Features of brand models

Rotary hammers of the P. I. T. company occupy one of the leading lines in the rating of power tools. Since 2012, the company has been using the technology of pouring the anchor with a compound, which prevents the accumulation of debris and dust inside the tool. Thanks to the high-strength light-alloy metals, the P. I. T. is also lighter than its competitors.

The brand's rock drills fall into two categories: vertical and horizontal. Let's consider each group in more detail.

Vertical

These rock drills are characterized by a vertical engine arrangement. In another way, they are also called rotary hammers with an L-shaped engine. Such a unit is heavier, more difficult to operate, requires more careful maintenance (frequent and abundant lubrication of the mechanism parts is required).

Such devices are loved by professional builders, as they are more reliable with prolonged use. In addition, the L-motor has the highest torque, and thanks to the air-cooled tool, the tool does not overheat under prolonged use. Most often, such tools are used for vertical drilling, that is, floors, ceilings. The mass of the entire unit is directed to one side, so drilling is easier and faster.

The disadvantages of a vertical rock drill are negligible. Since these are mostly professional tools, they do not have a drilling function. In fact, there is no need for it, because builders use different tools for each type of work. The inflated cost is also understandable - everything that is intended to perform a large amount of work will be heavier and more massive for a long time. Consequently, such models are more reliable and more expensive.

The P. I. T. vertical perforators include models RVN32-C2 and RVN26-C3. RVN32-C2 is a seven-kilogram tool with three modes. Suitable for wood, stone and steel. Power - 1500 W, and the maximum frequency of beats per minute - 4350. The noise level does not exceed 93 dB. РВН26-С3 already weighs less (about 6 kg). It also has three modes and is suitable for the same types of surfaces. Its power is less - 1200 W, and the maximum impact frequency is almost equal to the previous model and amounts to 4250. The noise level is 91 dB.

Horizontal

These rock drills have a motor located parallel to the drilling axis. This category includes all household (household) models. They do not have such high power, they are lighter, easier to operate and maintain. They are ideal for installing facades, drywall, and in general everything related to vertical installation. The main disadvantage of such models is the lack of cooling elements. Initially, such tools were not intended for long-term, but only for small household chores, so overheating was not expected. With prolonged use, be sure to make sure that the mechanism does not overheat, turn it off in time and let it cool down.

RVN20-D, RVN20-C, RVN24-D, RVN24-C1, RVN24-C, RVN26-C2, RVN26-C3, RVN28-C1, RVN28-C, RVN32-C2 - models of horizontal perforators from PIT All of them are included case, grease, stop and an extra very ergonomic handle that makes horizontal drilling easier. RVN20-D, RVN20-C - the very first, simple and lightweight perforators in the line. Modification D differs from C by the force of impact and the maximum number of revolutions per minute, and the force is greater in modification D, and the rpm - in C. The average cost of models is from 2,500 rubles.

The difference between RVN24-C, RVN24-C1, RVN24-D is also small. The latest modification has a wider set: this is not only a case and grease, but also 4 drills of various configurations. The average price is 3500 rubles. In addition to the RVN26-C2, RVN26-C3 models, there are also C1, C4 and C5, but they are not as popular as the first two modifications.These instruments are already more like professional-amateur. They have increased indicators of weight, impact energy and power. The price for them is correspondingly higher. The set includes drills and chisels.

RVN28-S and RVN28-S1 are exactly the same models. The only difference lies in the greater perfection of the C1 model in terms of power consumption, speed and impact energy. If the RVN28-S costs about 3000 rubles, then the improved one is a thousand rubles more expensive. RVN32-C2 - the "coolest" and most professional model in the line of rotary hammers.

Due to its greater weight (up to 8 kilograms), there is a vibration damping function. This is the only P. I. T. professional rock drill with a horizontal motor.

