Saw for cutting concrete

When performing wall and concrete cutting operations, hand-held reciprocating and chain saws for concrete with an electric drive are often used. The length of the chain allows making cuts to a depth of 300-400 mm, making the end entrance of the saw into the work surface, making cuts with turns at an angle of up to 90 °, which is indispensable when arranging arches, niches and openings.

Device and purpose

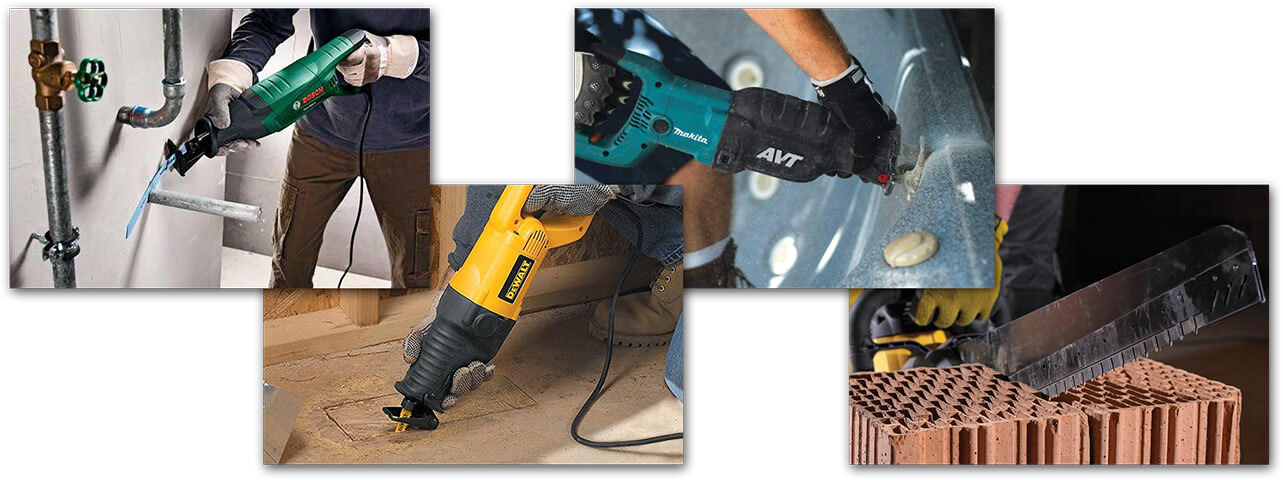

Electric concrete saws can be reciprocated and chain saws. The first models use a blade as a working tool, which cuts aerated concrete by a reciprocating method. An easily replaceable blade acts as a working tool, which can be changed in a matter of minutes for a blade for metal, wood, etc.

The main modifications of reciprocating saws are equipped with a battery power source. They have a low dead weight and can even be operated with one hand.

The bar with the chain can be disconnected from the main structure of the saw for the necessary repairs and maintenance.

The electric motor is located at the end of the saw opposite to the chain. It is often used as a brush single-phase electric motor powered by an alternating current having a voltage of 220 V and a frequency of 50 Hz. The motor power is 1-3 kW, although more powerful tools can be found on sale. The motor housing is made in a dustproof version.

Electric saws are equipped with a mechanism for supplying water to the sections of the chain for its effective cooling and washing away concrete and sand dust.

There is also a wide range of gasoline-powered hand saws on sale. Gasoline cutters with chain equipment have two-stroke engines with clutches or with an automatic centrifugal clutch mechanism that stops the chain when it gets stuck and at idle.

In Moscow and other cities of Russia, electrical circuits and concrete hacksaws represented by the following brands:

- BISON;

- Anchor;

- Husqvarna;

- Cardi;

- Elitech;

- Rotorazer;

- Einell;

- Bosch;

- Makita;

- Black & Dacker;

- Hitachi;

- Coccodrillo and others.

Specifications

The electric concrete saw has the following advantages:

- affordable price (in comparison with gasoline analogues);

- the presence of replaceable chains and accessories;

- low vibration and noise;

- lightness, compactness and mobility;

- high motor power;

- lack of exhaust gases.

