General classification

All types of wood splitter differ in the method of stacking logs, the volume of processed wood, mobility and the type of drive.

Horizontal

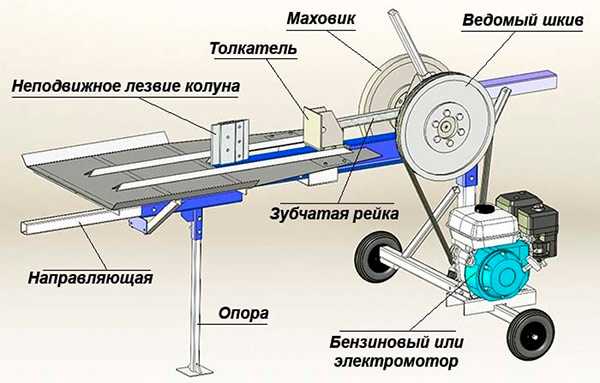

In horizontal models, the log is laid inside the horizontal chute, after which the laid element is pushed towards the knife. In some tools, the log can lie motionless inside the chute, and the knife itself moves in its direction. Horizontal models can be short-legged (tabletop) and long-legged (for full-length work).

The machine is a sturdy horizontal frame on which a splitting chute with a dividing knife is installed

Vertical

In vertical models, the log is installed vertically, and the knife is pushed from above by means of a hydraulic cylinder. The efficiency of this machine is higher than that of horizontal models, which is due to the lack of movement of the log during the splitting process without creating additional friction. Nevertheless, work with crooked sawn-off elements requires their manual holding, which goes against the safety of this equipment operation.

The machine is a robust vertical structure

Industrial

Industrial wood splitters, most often equipped with an electric motor, are used with a 220 or 380 V motor with a power of 3 kW or more.

Industrial wood splitters are very powerful, capable of handling huge volumes of firewood.

Household wood splitters

Household models are distinguished by maximum structural simplicity, extreme ease of use and absolute simplicity in terms of maintenance.

The design of the simplest mechanical wood splitter resembles a well crane

Types by drive type

With an electric, gasoline engine, with a power take-off shaft or with a hydraulic system and a combined type of drive (by type of drive).

Gasoline wood splitters are suitable for medium-sized businesses

Small electric wood splitter is great for home use

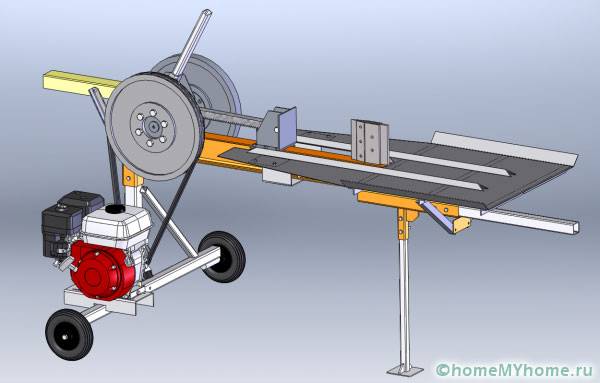

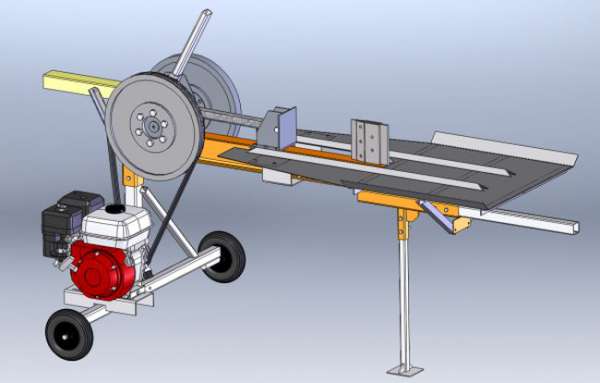

Stationary and mobile

The first version of such mechanisms, as a rule, is represented by massive industrial models or whole multifunctional machine tools. The operation of a stationary wood splitter in a domestic environment is most often not at all advisable. Mobile or mobile models are equipped with transport wheels, which greatly facilitate the movement of the device to almost any place of work and are optimally suited for domestic use.

