How it works

How does the tool work? This screwdriver is designed mainly for working with wiring accessories, fittings, automatic machines, relays, terminal blocks, etc.

Naturally, there are also quite small screws that are very easy to overtighten and rip off the thread.

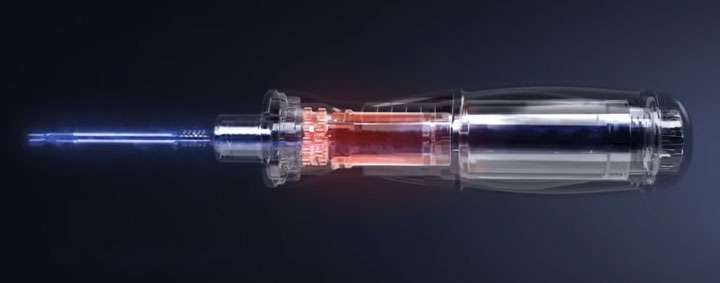

The designers installed a high-speed, sufficiently powerful motor in the WihaSpeedE screwdriver, which is connected to the drive through a two-stage planetary gearbox.

However, at the same time, the electronics of the screwdriver automatically limits the maximum tightening torque from the motor, preventing it from exceeding the value of 0.4 Nm.

As you understand, this is a very small moment, and it is unlikely that it will be possible to break anything with it. When it is reached, the electronics stops and blocks the drive.

Then you can safely manually, in the usual way, pull the fasteners to the required amount of torque.

The manufacturer claims that you can unscrew it by hand up to 8 Nm without breaking anything.

Cordless torque screwdrivers

Thanks to revolutionary progress in cordless tools, a wide range of screwdrivers for industry and assembly production has appeared. The innovative cordless screwdrivers are lightweight, ergonomic and autonomous, equipped with built-in torque and angle sensors and are successfully used in the most demanding assembly operations.

Modern cordless torque screwdrivers have a number of advantages:

- Cordless screwdrivers have built-in sensors and use advanced tightening strategies to control torque and / or angle.

- Wireless communication for remote control, transmission and data archiving in real time

- Instrument tuning is performed using the built-in keyboard, via a USB port or wirelessly with a PC using software.

- The screwdrivers are programmable by the operator and have a number of different parameter configurations: torque / angle / speed.

- Built-in multifunctional LCD display and keypad for quick setup

- Models available with built-in control board - no need to use a controller

- The flexibility of settings and the possibility of programming screwdrivers allows them to be used individually and as part of an assembly system - with data transmission over a wireless communication channel.

How to choose a ratchet screwdriver

What you need to know to buy a good quality product. Initially, you need to decide for what purposes the tool will be used. If it is planned to use it in rare cases, then inexpensive models of Chinese origin are suitable for such purposes.

When choosing the devices under consideration, you should pay attention to the following parameters:

- Rod design. The rod must be made of good alloy steel. The tool must indicate its characteristics, so the strength indicators should be in the range from 47 to 52 units. If the strength value is lower, then there is a high probability that the rod will simply break off during operation. Strength values above 52 units are unjustified, and contributes to a rise in the cost of the tool

- Manufacturing material. Rods and bits (if included) should be made from an alloy such as Chrome-Vanadium. It is from this material that many modern wrenches are made, providing them with strength and reliability.

- Lever. The ease of use of the tool depends on the quality of the handle. If the manufacturer wants to save money on the production of the product, then the handle is not covered with an additional layer.The best option is a handle with a polyurethane coating and rubberized inserts

- Equipment. The tool is sold as a set with a certain number of bits, and without them. It is recommended to buy a screwdriver separately only if there are replaceable bits in the arsenal.

Another important indicator is the manufacturer. Buying branded products speaks of quality, but at the same time the buyer overpays for the company. There are about 15 firms known that produce good quality reversible screwdrivers. Most of the products of Chinese companies are supplied in unsatisfactory quality, therefore, after the first use of the product, a failure of the reversing mechanism is observed.