Among the disadvantages of electric saws are the need for an electric power source and their low service life.

Reciprocating saws for aerated concrete have a number of limitations: they cannot be used for end entry into concrete or stone, or for cuts with turns. Also, their canvases are often deformed and are considered consumables.

Application area

The concrete saw is capable of making cuts in various building materials: aerated and aerated concrete, heavy polymer or slag concrete, ceramics and porcelain stoneware, brick, gypsum and drywall, chalk and limestone.

The most typical types of work for electric saws are:

- destruction of walls, bulkheads and other structures;

- changing the configuration of concrete and stone products;

- making openings, niches, corners;

- fitting concrete products to each other in size;

- cutting channels for pipelines, electrical cables and other communications;

- cutting of products.

It should be borne in mind that concrete saws with a saber structure are not suitable for work on reinforced concrete products. For manipulations of this type, it is necessary to use only disk or chain gasoline and electric machines.

Aerated concrete cutting line LRP-1200 Sh

The line for cutting foam concrete (hereinafter referred to as the "line") is manufactured in accordance with the requirements of GOST 25223 in climatic version UHL2 in accordance with GOST 15150 and is intended for cutting foam concrete massifs no larger than 1000x910x600 (up to 7 pieces at a time) into blocks using a belt and two circular saws that match the material to be cut.

Sawing is carried out in the vertical and horizontal planes by moving the machine and, accordingly, saws along the guide path with the stationary position of the aerated concrete massifs.

The line does not require a special foundation and is installed on a solid, even base within 4 ... 5 hours.

Technical characteristics of the line for cutting aerated concrete LRP-1200 Sh

| Specifications | ||

| Band saw head | ||

| Sizes of the monolithic block to be sawn | mm | 1000х910х600 |

| Number of simultaneously processed blocks | PCS | 6 ... 7 and more * |

| Saw blade lower position | mm | 200 |

| Saw band length | mm | 5430…5480** |

| Saw band width | mm | 27 |

| Saw band thickness | mm | 0,9 |

| Cutting thickness | mm | 2,0…2,5 |

| Recommended pressure in the hydraulic tensioning system for a 27 mm band saw. | kg / cm2 MPa | 200…220 20…22*** |

| Saw pulley diameter | mm | 600 |

| Feeding speed (electromechanical) | m / min | 1…20 |

| Lifting speed (mechanical) | mm / s | 12 |

| Power el. saw motor | kw | 4 |

| Rotation frequency | rpm | 2890 |

| Power el. feed motor | kw | 0,75 |

| Rotation frequency | rpm | 1365 |

| Power el. lift motor | kw | 0,25 |

| Rotation frequency | rpm | 1680 |

| Supply voltage | V | 380 |

| Performance | m3 | **** |

| Circular saw unit | ||

| Circular saw parameters: | ||

| - outside diameter; | mm | 600 |

| - landing diameter; | mm | 50 |

| - number of teeth; | PCS. | 72 |

| - number of saws. | PCS. | 2 |

| Range of adjustment of distance between saws | mm | 250…420 |

| Cutting thickness | mm | 5…6***** |

| Email saw drive motor: | ||

| - power; | kWh | 3 |

| - rotation frequency; | rpm | 1410 |

| - number. | PCS. | 2 |

| Lifting speed (electronic mechanical) | mm / sec | 12 |

| Email lift motor: | ||

| - power; | kWh | 0,25 |

| - rotation frequency. | rpm | 1680 |

| V-belts type A-1400 | PCS. | 4 |

| Supply voltage | V | 380 |

| Total power el. line motors | kw | 11,25 |

| Saw frame dimensions | ||

| - length (without road); | mm | 1670 |

| - width; | mm | 2500 |

| - height (without road). | mm | 2150 |

* - at the request of the customer;

** - taking into account the possible repair of the saw band;

*** - the recommended tension for this saw should be 1800-2500 kg / cm2;

**** - the time for cutting 4 blocks, depending on the grade and moisture content of the material, is 1.5 ... 2 minutes. in one pass (exit - 12 bricks with dimensions 200x300x600). Line productivity per shift depends on the level of mechanization of auxiliary operations (loading and unloading) and other unproductive time expenditures.

