For what purpose is angle grinder low speed?

The integrated wheel speed control option enables the gentle handling of materials such as wood or plastic. At lower speeds, comfort and safety are increased. This option is most practical in the radio and electrical installation business, service stations and restoration studios.

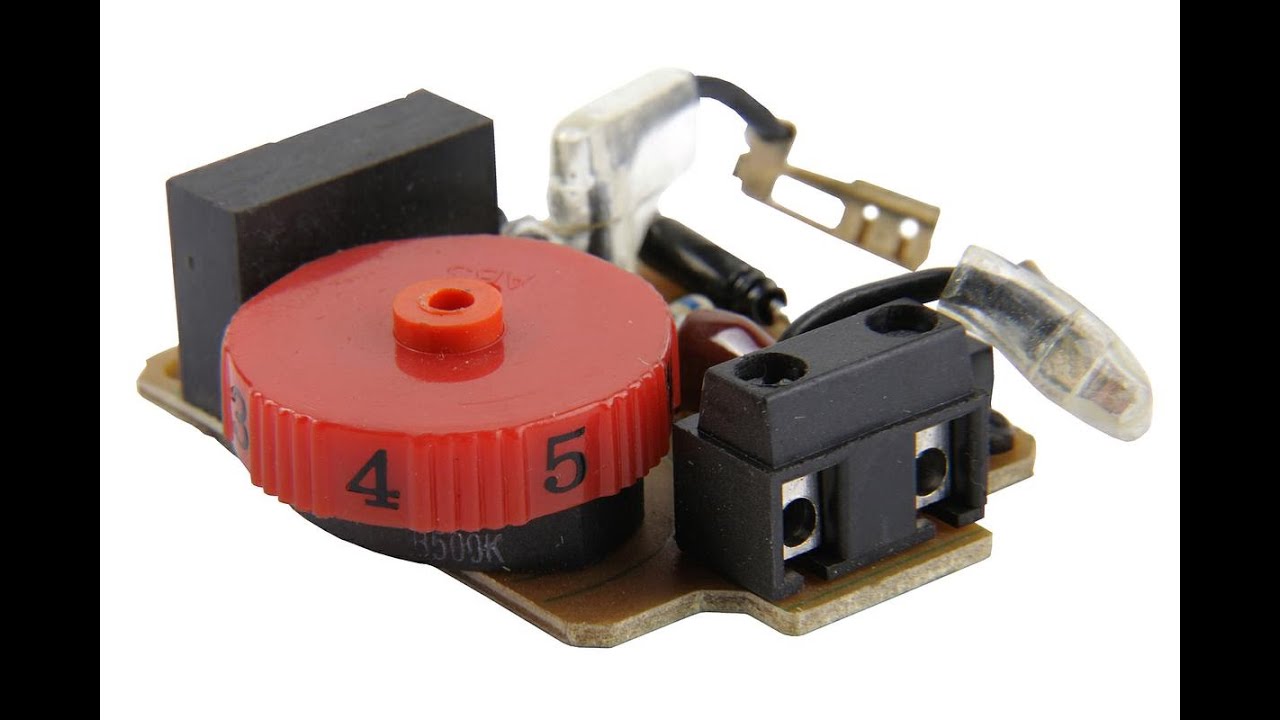

In addition, among professionals who use power tools, there is a judgment that the more trivial the device is arranged, the more reliable it is. And it is advisable to take the additional service "stuffing" beyond the borders of the grinder. With this approach, equipment maintenance is greatly simplified. In this regard, some firms deliberately produce remote individual electric regulators that are connected to the network cable of angle grinders.

This is interesting: How to work with a grinder correctly - cut, saw, hold, put a disc

Selection Tips

How to choose the right angle grinder? To do this, it is worth using several basic criteria.

To choose the right tool, it is worth deciding on the specific type of work to be performed with this tool. Grinders can be of different types: mains, with batteries, gasoline and pneumatic.

Network models are perhaps the most common. Such grinders work from a home network, that is, from a simple outlet. Such models of the tool have high power, compactness and high rotational speed of the cutting discs.

