Parts that may break

Each working part of such equipment is subjected to significant stress during use. Therefore, they require a systematic inspection of the condition and repair. First, you need to adjust the fuel pump and the ignition system of the cultivator. Since in winter the device stood, as they say, "idle", which may cause problems with the activation of the engine. It is also necessary to check the transmission. Do not forget that carelessness at this stage of work can easily cause significant malfunctions of the cultivator.

Before proceeding with self-repair, you should find out about the main causes of the problems. All cultivator malfunctions can be conditionally divided into two categories:

- motor malfunctions;

- malfunctions of other equipment elements.

Feedback from experienced home craftsmen suggests that Mole or Texas motor cultivators often encounter problems from the first category.

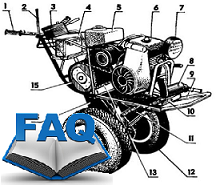

Walk-behind tractor design

An important driving part of the described device is the engine, which is capable of operating on both gasoline and diesel fuel. Such a component of the equipment can be either two-stroke or four-stroke

A characteristic feature of these motors is that they are equipped with specially designed speed controllers, which can simplify the operation process. Engine power can vary from five to ten liters. It is also worth noting that the specialists face the greatest difficulty during repairs in this part of the walk-behind tractor.

The next element of the device is the transmission, which has a number of variations:

- Toothed.

- Toothed-worm gear.

- Belt-toothed-chain.

- Hydrostatic.

An important component of the described device is considered to be an aggregated system, thanks to which it becomes possible to attach additional agricultural devices to the walk-behind tractor. This mechanism can be controlled either on its handles or on the steering rods.

And also in this place is the clutch and gas. In some complex structures, sometimes you can find a brake

This mechanism can be controlled either on its handles or on the steering rods. And also in this place is the clutch and gas. In some complex structures, sometimes you can find a brake.

Starting gasoline and diesel units

The walk-behind tractor is a multifunctional tool. It is indispensable for home gardening. Attached equipment allows you to perform land cultivation, grass mowing, snow removal, cargo transportation, planting and harvesting.

The equipment is equipped with gasoline or diesel engines. The launch of a diesel walk-behind tractor and a gasoline unit has differences. Therefore, analyze the reasons due to which walk-behind tractor does not start, follows for each specific type of engine.

Before starting the walk-behind tractor, the equipment is prepared. It is necessary to make sure that all the parts are present, make sure that the mechanisms are securely fastened.

Mechanisms often refuse to work after winter. A long break causes a malfunction of the walk-behind tractor systems. Storage in a cold and damp place will result in the following breakdowns:

- Oxidation of contacts.

- Violation of wire insulation.

- Watering of fuel and oil.

- Clogged carburetor jets.

Before starting a new walk-behind tractor, check all connections, clutch cable, reverse and gas. The movement of the cables should be smooth, effortless. Do not start the unit if there are clamps and twists of the harness threads.

During the first start, be sure to check the oil level in the crankcase. Lack of lubrication will damage the piston group.

The crankshaft rotates up to 1400 rpm at idle speed. A couple of seconds are enough for a scuff to form on the surface of the cylinder.

Old oil can cause engine failure. At the same time, the walk-behind tractor smokes with white exhaust gases. A complete oil change suggests itself.

It should be borne in mind that the walk-behind tractor does not start well with an insufficient amount of oil. Watch this parameter before starting the carburetor and diesel walk-behind tractor. On some models, the protection is set to a low level. The sensor blocks the start, and the unit stalls.

It should be remembered that each type of engine requires a specific brand of gasoline. For a two-stroke engine, fuel is prepared separately. The fuel mixture consists of gasoline and oil. The amount of ingredients is kept in a strict ratio.

Purchase gasoline for motoblocks at gas stations. The service life of the machines directly depends on the quality of the fuel. You should not start a walk-behind tractor on poor gasoline.

How to start a cultivator - troubleshooting methods

If the cultivator does not start, then the reason for this may be malfunctions of several main units of the unit. Below we will consider typical breakdowns of the main mechanisms of a household cultivator and methods for their self-elimination in more detail.

Malfunctions in the ignition system

Elements such as a magneto, a candle, a pre-installed hood and a high-voltage wire are most often susceptible to oxidation, as a result of which they inevitably fail. If dirt and moisture are found on a high-voltage wire, then they are the reason for its breakdown.

