Vibratory plates

Vibratory plate is a surface vibratory soil compactor designed for ramming incoherent or poorly cohesive soils and dumps of small thickness - from 10 to 30 cm. Vibratory plates of various capacities compact sand, gravel and crushed stone, as well as paving slabs and asphalt. The vibratory plate for soil compaction copes with ramming areas with a slope, where it is difficult or impossible to use a large-sized roller. Vibratory plates are rightfully in greatest demand among developers and are gradually replacing vibratory rollers.

Healthy! Sometimes the not quite correct name is attributed to vibrating plates - a surface vibrator. This misunderstanding is due to the fact that the operation of the surface vibrator resembles the compaction of sand with a vibrating plate. However, it has a different field of application - the compaction of thin-layer concrete fill in monolithic construction. A surface vibrator is sometimes used to make homemade vibrating plates.

The quality of compaction depends on the level of soil moisture: with sufficient indicators, the soil becomes plastic and the compaction process is faster. If there is a lack of moisture, the rammed layer is additionally spilled with water, if there is an excess of it, they wait for drying. The humidity level is controlled by an electronic moisture meter.

| Soil type | Moisture level at maximum compaction,% |

|---|---|

| Sandy | 8 – 14 |

| Sandy loam | 9 – 15 |

| Loamy | 12 – 18 |

| Clayey | 16 – 26 |

Healthy! When ramming loamy and sandy loamy bases with a vibrating plate, additional wetting of the working plate of the device is necessary to protect against soil adhesion.

The structure and principle of operation of the vibrating plate

The vibrating plate is equipped with an electromechanical eccentric, inside which unbalanced masses create mechanical vibrations. With the help of a belt drive, torque is transmitted from the engine to the eccentric shaft. The vibrations propagate to a metal plate (plate) that is in direct contact with the ground surface and causes it to vibrate. For convenience, the vibratory plate device has a handle for the operator.

Varieties of vibrating plates

Vibratory plates are classified by weight into:

- lightweight (up to 75 kg) - designed for landscaping and finishing works, effectively compacting a layer of soil 10-15 cm thick;

- medium weight (from 90 to 140 kg) - provide processing thickness up to 35 cm; designed for layer-by-layer compaction;

- heavy (from 200 kg) - used as an alternative to vibratory rollers;

- universal (75-90 kg).

Depending on the type of engine, the compaction plate can be diesel, electric or gasoline.

The most popular are gasoline models. They are economical and provide freedom of movement around the site and the ability to work at subzero temperatures.

Diesel vibratory plates are reliable and durable. Like gasoline, they are independent of the power source. Disadvantages are due to heavy weight, high noise levels and difficult work in frosty weather.

Electric vibratory plates limit the working area to the length of the power cable, but are the most environmentally friendly. They are used in closed rooms with limited access to fresh air, where the use of gasoline models is unacceptable due to the risk of poisoning from exhaust gases.

According to the method of movement, vibratory plates are divided into:

Reversible. Such models are more maneuverable, but they are distinguished by their high price and high weight. As a rule, they are equipped with a diesel engine.The advantage of reversible vibrating plates is the possibility of reverse movement without turning the equipment. Therefore, they are indispensable for compacting sand and bulk soil in narrow trenches.

The performance of vibrating plates is determined by:

- base area;

- operating frequency;

- vibration force;

- engine displacement (for gasoline and diesel cars).

Safety at work

Performing work by compaction of soil with vibrating plates assumes compliance with safety regulations. Basic safety rules when working with a vibrating plate:

During the work, personal protective equipment must be worn - clothing and footwear, goggles, and a hat.

Before starting work, check it for external damage - the detected faults must be eliminated immediately.

When the mechanism is started, it is strictly forbidden to leave it unattended, the operator of the vibrating plate must choose a safe position and be behind the mechanism.

It is important to observe the mode of work and rest, every 40 minutes of work, take a ten-minute break to prevent overwork.

It is forbidden to take any action that accelerates the operation of the mechanism.

When working on a slope, the operator must move above the machine and work from top to bottom.

Do not use the unit near explosive materials or those that are flammable.

If an abnormal situation occurs and the stove overturned, you must immediately turn it off, and then return it to its working position.

