, then the drive winding has burned out. In this case, you will have to seek help from specialists.

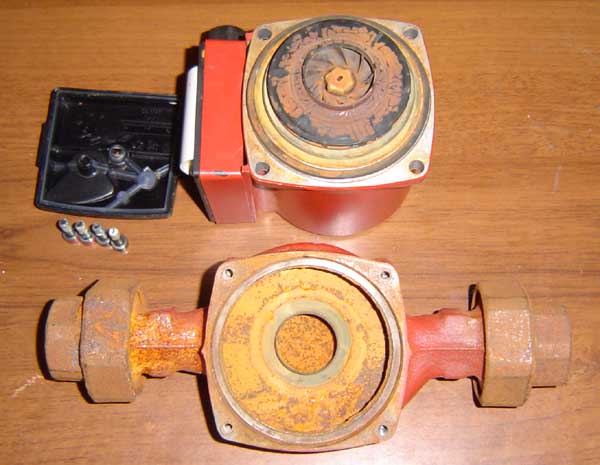

The internal surfaces of the pump must be free of rust

When diagnosing the equipment, you can use the indicator - a tester of the rotation of the circulation pump shaft. It allows you to make sure that the pump is working without being connected to the mains.

Repair of pumping station Dzhileks

The pumping station is a self-priming surface centrifugal pressure apparatus with an ejector and a piping system. Models of this series are designed for horizontal installation and pump from 3 cubic meters of water per hour. The models differ in the engine noise level and the presence of automation, which is needed to monitor the water level.

