Makita

A large Japanese company whose products are sold in almost all countries of the world. The manufacturer dates back to 1915, but has been producing power tools since 1958. Since then, the company has built several new factories. Today their number has reached 8: production facilities are located not only in Japan, but also in Europe and China. Needless to say, the equipment of the factories is the most modern?

Makita manufactures screwdrivers, hammer drills, drills, milling cutters, grinders, saws, planers, jackhammers, wall chasers, wrenches and other equipment - all in a decent range, so it is not difficult to choose the most suitable tool for your requirements. The choice is constantly expanding, the company is introducing new solutions, improving the entire range of equipment and striving for maximum ergonomics of products.

Experts call the Makita tool the best option for personal use, as it combines the highest quality and reasonable price. There is a separate product line for professionals. Every detail of the equipment is designed and manufactured with a large margin of safety from high-quality durable materials, so the equipment has served faithfully for years.

Views

It is necessary to select a glass cutter depending on the functions performed. This tool is presented by manufacturers in several types. They differ in design features and parameters of the dissecting element.

With lubricating mechanism

This device is different from others. Its handle is filled with special oil, which lubricates the cutting roller during operation. This system greatly increases the wear resistance of parts and the quality of cutting.

Diamond device

This type of glass cutter is used by professionals. He confidently processes any surface, due to which he is very popular. The cutting element is a diamond. Both natural and artificial materials are used. There is an adjusting screw at the end of the tool. With a Phillips screwdriver, you can change the position of the diamond tip.

Radial

The product is designed to perform work on an industrial scale. It is also suitable for cutting round holes. The tool is equipped with a carbide roller that effectively cuts the work surface. Some models have automatic oil supply. During operation, the device requires certain skills, knowledge and experience.

The tool is very convenient to use. It has a guide bar, cutting head, gauge and barrel of lubricant.

With measuring ruler

This glass cutter cuts surfaces quickly. The cutting edge is tailored to the taste of the customer. The tool is equipped with a lubrication system. This will allow cutting about 30 km of the treated surface. It makes no sense to install such a unit at home. It is perfectly suitable for a glass workshop or other organization providing such services.

For tubes

Such a product is used in the food or chemical industry. These industries are characterized by increased sterility. The glass cutter is used to cut different sized glass tubes.

Best Roller Glass Cutters

Such models are the most common, as they are as easy to use as possible, and also have a fairly low price. They will be the best choice for short-term work at home. Below are the best glass cutters of this type.

FIT 16927

It is used for working with glass, the thickness of which does not exceed 10 millimeters.It belongs to the roller type, as it has 3 cutting rollers. They do not wear off quickly, they have a comfortable shape. Together with this, several grooves are provided, they can conveniently grip the glass when breaking. The handle is made of high quality plastic and has a length of 140 millimeters.

Dignity

- Compactness;

- Good strength;

- Affordable price;

- Versatility.

disadvantages

The complex structure may be unusual at the beginning of use.

FIT 16927 is designed for professional processing of glass of different thicknesses. It is multifunctional: in the hands of a professional, the tool is able to work very quickly and efficiently with complex structures. Thanks to the use of high quality materials in the production, it provides a fairly long service life.

Stanley 0-14-040

A tool with a classic design, designed to be used in almost any environment. It is equipped with 6 rollers for processing glass at once, due to which cutting becomes the highest quality and fastest. They are made of high strength steel. The body is made of wood. A special lacquer coating is provided to increase durability and extend the life of the product. The design of the device contains grooves that provide a firm grip of the glass during processing.

Dignity

- Fast, high quality cutting;

- Easy to use

- High-quality assembly;

- Affordable price.

disadvantages

Not suitable for thin glass.

An excellent option for household needs. It has an attractive price and is very easy to use. The tool is able to actively serve for many years.