The unit must be turned with one hand, and in order to prevent injury, the limbs must be positioned so that they are located at a distance from the base of the plate.

When hitting an obstacle, the unit must be stopped immediately, and started again after removing the obstacle and possible breakdowns.

In the process of work, it is necessary to drive the unit so that it does not come close to ravines or pits.

It is necessary to remove from work with the unit employees who are under the influence of alcohol, drugs or psychotropic substances.

Remember that the higher the center of gravity of the machine and the smaller the footprint, the more likely it is to tip over.

THE BENEFITS OF A PNEUMATIC TRAMMER

The rammer is the tool used

workers for ramming or compaction.

For example, compaction of the soil with

earthworks or compaction

concrete mass in construction work,

as well as for sealing molding

mixtures in the foundry.

The use of rammers significantly

facilitates the work of workers and in several

times increases labor productivity.

There are several types of rammers:

electrical, mechanical, diesel,

pneumatic, etc. All rammers

perform the same function and

fundamental difference in application

this or that instrument is not present. Exists

the difference is only in the speed and

power of the tool. Consider

for example all the pros and cons of ramming

pneumatic.

The pneumatic rammer belongs to

manual impact machines.

The principle of operation of the pneumatic

rammers - energy use

compressed air. An important advantage

pneumatic tool is the ability

continuous long-term operation, as well

light weight. Such a tool is not subject to

overheating or combustion, the reason

this is the absence of an electric motor.

When working with pneumatic rammers, do not

electricity is used, which leads

to save energy and does not require any costs

to carry. This factor is

the most important plus for pneumatic

rammers, especially if working with her

use are carried out far from

electrical network. You also need to take into account that

factor that in pneumatic rammer

fewer parts than others

similar tools, and hence

there will be much less malfunctions!

What is the attractive factor

for the buyer when choosing a rammer.

Finding out that pneumatic rammers

have a number of advantages over identical

tools, consider how to do it correctly

choose a pneumatic rammer.

When choosing a rammer, you need to consider

several important technical

factors:

- dimensions;

- the mass of the tool;

- impact frequency;

- impact energy;

- air flow;

- diameter of the air-conducting hose.

These specifications take

into consideration when buying a tool with

specific purpose of its use

- will it be professional work

tools at the enterprise or

using it at home.

Household tool as opposed to

professional has a small

power that will not be enough

in production, respectively, and the price

such a tool will be below. When buying an instrument, you must

compare prices for similar products in order to

do not purchase an item at an overpriced price

and at the same time not of the appropriate quality.

You should also pay attention to the company -

manufacturer of this tool

She

must be trustworthy and have

positive feedback on your products.

Our region in the pneumatic market

rammer is represented by LLC Alchevsky

Mechanical Plant ", which implements and maintains this tool

When buying an instrument, you must

compare prices for similar products in order to

do not purchase an item at an overpriced price

and at the same time not of the appropriate quality.

You should also pay attention to the company -

manufacturer of this tool. She

must be trustworthy and have

positive feedback on your products.