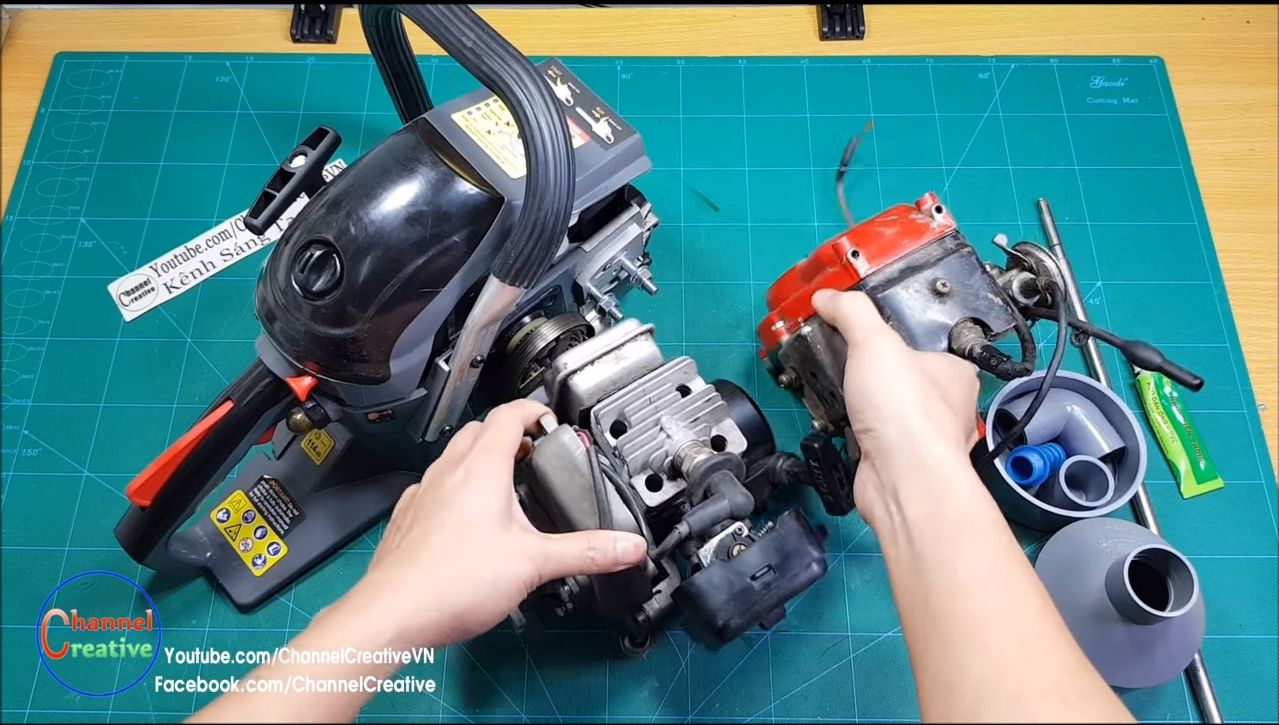

Partial disassembly of the Jlex pumping station

Consider an example of repairing the Jilex Jumbo pumping station. They are equipped with a pressure switch RDM 5, a tank with membranes (hydraulic accumulator), an electric motor, a centrifugal pump unit, a water intake with a filter and a piping system. The pressure inside the unit can be monitored using the arrow on the pressure gauge.

There are five main reasons why a station may fail or not work correctly:

- Buzzing but not working. This happens if you leave your device without water and movement for a long time. The impeller could just stick to the body. Twist it manually and try to connect. If it still does not work, check the voltage level of the mains and the condition of the capacitor.

- Doesn't turn on at all. Call the network, winding, cable with a tester. Perhaps somewhere the contacts just went away, and, as soon as they are connected, everything will work again.

- It pumps water constantly and does not turn off. You need to configure the relay. It can be adjusted with two fixing springs or screws (depending on which relay is installed in your station model).

- The flow of water is intermittent. The problem is the depressurization of the pipeline or joints. It is also worth checking the water level.

- Too frequent switching on of the device with an uneven flow of water. It is necessary to check the setting of the relay and the integrity of the constituent parts of the accumulator tank. Either you have to change the unusable membrane, or the tank is cracked, or the relay itself is broken.

Motor pump malfunctions and their elimination

1. The engine does not start.

Breakdown, which can be caused by various reasons. For elimination:

- First of all, we check if there is fuel in the pump tank. Sometimes it is enough to fill up with gasoline.

- When the oil gauge marks a low level, the engine needs to top up with the correct fluid to the required level for engine operation.

Check if the equipment is turned on correctly. The motor pump can only be started in a horizontal position.

A closed fuel cock can also cause engine silence. To make it work, open the tap, unscrew the drain plug located at the bottom of the carburetor chamber. Rinse the filter with gasoline, "blow" with air for cleaning and put in place.

Check if the choke of the carburetor is closed and clean.

Perhaps oil gets into the combustion chamber of the motor pump. To avoid this, remove the spark plug and turn the engine crankshaft by pulling the starter cord several times.

Make sure the air filter and spark plugs are clean. If the latter has carbon deposits, feel free to clean it off. Be sure to screw the candle tightly into place.

2. Unstable operation of the motor pump.

- The problem may be caused by a dirty air filter. It needs to be cleaned or replaced.

- The speed regulator may be defective. In this case, only specialists can help.

3. Malfunctions of the pumping part of the motor pump (no suction).

Most of these types of problems are caused by either damage to parts or misuse. To fix it:

- Check the intake hose - due to damage it can suck in air.

- The pump seal can also draw in air. If the problem is in it, the part must be replaced.

- There must be a sufficient water level in the pump section.

- The drain plug must be tightened securely.

4. Low performance of the motor pump.

If the equipment initially worked at 5 stars, but recently it barely pumps water, try the following instructions:

- Clean the intake filter and check that the water level is sufficient.

- Incorrect connection with the intake hose and mismatch in diameter. In this case, correct installation is required.

- If there is water in the outlet hose or, on the contrary, it is blocked, the motor pump cannot work at full capacity. By opening the valves and letting the fluid out of the hose, productivity can be increased.

5. Overheating of equipment.

- The temperature of the medium for normal operation of the motor pump should not exceed + 40 ° С.

- If the motor pump is operated at an altitude of more than 2 km above sea level, the unit must be adjusted before operation.

Troubleshooting methods

If the motor pump does not start, stalls under load, does not pump or pump water, does not start, you must carefully remove the impeller, disassemble and adjust it. For each type of breakdown there is an individual solution to the problem

If it is impossible to start the motor pump, the following measures must be taken:

- fuel filling in strict accordance with the manufacturer's instructions;

- checking the filling level with a dipstick and, if necessary, carrying out additional fuel filling;

- horizontal placement of the device;

- checking the operation of the engine shaft using the starter cord;

- cleaning the carburetor float chamber;

- removal of impurities in the fuel supply filter;

- full closure of the carburetor flap;

- removing carbon deposits from the spark plug;

- installing a new candle;

- opening the fuel supply valve;

- cleaning of filtering devices by unscrewing the bottom plug on the float chamber.