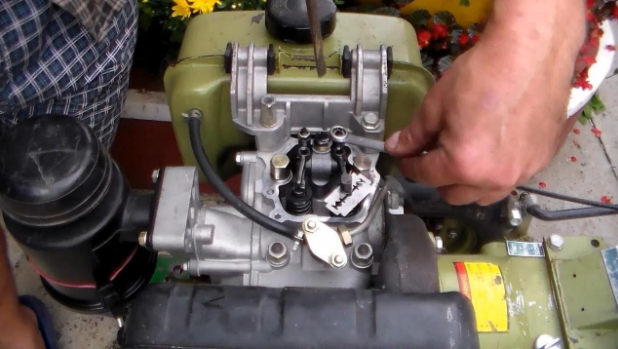

A weak spark or its complete absence most often indicates a lack of efficiency in the operation of the spark plug, which is why the cultivator refuses to start. In this case, check the condition of the gaps and the distance between them. It is best to do this with a special probe - the normal value for operation should be 0.8 mm. If there is such a need, then it is necessary to completely remove the formed carbon deposits from the outer surface of the insulator and the metal parts present in the candle.

The readiness of the engine before starting is affected by the serviceability of the elements of the piston group. Since they constantly work in harsh operating conditions, their surfaces lend themselves to strong heating, which leads to breakage of the internal combustion engine cylinder, pistons and ring. If the unit does not start, you will need to check its outlet and inlet valves. It often happens that they do not fit tightly to the seats, and in this case, it will be necessary to eliminate the malfunction as soon as possible, and then try to start the cultivator again.

Another detail that often breaks down is the standard cultivator muffler. Combustion products and residues of exhaust gases inevitably accumulate on the walls of the element, which leads to the inability to start the cultivator. With a large amount of these substances, the engine will sooner or later stop starting. To eliminate this malfunction, you will need to completely remove the muffler and clean it with compressed air from a cylinder.

All of the above malfunctions and methods of their elimination are suitable if the cultivators manufactured by the Sungarden, Texas and Neva brands do not start. Models from these manufacturers have a simple design, so even a beginner can easily cope with their repair.

Breakdowns of the carburetor and how to repair it

Often, the cultivator will not start due to blockages inside the jets or carburetor filter.A completely dry and clean spark plug of the unit will be a sign of this. Repairs are carried out in the following order:

- Remove the unit carburetor first;

- Disconnect the fuel connection and blow it out with compressed air from a cylinder;

- After that, blow out the combustion chamber and fuel pipes;

- Replace the carburetor and try starting the cultivator.

If after this the cultivator does not start, then the position of the float placed in the combustion chamber of the unit should be checked. The part is adjusted using special screws - by turning them clockwise, you raise the float, and when you turn the screws counterclockwise, the part is lowered.

Cultivator won't start - engine repair

Another mechanism, the breakdown of which does not allow the cultivator to start, is the engine of the agricultural machine. In the case of using low-quality fuel or non-observance of the proportions of preparation of the fuel mixture specified by the manufacturer, the fuel will begin to fill in the spark plug, which will lead to the absence of a spark.

In this case, you will need to shut off the fuel supply, disassemble the engine and thoroughly dry the cylinder. After that, it is necessary to unscrew the candle and start the cultivator using the manual starter. In most cases, after the listed actions, the cultivator will start up. At the end, you need to screw the plug back in and continue to operate the unit.

Preparing the walk-behind tractor for start-up

Problems with starting the engine can arise not only for a used walk-behind tractor and cultivator, but also for new ones that have just been bought in a store. Therefore, before starting a walk-behind tractor for the first time, whether it is Cascade, Neva, Mole, Bison, Centaur, Khoper, Tarpan, Oka, Salute, you must read the manual for its operation, then carefully examine all connections and, of course, check the oil level in the internal combustion engine.

It is necessary to study the instructions drawn up by the manufacturer in order to find out what operating cycle the engine has: four-stroke (like Forte, Centaur, Lifan, Bison) or two-stroke

This is important to know, since for models with a two-stroke engine (like the Mole cultivator), a special combustible mixture is needed, consisting in a certain proportion of gasoline and oil. Due to the mismatch of the fuel, the equipment will stall, and the spark plugs and the fuel line may also suffer, which is fraught with the failure of the gas pump - and this is already a direct path to expensive repairs in the service station

You can determine whether the fuel is suitable for motor vehicles by smoke. If the quality of gasoline is poor, it will have a white color, as is the case with a strong tilt of the car. If you have bad gasoline, replace it to prevent damage.

Fuel quality is also important for a diesel walk-behind tractor. It does not start in winter, or it does, but soon stalls if summer diesel fuel is poured into its engine, because at low temperatures it begins to thicken and clog the fuel line

In such cases, the risk of breakage increases. Select the correct fuel in cold weather.