Our region in the pneumatic market

rammer is represented by LLC Alchevsky

Mechanical Plant ", which implements and maintains this tool

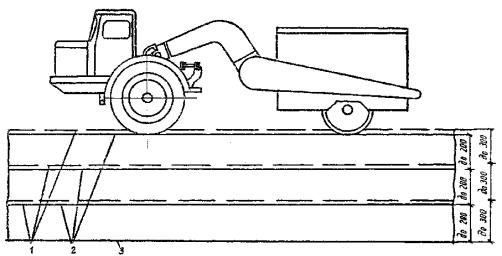

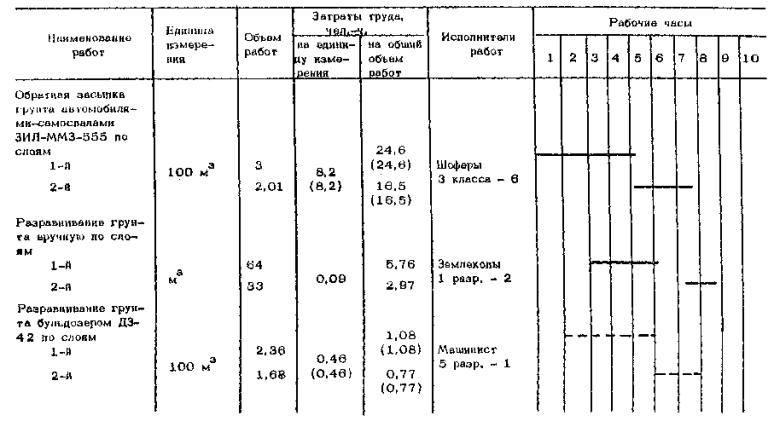

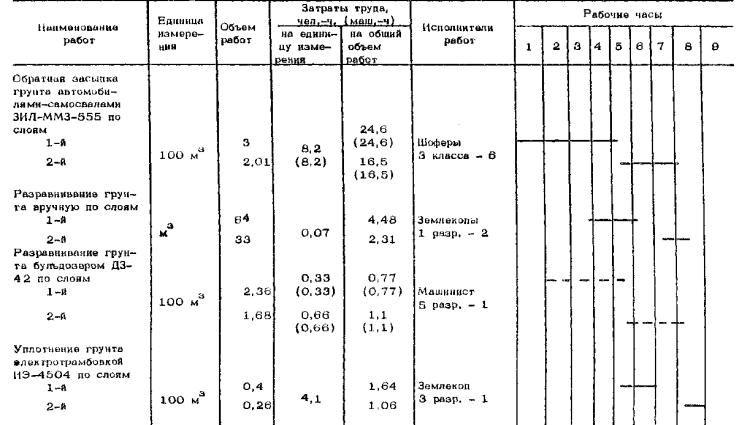

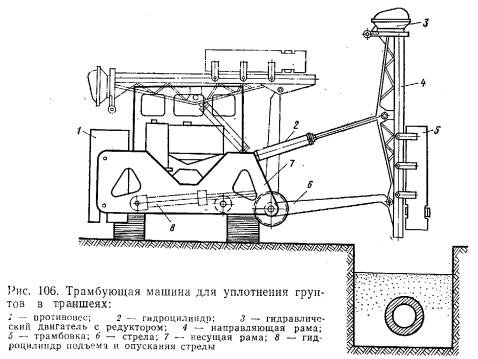

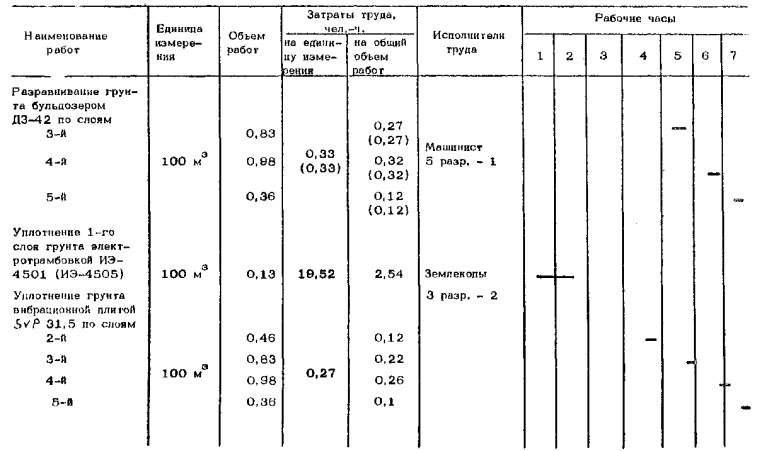

2.5. Soil compaction with mechanisms

(hydraulic rammers, vibroimpact rammers,vibrating plates, rollers)

2.5.1. Compaction of embankment and backfill soils should be carried out

layer by layer. Thickness of the compacted layers

should be prescribed depending on the conditions

production of work, type of soil used

compaction machines and pre-take

according to the table with subsequent refinement according to the results of an experimental compaction.