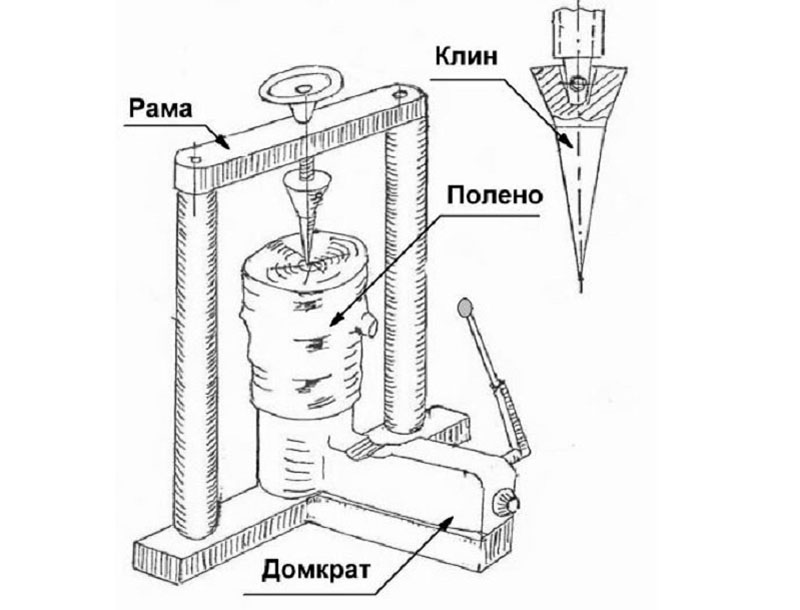

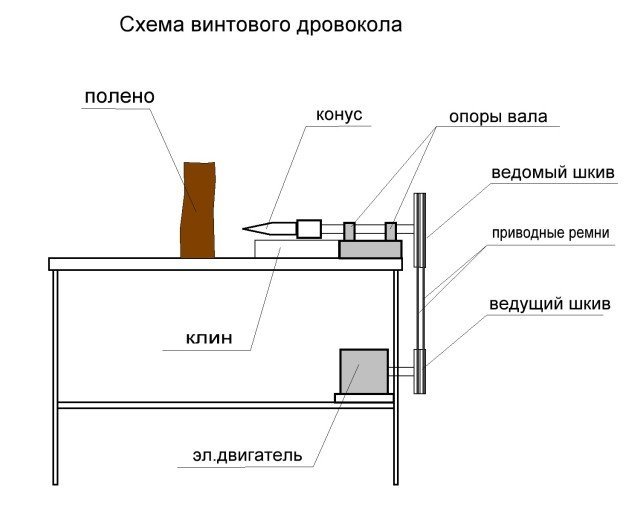

Electric Cone Log Splitter

The principle of operation of the mechanism - a steel cone with a thread of 3 depth and a pitch of 7 mm (most likely, it will have to be ordered from a turner) is put on an electric motor gearbox. Rotating, the cone works like a drill and breaks the blocks. Thicker logs begin to rip at the edges and then rip in the middle.

If an engine with the desired parameters is found, the cone is mounted on it without a gearbox. If not, they calculate how much to reduce the speed, and use the cone nozzle through the gearbox.

The main problem when assembling a structure is to find a suitable cone; with an electric motor and a gearbox, the situation is somewhat simpler. It makes sense to make such a device if you need to harvest large volumes of firewood.

Appointment of wood splitters

If you are the proud owner of your own country house, then you probably know well how hard it is to chop wood, swinging a heavy weighty ax.However, progress does not stand still, so nowadays the work of harvesting firewood can be greatly facilitated. To do this, use special machines called "wood splitters".

Of course, not everyone has a need for such a technique. If you chop wood once a month, then an ordinary cleaver is enough for you, but there are categories of homeowners who cannot do without a mechanical device. First of all, these are people who permanently live in houses with stove heating, fireplaces or solid fuel boilers. Such equipment is necessary in wood-burning boiler rooms, and, of course, do not forget about lovers of the Russian bath - after all, before they take a good steam, they will certainly need to stock up on firewood to kindle the hearth.

Homemade wood splitter

Do you use homemade wood splitters when preparing firewood?

Even for the simplest manual device, the store asks for several thousand rubles. You can save money by making a firewood cleaver on your own. For clarity, it is worth studying the video with different machines in operation.

Don't miss: Fireplace for summer cottages and baths: types of structures, step-by-step instructions, the best examples in the photo

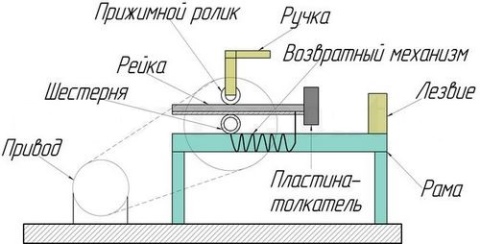

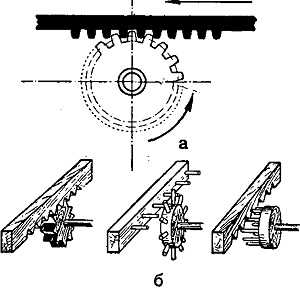

There are several variations on how to make a log splitter. One of them is a rack and pinion design. It is popular because the Internet offers a lot of photo instructions.

The base of the device must be made of thick steel. It must withstand the load and the weight of the components attached to it - the wedge, the gearbox and the motor.