Stayer MASTER 33613_z01

It is a high-quality version of the roller type for working with thin glass, the thickness of which does not exceed 5 millimeters. Equipped with comfortable grooves to effectively hold thin glass when cutting. The handle is made of lacquered wood, which provides protection against mechanical damage. The design provides for 3 high quality rollers with a total working life of 3000 meters.

Dignity

- Low price;

- Convenient structure;

- High efficiency of glass processing;

- Great working resource.

disadvantages

Not suitable for cutting thick glass.

In general, the tool is one of the most affordable models for professional processing of thin glass. It has a comfortable shape, durable working elements. A large working resource allows you to effectively use it for an extremely long period of time.

Types of glass cutters

The tools differ in several categories. By design, a glass cutter is:

- diamond;

- roller;

- oil;

- compass-glass cutter;

- victorious.

Glass cutter by type of attachment is:

- fixed;

- with a rotating mandrel.

The cutter can be in the form:

- sharpened edge;

- roller.

Oil glass cutter

One of the most popular tools for cutting glass. A special feature is the presence of a small reservoir for oil, which is supplied during operation to the cutting element in automatic mode. It is located in the grip, which has finger tabs for a comfortable grip. Understanding what glass cutters are, you need to know that oil can work on glass up to 20 mm thick. When used, the lubricant is supplied from the reservoir, which reduces friction and wear on the cutting edge.

In addition, due to the viscosity of the oil substance, small particles of the cut material are collected during operation. For home use, a device with a sharpening angle of 135̊ is used. Among the disadvantages, only the high cost is distinguished. The advantages include:

- the ability to work with a large volume;

- durability;

- even cut;

- independent oil supply;

- convenience of work.

Diamond glass cutter

This tool is more accurate and accurate than others. In production, artificial or natural stone can be used. The first option can work with thicker glass.The working element is a solid diamond crystal, which is of two types:

- with a curved cutting edge;

- in the shape of a pyramid.

The first is suitable for beginners, and the second for professionals with extensive experience. A diamond glass cutter is a device that has the following features:

- thin cuts;

- sensitivity to shock loads;

- the presence of a screw that helps to change the working edge.

These glass cutters differ in the size of the stone:

- small up to 0.05 carats for thin-leaf products;

- large 0.11 ct for 10 mm glass.

Among the advantages are:

- creating an even groove;

- high-quality cut;

- durability.

The disadvantages include:

- work experience;

- high cost.

Roller glass cutter

The most common type. The cut is made with a rotating roller made of carbide material such as tungsten carbide or HSS. When studying which glass cutter to choose for glass, you need to know that there are models with one, three and six rollers. The last products are considered the most durable, besides they allow you to work with large volumes of material. Another plus is the ergonomic handle. It can be presented:

- pencil;

- with a pistol.

In the first version, the pressure falls on the operator's fingers, and in the second, on the elbow joint. The roller glass cutter can work with glass with a thickness of 6 mm. Among the positive qualities are:

- low cost;

- ease of use;

- the possibility of replacing the cutting element.

The disadvantages include:

- poor groove quality;

- small amount of work.

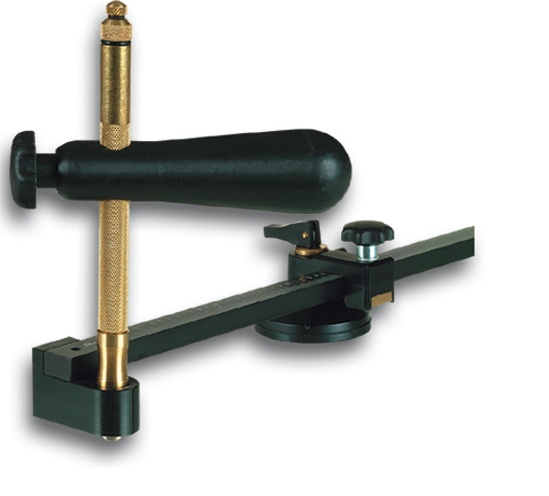

Compass glass cutter

The best tool for creating holes or shapes in the form of a circle or oval. The circular glass cutter has a circular mechanism at the heart of the design. The suction cup serves as a reference point, which fixes the entire structure on the plane of the glass. A scale and a cutting element are attached to it, moving along the latter to adjust the radius

For a high-quality cut, it is important to pre-select the radius on the measuring scales. The advantages of this glass cutter include:

- the ability to cut holes and complex shapes;

- the ability to work with thick glass;

- ease of use of the tool.