Table 1

Technical characteristics of machines for soil compaction

Thickness

soil layer in a dense body, cm

Number of passes or impacts in the ground

liaison

incoherent

liaison

incoherent

Cam roller weighing 3 - 5 t

15 — 20

—

6 — 8

10 — 15

8 — 12

Roller on pneumatic machines weighing t: 10

15 — 20

20 — 25

6 — 8

4 — 6

10 — 15

15 — 20

6 — 12

6 — 8

25

30 — 35

35 -40

6 — 8

4 — 6

20 — 25

25 — 30

8 — 10

6 — 8

50

35 — 40

45 — 50

6 — 8

4 — 6

25 — 30

35 — 45

8 — 10

6 — 8

Rammer

plate weighing 2

t at height

fall 2 m

80 — 90

100 — 110

4 — 5

2 — 4

70 — 80

80 — 90

6 — 8

4 — 6

Diesel ramming machine

60 — 70

80 — 100

75 — 85

—

Hinged

tractor rammer

60 — 70

80 — 10

—

—

NOTE. Above the line are the values required to compact the soil to a density of at least 95; below the line - to density

not less than 0.98

from the maximum.

2.5.2. To compact cohesive soils, rollers on pneumatic tires, cam and trellis, ramming and vibratory rammers should be used.

2.5.3. Compaction of the soil should be carried out by penetration of compacting machines along the embankment with

mixing from the edge of the embankment to its middle.

The smallest distance of the compactor's passage from the edge of the embankment should

be 0.5 m. Compaction of slopes should be done from the bottom up.

2.5.4. Each subsequent pass (impact) of the compacting machine should overlap the track of the previous one by 0.1 - 0.2 m.

2.5.5. When compaction of soil in earthen structures (except

hydraulic) with cam rollers the loosened part of the upper layer should be re-compacted

lighter compactors of other types.

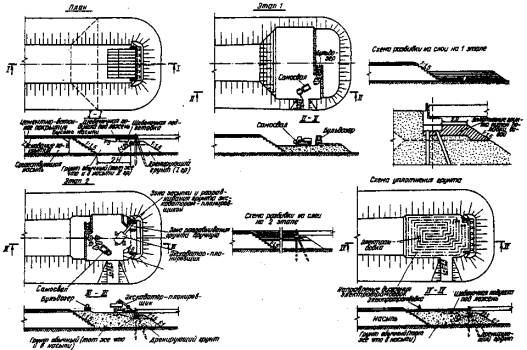

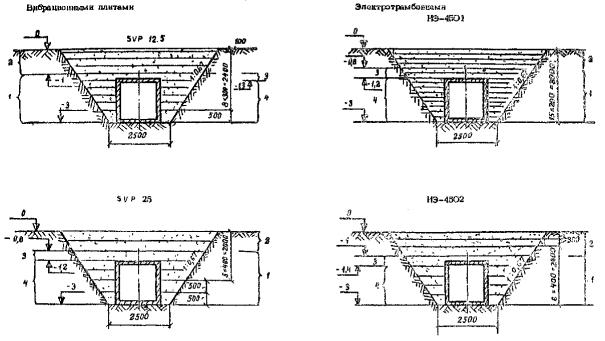

2.5.6. Compaction of soils in natural conditions with backfilling

soil in the sinuses of foundations, around various types of supports, pipelines, collectors, inspection wells, when installing soil bedding under floors, in

junctions of the subgrade with artificial structures and other places should be made by machines with ramming and vibrating ramming working bodies made

as a permanent or replacement attachment to the base serial production

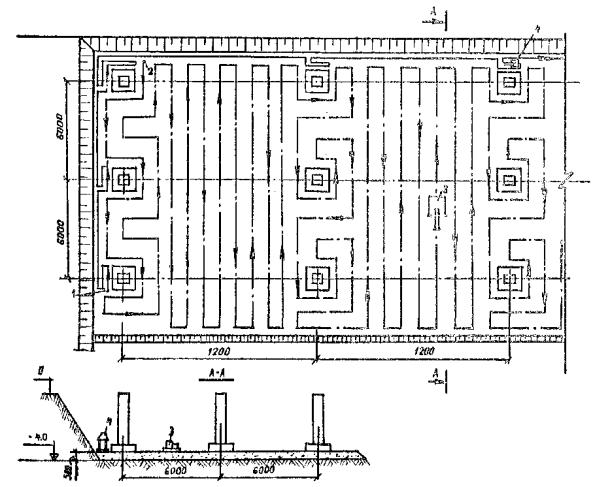

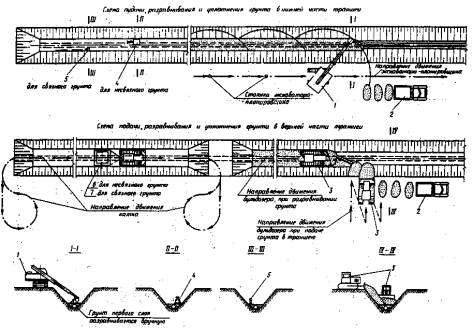

machines (cranes, tractors, excavators) (sheet 5, 6).

