The main types of metal files for jigsaws

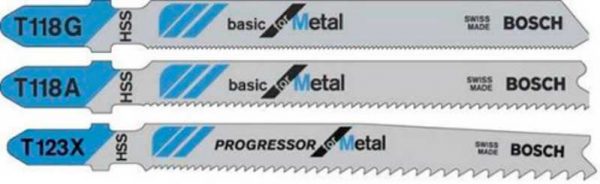

Now let's go directly to the cutting tools. The fact that this blade is intended for working with metal, you will be told by the inscription on the file itself or on the packaging. Such products are marked with the words: "For Metal" or "For metal", depending on the manufacturer.

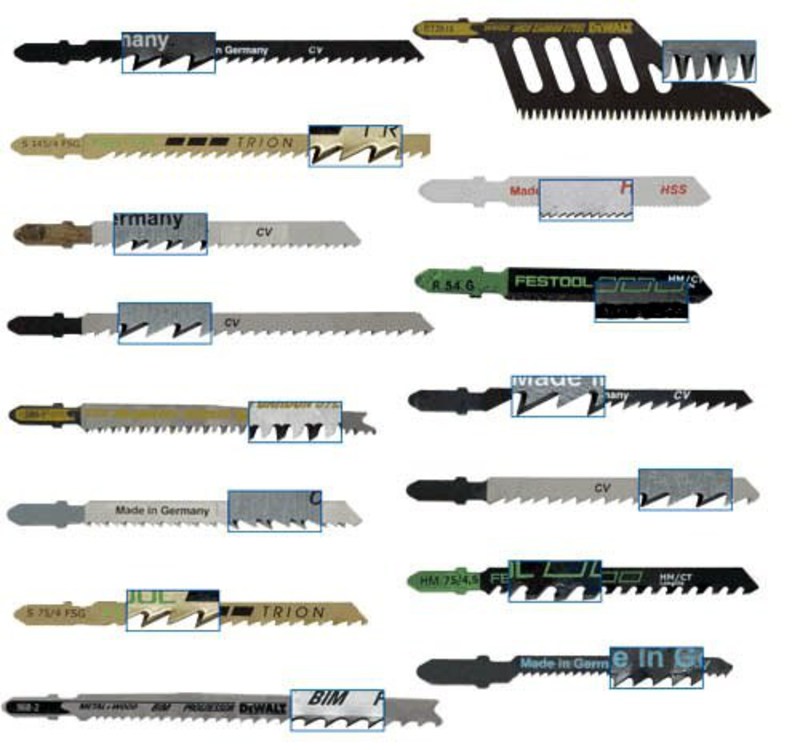

By marking, you can find out about the material from which the file is made. The most common steel is HSS. From the manufacturer's description it follows that this is high-speed steel.

Some products have BIM markings. This is the designation of Bimetal, hard cutting edge and softness of the blade body. Two materials of different density are connected by surfacing. The soft body of the blade prevents the brittle steel from breaking on the teeth.

The cutting tool differs in shape. The most popular products are those with fine milled wavy teeth. They give an even cut, if necessary with a slight twist. But such blades cut material 1-3 mm thick.

To cut parts with greater thickness, there are special files with a set "tooth" and modified geometry. The so-called "progressive pitch", in which the teeth increase from the jigsaw to the edge of the blade. Such models can cut parts up to 10 mm thick.

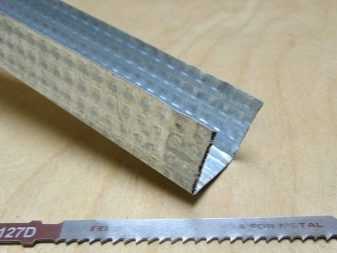

The split-tooth file can be used to cut non-ferrous metals (such as aluminum, copper, brass) and hardwoods. They can cut a metal profile (pipe or square) if the diameter does not exceed 30 mm and the wall thickness is 1.2 mm.

The conclusion is obvious: you can cut metals with a jigsaw. But it is necessary to approach this process competently. Remove the beating of the pendulum, lubricate and not overheat the cutting surface, use the correct blades for various materials.

Don't be discouraged if it didn't work the first time. A little patience and attention - and you will succeed!