Chainsaw features

The operation of this equipment has its own characteristics. For example, the smooth operation of a chainsaw is ensured by an air injection system. This also extends the service life of the tool, as the saw wears out much more slowly. The shape of the device itself is quite convenient, so the cutting process is quite easy and quick. For heavy loads, the installation provides for a three-section crankshaft. Ice can be cut with any chainsaw, but in each case the rule must be observed - do not use oil.

The fact is that in a different situation it reduces friction and prevents overheating, but when working with ice, it is not necessary.

Operating tips

Before starting to cut ice, use the following tips for use chainsaws:

- you do not need to use oil because it reduces friction and can also pollute the pond if fish are grown in it;

- it is recommended to carry out the work process with the tip of the tire, avoiding contact with water;

- after sawing, the tool should be thoroughly wiped and dried, and then lubricated with the chain, sprocket and tire;

- do not forget about personal safety measures - wear a waterproof uniform, stock up on a plywood shield, as when using a chainsaw, a lot of water and ice crumbs fly.

For an overview of the Finnish saw RAPALA, see the video below.

Ice screw Rapala knives are not removable. Ice saw. Winter fishing. Ice fishing

Ice screw Rapala good tool for winter fishing ! This is not a titanium ice screw, but it is very light. He has the knives.

When assembled, the saw teeth go into the slot on the handle:

(Due to the "arched" shape of the saw blade, the pipe must bend slightly to properly cover the teeth throughout)

On both sides of the saw (in the holes from the loop and on the other side in the loop itself) 2 ropes are tied so that the pipe does not fly off the teeth.

Then you need to spread the saw teeth (the wider the better). This is done with a file (be careful not to cut yourself)!

(We put a triangular file between the teeth and "spread" the teeth in pairs in different directions. Then we turn the saw over with the other end and do the same thing - so the impact on each tooth will be from both sides.)

The results of field tests showed that, in comparison with the Finnish ice pad, our "samopal" saws of course badly (subjectively, 1.5-2 times slower). However, the efficiency for normal sawing is quite enough and the device bites into ice quite well. In general, it turned out quite suitable for use (for my own money).

The ice saw can be used in a wide variety of situations. For example, many fishermen use this tool to cut holes or large-area holes to use set nets. The ice saw is often used by EMERCOM employees and scuba divers.

Another application this tool finds during extreme travel, for example, such a saw will free the car from the ice captivity.

Ice screw Rapala knives are not removable. Ice saw. Winter fishing. Ice fishing

Ice screw Rapala

good tool for winter fishing

! This is not a titanium ice screw, but it is very light. He has the knives.

When assembled, the saw teeth go into the slot on the handle:

(Due to the "arched" shape of the saw blade, the pipe must bend slightly to properly cover the teeth throughout)

On both sides of the saw (in the holes from the loop and on the other side in the loop itself) 2 ropes are tied so that the pipe does not fly off the teeth.

Then you need to spread the saw teeth (the wider the better). This is done with a file (be careful not to cut yourself)!

(We put a triangular file between the teeth and "spread" the teeth in pairs in different directions. Then we turn the saw over with the other end and do the same thing - so the impact on each tooth will be from both sides.)

The results of field tests showed that, in comparison with the Finnish ice pad, our "samopal" saws of course badly (subjectively, 1.5-2 times slower). However, the efficiency for normal sawing is quite enough and the device bites into ice quite well. In general, it turned out quite suitable for use (for my own money).

) and is not steamed. But if "hands itch" you can make it from scrap materials.

For this you will need:

1. Actually a two-handed saw (tool magazine - 230r)

2. Plastic pipe for sewerage with a diameter of 40mm and a length of 1m. (79r everywhere)

3. Bolt D6 50mm long and nut.

Wooden handles are removed from the saw and a loop is removed from one side (rivets can be drilled out, but it is better to cut them with a grinder).

The hole closest to the rear side is reamed to a diameter of 6mm (for the bolt).

Then we make a cut in the future handle. A fresh blade of a hacksaw for metal, which is held simply in the hand, is very good at sawing pvc.

First, one cut is made, but this is not enough, because the pipe will “wrap inward”. To get a slot with a width of 5 mm, you need to make another cut, thereby choosing 1-1.5 cm.

(Note the difference between the selected strip and the resulting slit.)

Then we attach the handle and drill through the pipe (getting into the drilled hole left after the loop). In this case, you need to press the future handle as tightly as possible to the back of the saw:

Then we insert the bolt and tighten the nut (it is better to use a lamb). If everything is done correctly, then the mount should turn out to be quite rigid.