2.5.7. Non-cohesive soil of group 1 is compacted with vibrating plates.

2.5.8. Backfilling of the lower soil layers in the trench is carried out

excavator-planner. Leveling

performed manually or, if the working area permits, with a planner excavator. The upper layers are filled up and leveled with a bulldozer.

2.5.9. The soil is compacted, starting with the areas near the collector (pipeline), and then

move towards the edge of the trench, while each subsequent passage of the tamping machine must overlap the track of the previous one by 0.1 - 0.2 m.

2.5.1. Backfill,

leveling and

seal

soil inside

buildings under the floors are performed sequentially in layers. Thickness

layer is adopted depending on the used compaction machine. Backfilling of soil is carried out by dump trucks, leveling - with a bulldozer. In hard-to-reach places (between slopes and foundations) and within 40 cm from the foundations, the soil is leveled manually.

NOTE.

Schemes for organizing the production of work on soil compaction are developed for vibrating plates

(sheet 8, 11, 12).

Criterias of choice

First of all, before buying, you must clearly understand which pneumatic rammer is best suited for the task at hand. It is the definition of the type of equipment that is the most important part of the selection of the tool, since the difference in price is significant

Next, pay attention to the characteristics. They are the result of many factors, but in the end it is these indicators that you should rely on.

Don't forget about dimensions and weight. If you need to compact the soil in the country or a suburban area, then the issue of transportation is important. Of course, here you need to understand the relationship between the performance of the tool and its size, so the choice of a model should be made deliberately, and not on one or several grounds.

It should be said about the material with which you will work

It is very important to consider its density, the degree of moisture, as well as how the pneumatic rammer of your choice will work with this component. For example, the selection of models for concrete, sand or paving slabs varies significantly.

An incorrectly chosen technique can, for example, easily damage paving slabs.

Of course, after determining the appropriate type of rammer, start to proceed not only from the technical characteristics, but also from the reviews. It is very useful to study them in connection with the experience of real people who have already tried the technique and can talk about all the advantages and disadvantages of the model. Sharing such experience will allow you to avoid mistakes when choosing a tool. In terms of price, the range in this component is as wide as the scope of the pneumatic rammer is varied.

The manufacturer of the equipment also matters. If you are already positively familiar with the technique of one of the companies offering rammers, then there is no need to doubt the quality of the chosen model.

Compaction of soil with pneumatic rammers

This is rolling with a roller (self-propelled or trailed principle of operation) on a pneumatic wheel drive. Such rollers are single and biaxial, semi-trailed or trailed, light and heavy, drum and cam rollers.

Depending on the characteristics of the roller, one machine in 4-12 passes can efficiently compact soil up to 50 cm thick with a maximum working width of 2, 8 meters.

Vibratory rammer pneumatic

The basis for the choice of the laying method (shuttle method or spiral-ring method) is also based on the degree of plasticity and deformation of the soil.

Vibrating plate

- the weight;

- the strength and frequency of vibrations;

- slab area;

- engine type.

By weight, the vibrating plate can be:

- easy;

- universal;

- moderate severity;

- heavy.

The vibrating plate can be with a diesel, gasoline or electric engine, and its control can be both manual and remote. Naturally, each type of machine always has its own functional advantages and disadvantages.

Therefore, when choosing a unit, always take into account its specific characteristics indicated in the technical data sheet. For example, you need to know that the higher the vibration force, the smaller the slab should be. The durability of the device's service life depends on this pattern.

Vibrating plate

In addition, it is worth considering the depreciation of the equipment and the approximate performance, depending on the technical requirements. For example, in rammers with gasoline engines, you need to check the candles, and the electric unit must be turned off every 2 hours for rest.