Cordless devices are deprived of this disadvantage. They have a special mount for power supplies that are charged from the mains. After charging, you can work with such a tool without any wires. Usually, such grinders have compact dimensions and small diameters of cutting discs. As a rule, such models are more expensive than standard tools. Also, the period of their operation is limited by the capacity of the power supply.

Gasoline models of grinders are rare. Such devices are large in size, because they need a fuel tank, as well as an internal combustion engine. Among the advantages, it is worth highlighting the high power of these models, a wide range of choice of disks and autonomy. The negative aspects include their weight and volume, high noise levels and, of course, additional fuel costs for the operation of the device.

Pneumatic models of angle grinders are often used for industrial purposes and very rarely for household work. These are unusual grinders that work on a stream of compressed air and need a special compressor. For such models, the problem of overheating is completely eliminated, and the period of operation can be limited only by the human factor. Also, such models are the lightest and quietest.

For simple work on the processing and grinding of surfaces, light models of grinders with a small diameter of the cutting wheel are suitable. For work on cutting durable materials, it is worth choosing more powerful and, accordingly, bulky equipment with a large disc diameter. The diameters of the discs can be from 125 (minimum size) to 230 (maximum size) mm - that is, the range of sizes is quite wide. The universal blade diameter is 180 mm. Such a circle can be used for both surface treatment and material cutting.

When choosing a disc, it is worth conducting a careful visual inspection. Even minor damage and chips can lead to extremely sad consequences.By the way, almost 90% of accidents when working with a grinder are due to a defect in the cutting discs.

Convenience of work is also an important selection criterion. The grinder should be equipped with comfortable handles, should not slip out of the palm and have a lot of weight. Many grinders have an electronic relay to protect against power surges and overloads. This is a useful feature, so it is worth choosing a tool with this fuse.

Models and their characteristics

Today, angle grinders equipped with speed control are in great demand among craftsmen. This type of tool is well suited for cutting, polishing and grinding workpieces. The construction market is represented by angle grinders produced by both domestic and foreign companies. Models of several brands have proven themselves well.

Bosch GWS 850 CE. This device is lightweight for easy handling. The machine has a power of 850W and is good for polishing marble and granite. The set of the tool includes a disc speed regulator with six positions. The minimum speed of revolutions is 2800, the maximum is 11000 per minute, a special nozzle designed for high speed is used for processing wood with a machine. The manufacturer additionally equips the device with a handle, a wrench, discs and washers for attaching nozzles.

The Hitachi G13SS modification can complete the review of popular angle grinders with speed control. Due to its high power indicators and the possibility of using it with discs with a diameter of 150 and 230 mm, it occupies a high rating among the types of this equipment. The device is perfect for both renovation and construction work. The device can cut metal workpieces and grind parts from different materials. A distinctive feature of the device is its narrow grip and low weight, which makes it comfortable to work with.

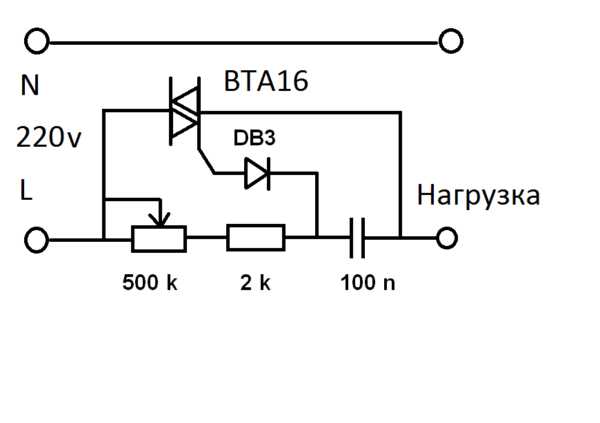

Bt136 600E: voltage regulation switching circuit

Manufacturers do not burden manufacturers with cheap grinders that do not have enough power with voltage control switching circuits, otherwise such grinders would not be cheap anymore. When starting the grinder, if it is smooth, the process is carried out through an adapter connected by contacts to the rectifier unit. The rectifier unit converts the current.