The glass cutter for thick glass has the following disadvantages:

- the need for operator experience;

- high cost.

Victory glass cutter

The cheapest tool option. A fixed victorious cutter is used as a cutting element. A good glass cutter for glass, it cannot be classified, but it is suitable for one-time use. Among the advantages are:

- cheapness;

- suitable for single use.

The disadvantages include:

- the need for constant sharpening;

- poor groove quality;

- not a neat cutting line.

The principle behind mechanical glass cutting technology

In practice, most people have to deal with ordinary silicate glass. It is installed in double-glazed windows, aquariums and dishes are made from it. In the future, we will talk specifically about the processing of this material. It is not advisable to use mechanical glass cutters for cutting triplex, organic or tempered glass, especially for non-professionals, the results can be very frustrating, and the money spent on the purchase of glass can be wasted.

Includes various impurities, and therefore distinguish between sodium-calcium, lead, borosilicate, potassium-calcium and quartz glass. A detailed analysis of each type goes far beyond the scope of the topic under discussion, therefore, one should dwell only on the general features of silicate glass.

Glass is an amorphous substance and combines the properties of a solid and a liquid. It has low fluidity. But still this property is present, which becomes noticeable on old windows, where the lower part turns out to be thicker than the upper one.

Glass must be handled with great care due to its fragility; it breaks easily under mechanical stress. At the same time, the material is quite hard, on the Moss scale, glass conditionally occupies the same position as quartz, only slightly inferior to it

The table also indicates with which material the selected can be processed. According to this criterion, diamond meets quartz.

So, due to the specifics of the material, the glass is cut in the following sequence:

- To begin with, the glass is prepared for work. For this purpose, its surface is wiped with a rag. When it is necessary to clean the glass from fat, it is washed with a solution of soda. If the glass was stored in an unheated room in winter or autumn, it is not recommended to start working with it right away; first, let it lie down for a while and take room temperature.

- Next, the glass sheet is placed on a flat, clean surface. The best option is a table covered with a soft cloth. The overhangs of the sheet must not be allowed beyond the edges of the tabletop.

- Using a wide wooden ruler, markup is carried out. The bar is applied at a distance of 1-2 mm from the future cutting line for roller glass cutters and 3-4 mm for diamond cutters. Then a risk is applied by the tool, after the glass cutter there should be a thin, almost transparent strip. A whitish or uneven track indicates insufficient sharpness of the instrument or excessive pressure on it by the master. The master begins to cut the glass from the far edge.

- The next step is to place the glass so that the cutting line protrudes 3-5 mm beyond the edge of the table top and at the same time runs parallel to it. The worker takes the sheet with both hands and with a sharp downward movement breaks off the desired part. When working with glass with a thickness of more than 5 mm, several light blows are applied along the cutting line with a small hammer. A small detail: the fracture is performed immediately after applying the risks, because due to the fluidity of the material, the applied scratch will be tightened. The curly cutting technology has several features, but the essence remains the same.

How to choose a good glass cutter for your home

Among the glass cutters sold in stores, there are definitely good models for home use. The answer to the question: "Which glass cutter to choose?", Should be based on the following initial parameters:

- the planned amount of work with the tool;

- the types of glass to deal with and their thicknesses;

- personal experience with the tool;

- financial ability to acquire.

In addition, a number of general recommendations can be formulated that explain how to choose a good glass cutter for your home:

For the repair and assembly of home furniture, there is no need to purchase expensive industrial equipment.

With a large volume of work and very high quality requirements, it is better to hand over the work to professionals, then there will be someone to ask if a defect is found.