SIBRETECH brand reversible tool

Some of the popular manufacturers produced by the products in question are:

- Intertool

- ZUBR

- Mastertool

- TopTul

- Makita

- Einhell

- Stanley

A reversible product, although it is not an obligatory tool in a DIY kit, will never be superfluous. With its help, not only the work of the master is simplified, but also the possibilities are increased. The average cost of a set is from 2000 rubles. There are products that are cheaper, but it is not recommended to buy them in the set. In a separate form, the cost of an average quality tool is from 1000 rubles.

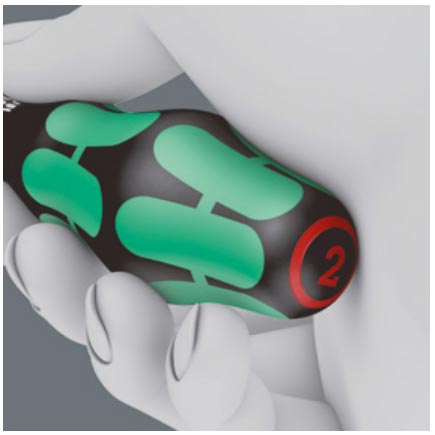

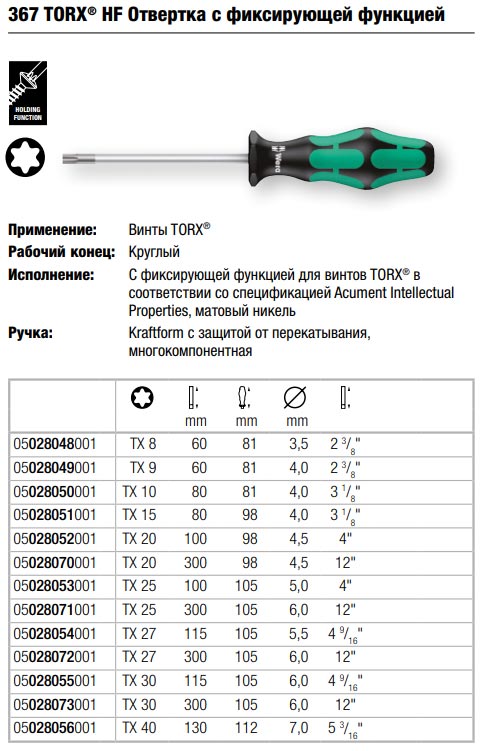

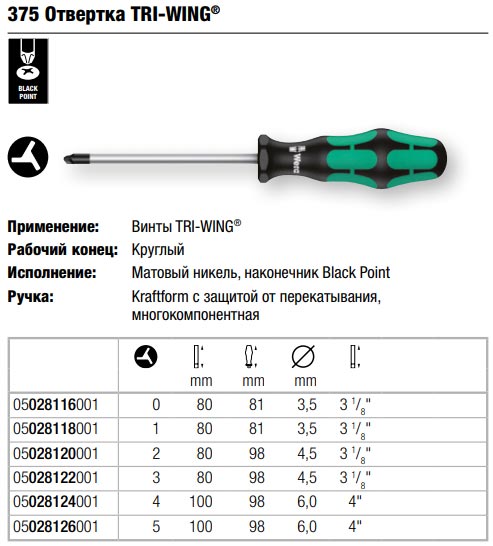

Wera black / green screwdriver

The ubiquitous black and green 300 Kraftform pen is the flagship of the Wera brand. From the very beginning, the company was convinced that it was the human hand that should set the shape of the handle, and not vice versa.

The ubiquitous black and green 300 Kraftform pen is the flagship of the Wera brand. From the very beginning, the company was convinced that it was the human hand that should set the shape of the handle, and not vice versa.

If you squeeze something like plasticine in your hand, then you will get just such a shape.

It effectively prevents calluses. In addition, the larger contact area guarantees a higher torque.

At the same time, the absence of protruding and sharp edges on the sides does not cut the palm and does not injure the hand, no matter how hard you press.

The handle itself is made of durable plastic, which securely holds the screwdriver shaft inside.

