What are they made of

Gloves are made from a variety of materials.

Household rubber gloves: technical characteristics

Gloves made of natural rubber - latex. Indispensable when you need increased sensitivity of the fingers when performing work, as well as protection against contamination of the skin of the hands and exposure to the aggressive environment of household chemicals and constant contact with water.

- thin and light, do not weigh down the hand, while maintaining the sensitivity of the fingers;

- resistant to tearing under tension, stretch well;

- in case of punctures or cuts, the place of damage does not creep away, making it possible to complete the work with minimal damage to the hands;

- perfectly protect the skin of hands and nails from pollution.

- not resistant to cuts / punctures, and therefore their service life can be reduced to one day;

- poorly resistant to highly concentrated chemicals;

- may be uncomfortable to use if the size is incorrect: pinch the vessels, contribute to the occurrence of edema;

They are used for wet cleaning at home, washing dishes (fruits and vegetables), can protect hands when carrying out paintwork, are useful when working with glass or ceramics that require high tactile sensitivity.

Latex Household Gloves

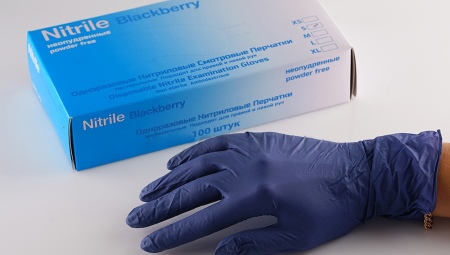

Artificial rubber - nitrile, vinyl. Due to the addition of artificial fibers to the composition, such gloves acquire greater wear resistance, increased resistance to mechanical damage.

Advantages of nitrile and vinyl gloves:

- resistant to aggressive chemicals;

- greater resistance to punctures / cuts in comparison with latex;

- less slippery than latex ones, especially when additional relief is applied to the palmar part.

- in case of mechanical damage, the puncture or rupture site creeps up;

- sit on the arm more freely, while losing tactile sensitivity;

- they do not stretch well, they break easily with diligent pulling.

They are used in cleaning sanitary rooms, cleaning tiles, taps, plumbing; cleaning of common areas in institutions; it is possible to use it when carrying out gardening works: transplanting plants, harvesting; spraying seedlings, etc.

Note! All types of rubber gloves can cause allergic reactions, as they are quite tight on the hands, and also do not allow air to pass through, preventing the skin of the hands from breathing. In these conditions, there is a high risk of allergies, prickly heat, skin irritations in especially sensitive people. Rubber gloves for cleaning

Rubber gloves for cleaning

Household textile: technical characteristics

Textile gloves: knitted and cotton. Produced from cotton threads of various thicknesses and quantities. Their wear resistance and their field of application depend on the knitting class:

7th class of knitting: rough work, high importance of protection from mechanical damage;

10th grade: work with high tactile sensitivity (assembly, small fasteners);

13th grade: high-precision work (electronics, jewelry).

Knitted mittens of the 7th class are often equipped with a point or continuous polyvinyl chloride (PVC) coating, which increases the number of useful performance characteristics.

Advantages of PVC knitted gloves:

- resistant to mechanical damage (especially with continuous PVC spraying);

- have a high tenacity with inventory;

- ensure the supply of oxygen to the skin of the hands;

- wide functionality due to the PVC coating, which increases the protective properties.

- not designed to protect hands from water;

- in the absence of PVC spraying, they lose most of their protective properties.

The scope of application of textile mittens is great: carpentry, horticultural work; warehouse, loading work, packing, cosmetology, auto mechanics, installation and various types of work in production.

Wide possibilities for exploitation

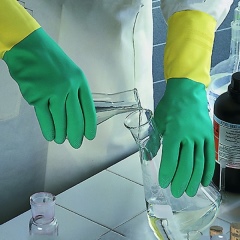

Protection against chemically active and aggressive substances

Type 1 acid and alkali resistant gloves withstand the effects of:

· Diluted acids in a concentration of up to 20%;

• free-flowing and coloring chemicals;

· Non-aromatic hydrocarbons;

· Alkaline solutions in concentration up to 20%;

· Vegetable and animal fats and oils;

· Salts of dilute acids and alkalis in a concentration of up to 20%.

Preservation of properties up to 8 hours

The maximum time of exposure to aggressive chemicals, during which the material reliably protects the skin, is 8 hours: a couple will last a full day or several shifts with interruptions and other activities.

