Power, revolutions and tooling diameter

Given the significant difference in parameters between different models of angle grinders, the question arises, which grinder is better to buy for home or work? It is necessary to decide: to perform, what operations it is necessary, and what are the volumes of the proposed work.

Rotational speed

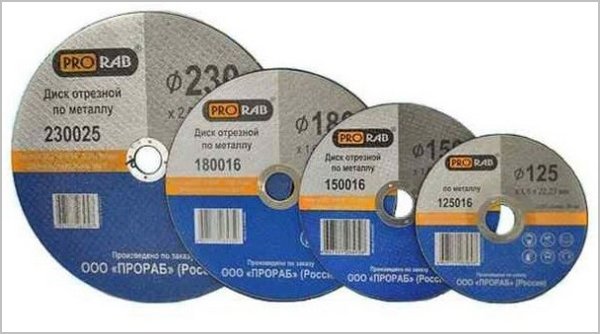

One of the main parameters of angle grinder is the linear speed of rotation of the circle, which depends on the diameter of the circle. The optimal value for this indicator is 80 m / s, a significant deviation of the speed towards an increase will lead to the destruction of the circle. Lower rpm causes faster disc wear. There are five types of angle grinders, which differ in the size of the cut-off wheels used.

The dependence of the spindle speed on the diameter of the working disk is as follows:

115 mm - 13290 rpm

125 mm - 12230 rpm

150 mm - 10190 rpm

180 mm - 8490 rpm

230 mm - 6650 rpm

Data on the permissible rotational speeds of the cutting wheel for each specific model must be indicated on a special plate that is attached to the body. In this case, the magnitude of the torque must be sufficient to overcome the emerging frictional force and maintain the required cutting speed. This characteristic is determined by the rated power of the electric motor of the grinder.

Power angle grinder

The rated power of the grinders ranges from 650 to 2700 W, and depends on the diameter of the disc used. Accordingly, angle grinders designed for large diameter discs have more powerful drives. With such parameters, the electric motor provides a force on the cutting edge of the wheel sufficient to effectively affect the material being processed.

For normal operation, it is necessary that the power consumption of the angle grinder with a disc diameter of 125 mm is at least 750 W. Moreover, the larger the diameter of the permissible equipment, the more powerful the engine must be. So in models with a tooling diameter of 230 mm, which are intended for intensive use on construction sites, the power consumption of the engine must be at least 2200 W.

Tool diameter

Be sure to decide what diameter of the tooling will be sufficient for your needs. Remember that you cannot use circles whose diameter is larger than the allowable one. Of course, you can do this by removing the protective cover, but such manipulations are prohibited, as they can lead to injury to the operator.

It is especially dangerous to use angle grinders without a protective casing when working with metal disks with hard-melting solders, which, flying apart, can cause significant harm to health and even death. If you have such a desire, just find on the Internet photos of people who were injured, neglecting safety when working with angle grinders, and this desire will disappear forever.

Tool diameter is deeply related to parameters such as depth of cut. This moment is especially important if you are going to cut curb stones and other materials with a large thickness with the help of angle grinders. The cutting depth of the model with a disc diameter of 125 mm is only 30 mm - 35 mm, depending on the model. This is because the dimensions of the gearbox will not allow immersing the circle in the material completely.

Of course, you can cut the curbstone by making cuts on both sides. But making such a high-quality cut is more difficult, and it will take more time. Therefore, if you you have to constantly cut such materials, then you should look towards the "grinders" with a maximum disc diameter of 230 mm.

LBMs with a small working circle are of little use for cutting superhard materials, and large models are inconvenient for grinding a car body.

How to choose a grinder for a house or a summer residence correctly

In order to make the right choice of a grinding machine that meets all the necessary requirements, it is necessary to determine the tasks that will be assigned to it. Most importantly, determine what you will be cutting with the angle grinder, and how often.