The black hard surface prevents slipping and allows you to quickly change the position of the hand. And green inserts help to achieve the best friction.

Thus, you can reliably control the turn effortlessly.

It is worth saying a few words about branded tips and bushings. Wera crosses have a special anti-slip technology.

The profile here is provided with special notches cut into the metal. They cut into the screw and prevent the screwdriver from slipping. The technology is called Lasertip.

It fits perfectly:

straight slot

Phillips

Pozidriv

And also thanks to such notches, there is no need to apply extra efforts for clamping when tightening the screws. The load on the hand and the screw itself with such screwdrivers is reduced by several kilograms.

The technical characteristics and varieties of these screwdrivers from the Kraftform 300 series are presented in detail in the tabs below (to view, click on the name).

Weidmuller screwdriver

Weidmuller torque screwdrivers are one of the best quality brands of such tools. It should be noted that the production of screwdrivers for Weidmuller is not a specialized occupation, therefore for them these screwdrivers are made by the Wiha company already known to us.

The entire line of screwdrivers consists of two types:

- designed for a moment from 2 to 8 Nm

- and from 0.5 to 1.7 Nm

They are quite weighty to the touch and feel like they are made of quality materials. The screwdriver itself is just an adjustable handle, so you will need to buy bits or a bit holder for it, like those used in screwdrivers.

The assortment of standard bits is small and limited to a few spline and cross-type options. The bit holder is the most versatile option. So it is possible to insert not only ordinary bits into it, but also, for example, bolt heads.

The installation of a torque screwdriver at the desired tightening torque is carried out with a special tool, which in fact is a simple hex screwdriver. Screwdrivers, like Wiha, are inserted into each other, and by turning, the desired torque is calibrated. The moment itself is displayed in a small window located at the top of the handle.

The tool's response to the required tightening torque is also controlled by clicking.After that, the screwdriver just starts to slip-slip inside, and the slot of the bit is in one place.

The cost of a large Weidmuller torque screwdriver (from 2 to 8 Nm) is about 12,000 rubles today. Small up to 1.7 Nm costs around 9,500 rubles.

Summing up, we can say that if you do not use small terminals in your shields, and in 90% of cases modular equipment prevails in them (automatic machines, RCDs, differential automatic devices, etc.), then the best choice will be in favor of buying exactly large screwdrivers with a moment from 1 to 5Nm. This is the one you will use most often.

Of course, all this increases the overall installation time. But you must remember that all these tightening torques, often written on the equipment cases, were made for a reason. The contacts are easy to both fail to reach (with its subsequent melting) and to overtighten (with the destruction of the contact).

Views

Today the construction market is represented by a wide range of tools, which provide a mechanism for measuring the tightening force. At the same time, an electronic screwdriver with a dynamometer is in special demand among specialists. It is adjustable, therefore it provides high-quality tightening of fasteners without the risk of breaking and damaging the mechanism.

Such screwdrivers are divided into three main types:

- torsion;

- limit;

- indicator.

Torsion screwdrivers are activated by bending a fixed arrow with a handle on which a special scale is located. Their measuring range is from 0 to 20 kg. m, drive size 1/2 inch. The error of such devices does not exceed 20%. The screwdrivers are easy to use as they can work in two directions. The advantages of the tool include an affordable cost, the disadvantages are the exclusion of the possibility of using in hard-to-reach places and low accuracy in measuring the moment. These devices are recommended for fixing fasteners that do not require high precision.

The limiting type screwdrivers are characterized by preliminary adjustment of the trigger torque. They are equipped with a special lock, scale and ratchet mechanism. This tool can control tightening forces from 0.5 to 150 kg. The units are available in a variety of drive sizes: 1, 3/4, 1/2, 3/8 and 1/4 inches. Screwdrivers function in two directions, their error rarely exceeds 8%.

Limit screwdrivers manage to tighten a lot of bolts in a minimum amount of time. The advantage of the tool is that you can work with it in hard-to-reach places without monitoring the indicators of the arrows.