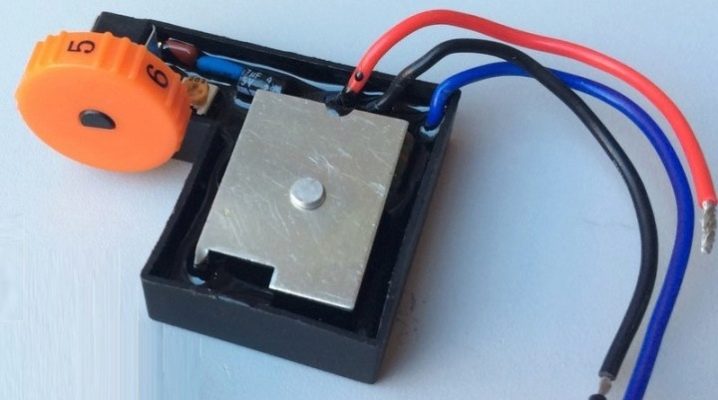

The speed controller will allow you to work for a long time without overloading the tool

But sometimes it makes sense to upgrade the grinder using the established scheme. The electrical circuit is assembled quite simply. It is not difficult to make it, and you can, if desired, connect not only a grinder, but any other tool to the finished circuit. However, the tool must have a brushed motor, not an induction motor.

A homemade approach to creating a schema would be as follows:

- To get started, download the board, if it is not there;

- The Bt136 600E triac is used as a power link;

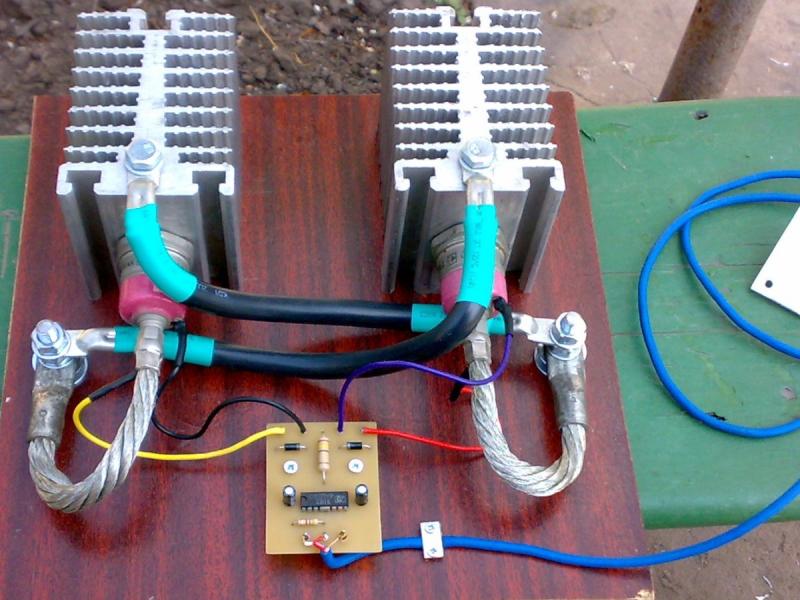

- During operation, the triac will heat up, to avoid this, a heat sink is installed;

- The resistors used give resistance to current, providing current damping;

- The regulator is tuned by means of a multi-turn trimming resistor;

- To check, connect a light bulb;

- After connecting, the light must be turned off - the triac must be cold;

- Connecting the resulting circuit to the grinder.

If the board is correctly connected, the triac and resistors of the angle grinder should start smoothly, and the use of the rotational speed should be regulated. After that, you can test the grinder in action. Such knowledge may be needed when repairing malfunctions of an electric motor. For example, when voltage rises or improper balancing occurs.

How to make a regulator out of a dimmer?

A very effective and easy solution to this issue will be the creation of an external frequency converter.In the role of a converter, you can use a dimmer - a device for regulating the level of illumination. When creating, you will need an electrical outlet and a plug. I must say that the implementation of such a device can be performed in different ways. Particularly simple are 2: with the use of the machine and without it.

- Screw 2 wires to the ends of the electrical outlet so that one is longer. Then connect the long end to one of the pins on the plug. The end of the 2nd wire is fixed on the contacts of the dimmer, and its other output is connected to the 2nd contact of the plug.