***** - depends on the saw blade preparation: forging, straightening and balancing.

Saw "Alligator"

Some inexperienced craftsmen often confuse the Alligator saw with a classic saber product. However, this model has some differences. In working order, the Alligator sets the saw blades in motion, which resembles the movement of the jaws of a crocodile.

Unlike saber models, such devices do not perform reciprocating movements, since the cut is carried out by a fixed saw bar.

The pluses of this saw include items such as:

- High engine power that allows you to handle thick.

- Due to the opposite way of movement of the canvases, the block remains stable.

- The design provides for the presence of a knife brake and switch interlocking.

- There is an enhanced protection against dust.

- It is quite convenient to use the saw.

- Replacing consumables is straightforward.

The saw is supplied with a hexagon and a pair of blades for cutting gas silicate structures.

Of the minuses of the product, the high cost is distinguished. Therefore, the purchase of such a tool is justified only in cases of its professional use at large construction sites.

Where is it used?

The tool is often used to make a hole in a material.A concrete saw is used in cases where the use of diamond wall saws is not possible:

- at high-rise works;

- for laying ventilation, cutting holes;

- in hard-to-reach places;

- for dismantling;

- in small-sized construction;

- when adjusting corners, openings;

- to save people from the rubble.

The hand saw is a versatile tool designed for cutting various types of this building material. Cellular blocks (foam and aerated concrete, gas silicate) and light types of building materials lend themselves well to cutting. It is possible to work with natural stone, brick, gypsum, porcelain stoneware. Before using each model, you must read the instructions. Some chainsaw models are capable of overcoming light reinforcement. For standard reinforced concrete, it is better to use diamond discs.

Such a tool can also overcome aerated concrete.

Classification

Sorting of devices begins with a division into special and manual equipment.

The special include floor saws, wall saws and wire rope machines. They are characterized by increased productivity, efficiency and power compared to manual units.

With the help of a hand tool, wall openings are created, but subject to a relatively small thickness. Manual equipment is divided into:

With the help of a hand tool, wall openings are created, but subject to a relatively small thickness. Manual equipment is divided into:

- electric;

- hydraulic;

- gasoline.

As a rule, the electric type includes hand chain saws, as well as reciprocating saws, reminiscent of a jigsaw. Equipped with a replaceable blade that cuts in a reciprocating motion. In some models, a counterweight is provided to reduce vibration during operation, the function of changing the saw without the use of special tools has been added.

The US brand ICS electric hand-held electric chain saw cuts walls with a diamond-coated chain with water supply along the entire cut, which washes away dirt and reduces the heating temperature of the chain. It is equipped with a single-phase electric motor and can be operated from a home electrical network, but with mandatory grounding. Due to the lack of exhaust gases, unlike gasoline, it can be used indoors. Fully equipped, the device weighs only 9 kg, the motor power is 3240 W, and the maximum cutting depth is 35 cm. The main limitation is the impossibility of vertical cutting. But, unlike analogs with hydraulic systems, such a saw does not require a bulky hydraulic unit and is much cheaper. The average price of this model is 80,000 - 85,000 rubles.

The hydraulic view is represented by concrete chain saws and circular saws. The main difference from all categories is the increased power. The most famous manufacturers in this segment are the ICS brand with a line of chain tools, which includes devices with a power of 11 hp (for example, ICS 814PRO hydraulic diamond chain saw), weighing 6.8-12.4 kg, tire length 32-62 cm and water supply from 30 liters per minute. Has the ability to cut at an angle of 90 degrees. The price of the "strongest" variant - ICS 880F4 is about 170,000 rubles.

The HYCON circular saw is distinguished by its ability to be used in underwater technical work. They have the following characteristics: diameter 35 - 45 cm, number of revolutions per minute 2,000-3,800, water flow 20-34 liters per minute, weight (without disc) from 9.7 kg. The cost of HYCON HCS18 is about 95,000 rubles.