It is very important when choosing a manual glass cutter to take into account your own previous experience with this tool.

For experienced craftsmen who are accustomed to working with a diamond, it will be a logical and reasonable choice, while beginners who have never dealt with a similar one should turn their attention to glass cutters with rollers.

A good glass cutter should have a comfortable, ergonomic handle. A significant part of experts prefer classic wooden handles, they do not slip and lie pleasantly in the hand

Artificial irregularities in the form of roughness and notches are provided on the surface of metal or polymer handles; in their absence, it is better to bypass the tool.

The roller at the glass cutter should not dangle in different directions

There is no need to chase a large number of cutting blades, realistically assessing the amount of work to be done and the availability of their replacement.

Before making a purchase, ask the seller to demonstrate the performance of the glass cutter being assessed.When checking diamond and oil models, close attention is paid to the thickness of the notch on the glass, with a high-quality cutter it turns out to be thin, almost invisible. For economical roller models, the quality indicator will be the absence of a squeak, the correct sound is a slight crackle.

Without a suitable tool, high-quality cutting of glass with smooth edges without chips is impossible. Finding your way in the assortment and buying the necessary device is already half the battle. We hope that our guide on how to choose a good glass cutter was complete and useful for you.

What are wire cutters

It is a manicure tool for manipulating nails and cuticles on hands and feet. The result of the master's work depends on their quality and ease of use. Do not forget about the image of the salon - high-quality nippers play an important role in this.

By purpose, wire cutters are divided into 3 main categories:

- Cuticle nippers or nippers. They are also called tweezers or cuticle tweezers;

- Hand nail clippers - for manicure;

- Toenail clippers - for pedicure.

Scissors or forceps for cuticles and rough skin around the nails are a must when performing classic edged manicure, as well as some types of combined.

Hand nail clippers are an alternative to nail scissors. The nippers are larger and stronger than the nippers and are designed to handle hard and rough nails.

Which is better, scissors or wire cutters? Depends on the situation. Manicure scissors with rough nails, such as age-related or affected by fungus, may not work.

Pedicure nippers have a larger size and strength, reinforced structure. The length of the blade starts from 15 mm to 21 mm. This size and durability makes it possible to work with rough and ingrown toenails, even for older clients, without crumbling or crushing them along the length.

General recommendations for selection

Today there are a huge variety of glass cutters, of various shapes and colors. Some instruments may have similar visual features, but differ drastically in the quality of their performance. Original glass cutters from renowned manufacturers are relatively expensive, but they also serve faithfully throughout the specified period. Chinese models will be cut, but they will become unusable much faster. In order not to overpay for unnecessary 20 thousand meters of cutting, before choosing a glass cutter for your home, we recommend that you answer a few questions for yourself.

How often do you need to cut glass? In private houses with an economy, such a task periodically appears, so it is better to have a more reliable device in your arsenal. If you plan to use glass in your design or stained-glass windows, you will need a high quality tool that can also make a very even cut. If you need to cut glass for the first time in your life and you don't know when else is expected, you can completely do with the most budgetary option.

To more accurately understand which glass cutter to choose, you need to know which glass you have to work with? The average thickness of the glass panes is 3-4 mm and such material can handle even the cheapest glass cutter. If you are dealing with a thicker blade, it is best to choose a tool based on its size. Oil can cut glass up to 9 mm, and diamond up to 20.

How to work

The following rules for working with pliers and tweezers should be adhered to:

- In order for the tongs to last longer, during work it is necessary to lay them with the blades up, work with neat movements.

- Do not drop the tool with a sharp edge down to avoid nicks and scratches.

- When working, the grip of the tool is carried out with the palm from above, and then the hand is turned over.

- The index finger should be under the undercarriage and the thumb should be on the top of the undercarriage.

- The index finger should not be placed close to the blade, so as not to cut the glove, skin, yourself or the client.

- The rest of the fingers should be in line with the left grip (for right-handers).