As practice shows, household grinders with a working disk size of 125 mm and a power of up to 1.5 kW are best suited for home and summer cottages. Such machines are lightweight and lightweight, easy to operate, and equipped with additional features. For a circle diameter of 125 mm, a lot of additional attachments have been released that turn the grinder into a universal tool.

The table shows the comparative characteristics of some brands of angle grinders from different companies on the market for electric tools.

Table: technical data of angle grinders with a disc diameter of 125 mm

| Trademark | Caliber | Energomash | Sturm | Resource | Hammer |

|---|---|---|---|---|---|

| Model | LNA 125 / 750K | UShM-90125 | AG9512 | RSHU-125 | USM 600A |

| price, rub. | 860 | 1000 | 930 | 900 | 990 |

| Warranty period, months | 12 | 7 | 7 | 12 | 12 |

| Service life, years | 3 | 3 | 3 | 10 | n.d. |

| Voltage, V | 220±10% | 230 | 230 | 220~230 | 220~230 |

| frequency Hz | 50±5% | 50 | 50 | 50 | 50/60 |

| Power, W | 750 | 1100 | 750 | 600 | 600 |

| Rotation speed, rpm | 12000 | 11000 | 11000 | 11000 | 11000 |

| Declared weight, kg | 2,2 | 2,3 | 2,2 | 2 | 2,1 |

| Measured weight, kg | 2,12 | 2,25 | 2 | 1,8 | 1,9 |

| Power cord length measured, m | 3 | 1,53 | 2 | 2,5 | 2,56 |

| Purpose according to the instructions | For cutting and grinding metal | For cutting and grinding metal | For cutting and grinding metal | n / a | Cutting, roughing, grinding metal and stone materials |

| Not allowed | Work on stone, tiles, concrete, asbestos materials | Work on stone, tiles | Working on stone, tiles, wet grinding | n / a | Stone material cutting, polishing |

| Working angle, degrees | 10–15 | 15 | 15 | 15–30 | 15–30 |

| Recommended work / rest time, min | 15 / 5 | 15–20 / 5; no more than 20 hours a week | 15–20 / 5; no more than 20 hours a week | 15 / 15 | n / a / 30 |

Technical characteristics of angle grinder

In Russia, it is customary to call a grinder an angle grinder. The name stuck because of the first angle grinders that appeared in the USSR in the 70s and were produced in Bulgaria.

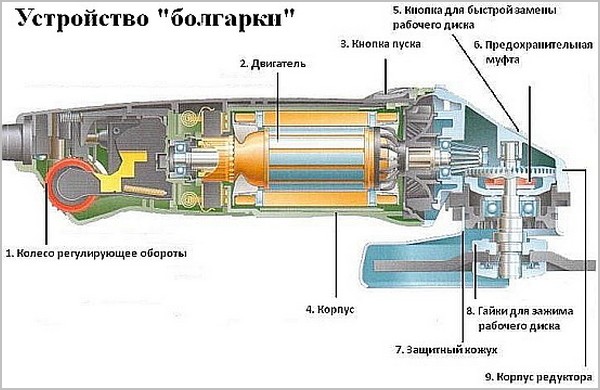

An angle grinder is a device designed for cutting off or grinding any products with an abrasive wheel.

The LBM includes:

- Frame.

- Electric motor.

- Reducer.

- Protective cover.

- Electronic soft starter (if equipped).

- Power cord.

Depending on the cost of the model, it can be equipped with additional options: soft start, vibration dampers, an engine shutdown system when brushes are worn out, etc.

Main characteristics:

1. The maximum diameter of the abrasive wheel. The characteristic determines what the largest circle can be installed in the angle grinder. The larger the circle, the greater the thickness of the cut part can be.

There are five standard sizes for which grinders are produced:

- 115 mm. Grinder for the smallest of the wheels produced, ideal for very small jobs or grinding small parts.

