Manufacturers

| Organization | Price * | Note |

|---|---|---|

| Yaroslavich, JSC Production company (Russia, Yaroslavl region) | RUB 1 991 200 | KBM-14.4PS-4P; CS No. 5 dated February 27, 2020 |

| Yaroslavich, JSC Manufacturing company (Russia, Yaroslavl region) | 1 192 300 rub. | KBM-10.8P; CS No. 5 dated February 27, 2020 |

| Yaroslavich, JSC Manufacturing company (Russia, Yaroslavl region) | RUB 1,772,800 | KBM-14.4P; CS No. 5 dated February 27, 2020 |

| Yaroslavich, JSC Manufacturing company (Russia, Yaroslavl region) | RUB 1,409,300 | KBM-11PS-V; two rows of harrows, single roller, TsS No. 5 dated 02/27/2020 |

| Yaroslavich, JSC Manufacturing company (Russia, Yaroslavl region) | RUB 1,833,400 | KBM-14.4PS-4; CS No. 5 dated February 27, 2020 |

| Yaroslavich, JSC Manufacturing company (Russia, Yaroslavl region) | RUB 594,000 | KBM-6NU; reinforced spring rack with a spring, leveler, single roller, TsS No. 5 dated 02.27.20 |

| Yaroslavich, JSC Production company (Russia, Yaroslavl region) | RUB 834,700 | KBM-7.2PS; CS No. 5 dated February 27, 2020 |

| Yaroslavich, JSC Production company (Russia, Yaroslavl region) | RUB 1,924,300 | KBM-15PS-V; two rows of harrows, single roller, TsS No. 5 dated 02/27/2020 |

| Yaroslavich, JSC Production company (Russia, Yaroslavl region) | RUB 935 600 | KBM-8PS-4; reinforced spring rack with a spring spring, single roller, TsS No. 5 dated 02.27.2020 |

| Yaroslavich, JSC Production company (Russia, Yaroslavl region) | RUB 706,900 | KBM-8.0NUS; CS No. 5 dated February 27, 2020 |

| Yaroslavich, JSC Manufacturing company (Russia, Yaroslavl region) | RUB 279,400 | KBM-4.2NU; CS No. 5 dated February 27, 2020 |

| Yaroslavich, JSC Production company (Russia, Yaroslavl region) | RUB 780,300 | KBM-7.2P; CS No. 5 dated February 27, 2020 |

| Yaroslavich, JSC Production company (Russia, Yaroslavl region) | RUB 894 800 | KBM-8.0PS; CS No. 5 dated February 27, 2020 |

| Yaroslavich, JSC Production company (Russia, Yaroslavl region) | RUB 631,300 | KBM-8.0NU; CS No. 5 dated February 27, 2020 |

| Yaroslavich, JSC Production company (Russia, Yaroslavl region) | RUB 1,279,200 | KBM-10.8PS; CS No. 5 dated February 27, 2020 |

| Yaroslavich, JSC Production company (Russia, Yaroslavl region) | RUB 2,025,400 | KBM-14.4PS-D; CS No. 5 dated February 27, 2020 |

| Yaroslavich, JSC Manufacturing company (Russia, Yaroslavl region) | RUB 1,839,400 | KBM-14.4PS; CS No. 5 dated February 27, 2020 |

| Yaroslavich, JSC Manufacturing company (Russia, Yaroslavl region) | RUB 1,431,200 | KBM-10.8PS-4; leveler, single roller, TsS No. 5 dated 02.27.2020 |

| Yaroslavich, JSC Manufacturing company (Russia, Yaroslavl region) | RUB 1,567,900 | KBM-10.8PS-4; leveler, tandem roller, TsS No. 5 dated 02.27.2020 |

| Yaroslavich, JSC Manufacturing company (Russia, Yaroslavl region) | RUB 878,700 | KBM-6NUS; two rows of cutters, single roller, TsS No. 5 dated 02.27.2020 |

| Yaroslavich, JSC Production company (Russia, Yaroslavl region) | RUB 554,700 | KBM-6NU; spring tine, reversible share, leveler, single roller, TsS No. 5 dated 02.27.2020 |

| Yaroslavich, JSC Manufacturing company (Russia, Yaroslavl region) | RUB 1,985,700 | KBM-14.4PS-4D; CS No. 5 dated February 27, 2020 |

| Yaroslavich, JSC Manufacturing company (Russia, Yaroslavl region) | RUB 312,000 | KBM-4,2NUS; CS No. 5 dated February 27, 2020 |

Prices are indicated in: Ruble with VAT (20%).

How to choose?

All seedbed cultivators are supplied complete with the main working implements that allow rolling, leveling and crushing the soil.

At the same time, when buying these devices, it is important to pay attention to their technical characteristics, which would correspond to the scope of work and the size of the site.

The main indicators when choosing a particular model are the following.

Loosening paws

Since these parts take part in loosening and mixing the soil, preference should be given to those that are made of durable metal and have large dimensions.

Skating rinks

These implements are available in various types and, depending on the type of soil cultivation, can be installed in different places of the frame. To increase their efficiency, it is recommended to additionally use a spring-roller attachment.

Double frame protection system

The hydraulic system of the cultivator includes the following safety elements:

Safety valve

Installed on the cultivator's hydraulic system. Controls the process of transferring the frame from the transport position to the working position. Eliminates the possibility of deformation of the center frame.

Chokes with non-return valve

Installed in the hydraulic system of the cultivator to control the transfer of the frame from the working position to the transport position. Provides smoother folding.

The system is adjusted at the factory, no additional adjustment is required.

Installed on all KBM-14.4 models.

Characteristic

Presowing cultivators are disc rollers that have high technical characteristics and are designed to prepare and cultivate the soil before sowing crops.

The main advantages of such devices include:

- a wide range of applications, from cultivation to complete tillage;

- robust construction made of low alloy steel;

- ease of use;

- the ability to adjust the deepening into the soil depending on the type of field work;

- weed removal;

- uniform processing and copying of the relief;

- high efficiency.

As for the drawbacks, the presowing cultivators do not have them, except that each model is designed for a certain amount of work.

In addition, many modifications have a simple design that allows you to customize the mechanisms even in the field.

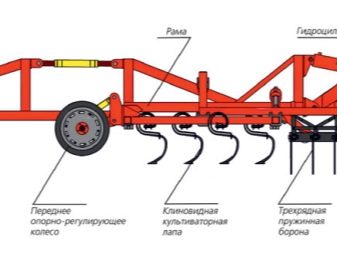

The presowing cultivator, unlike other types of devices, has a special design, it consists of:

- sturdy frame;

- side and center sections;

- lancet paws;

- recoil shoe;

- hydraulic system;

- drawbar;

- chassis;

- shock absorber;

- spiral roller.

Before starting to cultivate the land, the cultivator is prepared for work. Installation in the transport position is carried out using a hydraulic system, which consists of hydraulic cylinders, fittings, high pressure hoses and quick couplers. In the assembled position, the wings of the device are placed on special stops, they are fixed, give rigidity to the structure and make it possible to transport at speeds up to 25 km / h.

Adjustment of the tillage depth is carried out by means of stop screws.