Gasoline cutters of the brands Makita, ICS, STIHL and others are popular with a gasoline engine. Their main advantage is autonomy, and a serious disadvantage is the impossibility of working in a building. Chainsaw for cutting concrete structures can be equipped with both discs and chains, depending on the model. Due to their versatility, very often it is gas cutters that are used by rescue services to eliminate blockages during earthquakes and penetrate buildings.

There are some peculiarities during their operation - you cannot make great efforts, this will increase the service life of consumables.And also it should be remembered that with a dry cut, work is allowed no more than 30-45 seconds, otherwise, the disc will be damaged. The straightness of the cut should also be monitored. Deviation from the vertical or horizontal direction will damage the cutting ability of the blade. For the same reason, irregularities should not be removed with this apparatus.

If the rotation speed of the extreme point of the disk is 100 m / s, then it is considered high-speed. Therefore, there is a corresponding speed for each saw blade diameter. Namely:

If the rotation speed of the extreme point of the disk is 100 m / s, then it is considered high-speed. Therefore, there is a corresponding speed for each saw blade diameter. Namely:

- 300 mm. - 6300 rpm;

- 350 mm. - 5400 rpm;

- 400 mm. - 4700 rpm

A gasoline saw for ICS concrete, depending on the characteristics and size, costs from 30,000 to 170,000 rubles, the same equipment from Makita, for example, a Makita DPC 8132 WS gas cutter (DPC8132WS) with power parameters of 4500 W and a diameter of 400 mm, will cost about 40 000 rubles.

Professional equipment

Professional equipment includes several types of saws.

- Wall saw is a machine that consists of a motor, a hydraulic pump, guide rails, a cutting blade and a control panel. Advantages: the ability to perform large volumes of work of high complexity, fast cutting of reinforced concrete structures, high quality construction work, no noise and vibration, reliable installation on the working surface. Disadvantages: high price range, required special skills and practical experience, 380 W power supply.

- Seam cutter is a special equipment that allows horizontal cutting of building structures. The device consists of a metal frame, a motor and a cutting work surface. Manufacturers produce two types of this device: stationary and portable. Advantages: Cutting thick building materials, no vibration. Disadvantages: work only in the horizontal direction, high price.

- A wire saw is a special piece of equipment that can be driven either hydraulically or electrically. Its set may include an oil station, a rope band, rollers and a cooling system. Advantages: sawing structures with a thickness of 500 mm, performance of work in any direction. The cutting element is a diamond-coated wire rope. Disadvantage - use only by professional builders.

In modern construction, concrete structures most often require processing. The most difficult process is adjusting the concrete blocks to the required dimensions. This problem is solved by cutting reinforced concrete objects with diamond wheels. However, an even more efficient way, especially in hard-to-reach places, is to saw the blocks with a saw. What are their features?

Views

The main criterion for the classification of chain saws is the type of power supply of the devices. On this basis, gasoline, electric, pneumatic and battery tools are distinguished.

Electric saws

A chain saw is a device powered by an electric motor. The devices are the most economical type of saws, they produce little noise and are completely environmentally friendly. The devices are equipped with saw blades from 35 to 40 cm long. They are designed for solving technical problems of average complexity. The advantages of the type include the ability to use the tool in closed rooms, which is due to the absence of harmful exhaust and the presence of a dust collector, which is equipped with most models. The presence of an emergency brake is also noted, which instantly stops the movement of the chain in the event of any emergency situations. In addition, electric models are very easy to use, have ergonomic shapes and low weight.

The disadvantages of the species include complete volatility, which imposes restrictions on the use of power saws in the field and in places where electricity is not supplied. In addition, in terms of engine power electric models are significantly inferior to gasoline and cannot be fully used, for example, in the construction industry. Another significant drawback of the models is the too short electrical wire, which does not allow work at a considerable distance from the power source or requires an extension cord. When operating the electric saw, it is recommended to take a five-minute break after every 20 minutes of operating the tool under load, thus allowing the engine to cool down.

Petrol models

Such devices are equipped with a two-stroke internal combustion engine and an automatic centrifugal clutch mechanism. The presence of the latter prevents the movement of the chain when the engine is idling, which significantly increases the safety of the unit. Gasoline saws have an emergency shutdown function and are equipped with a recoil starter, electronic ignition, a membrane type carburetor and an air cooling system. Due to the large number of components and assemblies, the weight of gasoline models significantly exceeds that of electrical devices and is their main disadvantage.