The working algorithm depends on the selected materials, the device diagram. The main steps are as follows:

- Cut the edge out of sheet steel. Minimum thickness 10 mm, sharpen at right angles.

- For large logs, make a split blade. Thickness from 50 mm. As an amplifier, you can use a steel blank.

- Place the gear 5 cm above the bed. There should be double the length of the log to the knife.

- Run the carriage, moving along the bed, at the height of the installed gear.

- Attach the pusher to the front of the carriage. It is a transverse steel plate with a minimum thickness of 7mm.

- Ensure the mobility of the rail with the hinge by placing it on the carriage.

- The movement of the carriage to the gearbox is provided by a return spring. Attach it so that the rack rises above the gear.

- Install the pressure arm. When you press on it, the rack should be pressed against the gear and move forward. Make the length of the rail less than the gap between the blade and the feed plate.

Expert opinion

Igor Lebedev

Ask a Question

Advice! Instead of an electric motor, a gasoline engine is suitable. Its revolutions are high, therefore, an increase in the gear ratio of the gearbox is required.

If you plan to make a hydraulic log splitter on your own, you need to decide what kind of wood it will be used for.

| Wood species | Average force in kN | ||

| Diameter 200 mm | 300 mm | 400 mm | |

| Birch | 16 | 29 | 48 |

| Elm | 28 | 39 | 65 |

| Oak | 24 | 33 | 51 |

| Spruce | 11 | 18 | 26 |

| Maple | 18 | 10 | 49 |

| Linden | 3 | 4 | 6 |

| Aspen | 10 | 17 | 26 |

| Pine | 8 | 15 | 24 |

The indicators differ significantly. If the logs are very knotty, the load is at least doubled.

For a hydraulic home-made device, you need to prepare:

- electric engine (possible on gasoline), at least 2 kW;

- Control block;

- pump;

- oil filling tank (you can make it yourself);

- high-pressure hoses;

- hydraulic cylinder;

- beam (metal), U-shaped or I-beam No. 16;

- sheet steel, prepare pieces with a thickness of 5-20 mm;

- metal corner, shelf 30-40 mm.

A hydraulic cleaver is made on its own according to the following algorithm:

- Make the bed using a U-beam or I-beam. An important point is the width of the beam. With its increase, the permissible load increases, but the movement of the structure becomes more complicated. The average is 10-15 cm.

- Install a hydraulic cylinder over the beam, height 5-7 cm.

- End the stem with a pusher. It is better to use metal, thickness 7-10 mm.

- To move the knife along the bed, make a body.

- To fix the knife in different positions, make 12 mm holes at the bottom of the bed, 50 mm increments. Add 2 holes in the blade body in the same way, install 2 bolts, weld them.

Don't Miss: How to Make DIY Fuel Briquettes?

If you look at the photos of homemade wood splitters, you will notice that there are many different variations of such equipment.

Crowbar cleaver

This cone log splitter consists of a fairly long metal rod and has a pointed cone on one side. The other end has a handle.

The performance of such a device is quite low, but at the same time the expenditure of forces is quite large.

The next type of manual wood splitter is cylindrical. Such a device is very mobile, easy to carry and transport.

The device of such a wood splitter consists in the fact that on the stand with which it stands, a frame is fixed, the blades of which are directed upwards.

The log, which is located in the space of the frame, is hit with a sledgehammer. The blades pointing upward split the log into several separate pieces of wood.