To the set of rules for handling vibration rammers, you can add such moments as, do not forget to pre-warm the engine. Any engine will have enough to warm up 5-7 minutes. It is advisable to buy vibration-damping handles in the kit for the vibration layers. Ergonomics of work has not been canceled.

In addition, you always need to monitor the condition of the filters, the condition of which will directly affect the duration of the service life of the devices. Paper filters, as a rule, are simply shaken off, blown through. And foam filters should be washed more often in warm water and soap, and dried well before installing.

To summarize: there are three options for compaction of soils

Rolling - usually done with a manual or mechanical roller. Rolling the same place several times in a row, the roller compacts the layers of the surface soil to the desired state.

Vibration is an effective compaction method for loose and low-moisture soils. The rollers here are equipped, as a rule, with a vibrating plate or other device for vibro-hammering, in combination with rolling elements. Or vibratory rammers of various modifications are used.

Ramming - is done by laying a slab on the surface, the weight of which should be sufficient to compact the desired soil, but we will consider options for mechanical or manual, production and homemade rammers in another article.

3 179

Peculiarities

A pneumatic rammer is a tool for compaction of various surfaces, mainly loose and prepared for future development.

The foundation is the most important part of the building, because not only strength, but also the integrity of the structure depends on its quality. To quickly and effortlessly compact soil, sand, gravel and other similar materials, pneumatic ramming is best suited

It is worth mentioning the features of this type of equipment, as well as identifying the main technical characteristics.

- Simplicity. Since this tool does not need detailed and special study, any builder and even a person without experience can cope with it. The main factors are the correct preparation and selection of a suitable model.

- Diversity. In terms of their types, pneumatic rammers do not differ in fuel and electric, which is inherent in most models of such equipment, but each manufacturer equips products with different functions. Do not forget about the various modifications designed for specific construction conditions. There are many models from a large number of manufacturers on the market, so the selection of the right tool is not difficult.

- The ability to work manually.Unlike full-fledged vibratory plates, pneumatic rammers are simpler in structure, therefore, their operation and maintenance are also elementary. Here it can be noted that each model can differ significantly qualitatively, as the scope of application can also differ.

- Small size. The rammers are more compact compared to large, full-fledged construction equipment. In this regard, transportation, possible repair and operation are much easier and possible in the living conditions of a house or summer cottage.

- Versatility. Rammers are used in many areas of construction, for example, in laying roads, sidewalks, laying tiles, sand and other bulk materials that form the basis of the foundation. Also, this tool allows you to effectively interact with soil of various densities and moisture levels.

- Price. Considering the simplicity of the design and the large assortment from different manufacturers, the pneumatic rammer is relatively cheap in comparison with similar construction equipment, which is designed to work on large-scale objects.

Now it is worth listing the main characteristics, the study of which will allow you to better understand the technique of such a plan.

- Dimensions and weight. As mentioned earlier, pneumatics does not have extensive dimensions, therefore, working with this tool does not cause any particular difficulty, and also does not require special construction qualifications. The dimensions and weight of the model are individual and depend on the application. Naturally, the more powerful and versatile the device is, the larger its dimensions and weight will be. If we are talking about simple domestic use, then in this case the equipment has less weight, which improves mobility and expands the possibilities for transportation.

- Piston. A part that performs one of the most important functions, namely, is responsible for the movement of the entire device. The physical parameters of the pistons may vary. Accordingly, the better the performance, the more reliable and efficient the rammer is.

- Union. This part serves to supply air to the tool, after which, through other mechanisms, the rammer begins to provide a vibration shock to the surface.

- Air diffuser. As the name implies, this part of the device is responsible for switching compressed air flows, which allows you to change the intensity of the tool.

- Valve handles. The part with which the worker contacts the most. It would seem that the handles are a fairly simple part of the rammer, but their role is much more important. This is especially true for long working sessions, where the poor quality of the handles can affect the ease of use of the equipment.

- Frame. The basis of the rammer, on which many factors depend. First of all, it is the strength of the structure. When doing a lot of work and taking on a lot of force, the chassis must be able to withstand significant peak loads. It should be noted that the material used to make the body is important not only for strength, but also for the lightness of the instrument. Modern technologies make it possible to use high-quality raw materials from which a strong and at the same time lightweight structure can be made, so carefully consider the quality of this part of the device.