KShchS gloves - reliable grip and full protection against acids, alkalis and other aggressive chemicals

Protection against mechanical damage

KSC gloves 1 are made of a material 0.8 mm thick, due to which latex reliably protects the skin from mechanical damage (for example, abrasions, punctures), from moisture and dirt.

The convenience of use

· Anatomical shape reduces hand tension, prevents the emergence of "fatigue syndrome" after a long time in gloves.

· The corrugated working surface additionally "secures" the grip: the risk that a heavy load will slip out at the wrong moment is minimal.

· Gloves in a pair are made according to volumetric models for the right and left hands, which makes them fit well.

· Cotton lining on the inner surface adds comfort.

· The edge of the product in the form of a thin roller makes the gloves more tear resistant and comfortable to put on.

Peculiarities

The conventional designation KShchS (decoding - acid-alkali-resistant) indicates the resistance of objects to the action of highly aggressive and chemical substances. Acid-resistant PPE is not only hand protection, but also protective clothing. The mandatory parameters of protective equipment include waterproofing.

KShchS gloves are used when working with acids and alkalis, salts and chemical compounds. Thickness ranges from 0.35 to 1.2 millimeters, but thicker can be found. The maximum thickness (1.2 mm) allows you to work with highly concentrated acids - up to 80%. The gloves are made of rubber and latex, these materials provide complete protection. The products have a two-layer structure, and some models have an additional insulating layer. There are two types of KShchS gloves.

- For packaging, distribution and handling of various objects, the coating of which contains hazardous substances. The thickness of such gloves is 0.6-1.2 millimeters. Protection against chemical solutions 80% concentration.

- For jobs that require precision. Should be 0.35-0.5 millimeters thick and protected from solutions of 20% concentration. Safe operation time - up to 4 hours.

The type of work performed depends on which protective gloves it is better to opt for. For oil and petroleum products, MBS gloves are suitable - oil-resistant or nitrile. Nitrile is an artificial rubber. Gloves are made of HB material, doused with PVC (nitrile), they are quite thin, durable and heat-resistant, at temperatures from -20 to +130 degrees do not lose their working properties.

MBS gloves are divided into two types - with an incomplete coating (the protective coating is not applied to the back side, but covers only the palms and fingers) and with a full coating - a nitrile coating is applied to the entire surface of the glove.

1 Technical requirements

1.1 Gloves should be manufactured in accordance with the requirements of this standard. The recipe for the mixture for the manufacture of the layer of gloves in contact with the skin of the hand must be agreed with the Ministry of Health of Russia.

1.2Basic parameters and dimensions

1.2.1 Depending on the purpose, gloves are produced in two types:

I - for rough work;

II - for delicate work.

1.2.2 Gloves are manufactured in the following numbers:

1, 2, 3 - for type I;

1, 2, 3, 7, 8, 9, 10 - for type II.

1.2.3 Length of gloves L must be at least 300 mm. Other dimensions should correspond to those indicated in the figure and in table 1.

Table 1

| Glove type | Glove number | Width at the fifth metacarpophalangeal joint b, mm | Wall thickness S, mm |

|

I |

1 |

110 ± 5 |

0,6 – 0,9 |

|

2 |

120 ± 5 |

||

|

3 |

130 ± 6 |

||

|

II |

1 |

88 ± 5 |

0,2 – 0,4 |

|

2 |

100 ± 5 |

||

|

3 |

107 ± 6 |

||

|

7 |

101 ± 8 |

||

|

8 |

108 ± 8 |

||

|

9 |

119 ± 8 |

||

|

10 |

126 ± 8 |

An example of a symbol of type I gloves No. 2:

Sch20K200nHfNSmI №2. GlovesrubbertechnicalGOST 20010-93

1.3 Features

1.3.1 Gloves must be five-fingered, seamless, shaped to match the volumetric model of the hand and made for right and left hands. The fingers can be straight or curved.

1.3.2 Gloves should be made in two layers.

1.3.3 Gloves can be made in any color.

The inner and outer layers of two-layer gloves should be different in color. Protrusion of the inner layer along the edge of the glove guard is allowed.