- On the work table, the nail clippers should be positioned with a sharp edge away from the client and from the master to avoid injury from accidental movements.

AEG

Power tools under the AEG trademark are known even to those who carry out repair work at most once a year. It all started in Germany in 1883 with the production of light bulbs, and later the young company actively responded to the development of industry in the country, and already in 1898 presented the first compact drill. Within a few years, the manufacturer's products conquered many countries. Later, the company introduced the first drill with a pistol-like handle, a form factor that is still popular today. This was followed by variable speed drills with double insulation, the first rotary hammers and straight grinders. The company has become one of the pioneers in the world of cordless power tools.

The manufacturer has always focused on the constant development of innovative technologies. Also, great importance has always been paid to the design and ergonomics of the instrument, and at the beginning of the last century, designers were invited to work on the development of new equipment. The company's factories have always been a model of innovation, both inside (state-of-the-art equipment) and outside (futuristic design).

Today, the AEG brand produces tools for drilling and chiselling, wood and metal work, fasteners, various auxiliary equipment and accessories. After the Swiss company Atlas Copco bought the company, it sold the power tool part, so today the power belongs to the Chinese from Techtronic Industries. Part of the production was transferred to China to a modern plant, and perforators are still produced in Germany, but this is all lyrics - the main thing is that the quality and approaches to production have not changed. AEG tools are durable and virtually indestructible.

4 STAYER 8000 M 3369

Quite a good option for an oil glass cutter with solid tungsten carbide rollers. It is designed for cutting glass with a thickness of 3 to 8 mm. The spring-loaded head and the use of oil, which is poured into the hollow handle, greatly facilitate the process of work, allow you to achieve a smoother cut. The handle is made of plastic, which some users consider a disadvantage, since it is not the most durable material. But this solution has its advantages - it is transparent, which allows you to immediately determine the need for oil filling.

Users note the high working life of the cutting rollers - up to 8000 meters. If the instrument is purchased for home use, you will never need to change it. Comes with a handy pipette for refilling the cutter with oil. Many in the reviews share that it is simple and convenient for them to work, so the only drawback is not the most reliable plastic handle.

DeWalt

There are also decent power tool manufacturers overseas, and the main one is DeWalt. The history of the company began in 1922 with the invention of the radial arm saw, which was able to significantly increase the productivity of woodworking. Since then, the name of the company has been inextricably linked with innovation, and it can take a long time to list the manufacturer's developments and inventions.

The factories of the company are located in the USA, Canada, South America, Europe, and also in China. The range of electrical equipment includes more than three hundred items and includes various models of drills, jigsaws, planers, hair dryers, polishers, jigsaws and jackhammers. DeWalt is the number one brand in the North American professional power tool market. In recent years, sales of tools in Europe have also sharply increased, and experts recognize the company as one of the fastest growing in its field.

The quality of the products is the highest, and thanks to a well-thought-out design and the introduction of our own developments, the tool comes out convenient and durable. With this, no repairs are terrible! You have to pay for overseas quality - the company's products are worth higher than similar ones from the already listed competitors, and not the entire range is presented on the domestic market.

Sharpening

It is recommended to sharpen the tongs at least once every 6-12 months, depending on the flow of customers in the salon. When used at home, a professional tool can last about 3-5 years without the need for sharpening.

It is recommended to give nippers for manicure and pedicure to a professional sharpener service, without experimenting with home methods. This leads to the risk of spoiling an expensive tool, sometimes without the possibility of recovery.

Choosing high-quality nail clippers for manicure and pedicure, take care of their correct operation and timely maintenance. The listed brands are top-end, and in each of the lines you can choose an excellent professional tool for your needs.

Share this

Output

Using the above recommendations, any beginner will be able to determine which glass cutter is best for him and make the right choice of tool. And then perform the necessary work efficiently and safely for yourself and the tool.