2.4. Characteristics of the properties of compacted soils

2.4.1. Required soil density, expressed by the bulk density of the soil skeleton or by a factor

seals, assigned by the project based on

data from soil studies by the method of standard compaction, in which it is installed

maximum density and optimal

humidity.

2.4.2. Compaction of the soil should be done at optimum moisture content.

Permissible deviations for cohesive soils - ± 10

%; for non-cohesive soils - ± 20%.

2.4.3. If there is insufficient moisture, the connected

soils they should be moistened, as a rule, in the places of development (in reserve, quarries).

2.4.4.With insufficient moisture content of incoherent and poorly cohesive soils, it is allowed to moisten them in a dumped

layer.

2.4.5. With excessive soil moisture, it should be dried.

2.4.6. Amount of water - g "tons,

necessary for soaking 1 m3 of soil by volume in the excavation in order to

increase in its moisture content, should be determined by the formula given in SNiP

III-8-76:

g = Yc (Wo - WTo + WNS), where

Yc- volumetric weight of the soil skeleton in the quarry, t / m3;

Wo- optimal humidity;

WTo - soil moisture in

career;

WNS - moisture loss during development,

transportation and laying of soil.

2.4.7. To determine the basic properties of the soil

must be guided by technical

conclusion on engineering and geological

conditions of the construction site of Mosgorgeotrest.

Design and principle of operation

Externally, the pneumatic rammer resembles a conventional bicycle pump. In fact, this is what it is, the difference is that the pump swing frequency set by the cyclist cannot be compared with the stroke rate of the piston driven by compressed air.

A pneumatic rammer, designed to compact soil or any other bulk material with a fine particle fraction, includes:

- The case, it is also a pneumatic cylinder.

- Air diffuser.

- Stock.

- Piston.

- Control handle.

- Connecting nipple.

- Air duct to the compressor.

- Replaceable ramming foot.

- Vibration damping unit.

The design capabilities of the device are preliminarily coordinated with the performance of the compressor: in particular, its minimum capacity and the pressure created in the system must be acceptable to create the required frequency of impacts of the rammer foot and the required pressure on the rod. If the specified parameters are exceeded, excess air will be vented, destroying the sealing elements of the piston unit, and if the characteristics are insufficient, the frequency of piston strokes will sharply decrease, and the sealing process will be ineffective. In this case, the excess air consumption of the compressor unit is not critical. If the compressor does not have quality air filters, the pneumatic rammer will also be unstable, since the air pressure will fluctuate within unacceptable limits.

Safety precautions for work

When compacting the soil with a pneumatic primer and using it for other materials, you should first go through the safety rules.

From the recommendations that already exist, remember the following:

- For safe work, the operator must always cover the body and face with personal protective equipment, namely headphones, glasses, hard hats, durable clothing and shoes.

- If the work will be carried out on a small hill, then the operator and other workers must be above the device. In this case, the work should be done from top to bottom.

Work especially carefully with a vibrating plate that has a soft start button, since if the work is done in a closed room, then it will be much safer for a person to use models with remote control. Naturally, such devices are more expensive, but they fully justify their cost. Tamping with a vibrating plate helps to cope with any tasks that are associated with the compaction of bulk materials. To obtain a high-quality result, you should take into account the characteristics of specific surfaces, and also calculate the appropriate thickness for the layer.

The main attention should be paid to safety. Failure to follow basic rules can result in serious injury and damage to the instrument.

Operating tips

Since the tamping process itself is a preparation for construction, it is worth carefully considering the operating conditions of the device. The basis of the work is the condition of the surface during compaction.It should not contain any foreign objects, stones, debris and anything that could negatively affect the final result. After cleaning the place, monitor the condition of the treated substance. If it is sufficiently wet, settled or dense, then this should be taken into account during the working process.

When using the rammer for the first time, start using it gradually and at low power. The working session should not last long, after which it is worth increasing the load. Ignoring these safety measures can lead to rapid wear and tear of the equipment and a decrease in the quality of its work.

The process of compaction of soil using a pneumatic compaction, see the video below.

Independent production of a vibrating plate with a gasoline drive

To create a device, you will need the following materials:

- Wheels.