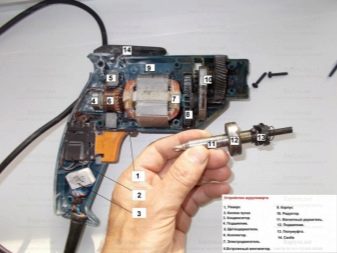

Device

The device includes the following internal components:

- an electric motor (or a pneumatic motor), which ensures the operation of the device as a whole;

- planetary gearbox, the task of which is to mechanically link the engine and the torque shaft (spindle);

- the clutch is a regulator adjacent to the gearbox, its task is to switch the torque;

- start and reverse (reverse rotation process) carried out by the control unit;

- clamping chuck - fixing all types of attachments in the torque shaft;

- removable battery power supplies (for cordless screwdrivers) with chargers for them.

What to give preference to?

The choice of a cordless or cordless screwdriver is a matter of preference. Let's try to analyze the operation of the tool with a removable power source:

- a definite plus is mobility, which allows you to work where it is difficult to stretch the cord;

- the lightness of the models in comparison with the network counterparts - even the weight of the battery turns out to be a positive point, since it is a counterweight and relieves the hand;

- low power, compensated for by mobility;

- inability to drill solid materials such as thick metal, concrete;

- the presence of a second battery allows you to work smoothly;

- increased level of safety due to the absence of the possibility of electric shock;

- after the guaranteed three thousand cycles, the battery will need to be replaced;

- failure to recharge the power supply will stop operation.

Each manufacturer, characterizing its screwdrivers, indicates additional functions:

- in all P. I. T. models, this is the presence of a reverse, which allows screws and self-tapping screws to be turned out during dismantling;

- the presence of one or two speeds (at the first speed, the wrapping process is carried out, at the second - drilling);

- backlight (some buyers in their reviews write that this is superfluous, while others thank for the backlight);

- the impact function (usually it is in the P. I. T. drills, although it also appeared in the new model - the PSR20-C2 impact driver) actually replaces the drill when drilling durable materials;

- the presence of a non-slip handle allows you to hold the tool on weight for a long time.

Specifications

At the time of purchase, you need to understand what this device is for: for home or industrial use, for performing basic functions, or additional ones must be taken into account. It depends on what power the device should be, what characteristics it should have.

The main criterion is torque. It depends on it how much effort will have to be made to do the work when the tool is turned on. This knot is an indicator demonstrating the ability of the tool to drill the maximum hole size in any material or tighten the longest and thickest screw.

The simplest instrument has this indicator at the level of 10 to 28 newtons per meter (N / m). This is quite enough for the installation of chipboard, fiberboard, OSB, drywall, that is, you can assemble furniture or lay the floor, walls, ceiling, but you will no longer be able to drill through the metal. Average indicators of this value are 30-60 N / m. For example, the novelty - the P. I. T. PSR20-C2 impact screwdriver - has a tightening force of 60 N / m.A professional shockless device can have a tightening force of up to 100 - 140 units.

The maximum torque can be soft or hard, or continuous torque that develops during extended non-stop spindle operation. These characteristics indicate when the battery is fully charged. The regulator clutch can be used to adjust the torque to avoid premature wear to which replacement bits are prone and to avoid thread stripping. It is believed that the presence of a regulator-clutch indicates the quality of the product.

The second criterion for tool power is the head speed, measured in revolutions per minute at idle. Using a special switch, you can increase this frequency from 200 rpm (this is enough for tightening short self-tapping screws) to 1500 rpm, at which you can drill. The P. I. T. PBM 10-C1, one of the cheapest, has the lowest RPM. In the P. I. T. PSR20-C2 model, this figure is 2500 units.

The third criterion is the power source. It can be mains, accumulator or pneumatic (operating under air pressure supplied by the compressor). No pneumatic power supply was found among the P. I. T. models. Some models of drills are networked, but ordinary screwdrivers are cordless. Of course, network tools are more powerful and will last for a long time.