As for the indicator type, it has a triple function. The ratchet mechanism is responsible for locking, twisting and unscrewing. The design of the screwdriver is provided with a panel with a button for turning on and measuring torque, an LED indicator, a buzzer and a button for recalling the last operations from memory. In addition, the multifunction display allows you to edit and set parameters. At the push of a button, the instrument returns to standard operation.

Thanks to indicator screwdrivers with built-in dynamometer, it is possible to monitor the behavior of the fasteners. Manufacturers also complement the design with a scale on which one or two arrows (setting and signaling) can be placed. One of the arrows is usually set when choosing the value of the tightening torque, and the second - to fix the current indicator. The fasteners are tightened when both arrows are aligned. This device is designed for double-sided operation and is used when tightening elements with both left and right threads.

The main advantage of indicator devices is that their error is up to 1%. In addition, the tool is easy to customize for any unit of measurement: kg / cm, kg / m, Nm / cm, Nm / m, ft / lb.Screwdrivers of this type can compensate for temperatures and keep the data of the last operations in memory. Upon reaching the tightening torque, the device emits sound and light indication. The disadvantage of the device is its high cost.

To expand the capabilities of torque screwdrivers, they are additionally equipped with special nozzles that allow you to work in hard-to-reach places where the head cannot reach the fasteners. The most commonly used nozzles are ratchet, horn and cap type. They differ in landing area and profile size. Thanks to such devices, a tool with a dynamometer becomes universal. Therefore, each master is recommended to have a complete set of interchangeable nozzles in a complete set with screwdrivers.

Main characteristics

The handles are made of injection molded or powder-coated plastic.

The first version has a soft base, and is characterized by elasticity, due to which the tool is comfortable to hold in the hand.

Powdered plastic is fragile, but at the same time hard.

A good tool usually has a rubberized handle.

She, in addition to ergonomics, has moisture-repellent properties.

Such a tool almost does not get dirty, and to clean it, it is enough to wipe the surface with a damp cloth.

In addition, the rubber layer has dielectric properties, which means that it is very convenient to work with elements of live electrical networks with such a screwdriver.

Another prerequisite for a high-quality handle is its resistance to aggressive chemical compounds.

For this, again, special rubber is used, which is able to withstand contact with chemical components.

However, prolonged contact with solvents or gasoline will damage the coating.

In this case, a plastic handle is a suitable option.

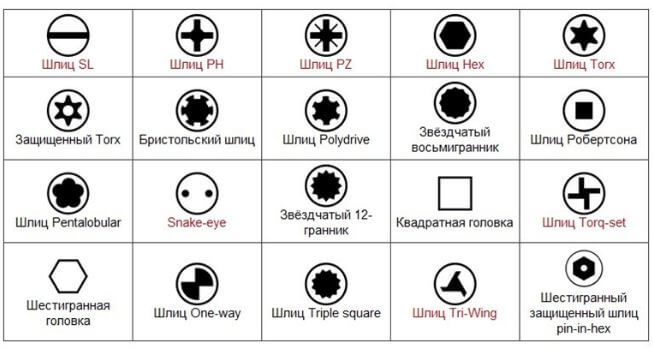

The most common types of reversible screwdrivers are:

• With reversible swivel handle.

As a rule, they are equipped with an adapter-adapter for socket heads.

These sticks are often used to work with head sizes 5 - 13 and profile bits SL - SL6, PH0 - PH2, PZ2, T6 - T30, SP4, TW2, TW3, HEX4 - HEX6.

• With reversible stick for precision work.

The dimensions of the tool are much smaller, most of the kits are supplemented with a flexible extension.

Often these screwdrivers are used to work in tandem with heads of size 2.5 - 5.5 and profile bits SL1 - SL4, PH000 - PH1, T4 - T10, HEX0.9 - HEX2, SP2.6, A0.8 - A1.2.

Screwdrivers with a set of bits and heads have a hardness of 45 - 50 units (Rockwell scale).

Made of chrome vanadium alloy.

The handle is covered with plastic and / or thermoplastic rubber.