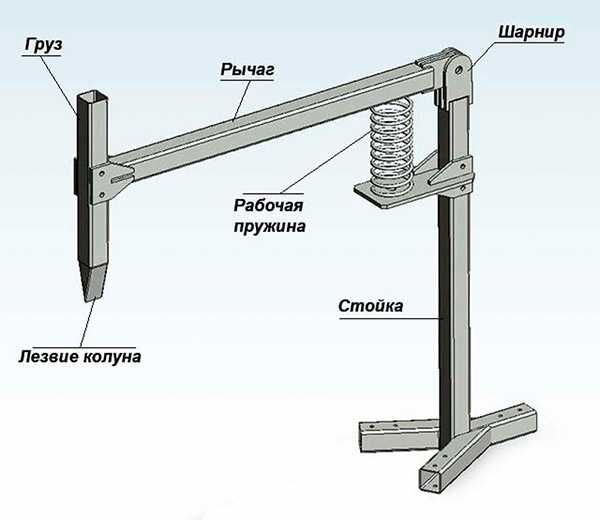

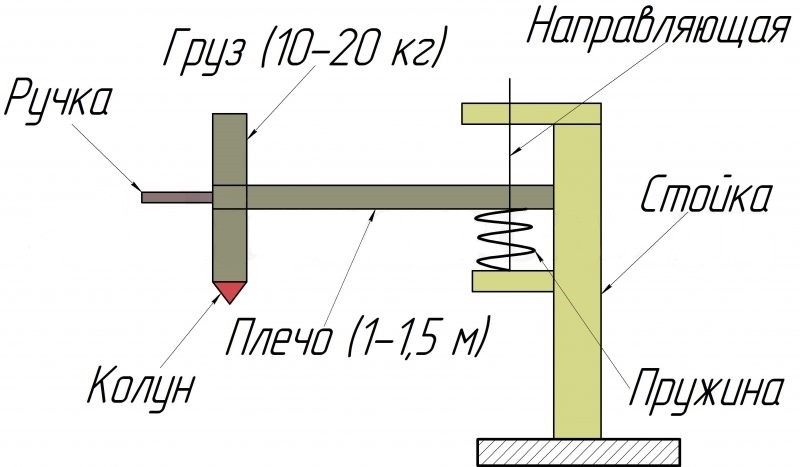

Spring log splitter

The point is that it is very productive. The prepared log is split by means of a special working part, which is fixed on the crossbar, which works with the help of shock absorbers.

Working with such a device does not require much effort, but with prolonged use, a person will get quite tired.

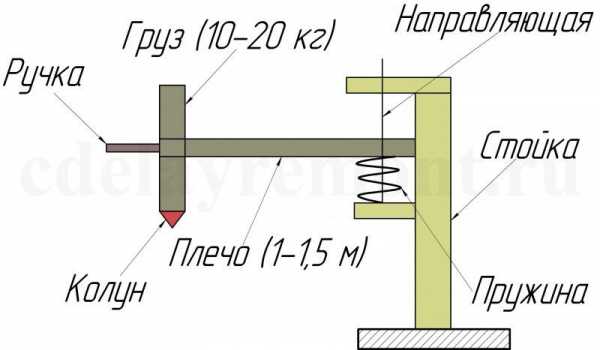

Mechanical wood splitter on a spring.

This wood splitter uses the physical strength of a person just like the scrap-cleaver. But physical strength is needed a little, only to unbalance the balancer with a cleaver. This wood splitter is a little more difficult to make than a splitter, but more efficient.

The force that needs to be applied for splitting logs is directed downward, so there is practically no load on the back. Compared to the splitter, it requires significantly less physical effort. The power of the blow depends not only on the physical strength of a person, but also on the mass of the cleaver. With this wood splitter, you can make a powerful enough blow that will split almost any log. Quite high performance.

But this wood splitter has large dimensions and weight. Traumatic, but no more than an ordinary ax. Requires the delivery of each log to him. Slightly more difficult to make than a scrap cleaver.

The principle of operation of this wood splitter is based on the impact of a cleaver blade with a large mass. The human task is to bring the wood splitter shoulder out of balance, that is, with a downward movement, you need to move the cleaver blade, and because of its large mass, it will go further by inertia. The return of the wood splitter arm to its original position occurs automatically by a spring.

Wood splitter construction drawings. Important points.

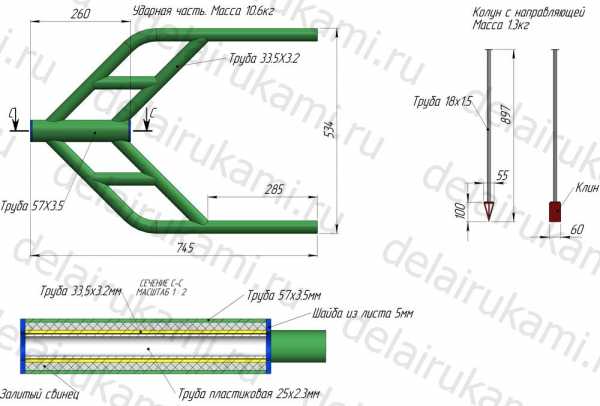

The drawings below show a wood splitter on a spring. During its manufacture, all pipes can be replaced with any others, the main thing is that the rigidity of the structure is sufficient. Instead of one thick-walled pipe with a section of 40x60x6 mm, you can use two pipes welded together with a smaller wall thickness and a different section.

Force

impact of a given cleaver depends on the mass of its moving part. The greater the mass

a cleaver with a load, the greater the impact energy. Cargo can be picked up from any heavy

metal parts, for example weld on two pieces of rails. The main thing is that the cargo

was as large as possible, ideally it is necessary that the cleaver with a load weighs 50-55kg.

Spring

must be strong enough to keep the cleaver's shoulder horizontal

position. That is, there must be a balance between the mass of the cleaver with the load and

the compression force of the spring. If there is not enough spring force, then you can add a second

a spring of a smaller diameter by simply inserting it inside the first spring. Spring

can be taken from the car, the approximate spring diameter is 110mm and the height is 450-500mm.

In the compressed state, when the log splitter console is horizontal, the spring

will be 300mm long.