If there are interruptions in the operation of the device, you must carry out the following manipulations:

- cleaning the filter and all approaches to it;

- installation of new filter parts and snails;

- determination of the nominal value of the rotor speed;

- increase in compressor pressure.

In case of severe overheating of the engine, it is imperative to perform several actions:

- engine adjustment;

- observance of the temperature regime of the environment during the operation of the device.

Often, when performing work, the motor pump stops sucking in liquid and pumping water. In the event of this problem, there is an established sequence of actions:

- adding water to the pumping section;

- tight closing of the filler plug;

- replacement of seals and oil seal;

- replacement of the suction hose;

- sealing of places of penetration of air flows.

Many owners of motor pumps over time notice a decrease in the volume of pumped liquid and a sharp drop in the performance of the device. Elimination of this breakdown consists of several manipulations:

- checking the connection of the intake hose to the pumping equipment;

- fixing the fastening clamps on the branch pipe;

- flushing of filter parts;

- connection of a hose of the appropriate diameter and length;

- moving the installation to the water mirror.

To eliminate the breakdown of the time relay, it is enough to clean the internal equipment of contaminants, add the missing volume of oil and check the integrity of all parts. To resume the silent operation of the motor pump, it is necessary to check the absence of mechanical damage and various defects in component parts. Only the electricians of the service center can eliminate the breakdown associated with the disconnection of the device. Before calling a technician, you can only check the junction box for the possibility of a voltage drop and remove visible soil particles inside the apparatus.

Replacement and repair of defective parts

Now that you know how the hydraulic machine is disassembled, you can try to repair the submersible pump with your own hands.

Impeller

Basically, the blocking of the impellers occurs due to clogging with sand or due to the formation of a deposit of dirt on them. In addition, the impellers can be soldered together when a high temperature occurs in the unit, when the pump is idling (dry running). To repair this section of the unit, it is necessary to remove the impeller (s) and remove the accumulated dirt. If the impellers are damaged, they will need to be replaced with new ones.

Engine

Self-repair of the pump motor is not recommended, since the diagnosis of this unit and subsequent repairs require special knowledge and the necessary equipment.

On some pump models, removing the motor will require pressing it out using special equipment. Replacement of the oil seal and bearing is also carried out at the service center.

Capacitor

If the engine hums and does not start, then the capacitor should be checked. It is located in the pump block in which the motor is mounted.

Advice! Before disassembling the engine block, try turning its shaft with the pump block disconnected. If the shaft rotates, the cause may be a jammed impeller.

But when the shaft with the impellers rotates without problems, then in order to remove the hum in the water pump, you should disconnect the condenser and replace it with a new one. Of course, it is better to check this part with a multimeter, since similar symptoms can be caused by a short circuit in the motor windings.

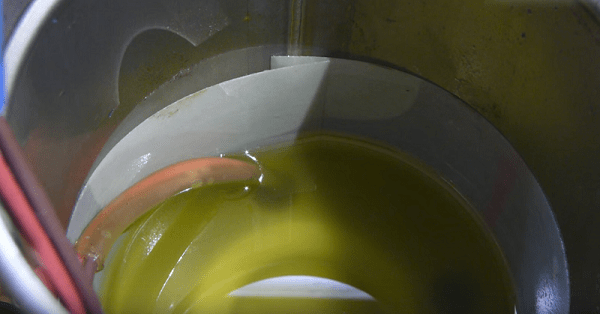

Butter

The water pump motor is located in a special glass filled with oil, and by its condition it is possible to determine some breakdowns in the electric motor block.

- The oil has a characteristic, unpleasant odor. This means that the engine is still in working order, but it has been working with great overloads.

- Cloudy oil - water has entered the engine housing due to a cracked housing or failure of the oil seal (cuff).

- Black oil with an unpleasant odor. In this case, we can say with great confidence that the varnish burned on the engine coils.

If, when opening the engine, the above changes in the quality of the oil were noticed, then first you need to repair this unit, and only after that fill in new grease.