The mode switches can be circular (part of the handle is rotated relative to the longitudinal axis), flag (a small lever is installed on the body) or sliders.

What is a reversible screwdriver

The name of the tool in question was due to the presence of a reversing mechanism in the design. Reversible screwdrivers are equipped with a ratchet ratchet that allows one hand to operate the tool. This way of using the product is very convenient, especially when work is done in a hard-to-reach place.

Reverse switching allows you to change the direction of rotation of the handle relative to the rod. This is very convenient when the work is done with one hand or in inconvenient for work with a conventional screwdriver.

The appearance and shape of the tool differs depending on the purpose. Usually, such products come on sale complete with a set of replaceable bits. These bits, depending on their number, are intended for unscrewing fasteners of different configurations. In addition, reversible instruments can be either mechanical (using physical force) or electrical.

Wera torque screwdriver

Consider a wera torque screwdriver designed for tightening screws and contacts with a torque of 0.3 to 1.2 Nm. These are mainly small terminal blocks. Bits are not included with purchase. Therefore, either use those that you already have, or buy separately.

Consider a wera torque screwdriver designed for tightening screws and contacts with a torque of 0.3 to 1.2 Nm. These are mainly small terminal blocks. Bits are not included with purchase. Therefore, either use those that you already have, or buy separately.

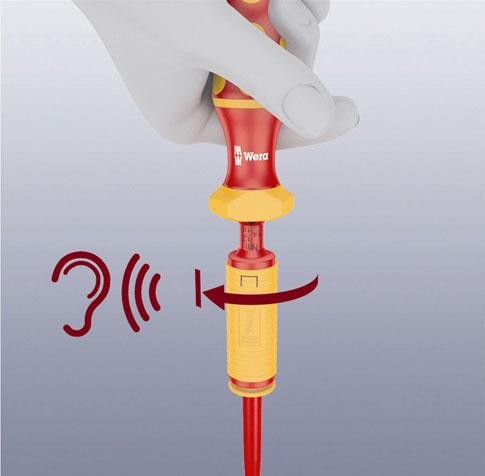

Has a keyless chuck for easy bit fixing. The torque is set in the middle of the screwdriver.

Press the upper element of the handle down and turning it around its axis, set the moment you need. It is determined by the number that should appear immediately on the border of the end of the handle, opposite the triangular risks.

The end of the tightening torque is audible. It indicates that the screw or terminal is tightened with the torque set on the scale and it is no longer necessary to tighten it.

For those whose hand slips when tightening the contacts, there are pistol-shaped screwdrivers.

They are mainly used for torques of 3.0 Nm and above. If an ordinary person is still able to tighten 2.5 Nm without resting too much, then very great efforts must be made to tighten the contacts above 3.5 Nm.

The main plus and difference between Wera and most other similar screwdrivers is that you do not need to have a special installation tool in the kit to set the required torque. All this is already implemented in the screwdriver itself.

Otherwise, the accuracy of the torque is no longer guaranteed.

The price for Wera torque screwdrivers starts at 8,000 rubles just for the handle itself. Is it expensive or not? Decide for yourself.

Imagine that you are assembling a custom-made shield. And in the process of tightening the contacts, your 3-phase difavtomat worth ten thousand cracked or cracked? The only way to prove your “innocence” to the customer and the store and not get serious money is to have a torque screwdriver and use it correctly.

You can get acquainted with the current price and choose the right screwdriver for yourself here.

Pneumatic screwdrivers with torque control

Modern pneumatic screwdrivers are high-tech and reliable. Torque controlled pneumatic screwdrivers are a separate class of precision tools and are widely used in many areas, including assembly in mass production.

The range of screwdrivers is huge:

- Available in straight, pistol grip and angle drivers

- The range of moments is wide - from 0.4 to 20 Nm (and more).

- Speed - from 250 to 2000 rpm.

- The pneumatic tool is made in the best traditions of ergonomics, lightweight and comfortable.

- Pneumatic screwdrivers have a similar series - like electric screwdrivers: from low torque for small fasteners - to loaded screwdrivers.