An adjustable console will help to find a balance between the weight of the cleaver with the load and the spring force, the closer the cleaver is to the spring, the higher the console will rise.

Wood splitter drawing.

Wood splitter drawing.

Frame drawing.

Frame drawing.

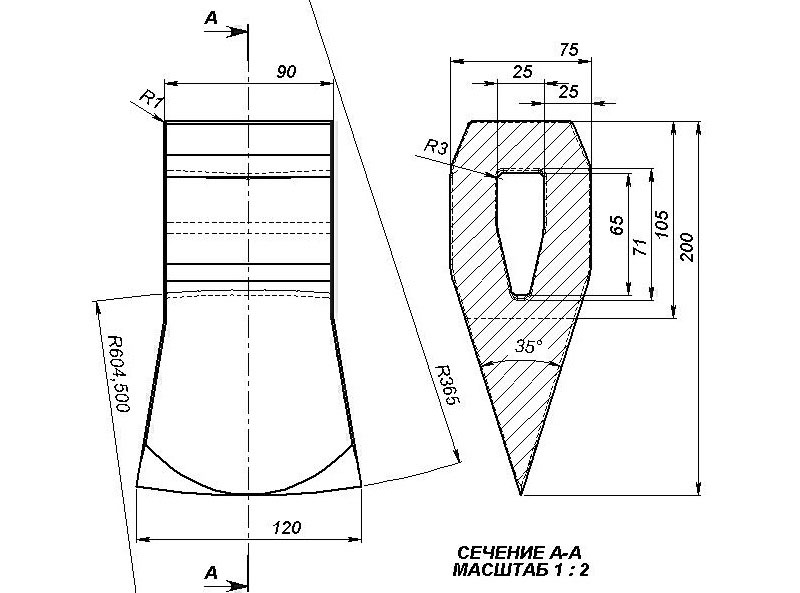

Cleaver drawing.

Console drawing.

Bracket drawing.

How to organize your workflow?

Having built a homemade wood splitter, you can safely start chopping firewood

But to facilitate the work, it is important to correctly organize the entire process. So, the sliced fragments should be located on one side at a distance of two or three steps (so as not to get tired)

It is recommended to put chopped wood in a cart. It has a small volume, a maximum of 30-40 kg of firewood will fit in it.

Firewood chopped by a homemade wood splitter

After each filling of the cart, take away the wood and place it on the woodpile. During the transportation, by the way, there will be time to take a break from the main work, because the change of occupation is also a rest!

5/5 (7)

Homemade devices

"Homemade products" are often used to solve everyday problems

"Homemade products" are often used to solve everyday problems

during preparation for the cold season. Some craftsmen manage to make truly "masterpiece" wood splitters - homemade hydraulic ones, using available materials and devices.

A homemade cleaver should include certain details. So, before assembling, you need to acquire the following items:

First you need to weld the frame frame. After its manufacture, the structure must be firmly fixed on the platform. At the bottom of the frame, you need to put an auto jack. At the top of the assembled frame, you need to provide a connector that will be used for splitting logs with different lengths and diameters.

The device in the photo was made by hand, but with its help you can quickly and easily harvest a large amount of firewood. Its design is rather complicated. A hydraulic jack on a stationary bed was taken as the basis. To make such an installation, you must have certain locksmith skills. In addition, it is necessary to manufacture equipment, be sure to take into account all safety requirements, otherwise you can face very undesirable consequences.

In order to save resources and time in the future, it is better to install wedge-shaped knives with several blades in the installation. The bottom line is that an ordinary knife divides the log into only two parts, and such a model can process it entirely at a time.

In order to save resources and time in the future, it is better to install wedge-shaped knives with several blades in the installation. The bottom line is that an ordinary knife divides the log into only two parts, and such a model can process it entirely at a time.

If you do not have the appropriate skills and materials for self-assembly of a cleaver for preparing firewood, then carefully consider whether you need to spend time experimenting or “building a bicycle”. If in doubt, it is better to buy a tool in a specialized store.

... Moreover, the cost of the simplest models of wood splitter is quite affordable. And all financial expenses are fully compensated for by the speed and convenience of preparing firewood before the start of the heating season.

A wood splitter (also called a machine for preparing firewood) is a mechanism by which the trimming and mechanical splitting of large chocks into small logs, which are convenient to use in everyday life, is performed.

The advantages of such a product are obvious:

- it is an excellent replacement for heavy mechanical labor for chopping wood;

- the device serves for a very long time;

- the mechanism is simply designed - there are no complex elements in it, which makes it easy to maintain;

- the mechanism is mobile - it can be transported to different places.