Prevention recommendations

Almost all causes of breakdowns are associated with improper use of the device. Before turning it on for the first time, be sure to read the instructions. It is also necessary to study those sections in which it is written how to properly care for the equipment.

Regular cleaning will contribute to durability and reliability. If the drain pump has not been used for a long time, it is recommended to revise it before turning it on. All units that need to be greased are greased.

Drain pump position

The resulting products of corrosion or other formations are disposed of. After inspection and elimination of all that is superfluous, the equipment is connected to the electrical network and started.

It is recommended to carry out cleaning and revision after each use. If you follow this rule, the drain pump will last a long time. Aged dirt often becomes the cause of early breakdown, even before the warranty period has been fulfilled. Take care of the equipment and its service will help you for years to come.

Prevention and maintenance

In order for your pump to serve for a long time and reliably, you should follow the operating rules and carry out regular preventive maintenance. The apparatus should be inspected periodically:

- If a leak is detected at the joints, replace the gaskets and seals.

- Check the grounding.

- Extraneous sounds should not be present when the engine is running.

- There should be no strong vibration.

- The line pressure is measured.

- The pump must be dry and clean.

Every two to three years the device is cleaned, all its components. Regarding models that can be disassembled.Pumps with one-piece or press-fit casing cannot be repaired, and if a breakdown occurs, it is replaced with a new one. How to disassemble a circulation pump yourself?

Testing and repair of the electrical unit of the circulation pump

To do this, you need a hex wrench, a flat screwdriver (slotted) 4 and 8 mm, a Phillips screwdriver.

First, all the water is drained from the system, the pump is dismantled and then disassembled.

- Using a wrench or a screwdriver, unscrew 4-6 bolts on the body at the point where the pumping part is connected to the shell.

- The shell is removed, while the impeller remains on the rotor shaft with the engine.

- Drainage holes are found around the perimeter. There should be four of them. With a slotted screwdriver, little by little pry off the jacket of the electric motor compartment under the impeller. The shaft with the rotor and the impeller must come out of the grooves and the stator cup.

The disassembly of the unit is now complete. Next, the rotor, impeller, shell are cleaned from scale and plaque without damaging the parts. Do not use coarse abrasives. It is recommended to clean the parts with a hard polymer bristle brush. You can use cleaning agents that contain a weak solution of hydrochloric acid. Sometimes they use fine emery - "zero".

Self-repair of the drain pump

They consist of three main structural parts:

- Electric motor - rotates the shaft and blades, creating a water pressure.

- A float switch designed to automatically turn off the apparatus when draining a well.

- A pumping unit consisting of a shaft with blades strung on it.

All of the above units of the unit, with the exception of the float, are housed in a durable metal or polymer casing. The float can be either built into the body or remote. The most common malfunctions of pumping equipment intended for drainage work should be recognized:

- Burnout of the motor winding. It is possible with prolonged non-stop use of the device, or due to dry work.

- Deterioration of mechanical parts and assemblies.

- Plugging of filters and pump cavities with large mechanical fragments, sand or silt.

Diagnostics

It is possible to repair the drain pump on your own in situations where the breakdown is not so significant. To do this, you will need to diagnose the operation of the device, identify the malfunction and try to eliminate it. For example, it will not be difficult to replace a worn or broken part, or to clean filters. It is also possible to make simple electrical repairs at home - replace a broken electrical cable, a capacitor.

But if a crack appears in the body of the device, the winding of the electric motor burns out, or the valve stops working, it is better to contact a specialized workshop, or purchase a new pump.

It is quite easy to repair a break in the power supply cable if it breaks near the plug. It will be more difficult to close the gap on submersible drainage pump models, in an underwater location. Here, due to the likelihood of a short circuit, it is impossible to connect a break with a simple twist.

You will need to cut the cord at the fracture site and reconnect it to the engine. To do this, you have to remove the cover and remove the cut off cable remainder. Instead, using a tensioning element, we attach a long cord with a plug, after which we put the cover back in place, carefully and carefully tighten the fastening bolts.

The pump is running but not pumping water

In the case when the electrical part of the pump, judging by the sound, is working properly, but water is not supplied to the surface, or its pressure is significantly weaker than before.