1.3.4 In terms of physical and mechanical parameters, gloves must comply with the standards specified in Table 2.

table 2

|

Indicator name |

Norm |

|

1 Conditional tensile strength MPa (kgf / cm2), not less |

16 (160) |

|

2 Relative elongation at break,%, not less |

800 |

|

3 Relative residual elongation after rupture,%, not more |

12 |

|

4 Tear resistance, kN / m (kgf / cm), not less |

20 (20) |

|

5 Acid-alkali permeability, pH, no more |

1 |

|

6 Change in mass after exposure to a 20% alkali solution or 20% sulfuric acid solution for (24 ± 1) h at a temperature of (23 ± 2) or (27 ± 2) ° С,%, no more |

10 |

|

Note. - Indicators for PP. 1 - 4 is determined after exposure in a 20% solution of sodium hydroxide or potassium hydroxide at a temperature of (45 ± 2) ° С for (24 ± 1) h. |

1.3.5 On the surface of the gloves there should be no defects exceeding those indicated in Table 3.

Table 3

|

Defect name |

Checked part of the glove |

|

| Fingers (working surface), interdigital spaces, palmar part | Back, leggings | |

|

1 Holes |

Not allowed | |

|

2 Foreign inclusions of a non-rubber nature |

Also | |

|

3 Bubbles on the face of the glove with a diameter of more than 1 mm or the absence of a protective layer on the face with a total area of more than 10 mm2 |

Not allowed | Allowed |

|

4 Inclusions of coagulum on the seamy side of the glove |

Not allowed with a height of more than 3 mm | Allowed |

|

5 Smears on the seamy side of the glove |

Allowed |

Notes (edit)

1 To control the appearance of gloves, it is allowed to use control samples agreed between the manufacturer and the consumer.

2 Transmission of the relief pattern of the protective layer on the inside of the glove is not a defect.

1.4Marking

1.4.1 The face of each glove must be marked with the glove number.

1.4.2 Each packaging unit must be marked with:

trademark and (or) name of the manufacturer;

product name;

type and number of gloves;

number of pairs;

date of manufacture (month, year);

designations of this standard;

gloves designation in accordance with GOST 12.4.103;

guaranteed storage period.

It is allowed to apply additional or informational inscriptions.

Each packing unit must be supplied with rules for the use and storage of gloves (attachment).

1.5Package

1.5.1 Gloves of the same type and numbers, matched in equal quantities for the right and left hands, are packed in an amount of not more than 150 pairs in boxes or packs of cardboard in accordance with GOST 7376, GOST 7933, GOST 9421, GOST 12303 or cardboard boxes in accordance with GOST 13511, GOST 13512, GOST 13513, GOST 13514, GOST 13515, GOST 13516 or in another container that ensures the safety of products as agreed with the consumer. Each box must be bandaged, overtightened, or sealed.

Manufacturers

Gloves are made of durable and resistant material - latex. They have elasticity and take the shape of a hand without causing an uncomfortable feeling during use. They are produced on the basis of natural raw materials - a rubber tree.

Gloves, like other products, have quality standards. Modern KShchS gloves have 2 layers.

- The top is made with the addition of soot.

- The inner one consists entirely of high quality latex, which does not cause allergies to the skin of the hands.

Glove manufacturers use the classic size range, where S is the smallest size and is used mainly by women, while the maximum sizes L and XL are suitable for men.

Among the manufacturers, it is worth highlighting the Mapa professional brand, which offers high quality products:

- Superfood 174, 175 - suitable for food handling;

- Vital 115, 117, 124 - can be operated in a slightly aggressive environment;

- Optimo 454 - provides protection when interacting with a moderately aggressive environment and others.

Scope of application

KSChS gloves of the first type are indispensable in many areas of industrial labor. Most often they are used for manual loading of various containers with aggressive chemicals. But they are also used to perform technical work that does not require high precision. They have found their application in factories, in auto repair shops and even in agriculture, where various hazardous chemicals are also often used. They are used in the manufacture and application of fertilizers, when working with electrolyte in batteries, disinfecting premises, working with hazardous compounds in chemical laboratories and many other places.

They must be used for any contact with chemicals that pose a threat to human skin. If you work in an area at least indirectly related to the chemical industry, or your hobby is somehow related to hazardous chemical compounds, you should have such gloves. Otherwise, you are at very high risk - any oversight can adversely affect both your hands and your health in general.

In the next video, you will find an overview of the MAPA Vital 117 Alto KShS gloves.