An overview of the difference between factory and homemade wood splitters

As mentioned above, you can not only make a wood splitter with your own hands, but also buy it in a ready-made factory assembly. The whole difference here is mainly in the price. For example, a hydraulic wood splitter Engy Els-5030 with a splitting force of about 5 tons will cost you somewhere in the 14-15 thousand rubles.And the model is more powerful, the splitting force of which is 12 tons - 85-90 thousand rubles. For that kind of money, you can easily assemble a couple of wood splitters with your own hands, then post the video on the Internet.

The principle of splitting logs with a hydraulic log splitter

The main advantage of factory-assembled wood splitters is that you do not need to waste extra time and effort. You just buy a ready-made mechanism and use it for your pleasure. On the other hand, a homemade model can be customized as your heart desires. You can install any engine, any type of transmission and adjust the unit for any size of firewood. A home-made model will cost 2-3 times cheaper than the average factory one.

As for the appearance, here self-made mechanisms are clearly inferior to the factory assembly, but when it comes to efficiency and productivity, the appearance recedes into the background.

Factory models have a more presentable appearance than homemade wood splitters

As a result, we can say that homemade models of wood splitters are much cheaper than factory ones and are great for home use. If you need to regularly chop wood on an industrial scale, then it is better to use a factory wood splitter. The choice of the type of engine, the location of the logs, the type of cleaver and other nuances depends solely on your personal needs and preferences. In addition, no one bothers you to modify the already existing model of the hand-assembled wood splitter and submit your own original model to the users' judgment.

When firewood is needed sometimes

That is, for a decorative fireplace or temporary heating with improvised waste fuel; ex. in the country. Churaks of low-value soft wood are sold abroad especially for fuel for fireplaces: poplar, aspen, willow, etc. And to them - wood splitters like the one in pos. 1 fig. below. The core of marketing promotion - the combs on the knife immediately give a splinter for kindling. But in general, the idea is strange: a churak, which can be split with a slight blow of an ax, is put into a clip and several times hit hard with a sledgehammer. True, splitting firewood is, on the contrary, safer. Maybe there it is also relevant. In America, there is a saying (translated into Russian): "If the average American, in a hurry to get to work, does not slip and break his neck in the shower, he will cut his throat while shaving."

Simple wood splitters for preparing a small amount of firewood

Much more convenient and no more dangerous is a saber wood splitter (item 2). He acts according to the famous saying: a bummer was asked why he chops wood while sitting? "And I tried lying down - it's uncomfortable." The saber log splitter can be mounted both to the wall and to the floor. Cutter arm from 0.8 m for soft straight grained wood; for birch and pine from 1.2 m.

Use a saber log splitter to split oak, etc. or the wood of fruit trees is already difficult and not always obtained. Therefore, at the dacha, visited in the cold season, a foot lever log splitter (pos. 3) will not interfere: it copes with churads of any tree with a diameter of up to 25-30 cm; however, the performance is low. In this wood splitter, a sliding fence pulls the shackle (arrow) when the pedal is depressed. The swinging lodgment is raised until the churak fits in it, then released and pressed on the pedal until the piece of wood cracks.

Mechanical wood splitters

A small amount of work can be done with a simple device. The wood splitter is distinguished by its simple design and possible production from any available material. The performance of this device is low, but it makes it possible to safely carry out work on the preparation of firewood with your own hands. There are some perfect firewood choppers that can be made at home.

The easiest and simplest option for assembling a wood splitter with your own hands is similar in design to a well crane.The racks are connected in a hinged way; instead of a container, handles with a cutter are installed. With this mechanism, work occurs due to physical strength. The assembly can be done from any available means, you will need corners and several pipes, you can use a broken ax as a cutter.

Mechanical wood splitter diagram

A self-made mechanical cleaver has a number of disadvantages. For a more simplified process, an elongated lever should be used, which affects the dimensions of the mechanism. The most common option is to install a lever system with a heavier cleaver. Due to the increased weight, it is easiest to pour the structure into the ground with concrete. This device is more compact, more efficient than its competitor.