- Torque control - using an adjustable shut-off clutch or friction clutch. There are models with direct drive - with air regulation.

- In assembly operations, controllers are used for more accurate control of the technological process.

- The controllers are used to monitor errors, count cycles and batches, and monitor tightening operations for threaded connections. The controller has error control functions and is not intended to measure or adjust the tightening torque.

Where to buy torque screwdrivers in Ukraine?

The Automechanika company specializes primarily in tools for car service, and therefore we will not be able to the entire range of screwdrivers presented in this article, but still we are guided in the subject and in the manufacturers.

Today our assortment includes:

Professional hand torque screwdrivers from the world's best manufacturers - Snap-on USA and Hazet Germany. Contact us - we will always be happy to help.

Pneumatic, pulse and electric torque wrenches and hand multipliers

Electronic torque wrenches

All about torque wrenches: types, classification, features

Do you know how to work with a torque wrench?

Varieties of torque screwdrivers

Torque format fixtures differ significantly from simple tools. There are 5 screwdriver options in total:

- With manufacturer-fixed customer parameters that determine the torque. The screwdriver is applicable when installing electrostatically sensitive assemblies and electronics components. The devices regulate and dissipate energy, focusing on the cover of the tips and the handle. A striking representative of this group of dinanometric devices is the Vario-S ESD. The range in which the screwdriver is made is from 0.1 to 2 Nm.

- With integrated size scale. The scale is equipped with a torque pointer. She also fixes the maximum indicator. Simple tools help out if you need to tighten miniature threads. The screwing error can be as low as 3-6%. Those who work with electronics buy the tool.

- Without drawing the scale. The torque varies according to the purpose of the tool. A screwdriver is preferred for tightening expensive and fragile parts. The torque indicator is recorded on the toriometer. In this category, choose TorqueVario. The range of the attachment is 0.4-8 Nm.

- With setting scale. These screwdrivers are multifunctional and perform different tasks. The TorqueVario-S comes with interchangeable blades. The integrated scale is responsible for high safety values when working with equipment connected to high voltage.

- With T-lever. The tool tightens the fasteners with the torque set at a certain level. The craftsmen emphasize that the handle is very comfortable in them. The tightening is simple, there is no fatigue in the hands. When the torque is held at the desired value, the clutch slips. Padding is extremely rare, and only through the carelessness of a specialist. The arm of the attachment is covered with a special shell, which ensures the durability and wear resistance of the attachment. Additional stings are a nice bonus.

Equipment

The screwdriver is available in three configurations. They are all supplied in L-boxes.

The first starter kit includes:

the screwdriver itself

2 batteries

Charger

set of 5 insulated Slim bits

In these slim bits, the insulated part is a natural extension of the blade and in no way protrudes outward.

In these slim bits, the insulated part is a natural extension of the blade and in no way protrudes outward.

Due to this, it can be immersed deep enough into small holes limited in size and diameter. Nothing will interfere and rest against the walls.

The second assembly already includes more bits. Plus one adapter is added with a set torque of 2.8 Nm.

And the third, the richest and most expensive package, contains 16 bits and as many as 5 adapters with different preset points.

And the third, the richest and most expensive package, contains 16 bits and as many as 5 adapters with different preset points.

Reversible screwdriver purpose and how to use

A reversible screwdriver, called a ratchet, is designed to screw and unscrew fasteners (screws and screws) with a single hand movement. The need to use such a tool arises when the part is held with one hand, and the fastening element is twisted or unscrewed with the other. Instead of the device in question, you can use a screwdriver, but the power tool is not always suitable for performing certain tasks.

Stanley product design with nozzles

Ratchet screwdrivers get their name due to their reverse function. This means that the tool, or rather the handle, can rotate in both directions for the convenience of screwing or unscrewing fasteners. The device under consideration is based on a reversing mechanism located inside the handle. The considered device is presented in the form of a ratchet with a ratchet mechanism, which provides comfortable work with the tool.