- When using the 2nd option, it is required to make a number of modifications to the circuit, specifically to place an automatic machine on the cord between the plug and the dimmer. Basically, ordinary switches are provided in the dimmers, but we need an automatic one, which, if something goes wrong, will turn off our device from the mains.

So, the frequency converter of the angle grinder is ready, and for practicality it can be placed in a specialized case or fixed on a wood panel. It should only be taken into account that such a device is homemade, and when working with the power grid, one must be careful.

To learn how to make a speed controller for a grinder with your own hands, see the video below.

Devices for 800 W grinders

800 W grinders work with low frequency starters. Triacs are quite often used at 15 A. If we talk about the circuit of models, then it is worth noting that they use expansion transistors, in which the current carrying capacity starts from 45 microns. Capacitors are used with and without filters, and the capacitance of the elements is no more than 3 pF. It is also worth noting that starters differ in sensitivity.

If we consider professional grinders, then 400 mV modifications are suitable for them. In this case, the current conductivity can be low. There are also devices with variable transistors. They quickly warm up, but they are not able to maintain the high speed of the grinder, and their current conductivity is about 4 microns. If we talk about other parameters, then the nominal voltage starts from 230 V. The minimum frequency for models with broadband triacs is 55 Hz.

The need to adjust the speed of rotation of the disk

There are several reasons:

- When cutting metal (regardless of the thickness of the material), the result of the work carried out depends on the speed of rotation of the blade. If you are cutting thick metal, then the speed should be the highest. If you work with a material with a small thickness, then the speed must be reduced, since at high speed the surface of the disc is quickly blurred.

- If the tiles are cut at high speed, then this poses a certain danger. Also, the disk, spinning at great speed, begins to beat off small pieces of material, thereby making its surface chipped. Since the stone has a variety of types, a specific speed is used for each type. For many minerals, high revs are used.

- If grinding or polishing is carried out, then adjusting the speed of the grinder is simply necessary. If the revolutions are set incorrectly, the surface of the material will be damaged. For example, a material that has a paintwork may be damaged.

- If discs that have different diameters are constantly used, then the speed regulator for the grinder must be available. If you change the grinder disc to another one with a larger diameter, the speed must be reduced. You cannot hold in your hands a grinding machine, which has a disc with a huge diameter.

- The choice of the speed of rotation when polishing concrete material depends on the use of a particular type of crowns.When the speed of rotation is reduced, the torque should not decrease.

- If you use a diamond disc, then the number of revolutions must be reduced, otherwise the surface will start to fail due to overheating. Of course, if you are using an angle grinder to cut pipes, angles or profiles, then you do not need a regulator. But if the grinder is used for various purposes, then the speed regulator for angle grinders is simply necessary. All these reasons show that the presence of a grinder regulator is required.

Manufacturing a soft-start socket

The most important requirement for such an outlet is its mobility. Therefore, you will need a carrier.

With the help of it, it will be possible to smoothly launch the tool anywhere - in the garage, in the country, when building your house on different parts of the construction site.

The first step is to disassemble the carrier.

The main power wires in it can be either soldered or connected on screw terminals.

Depending on this, your additional outlet will also be connected. It should be just an additional socket near the carrier in order to be able to simultaneously connect the instrument in different modes.

By the way, if you mistakenly turn on a grinder or circular that has a factory built-in soft start into an outlet, also equipped with such a soft starter, then surprisingly everything will work. The only thing is that there will be a delay in starting the saw or turning the blade for a couple of seconds, which is not very convenient in work and can be puzzling without habit.

Here are real tests of such a connection, carried out by one master with YouTube BaRmAgLoT777. His comment after such trials on a Dremel-type engraver, Bosch drill, Makita milling cutter, Interskol circular saw:

Next, to assemble the outlet, take a stranded copper wire with a cross section of 2.5 mm2 and strip its ends.

Then it is necessary to tin the contact pad on the carrier, where this wire will be soldered.

Solder the cable strands securely to these pads.

Place the wires carefully and cover the extension cord.

Take a square external socket for installation on the outer surface of the walls, and try on a soft starter into its case. Since it has compact rectangular dimensions, it should fit there without any problems.

Mount and fix the socket housing on the same site with the extension cord.