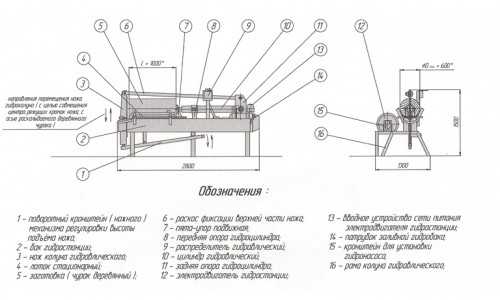

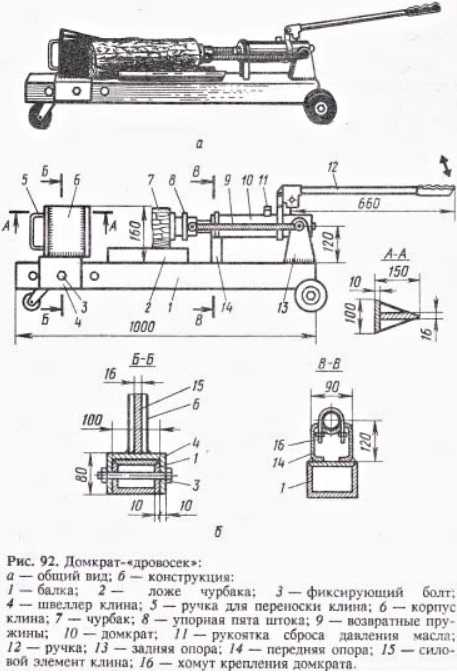

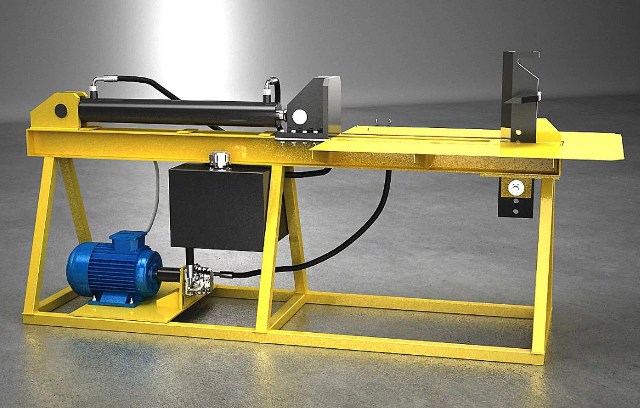

Hydraulic wood splitter

A hydraulic log splitter works on the principle of creating high pressure transmitted to the log, which, under its influence, is pressed against the cleaver (knife). Thanks to this effort, the block splits into two or more parts.

Prefabricated hydraulic wood splitter.

Prefabricated hydraulic wood splitter.

- Models designed for household needs have one function - splitting firewood.

- Professional devices are capable of not only splitting, but also feeding, trimming and unloading firewood.

For self-production, a simpler household option is most often chosen. It is equipped with an electric drive, which transfers the torque to the hydraulic pump. The electric drive is reliable and easy to maintain.

The disadvantage of this option is its dependence on the power source.

There are also manual models, organized on the principle of a hydraulic press, when even a small effort on the lever is transformed into a very high pressure on the working part of the wood splitter.

Stationary hydraulic log splitter with vertical movement of the cleaver.

Stationary hydraulic log splitter with vertical movement of the cleaver.

Hydraulic wood splitters can be of horizontal or vertical design. In horizontal wood splitters, most often, the block moves under pressure on the knife. And in vertical models - the cleaver is fed from above onto a log fixed from below.

The main units that make up the design and determine the performance and power of the wood splitter are the electric motor. For household installations, the force developed on the cleaver is sufficient, 4 ÷ 5 tons.

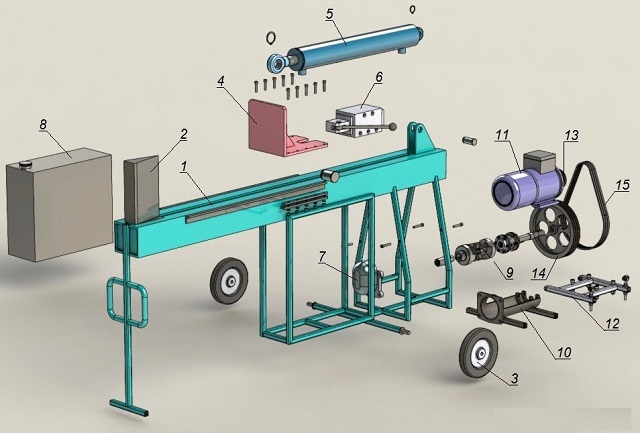

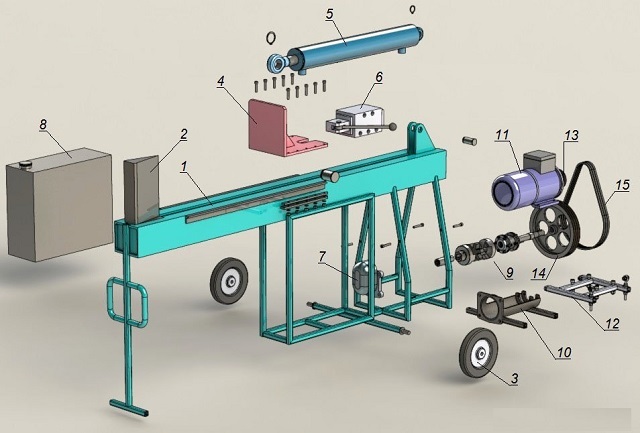

The main parts and components of the construction of a hydraulic log splitter with horizontal log feed to the splitter

The main parts and components of the construction of a hydraulic log splitter with horizontal log feed to the splitter

1 - Frame (bed) of the wood splitting machine.