It is interesting! The tool may seem unnecessary, however, this is a misleading opinion. With such a screwdriver, work is performed in hard-to-reach places with the movement of one hand.

Price and where to buy

What is the main disadvantage and why most of us are unlikely to run to the store for this tool in the near future? As trite as it may sound, it's all about its price.

Even in the smallest configuration, the cost of a Wiha SpeedE screwdriver set at the beginning of summer 2018 is more than 20,000 rubles. And in the maximum set it reaches almost 40 thousand.

As you can imagine, this is the salary of an ordinary electrician for a month or two. For ordinary fitters and craftsmen who do not turn hundreds of screws every day, such a device is unlikely to pay off.

In addition, when working with such a screwdriver on a construction site, there is no guarantee that it will not be accidentally damaged. You can skip watching and put it in the place where something heavy will fall or accidentally drop it from your hands, working at a height.

Situations are different, you cannot be insured against everyone. At the same time, it is a pity to break a screwdriver for 1000-1500 rubles, but not fatal. But to spoil a screwdriver for 40 thousand is a completely different matter.

You can get acquainted with the current prices in force today here.

Most of us can only hope that this revolutionary model will push other manufacturers to produce similar products. And then, due to competition, its price will drop significantly.

Well, at the end, I would like to cite a video from a German blogger, which shows a small test comparison of the work of a conventional screwdriver and Wiha Speed. See how much it really saves time on just 10 cogs.

Chisel screwdriver

If you've ever used a screwdriver as a chisel, then you know how traumatic it can be. The special line from Wera, the 900 series, makes this process much safer and more comfortable.

If you've ever used a screwdriver as a chisel, then you know how traumatic it can be. The special line from Wera, the 900 series, makes this process much safer and more comfortable.

The impact cap and shaft that runs through the handle prevent the blade from breaking or breaking.

Such products can be without fear:

screw

hollow

press out and release jammed screws and nails

In fact, it is a mini chisel with all the benefits of a screwdriver.

Among the impact screwdrivers, there are models with a square cap.

A key is inserted there and force is given due to an additional lever.

Blade modifications

In addition to the usual slot and cross blade, you can find an outlandish hexagonal ball head on Wera screwdrivers. For what is she needed?

Thanks to the hemisphere, such a sting can be used to unscrew and tighten the screws even at an angle in hard-to-reach places.

And if you need to tighten a screw, where it is generally impossible to get it with your hands, use special screwdriver clamps.

This is how they work.

By the way, they can be used not only with screwdrivers, but also with L-shaped keys and bits.

In general, Wera has a lot of modifications. Do you want unauthorized personnel to be able to unscrew any elements in your equipment, for example, in switchboards?

Use special fasteners with a protruding trunnion. It will no longer be possible to unscrew such a screw with a simple Torx or any other tool.

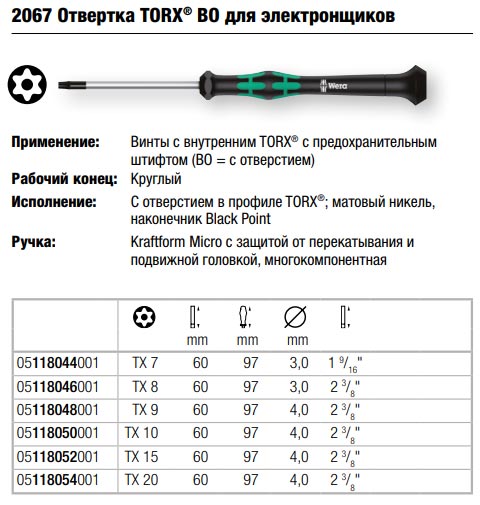

Here you will need a Torx BO screwdriver with a hole in the middle of the tip (see the link to it in the tabs above).

Provide such a device only to trained personnel and you will be calm about the safety of operation.

This handle design is nearly universal among all other Wera models.

Which set should you choose?

The German brand Wiha today offers its customers 3 main types of screwdriver sets.