- Catalog

- Stained glass tools

Stained glass craftsmen cannot do without a special hand tool for cutting glass. We offer to buy professional glass cutters made in Germany, Japan and other countries in Moscow. Proven models in different price categories are on sale. Experienced stained glass painters advise not to save on a glass cutter - glass damaged by a bad tool will cost more. Descriptions and photos in the catalog will help you choose a tool. Managers will answer in detail questions about characteristics, purpose, cost. When buying a glass cutter, you can immediately purchase spare heads, rollers for the selected model in order to timely replace worn out ones.

Choosing a glass cutter for the manufacture of stained glass

Only a roller tool can handle artistic glass cutting; a diamond cutter cannot handle complex lines with bends. The professional glass cutter is most often equipped with an automatic lubrication system and a lubricant container. Models that are dipped in oil are already less popular, and it is difficult to perform a large amount of work with them. Different brands of lubrication systems may differ, but their principle of operation is identical - oil gets on the cut surface when pressed on the glass, like ink on a ballpoint pen. The tools differ depending on the intended tasks (straight or curved cut), the thickness of the glass being processed:

- type and width of the cutting head;

- sharpening angle and roller diameter;

- the type of lubricant and the method of its receipt.

Handles are made of metal (usually brass) or plastic; craftsmen select them based on personal preferences.

Bohle glass cutters

The Bohle brand Silberschnitt glass cutter is recognized as one of the best in the world, especially in terms of durability. With proper use of the roller without replacement, there is enough for 5000 m of glass, spare heads are on sale.

The line includes models for thin, regular and thick glass, straight and curved cutting. Developed a unique lubricating fluid supply system and a smoothly driven roller.

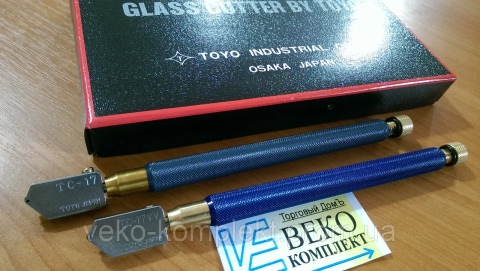

Professional glass cutters Toyo

The Japanese company uses special tungsten rollers, which increase the service life by 40% - the roller serves without replacement for at least a year. Ergonomic handles, perfect sharpening make work easier. For curved cutting, the toyo glass cutter with a pivoting head is convenient. Call us, we will help you buy a glass cutter that will provide high performance and will last for many years.

Glass cutter Russia "Profi", 3-roller, with anti.

Diamond glass cutter with curved cutting edge Ross.

Diamond glass cutter 0.07 ct

Glass cutter "Sparta", diamond

Diamond glass cutter with curved cutting edge, 87.

Glass cutter KRAFTOOL-SILBERSCHNITT professional oil.

Diamond glass cutter Brigadier Extrema

glass cutter roller fit 8 mm 145 mm with oil

Professional oil glass cutter

Glass cutter KRAFTOOL-SILBERSCHNITT professional oil.

Diamond glass cutter with Ross curved cutting edge.

Diamond glass cutter FIT 16930

Diamond glass cutter Bison Profi 3362

Cutting tool Diamond glass cutter 87225

diamond glass cutter ugo loks up to 4mm

Professional diamond glass cutter

Stayer Diamond Glass Cutter

Diamond glass cutter. Russia

Russia Diamond glass cutter with a curved cutting edge.

Diamond glass cutter FIT 16930

Diamond glass cutter Course, metal striker, up to 4 mm

FIT 16930 Diamond glass cutter (up to 5 mm, resource up to 10000.

Glass cutter KRAFTOOL-SILBERSCHNITT professional oil.

diamond glass cutter fit 5 mm 145 mm

Diamond glass cutter. SPARTA

Diamond glass cutter with a curved cutting edge // Be.

Glass cutter KRAFTOOL-SILBERSCHNITT professional oil.

Glass cutter "Sparta", diamond

Diamond glass cutter Course, plastic firing pin, up to 4 mm, F16.