There are several reasons for this:

- The water supply line is clogged - a hose or a pipe. It will be necessary to disconnect the hose supplying water to the top from the nozzle and clean them from dirt.If the new pump cannot create the required pressure, it is likely that the length of the water pipes exceeds the technically recommended indicators, and the device simply cannot create the required pressure. A similar reason lies in the too small diameter of the pipeline. To increase the pressure, you will need to reduce the length of the line, or increase the diameter of the pipes (hose).

- Wear of the working mechanism - the water wheel. Due to constant contact with mechanical debris contained in the water, his blades may wear out, bend, break off over time. This problem can be eliminated only by replacing the part with a new one.

- Difficulties with the water supply can arise due to the too low position of the pump or its suction tube. At the bottom of the well, there is always an increased concentration of silt, suspended sand and clay. Such a suspension hardly passes through the filters, and the pressure drops. To solve this problem, you should raise the pump higher from the bottom of the well.

- Filters clogged. You can rinse them with a powerful jet of running water. In especially "difficult" cases, you will have to disassemble the case and clean the mechanism manually.

- With a decrease in the power of the electric motor, it is possible that the housing or water hoses are depressurized, the bearings are out of order, and there is insufficient voltage in the power supply network.

- Malfunctions of the electrical part can be determined by "ringing" the wiring of the device using a special device - an ohmmeter. It will show a break in the wiring or a burnt out winding of the electric motor.

To accurately determine the malfunction and self-repair the drainage pump, you will have to disassemble it. This should be done carefully so as not to damage the parts and assemblies of the device.

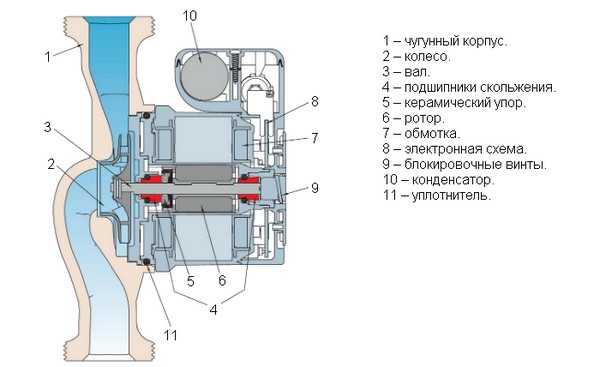

Circulation pump device for heating

Main details:

- A metal case, inside of which operating units are located. In the manufacture of the case, stainless steel, aluminum or various alloys are used.

- The electric motor is the main part of the pump.

- An impeller, which is a wheel with blades. It is installed on the rotor and provides pumping of the heat-carrying fluid. Most often, the impeller is made of polymer.

Photo 1. The diagram shows the structure of the circulation pump: all the most important details are indicated.

Circulation in the circuit occurs when the rotor rotates with the help of an electric motor. The rotating blades push the incoming liquid into the pump further, into the discharge pipe. Two types of pumps are widely used:

- Wet - used for household heating systems. During operation, their rotor stays in a liquid, which provides constant lubrication and timely cooling of moving elements.

- Dry - are found in large and medium-sized boiler houses, and are also used to heat large areas. The dry rotor motor is housed in a separate unit and the rotation is transmitted to the blades using a special clutch.

Types of malfunctions

There are several types of malfunctions that most often occur with submersible water pumps.

Does not turn on

There are 4 possible reasons why the device does not respond to switching on.

- Electrical protection. In modern products, a protection function is provided that is triggered by the principle of traffic jams on the electricity consumption meter. In the event of unexpected loads or power failures, the protection works automatically and stops the operation of the unit. It is recommended to start the mechanism again only after the reason for the automatic activation has been determined.

- Damage to fuses. Fuses can burn out due to wear and tear, but sometimes they fail due to external reasons. With regular burnout, experts advise checking the integrity of the power cable, as well as the place of its connection.

- Damage to the cable.The equipment must be removed to check the power cable, as most of the power cord goes under water.

- Dry running protection. In addition to electrical protection, submersible devices are equipped with a device that controls the level of immersion in the liquid. If the level of the liquid medium is insufficient, the operation of the device automatically stops.

Turns on, but does not pump

In a situation where the included mechanism does not supply water, there can also be 4 reasons.