When assembled, the saw teeth go into the slot on the handle:

(Due to the "arched" shape of the saw blade, the pipe must bend slightly to properly cover the teeth throughout)

On both sides of the saw (in the holes from the loop and on the other side in the loop itself) 2 ropes are tied so that the pipe does not fly off the teeth.

Then you need to spread the saw teeth (the wider the better). This is done with a file (be careful not to cut yourself)!

(We put a triangular file between the teeth and "spread" the teeth in pairs in different directions. Then we turn the saw over with the other end and do the same thing - so the impact on each tooth will be from both sides.)

Efficiency.

The results of field tests showed that, in comparison with the Finnish ice pad, our "samopal" saws of course badly (subjectively, 1.5-2 times slower). However, the efficiency for normal sawing is quite enough and the device bites into ice quite well. In general, it turned out quite suitable for use (for my own money).

Addendum: apparently due to the fact that we spread the saw crookedly (in one direction the teeth were bent more), it began to cut not along the line but along the arc (which is rather inconvenient). Next year (when there is ice) we will try to spread the teeth more symmetrically - hopefully this will correct the situation.

The ice saw can be used in a wide variety of situations. For example, many fishermen use this tool to cut holes or large-area holes to use set nets. The ice saw is often used by EMERCOM employees and scuba divers.

Model rating

For ice masses of short length, a standard household chainsaw is also suitable, and for larger volumes of work, you should choose a professional tool. It is worth considering the most popular models.

Stihl MS 661.

This unit has a capacity of 7.3 liters. with., and this is quite enough for cutting ice. The base tire is 71 cm.

Chainsaw Stihl MS 880.

It is recommended for a thickness of 90 cm. This is the most powerful model.If this length is not enough, then it is allowed to install a longer tire - Rollomatic ES 0.404 ″, but judging by the opinions of experts, it is rather difficult to find such a tire.

Husqvarna 395 XP.

The length of the tire is 106 cm. According to professionals, this is a very convenient, powerful and efficient unit.

) and is not steamed. But if "hands itch" you can make it from scrap materials.

For this you will need:

1. Actually a two-handed saw (tool magazine - 230r)

2. Plastic pipe for sewerage with a diameter of 40mm and a length of 1m. (79r everywhere)

3. Bolt D6 50mm long and nut.

Wooden handles are removed from the saw and a loop is removed from one side (rivets can be drilled out, but it is better to cut them with a grinder).

The hole closest to the rear side is reamed to a diameter of 6mm (for the bolt).

Then we make a cut in the future handle. A fresh blade of a hacksaw for metal, which is held simply in the hand, is very good at sawing pvc.

First, one cut is made, but this is not enough, because the pipe will “wrap inward”. To get a slot with a width of 5 mm, you need to make another cut, thereby choosing 1-1.5 cm.

(Note the difference between the selected strip and the resulting slit.)

Then we attach the handle and drill through the pipe (getting into the drilled hole left after the loop). In this case, you need to press the future handle as tightly as possible to the back of the saw:

Then we insert the bolt and tighten the nut (it is better to use a lamb). If everything is done correctly, then the mount should turn out to be quite rigid.

When assembled, the saw teeth go into the slot on the handle:

(Due to the "arched" shape of the saw blade, the pipe must bend slightly to properly cover the teeth throughout)

On both sides of the saw (in the holes from the loop and on the other side in the loop itself) 2 ropes are tied so that the pipe does not fly off the teeth.

Then you need to spread the saw teeth (the wider the better). This is done with a file (be careful not to cut yourself)!

(We put a triangular file between the teeth and "spread" the teeth in pairs in different directions. Then we turn the saw over with the other end and do the same thing - so the impact on each tooth will be from both sides.)

Efficiency.

The results of field tests showed that, in comparison with the Finnish ice pad, our "samopal" saws of course badly (subjectively, 1.5-2 times slower). However, the efficiency for normal sawing is quite enough and the device bites into ice quite well. In general, it turned out quite suitable for use (for my own money).

Addendum: apparently due to the fact that we spread the saw crookedly (in one direction the teeth were bent more), it began to cut not along the line but along the arc (which is rather inconvenient). Next year (when there is ice) we will try to spread the teeth more symmetrically - hopefully this will correct the situation.

Nyryalka.ru - atlas of places for diving, shop of used equipment for diving, diving communication. - diving is available to everyone!