- 125 mm. The most common type of homework device. With a disc of this size, it is convenient to cut parts when repairing at home or grinding. The range of abrasive wheels of this size in stores is the largest.

- 150 mm. The tool is suitable for those who want to save money when buying two grinders, 150 and 180 mm. Of course, it is not as convenient to work with it as with a small or large angle grinder, however, when carrying out diverse work and a limited budget, buying such a grinder will be a good decision.

- 180 mm. Well suited for capital construction, for example, in a private house, but still, for cutting bricks, a grinder of this size will be too small.

- 230 mm. A device for the largest of the existing circles, with the help of this grinder, you can easily cut pipes of any diameter, channels, bricks or boards, however, it is not very suitable for grinding due to the large size of the circle and its weight.Buying a tool of this size makes sense when building something large, for example, a house.

2. Power of the electric motor. An important indicator when choosing a device. The higher the power, the faster you can cut through hard materials without the risk of blade jamming. However, with an increase in engine power, the weight of the grinder and its dimensions increase.

3. The presence of a soft start system. The starting current of the motor of powerful angle grinders can reach significant values (approximately 6 times higher than the nominal), which can trigger the automatic devices that protect the electrical network in an apartment or private house. Therefore, for a device used at home, a system is important to reduce inrush currents by gradually accelerating the motor. In addition, the smooth start-up helps reduce gear wear.

4. Type of nut for fastening the disc. The classic fastening of the disc to the spindle of the device is a nut for a "horned" key. However, this nut can be difficult to unscrew when using grinding wheels.

Therefore, if the device is purchased mainly for grinding any parts, then it makes sense to pay attention to grinders with quick-locking nuts or support flanges

Quick release nut

Quick release nut

5. Rated spindle speed. Determines what type of material the angle grinder is best suited for. The best option would be to buy a grinder with the highest possible speed with a gearshift system.

6. Ergonomic performance

With long-term work, it is very important that the grinder is comfortable to use. When buying, you should check how convenient the power button of the device is and how it feels in your hands

Rubber anti-slip pads on the case will be a nice addition.

7. Fastening the protective cover. Fasteners can be made by friction, "under a screwdriver" or using special grooves.

For home use, it doesn't make much of a difference, but a sheath that is held in place by friction alone is the least preferred (but cheapest) option.

8. Vibration damping. The presence of special tabs on the LBM body, absorbing vibration, will significantly increase the convenience of working with the tool during long-term work.

9. Additional options. More expensive models have additional options. For example, a system for shutting off the electric motor with increased wear of the brushes, automatic balancing of an unevenly worn disc, a safety clutch when the disc is jammed, dust removal, etc. These functions do not affect the quality of the device, but undoubtedly increase the convenience of its use.

Video:

Specifications

Like any power tool, an angle grinder has several characteristics that you should pay attention to when buying:

- maximum diameter;

- power;

- spindle rotation speed.

In the future, this will affect performance.

The power and rotation speed will depend on the diameter, therefore this is the main characteristic of the angle grinder. In simple units, discs up to 150 mm are used and this is enough for most household operations. Diameter from 180 mm and more is already used in professional machines and allows cutting concrete, brick and other thick solid products. For cutting thin materials such as ceramic tiles or sheet metal, use smaller discs as they are less subject to vibration and reduce the weight of the machine.

Angle grinder Hitachi HTC-G12SR4-NU

The power of angle grinders has a wide range (0.6-2.7 kW) and depends on the discs used in the work. Grinding machines up to 1.5 kW are used with wheels up to 125 mm and are not professional equipment. They heat up quickly and don't have a lot of extra features. More powerful grinders are able to work for a long time under load and are used for cutting concrete and stone.Grinding the surface or cutting a sheet of metal can be done with low-power units.

There is a speed limit for each diameter, violation of which may result in damage to the tool and injury. Many angle grinders now have a lever-like speed controller that allows you to change the speed during operation.