2 - Cleaver.

3 - Wheels for the convenience of moving the machine to the place of work

4 - Carriage (heel) pushing the block onto the knife.

5 - Hydraulic cylinder.

6 - Hydraulic distributor with a lever that drives the machine.

7 - Hydraulic pump, in this design NSh-32.

8 - Oil filling tank (this is what is used in the hydraulics of the machine), with a capacity of 32 liters.

9 - The drive shaft of the hydraulic pump with the transmission unit (cardan).

10 - Drive shaft casing.

11 - Electric motor (in this case, the AIR80V2 model is installed).

12 - Turning platform.

13 - The leading pulley of the belt transmission.

14 - Driven pulley.

15 - V-belt.

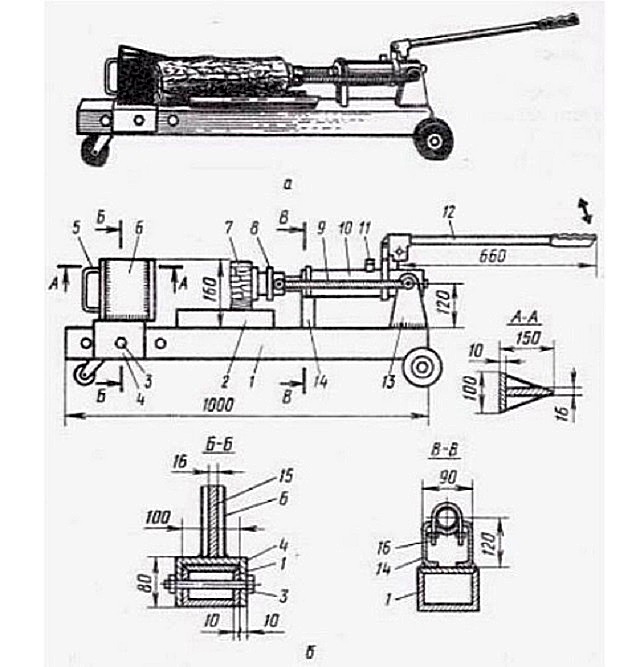

Drawing of a hydraulic wood splitter with real dimensional parameters.

Drawing of a hydraulic wood splitter with real dimensional parameters.

The features of the functioning of the hydraulic wood splitter include a smooth increase in the force on the cleaver, which cannot be said about other device designs. Thanks to this, the device is more reliable and safe to use.

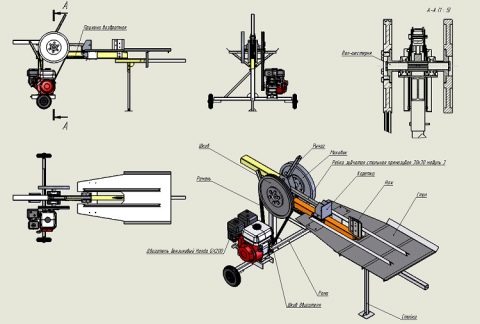

Instructions for making a rack and pinion wood splitter

For obvious reasons, no one can give any exact dimensions. We provide dimensions on the drawings only for those devices that have been tested and built for the conditions in which they are used. Nevertheless, there are general principles for assembling a wood splitter:

A competent drawing is half the job.It is necessary to provide not only the type of wood with which the wood splitter will mainly work, but also the place of installation, the desired performance

The choice of engine will depend on this.

A stationary or mobile frame is welded from a metal profile, a corner, and if the device is stationary, then a heavier and more massive channel or I-beam will do.

When welding the frame, it is necessary to accurately verify the dimensions, horizontal and vertical, all this affects not only productivity, but also the safety of the worker.

Particular attention is paid to the stability of the structure, during operation it should not sway, and in the case of a mobile device being built, the wheels must withstand the weight of the device with a small margin.

The speed of feeding the logs onto the knife is calculated only empirically. If the speed is high, wood chips can injure the worker, and if it is too low, it will be possible to fall asleep near the wood splitter.

Actually, this is all that can be guided by when building a wood splitter on a toothed rack. Good luck to everyone in your work and warmth in your homes in the coldest winter!

Recommendations from our expert

In order for the wood splitter to be reliable and serve as long as possible, it is worth listening to the following tips:

- Do not ignore the painting of the structure, especially when it is planned to be installed outdoors.

- Make calculations with a margin. This applies to the power of the engines, the thickness of the steel and other indicators.

- Start with diagrams and drawings. Proper preparation will save installation time and help avoid material loss due to mistakes.

- First try on, and then do welding or other fixation.

The log splitter makes life much easier for users who often have to deal with logging. Once assembled, the structure will save time and effort in the future. Making it yourself allows you to avoid unnecessary expenses.