Connect the PP block to the break of any wire, phase or zero. Do not confuse it, phase and zero are not supplied to it at the same time, i.e. 220V.

It is installed on one of the wires.

Also for this BPP, there is no difference from which side to make the entrance, and from which exit. The strands are soldered and insulated with heat shrinkage.

After that, all the insides of the outlet are assembled into a case and it remains to close the entire structure with a lid.

This completes the entire modification of the carrier and the manufacture of the outlet. It will take you no more than 15 minutes in time.

Features and service life

They can operate on direct and alternating current.

For their power supply, in most cases, a normal 230 V 50 Hz mains is used. Previously, a 380 V network was used for a professional tool. Now, with the growth of consumer power in single-phase networks (offices and the residential sector), professional 220 V power tools have also appeared.

The collector motors have high torque and starting torque, are compact, easily manufactured for increased voltage. The torque is decisive here. With a low weight of the machine, it is just suitable for hand-held power tools. But such electric motors have drawbacks and weaknesses. One of these weak points is the brush assembly.

Compressed graphite brushes with fillers rub against the copper plates of the collector and are subject to mechanical wear and electrical erosion. This increases sparking and increases the fire and explosion hazard of the power tool.The penetration of mineral dust into the interior accelerates wear. Although the fans are designed to blow air out, dust and cement can easily get inside. During standstill, if the tool is unsuccessfully laid down, dust easily gets inside. In practice, this is a constant phenomenon.

Compressed graphite motor brushes

Another drawback of the power tool is the frequent breakdown of the gearbox. This is precisely because of the large starting torque. Dignity turns into a disadvantage. With a breakdown of the gearbox, you have to change the tool, they usually cannot be repaired. Unfortunately, the industry, in an effort to reduce the cost of production, does this at the expense of quality. If you want to use a good power tool, pay a lot of money.

Soft start and speed control + (Video)

Smooth start-up of power tools is the main guarantee of its longevity. Remember when a light bulb burns out? Most often at the moment of switching on. Because after connecting to the electrical network, the load increases sharply. The worn-out places of the spiral do not stand up and it burns out.

The same processes take place in the grinder. At the moment of switching on, the current rises sharply, because the driving forces need not only to move the armature, but also quickly gain the required speed. The effect of such a hard start can be the most deplorable - a winding break.

To reduce the likelihood of tool failure due to a hard start, it is necessary to modify the grinder and equip it with a small built-in soft starter.

Another refinement is the rotation regulator. From their own practice, everyone knows how inconvenient it is to work with a tool that does not have a rotation adjustment. If there is no such device in an electric drill, then it is difficult to choose the rotation speed and drill feed. This will either cause the drill to jam or break.

The lathe works in a similar way, in which there is a whole set of special gears for adjusting the spindle rotation. This largely determines not only the safety of the cutter, but also the quality of material processing.

Combine two advantages - smooth start-up and shaft speed adjustment you can use an electronic circuit. It is quite possible to assemble it with your own hands and install it directly into the body of the machine. With such a scheme, it will start smoothly without creating overloads in the windings and the network. And with the same scheme, it will be possible to adjust the speed in order to select the mode of operation with any material.

Why does a grinder need a smooth start and a speed controller?

In modern angle grinders, 2 necessary options are used that increase the characteristics and safety of the equipment:

- speed regulator (frequency converter) - a device designed to convert the speed of the motor in different modes of operation;

- soft starter - a circuit that provides a leisurely increase in engine speed from zero to the limit value when the unit is connected.

They are used in electromechanical equipment, in the structure of which an alternating current electric motor with a collector is practiced. They help to reduce the wear of the mechanical part of the unit when it is turned on. Reduces the stress on the electrical components of the machine by bringing them into operation smoothly. As studies of the qualities of materials have revealed, a particularly strong development of contacting nodes is produced in the process of a sudden transition from a stationary state to rapid activity. For example, one start of an internal combustion engine in a car is equal to the wear of a piston and a group of sealing rings to 700 kilometers.