- Shut-off valve. The simplest reason explaining the lack of pumping water is a closed shut-off valve of the device. In this case, the pump is turned off, then the closed tap is turned off. Frequent start-up of the unit with the shut-off valve closed may result in breakdown, therefore it is recommended to check the valve before each start-up.

- Low water level. If the shut-off valve is open, the next step is to check the dynamic water level and adjust the immersion of the apparatus to the desired depth.

- Check valve breakage. If the check valve is clogged, it can “stick” and stop allowing water to pass through. In this case, cleaning the part or replacing it with a new one can help.

- Clogged intake filter. A clogged filter can also interfere with the flow of water into the system, so you should check its condition and, if necessary, clean the filter mesh.

Performance drops

In the event that the equipment began to supply significantly lower volumes of water, it is recommended to check several assumptions.

- Decrease in voltage in the network. At low voltages, the machine is unable to operate at full power.

- Rising pipe clogged. With a decrease in the permeability of the lifting pipe, the performance of the mechanism decreases markedly.

- Clogged fittings in the water supply network. Valves and valves in the water supply system can become clogged and prevent full fluid flow.

- Incorrect pressure switch settings.

Too frequent on-off

The problem arises in the case of equipment working in tandem with a hydraulic accumulator. Frequent switching on and off can occur for several reasons.

- The pressure in the hydraulic tank is too low.

- Rupture of rubber tank components.

- Incorrect pressure switch settings.

Pulsating water supply

A pulsating stream of water from the tap indicates a decrease in the water level in the well below the recommended one. In this case, the mechanism should be lowered to the design depth as soon as possible.

Leaking case

When the seals are worn out, the housing of the unit begins to leak. The place of the leak is easy to detect by the appearance of streaks and corrosion. If the seals are not replaced in a timely manner, the product may finally become unusable.

Buzzing, not pumping

The machine may make a humming sound, but it will not supply water for the following reasons.

- The impeller is stuck to the body of the device due to long-term dry storage of the pump.

- The impeller is jammed due to sand, silt, dirt.

- Breakdown of the engine start capacitor.

- Low voltage in the mains.

Vibrates strongly

Severe vibration mainly occurs in centrifugal pumps due to bearing wear or loose fittings. The problem is solved by replacing parts and strengthening elements.

Doesn't turn off

The submersible pump stops automatically turning off if the pressure switch fails, or if the relay has incorrect settings.

The nuances of breakdowns depending on the brand of the pump

During the operation of pumps from different manufacturers, it was noticed that some brands of apparatus are often subject to the same breakdowns. It follows from this that these models of units have their own distinctive features in terms of the occurrence of malfunctions.

Aquarius

Pumps "Aquarius" are prone to overheating, especially if they work in shallow wells. If a cheap model breaks down, its repair costs about 50% of the cost of a new device.If the device is out of order, it is easier to throw it away than to repair it.

Grundfos

Most models from this manufacturer have a valve system. There is also a special thermal insulation around the engine. Sometimes pump malfunctions occur due to the failure of the listed parts. Since the thermal insulation is around the engine, it will need to be removed from the housing for repair.

Baby

Devices "Malysh" are products of domestic manufacturers. The cost of repairing units of this brand is not high, and the owners of the devices eliminate most of the breakdowns with their own hands. The main breakdown that often occurs in this pump is the occurrence of strong noise during the operation of the hydraulic machine without pumping out the liquid. This behavior of the apparatus means that there has been a rupture of the central axis holding the armature and the membrane.

Gilex

The engine in pumps of vortex and rotary type "Dzhileks" is oil-filled. Therefore, a frequent breakdown of these units is the leakage of oil from the engine. It can only be refilled at a service center.

Brook

There is an opinion that the operation of the trickle drainage pumps can continue without interruption for 7 hours or more. This is explained by the peculiarity of their design, which meets all European standards. But despite this, the device is exposed to overheating in the same way as pumps from other manufacturers. Therefore, it is recommended to give it time to “rest” after every 2-3 hours of device operation.

Marquis (Marcus)

Owners of the pump for the "Markus" well sometimes notice that the device turns on only after a slight blow either on the pipe going to it, or after hitting the hydraulic machine itself. This malfunction is explained by the “acidification” of the impeller, which will have to be cleaned by disassembling the unit.