The start-up of motor vehicles, both in summer and in winter, must be carried out in a certain sequence. For example, to start a Krot brand motor-cultivator, the following procedure is carried out:

- Open the gas tap;

- Place the choke lever in the “Choke” position;

- Turn off the ignition and turn the engine over several times with a manual start-up starter;

- Restart the engine and move the lever to the "Run" position.

Situations often arise when the power unit starts easily, but after a few seconds it stalls. In this case, it is necessary to check the permeability of the sump, perhaps the reason is that the tap is clogged - then it is cleaned with gasoline.

Starting a motorcycle with a diesel engine (such as Bison, Cascade, Centaur, Neva) will be somewhat more difficult than Mole.The diesel engine starts up with "airing" the fuel line, that is, with the release of it from air accumulations. For this:

- Open the fuel supply valve;

- Unscrew the fuel outlet duct connections until the fuel appears;

- Tighten the connections and blow through the nozzles.

If, after the actions taken, the engine does not function properly, and the equipment smokes heavily with white smoke, the reason is in the old grease and it should be completely replaced. The diesel engine does not start due to an insufficient volume of oil liquid, so do not forget to control this parameter.

Starting a cultivator after winter or a long downtime also has its own nuances. In order to bring the machine into working condition, the following manipulations are performed:

- Open the gas tap;

- Check if the power is on;

- Check for lubrication;

- Give gas, up to about half.

And, of course, before starting motor vehicles, be it Centaur, Cascade, Neva, Patriot or Bison, they check all connections, including transmission units, clutch, starting mechanisms and, if necessary, adjust them.

Elimination of breakdowns

If you have any problems with your walk-behind tractor, then do not panic. Many of them are quite possible to eliminate with your own hands. It will be possible to make the setting or adjustment of certain systems without any problems, for example, to adjust the valves or idle speed.

Replacing many parts will also be pretty straightforward and straightforward. The main thing is to clearly follow all points of the instructions and act carefully so as not to damage the device.

The first step is to consider how to proceed if the walk-behind tractor stops starting normally and starts to stall during operation. So, first, let's figure out what to do if the indicated motorcycles do not develop revs to hot.

It is important to pay attention to several nuances.

- If you failed to start the technique with several attempts, then you need to inspect the candle. It is advisable to change it immediately.

- Check also the decompression and vacuum level in the tank.

- See if there is a spark coming from the wiring (this is best done in a fairly dark room).

- Make sure that the spark does not disappear under heating conditions.

If there are problems with the gearbox of the walk-behind tractor, then it is important to take into account the fact that it will be possible to repair it only if it is collapsible

If there are shortcomings with the fuel supply, then here it is necessary to act as follows:

- look at the spark plugs - if they appear completely dry in front of you, then this indicates that the fuel does not penetrate the cylinders;

- fill the tank with fuel and restart the engine;

- look at the fuel cock - if it turns out to be closed, then you will need to replace its location to open;

- be sure to thoroughly clean the drain hole of the fuel tank;

- drain fuel, remove the tap and wash in clean fuel;

- and now remove the connecting hose located next to the carburetor, purge it together with the jets.

If we are talking not about a gasoline, but about a diesel walk-behind tractor, then here you can face the problem of turning the starter too lightly. This is usually due to poor cylinder decompression. To solve this problem, it is necessary to tighten all the nuts on the cylinder in turn, and also replace the gasket located on its head. You will also need to take a close look at the piston rings. If necessary, they will need to be washed or replaced with new ones.

But also diesel engines quite often suffer from clogged injectors. To get rid of such a nuisance, you will need to remove the damaged part, clean it thoroughly, and then install it in its original place. The main thing is to act carefully and consistently.

Often in motoblocks, a component such as a starter is damaged.Such a malfunction can seriously affect the operation of the motor vehicle engine. Basically, it happens that the screws of the starter fastening in the housing base are noticeably weakened. In this situation, the launch cord simply cannot move back to its original position.

If starter malfunctions are a sign of wear on a part such as a starter spring, then you need to be prepared for the fact that it will not be possible to repair it. A part that has undergone serious wear and tear will only need to be changed.

Consider what to do if there are problems with the engine speed.

- If the revolutions of motor vehicles grow on their own, this will indicate that the control levers and traction control have become weaker. These components will need to be adjusted again to resolve the above problem.

- If, when exposed to gas, the revolutions do not pick up, but fall, then you need to turn off the equipment - it may have overheated. Let the walk-behind tractor cool down.

- If the engine of motor vehicles functions with certain interruptions, then this may be due to a clogged filter or muffler. Turn off the walk-behind tractor, cool and remove all dirt and blockages of the necessary components of the structure.