When power is applied, an abrupt transition is made from a stationary state to the rotation of a circle with a speed of 2.5-10 thousand revolutions in 60 seconds. Anyone who has used an angle grinder is well aware of the feeling that the tool "flies out of hand".It is at this moment that most of the accidents associated with the mechanical part of the unit happen.

The rotor and stator windings are equally stressed. An alternating current electric motor with a collector starts up in a short-circuit mode, the EMF already pushes the shaft forward, but the inertia force still does not allow it to rotate. A jump in the starting electric current arises in the coils of the electric motor. Despite the fact that by design they are designed for such work, over time a moment comes (for example, with a voltage drop in the mains) when the winding insulator is not able to withstand and a short circuit occurs between the turns.

With the introduction into the electrical circuit of the instrumentation schemes for adapting a soft start and changing the frequency of rotation of the motor, all the above troubles spontaneously disappear. In addition, the issue of a sudden and significant decrease in voltage in the general power grid during the start-up of the tool is being resolved. Hence, it is clear that household electrical appliances will not be at risk of failure. And the automatic switches on the electric meter will not work and turn off the current in an apartment or house.

The soft start scheme is used in angle grinders of the middle and high price segment, the speed control unit is more and more in professional modifications of grinders. The speed control makes it possible to process soft materials with an angle grinder, to carry out delicate grinding and polishing, since at high speeds the wood or paint will simply burn out. The auxiliary electrical circuit increases the cost of the toolkit, but extends the service life and the degree of safety in use.

How to make a speed controller with your own hands + (Video)

In order not to complicate the perception of the principle of operation in complex terms, the principle operation of the circuit can be explained simply. It has a sensing element that reads the amount of load. Depending on the read value, this element controls the shut-off device.

The principle of operation is similar to that of a water tap. In this case, you are the sensitive element that controls the water tap. The flow of water, depending on the need, becomes more or less. The same process takes place with the current.

It is necessary to correctly understand the moment that we will in no way be able to increase the rotation speed more than that indicated in the characteristics of the grinder. We can only lower the turnover. If the maximum rpm is 3000, then the range in which we can regulate the rpm will be below this value.

In its simplest form, you can use a thyristor-based regulator circuit. He will both feel and regulate. Two in one. This diagram has only five parts. It is very compact and fits easily into the case. Such a regulator will not work from zero rpm, but this is not necessary for the grinder.

If lower speeds are needed in the work, then it is necessary to use a different circuit on an integrated microcircuit, where a triac will be the locking element. Such a scheme will be able to regulate the speed from almost zero to the desired value.

And in that, and in the other scheme, the main load falls on the shut-off element. It should be rated for voltages up to 600 V and for currents up to 12 A. If your grinder is more powerful than 1 kW, then the locking element must withstand a load of up to 20 A.

All the details of the circuit on the thyristor can be placed on a printed circuit board or simply surface-mounted. According to the second option, the parts are soldered onto the printed circuit board. The printed circuit board can be manufactured in different ways. It can be etched out of foil-coated PCB, you can even cut it with a cutter, but it will turn out very roughly. In principle, she can be asked to make a familiar radio amateur for a very modest remuneration.

Electronic elements are inserted into the manufactured printed circuit board.They can be purchased from specialized stores or radio markets. The ratings of each should not differ in terms of rating and design power. It is advisable to install a thyristor or triac on a heat sink - an aluminum or copper heatsink.

When the finished board is ready, you need to choose a convenient place in the grinder's body to install it. It is desirable to install it so that it is convenient to use, and so that it does not interfere with the work process.

Before installing the circuit in the car, you need to check it. To do this, instead of a grinder, an ordinary incandescent lamp must be connected to the output. A copy with a power of 60 - 40 W at 220 V. The efficiency will be obvious by changing the glow of the light bulb.

Now it remains to mount the device in the selected place and make a test run of the grinder. It will stop breaking out of your hands during start-up, and the speed will be smoothly adjusted by rotating the regulator.