- Petrol drive.

- Damping cushions from the car engine.

- A sheet of metal with a thickness of 0.8-1 cm and a size of 0.8 * 0.45 meters.

- A pipe with a diameter of 1.5 * 2.5 cm to create a handle.

- 2 pieces of channel.

- M12 bolts for installing a petrol-type drive.

When performing installation work, you will need the following tools:

- Bulgarian.

- Protective glasses.

- Welding machine, electrodes.

- Cutting wheels for the grinder.

- Electric drill.

- Hammer.

The second step is to adjust the channels. This is done so that they do not protrude beyond the edges of the work plane. Finished channels should be welded at a distance of 7 to 10 cm from each other to the working surface. The channels must be well welded, since the integrity of the entire structure will depend on this. Then you can start installing the engine. To do this, holes should be made in the channels using an electric drill. The motor should be fastened with M12 bolts. When the engine is installed, you can begin installing the handle. The fastening of this element should be carried out with a shock absorber. This is necessary so that the load on the operator's hands is relieved.

As you can see, even making such a device with your own hands is not as difficult as it might seem at first glance.

Compaction of a layer of building material located in a hard-to-reach place, or having a small area with a complex configuration is a task that can be solved using a pneumatic rammer. Even in spite of the fact that a pneumatic rammer requires a small compressor, it is still more profitable than using an electric motor or, moreover, an internal combustion engine.

Compaction of a layer of building material located in a hard-to-reach place, or having a small area with a complex configuration is a task that can be solved using a pneumatic rammer. Even in spite of the fact that a pneumatic rammer requires a small compressor, it is still more profitable than using an electric motor or, moreover, an internal combustion engine.

Description of species

Pneumatic rammers are divided into three types.

Manual

The standard model, which is equipped with all the necessary rammer functions. It is worth mentioning a large assortment of manual units. As noted earlier, the main advantage of a handheld tool is ease of use. As for the cost, the price range varies depending on the final configuration and technical equipment, because this allows you to do more work and has a positive effect on the durability of the device.

Do not forget that resistance to mechanical damage is also one of the most important advantages of manual rammers. This feature allows you to work with materials of different densities and physical properties.

Vibration proof

The main difference between a vibration-proof rammer and a conventional manual rammer is the presence of a special handle, the main purpose of which is to damp vibration using the energy of compressed air, and not a shock-absorbing spring. As a rule, vibration-proof models are used in steel mills to work with layer-by-layer compaction of molding sands.

Since the operating time in a factory is much longer than in a domestic environment, the vibration protection function improves convenience and allows a person to less fatigue while using this device. In addition to steel production, this type of rammer is used in road construction, and is also used to compact the soil in places where large and massive equipment cannot be used due to its irrationality in small areas.

Manual electric

This type of rammer is the most expensive and is designed for a fairly narrow range of applications. The thing is that these units are needed to seal the lining. It is a cladding with various refractory, wear-resistant and heat-insulating materials of the inner parts of furnaces, ladles, boilers and other heating equipment.

Due to the special arrangement of the lining, specialized equipment is required for its sealing, which requires not only reliability, but also the utmost accuracy. A distinctive feature of this type of technique is the presence of attachments of different shapes. Do not forget about electricity consumption, since these models are equipped with batteries.

In custody

Regardless of the scale of work, the problem of soil compaction, one way or another, arises at any construction site. Sand or gravel in small areas can be compacted manually, but for a large area and problem areas, it is optimal to use a modern vibratory soil compactor, which will provide a high-quality result as soon as possible.

A rammer for compacting soil, sand or gravel. Vibratory plates (rammers) are rightfully called professional construction machines. They are used to compact the soil, lay asphalt, paving slabs, and also eliminate various defects and unevenness of the road surface.

A rammer for compacting soil, sand or gravel. Vibratory plates (rammers) are rightfully called professional construction machines. They are used to compact the soil, lay asphalt, paving slabs, and also eliminate various defects and unevenness of the road surface.

Such a tool is quite simple to operate, but still do not forget about the standard safety precautions, as well as about the peculiarities of performing work for different materials, such as soil, sand, crushed stone, asphalt, tiles and "litter" under the floor.