The disadvantages also include the emission of exhaust gases during operation, which imposes a ban on the use of devices in closed rooms. Among the advantages, one can note the high mobility of gasoline saws, which allows you to work in any conditions and on any terrain, including in the forest, as well as the ability to work for several hours in a row without technical breaks. In addition, the units have a very high engine power and can be used when cutting industrial wood and thick logs.

Petrol saws are divided into 4 categories: household, semi-professional, professional, special and mini saws. The former are used for sawing firewood, trimming excess branches and cutting thin trees. The latter are intended both for the construction industry and for sawing medium-thick trees. The third category is represented by powerful units that can operate continuously throughout the working day and have a resource exceeding 1000 hours.

Such models are used for felling commercial timber and its subsequent sawing. Special saws are devices equipped with a telescopic handle in the form of a rod and designed for the maintenance of tall trees.

Cordless saws

Such devices are equipped with an electric motor, and a rechargeable battery is used as a power source. The saws are not very powerful and are only suitable for home use. Among the advantages are high mobility, the absence of strong noise and environmental friendliness. The disadvantages include the need for regular battery charging and limited operating time on a single battery charge.

Pneumatic models

Such devices are used when working in rooms that are subject to increased safety standards for humidity or explosion hazard, and the use of gasoline or electric saws is prohibited. The devices are equipped with motors with a power of more than 2.3 kW, have a shaft rotation speed of about 8,000 rpm and weigh only 6-8 kg. The disadvantage is the need to purchase a compressor unit. Pros: high power and long working life.

Tool features

Usually, concrete hacksaws are used when it is necessary to obtain blocks that have non-standard dimensions, and they are called additional.

The hacksaw models differ:

- Along the length of the canvas;

- By the thickness of the steel, which affects the quality of the cut of the part;

- Soldered on the teeth, it happens on each tooth or through one.

Manufacturers produce two types of hacksaws:

Electrical. These are more complex and more functional tools. But they can be used if there is and the ability to connect to the mains.

Hand hacksaw for foam concrete

Manual. This is the most versatile tool.It can be used under any conditions, including no power supply. The weight of the product is less than an electric saw, and the cost is much lower.

Popular models of hand saws

Cutting the block with a hand saw

When choosing a tool, you should pay attention to its manufacturer. Some of them are presented in the table:

Some of them are presented in the table:

| Manufacturer and photo of the tool | Tool features |

|

YTONG |

Hand saws from this company are considered one of the most popular.

Their advantages:

|

|

Anchor |

The company admits reliable and durable hand-held concrete hacksaws, has a lot of positive customer reviews.

Tool advantages:

|

|

Aerated concrete hacksaw Delta |

Product advantages:

|

|

Bison |

It is the most popular manufacturer on the Russian market.

Tool advantages:

|

The best manufacturers of electric hacksaws

Cutting concrete with a reciprocating saw

The most popular and inexpensive reciprocating saw is the model of the American manufacturer Dewalt DCS380M2. The tool kit does not include a blade; it must be purchased additionally for cutting foam concrete.

Saw model Dewalt DCS380M2

Cheaper instruments are also available. Their quality is not lower than that of other manufacturers.

Some of the models are presented in the table:

| Hacksaw model | Peculiarities |

|

Bosch |

The company produces a wide range of electric hacksaws for cutting aerated concrete. Most popular models: GSA 1300 PCE; Bosch GSA 36 V-Li. |

|

Makita |

The JR 3060T reciprocating saw is a fairly strong unit with a power of 1250 watts. With its help, you can easily saw aerated concrete blocks and other materials. |

|

Metabo |

These are German instruments, they have high reliability and versatility. |

|

Black & decker |

On the Russian market, a German manufacturer offers an electric model for cutting aerated concrete. Disadvantages of equipment: relatively fast wear of working parts, high cost. Main advantages: ease of use, safety. |

Options

Each file has a marking on its surface that characterizes the parameters of the working blade. Let's consider these characteristics in more detail.