How to make a do-it-yourself smooth start diagram for an angle grinder

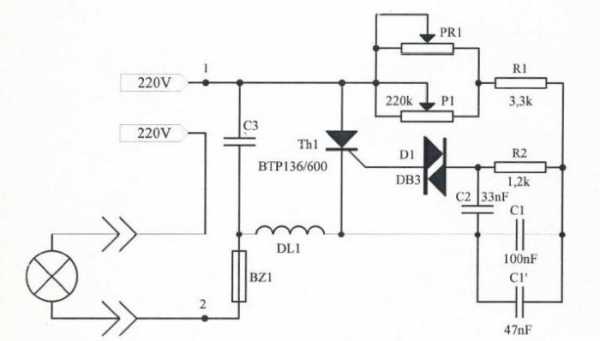

The popular circuit is implemented on the basis of the KR118PM1 phase control microcircuit, and the power section is made on triacs. Such a device is quite simple to mount, does not require additional adjustment after assembly, and therefore, it can be made by a master without specialized education, it is enough to be able to hold a soldering iron in his hands.

Electric circuit for adjusting the soft start for the grinder

The proposed unit can be connected to any power tool designed for 220 volts alternating voltage. A separate removal of the power button is not required, the modified power tool is turned on with a standard key. The circuit can be installed both inside the body of the grinder, as well as in the break of the supply cable in a separate case.

The most practical way is to connect the soft starter to an outlet that supplies power to the power tool. The input (connector XP1) is powered from a 220 volt network. The outlet (connector XS1) is connected to a supply socket, into which the plug of the angle grinder is inserted.

When the start button of the grinder is closed, voltage is supplied to the DA1 microcircuit through the common power circuit. A smooth increase in voltage occurs on the control capacitor. As it is charged, it reaches its working value. Due to this, the thyristors in the microcircuit do not open immediately, but with a delay, the time of which is determined by the charge of the capacitor. Triac VS1, controlled by thyristors, opens with the same pause.

Watch a video with a detailed explanation of how to make and which scheme to apply

In each half-cycle of the AC voltage, the delay decreases in arithmetic progression, as a result of which the voltage at the input to the power tool rises smoothly. This effect determines the smooth start of the grinder's engine. Consequently, the disc speed increases gradually, and the gearbox shaft does not experience inertial shock.

Speed up time to the working value is determined by the capacity capacitor C2. The value of 47 μF provides a soft start in 2 seconds. With such a delay, there is little discomfort for starting to work with the tool, and at the same time, the power tool itself is not subjected to excessive stress from a sudden start.

After turning off the angle grinder, the capacitor C2 is discharged by the resistance of the resistor R1. With a nominal 68 kOhm, the discharge time is 3 seconds. After that, the soft starter is ready for a new start cycle of the grinder.

With a little refinement, the circuit can be upgraded to an engine speed governor. To do this, the resistor R1 is replaced with a variable resistor. By adjusting the resistance, we control the power of the engine by changing its speed.

Thus, in one housing, it is possible to make an engine speed regulator and a soft starter for an electric tool.

The rest of the circuit details work as follows:

- Resistor R2 controls the amount of current flowing through the control input of the triac VS1;

- Capacitors C1 and C2 are control components for the KR118PM1 microcircuit used in a typical switching circuit.

For simplicity and compactness of installation, resistors and capacitors are soldered directly to the legs of the microcircuit.

Triac VS1 can be any, with the following characteristics: maximum voltage up to 400 volts, minimum throughput current 25 amperes. The amount of current depends on the power of the angle grinder.

Due to the smooth start of the grinder, the current will not exceed the rated operating value for the selected power tool. For emergency cases, for example, jamming of the angle grinder disk, a current reserve is required. Therefore, the nominal value in amperes should be doubled.

The ratings of the radio components used in the proposed wiring diagram were tested on a 2 kW angle grinder. The power reserve is up to 5 kW, this is due to the peculiarity of the operation of the KR118PM1 microcircuit.

Working scheme, repeatedly executed by home craftsmen.

If you have an old angle grinder in your arsenal, do not rush to write it off. Using a simple electrical circuit, the device can be easily upgraded by adding the function of changing the frequency of revolutions. Thanks to a simple regulator, which can be assembled with your own hands in a few hours, the functionality of the device will increase significantly. By reducing the rotational speed, the grinder can be used as a grinding and sharpening machine for various types of materials. New possibilities appear for the use of additional attachments and accessories.