Design features, pros and cons

Band and circular saws have their own advantages and disadvantages. Determining which is better is difficult. Circular saws are available in manual and stationary versions. The simplest hand-made design consists of a knife in the form of a disc, a body and an electric motor. Such devices are designed for cutting small quantities of raw materials. Stationary equipment is used for cutting large carcasses.

The advantages of circular saws include:

- Possibility of cutting meat in any position.

- Convenience in work.

- Low cost.

- Long service life.

- Easy to maintain.

The disadvantages of circular saws include:

- High degree of heating of the cutting edge.

- A large percentage of waste when cutting raw materials.

The size of the discs for cutting meat is selected depending on its type.

Have you ever worked with a meat and bone band saw?

There was a case!

The main disadvantage of band saws is their high cost.The high cost of the equipment is compensated by its advantages.

Among them:

- Low noise level when operating devices.

- Long service life.

- Smooth cut.

- Energy efficiency.

Expert opinion

Dmitry Levin

When cutting bones with band saws, small fragments are not formed.

How to choose?

When choosing a saw for cutting ice, you should familiarize yourself with the various options for household saws, since each of them is designed for a certain volume of work, has its own advantages and disadvantages. There are several types of saws that can be used to cut the ice sheet.

-

Handmade Finnish.

The advantages of the specimen include lightness. Ice masses up to one meter thick can be cut. Among the minuses, it is worth noting the low speed of work when compared with a gasoline tool. But if we compare the speed of work on metal or wood, then such a saw will cope with ice much faster. As well as hand-held Finnish saws, which are recommended for cutting out polynya or myna, can be divided according to the following criteria:- a tool with a wooden handle is an environmentally friendly accessory, it fits well in the hand, it is easy for them to work;

- a saw with a metal handle - compared to the above option, this is a more durable version.

-

Chainsaw.

This is a fairly convenient option to work with. Sawing a hole in the ice is simple and quick for them, but this variety has the following disadvantages:- it is possible to work only with a thickness of no more than 37 cm;

- during the cutting process, a lot of ice splashes get on the saw, which is fraught with icing of the tool and malfunctioning;

- this weapon is quite massive.

What it is?

The devices are related to auxiliary equipment, which is widely used in industrial production, catering and trade.

The devices are related to auxiliary equipment, which is widely used in industrial production, catering and trade.

Power saws consist of 4 main elements:

- Countertops.

- Limiter.

- Pusher.

- Cutting saw.

Most saw models are based on the same operating principle. Cutting of meat blocks is carried out without crushing bones. This prevents small debris from getting into the pulp of the processed product. All types of power saws give a smooth cut. It does not spoil the presentation of the product and affects the duration of its shelf life.

Neatly cut cuts of meat have an appealing look to customers.

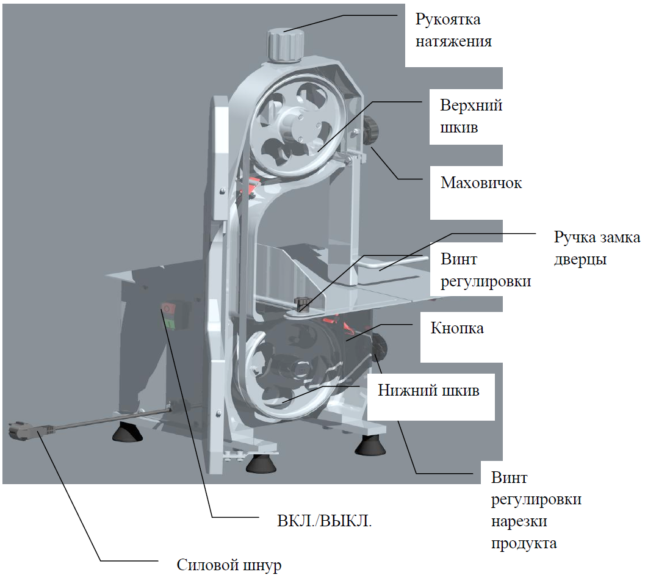

Band saw device for cutting meat and bones.

Band saw device for cutting meat and bones.

Principle of operation

The cutters are used to adjust the thickness of the slices of meat. The raw materials laid in a tray installed on the tabletop are fed by a pusher to the saw blade closed with the help of 2 rollers.

During operation, it moves perpendicular to the bed. Sliced pieces fall on the countertop in different directions.

At the end of the operation, the pieces are sorted. Waste is separated from them.