Shank type

Most of the saws available have a universal shank. Some products are only suitable for branded saws. To make it easier to understand which tool this file is suitable for, letter marking has been created.

Legend:

- T-shaped;

- U-shaped;

- M - Makita firm;

- F - Fein standard.

Canvas

The first number following the shank letter indicates the size of the working blade. The next two or more numbers indicate the specific size of the instance. The size of the canvas is expressed in millimeters:

- 1 - short, up to 75 mm;

- 2 - medium, up to 90 mm;

- 3 - long, up to 150 mm;

- 4 - the longest, more than 150 mm.

The letter after the numerical designation is responsible for the size of the teeth in ascending order. You can consider the letters from A to D. The last letter characterizes the additional parameters of the canvas:

- F - bimetallic working part;

- O - narrow back;

- P - exact cut;

- X - progressive tooth pitch;

- R - reversible teeth.

HCS

This abbreviation denotes a blade made of high carbon steel. HCS saws are used for sawing soft materials: fiberboard, chipboard, rubber, plastic, aluminum, sheet or profile metal. Saws for wood differ in the arrangement of the teeth. Most models come standard with the same cutting spacing. Variable pitch is used for surfaces with foreign objects such as nails. The length of the working part is on average no more than 400 mm.

HSS

The canvas is presented in a curved and curved shape. The design features of the product allow you to make through cuts in the material. The length of the working file is 300 mm. The main manufacturers of HSS canvases are DeWalt, Metabo.

Bim

BIM canvases are made of bimetallic material. These files have increased strength, flexibility, long service life. They are used when processing materials of various density - from aerated concrete to wood with nails.

HM and CV

HM blade is made of vanadium carbide alloy, CV blade is made of chrome vanadium steel. Both blades are used for cutting porous materials with increased abrasiveness or hard surfaces: fiberglass, ceramics, aerated concrete, tiles, concrete, steel, fiberglass. CV saws are more wear resistant than HCS.

Types of reciprocating saw blades

Reciprocating saw blades are a hacksaw with teeth on one side sharpened at a certain angle. They are made from high-strength steel alloys and various types of durable metals. All reciprocating saw blades are marked, and by the brand you can always determine for what needs the blade can be used. We list the main brands of files:

HCS. This variety is used for cutting not the most durable materials: wood, plastic, rubber and others. Made from high carbon steel. Their length does not exceed 40 cm

It is very important to choose the right hacksaw for the location of the teeth. Most often they are located along the canvas at the same distance.

But if there is a need, for example, to saw boards in which nails can get caught, then a canvas with a variable pitch is used.

HSS. These files are used when it is necessary to cut sheet metal or profile, as well as any shape and size of an aluminum workpiece. Manufacturing material - tool steel. The length of such canvases varies within 30 cm.

BIM. These canvases have the combined properties of the previous two. Therefore, they can be used for cutting hard materials as well as soft ones. For example, if the conversation is about a saw for aerated concrete, then just such blades should be used in it.

HM / CT. These files are made from hard steel alloys. They are the most durable and expensive. They can be used to cut metal, concrete, fiberglass and other durable materials. Their length varies between 75-150 mm. The photo below shows a Bosch reciprocating saw blade.

Reciprocating saw blade

How to choose the right blade by teeth

Before you buy a blade for a reciprocating saw, you need to pay attention to the following parameters regarding the size, shape and method of sharpening the teeth. Let's make a reservation right away that, along with the power of the electric motor, it is the teeth that affect the performance and quality of the cut of the power tool:

- The larger the teeth, the faster they cut the material. But at the same time, the quality of the cut leaves much to be desired. Conversely, the smaller the teeth, the longer it will take to cut.

- Manufacturers produce blades with ground and milled teeth. The former are used for cutting soft materials, the latter for hard materials.

Coarse toothed blade

It is also necessary to indicate the method of fastening the saw itself in the saw chuck. Usually, the parameters and shape are unified, so the files are suitable for almost all chuck models.We only add that the shank of the blade can have different shapes: T-shaped, U-shaped, F - standard. All this is necessarily indicated in the marking. For example, T144DF is BIM. Here "T" is the type of shank, 144 is the length of the blade in mm, "D" is the largest tooth size, where the gradation occurs in ascending order from A to D, and "F" is the designation that the working edge of the tool is made from bimetal.

Blade sharpening

When sharpening the working blade, refer to the instructions that come with the tool and files. If it is absent, you should carry out the wiring according to the standard rules.

- The overhang of the cutting edge should not exceed one and a half or two blade thicknesses.

- Exceeding the indicators is permissible only for laying wet wood or cutting material along the grain. When processing such wood with a blade with teeth located at a small distance from each other, the blade gets stuck in the cut.

- Wide spreading of more than 2 thicknesses is not used when processing wood across the grain. When working with such a canvas, you have to apply more effort, the cut turns out to be sloppy, uneven.

- The teeth are sharpened using a file or a file. The canvas should be fixed at an angle of 45 degrees before the procedure. The teeth are machined on each side in turn.

- Checking the quality of sharpening is carried out by the control cut of wood material. If an uneven cut and chipping are detected, the teeth of the blade should be re-sharpened.

About, how to select and install canvases for a reciprocating saw, see the next video.

Hand circular saws

Circular saws as a compact form factor tool that gives the user complete freedom of action. The worker depends solely on the availability of power (you need an electrical network near the work area). In all other respects - complete convenience - you can get anywhere and do work in hard-to-reach places. These saws will work wherever there is electricity. Despite the relatively low productivity of hand tools, saws are used both by private users and in the working arsenal of professionals. The most popular among users are hand-held circular saws with a power of up to 1200 W

Hitachi C7SS

- Circular Saw

- power 1200 W

- disc diameter 190 mm

- weight 4.9 kg

LEARN MORE

- Circular Saw

- power 1050 W

- disc diameter 190 mm

- weight 3.4 kg

LEARN MORE

The main design feature of compact circular saws is the lateral position of the motor relative to the blade. The handle for holding the tool during operation is on top. To carry out the task in special conditions, there are plunge-cut saw models. With their help, you can easily make cuts of material at angles of 45 or 90 degrees

What is especially important is that you can work with the active part of the saw from anywhere on the workpiece, from the edge and even the middle. The user of the tool can adjust the speed, which ensures work with different density of materials

DeWALT DWS520K

- Circular Saw

- power 1400 W

- disc diameter 165 mm

- smooth speed control

- smooth start

- weight 4.7 kg

LEARN MORE

- Circular Saw

- power 1300 W

- disc diameter 165 mm

- smooth speed control

- weight 5.1 kg

LEARN MORE

Hand circular saws are most often used for woodwork. There are modifications that can perform cutting on metal, in that profile force, as well as with plastic products. When planning such work, it will be useful to choose a saw model in which it is possible to regulate operating parameters (for example, the number of revolutions of the torch per minute)

This is important because the load on the tool changes with different materials. If it is not difficult to change the cutting part, then the structure should be adaptive when carrying out work of different profiles.

Saws with such parameters are classified as professional tools and are more expensive than standard equipment. Of course, the difference in parameters does not always mean different manufacturers. In any case, an expensive tool means user comfort and quality at high productivity.

Direct work with the workpiece is provided by the cutting disc. According to its parameters (diameter), the cutting height is determined. For workpieces up to 30 mm thick, it is recommended to use 110 mm circular saws. If you need to work with parts with a thickness of 85 mm, it is better to purchase a saw blade with a diameter of 235 mm.

The needs of a private economy can well be provided with saws with a power of 600 to 800 watts.

Interskol DP-140/800

- Circular Saw

- power 600 W

- disc diameter 130 mm

- weight 2.4 kg

LEARN MORE

- Circular Saw

- power 800 W

- disc diameter 140 mm

- weight 3.7 kg

LEARN MORE

For high loads, such a tool will not work; you need fault-tolerant models that consume 2000 watts.

The increased power supply mode is accompanied by structural reinforcements, including the equipment of special nozzles and cutting tools, which are designed for processing large workpieces.