- No. 1 - the simplest set, which consists of instructions, box, charger and two batteries. The manufacturer has equipped such a screwdriver with 5 replaceable bits. The device itself is convenient and safe to use and allows you to cope with tasks 2 or even 3 times faster. This set allows you to perform a wide range of jobs using just one tool.Set No. 1 is an irreplaceable assistant for private home use.

- No. 2 is a unique screwdriver equipped with the latest ratchet mechanism to get the job done faster and easier than ever. The unique shape of the handle and its material relieve stress during work and allow for a long time not to experience fatigue, which is why such a tool is recommended for use by many doctors. The set itself consists of a screwdriver, a charger, a battery, a limiter, a storage and transport box, as well as 8 different replaceable bits. This set is universal, as it is suitable for both home and professional use.

- No. 3 is the most extensive set in terms of content. In addition to the battery, charging and boxing, 21 bits are already included in it. With such a set, you can easily cope with the most time-consuming and hard-to-reach tasks quickly and easily. There is no discomfort or fatigue while working, and safety and reliability remain at the highest level. Such a set is professional.

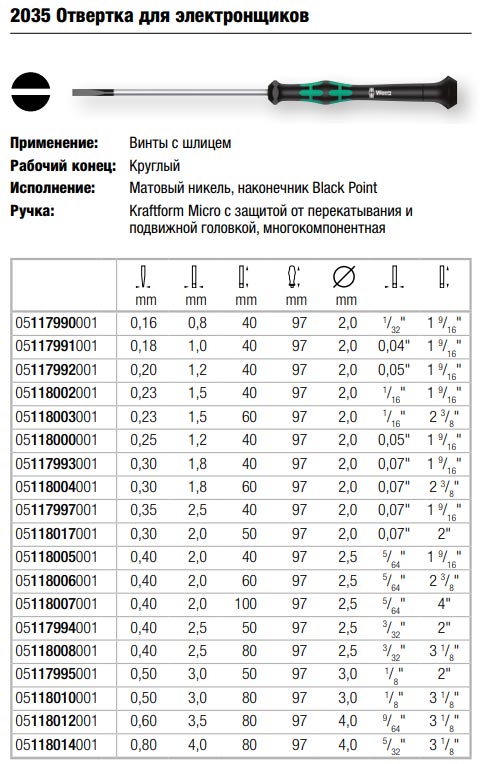

For electronics and precision mechanics

And finally, a line of the smallest screwdrivers.

Their handle combines three zones at once:

high-speed rotation zone

zone of effort

a precision zone that plays an important role in alignment work

They are available in both standard coating and antistatic finish.

They are available in both standard coating and antistatic finish.

The latter is used to work with electronics such as computers, tablets or phones.

By screwing the microscrews into your smartphone, electrostatic discharges must not be allowed. This will cause further electronics problems and may damage the precision components of the device.

You can work here only with an ESD tool that meets all the requirements of the DIN EN61340-5-1 standard. For ESD screwdrivers from Wera, the surface resistivity of the tip meets these requirements.

Full names of models for electronics and their decoding:

I would like to mention one more fact that you might not know about - the year of its creation is always printed on the handles of the original Wera screwdrivers.

So you will never forget how old your instrument is.

All of the aforementioned screwdrivers come with a limited lifetime warranty and come in a variety of colors that just look to help you instantly understand the product types and their uses.

You can view the current prices for this tool and buy your favorite models, or whole sets at once, here.

Source - Forumhouse

Types and varieties of screwdrivers

The types of screwdriver sets are very different, and you need to choose them based on the needs of a particular person. An ordinary person who is not engaged in repairs will also do classic equipment, but if you are, say, an electrician, everything is more complicated here.

Repair screwdriver set

The small case of these tools includes several sizes of Phillips and flat head screwdrivers. The middle package contains additional phase adjusting devices as well as devices with an insulating cover and magnetized tips.

Dielectric screwdriver set

It contains tools with hardened steel and material capable of withstanding up to 1000 VAC. With the help of such screwdrivers, you can work in energized electrical networks.

Precision screwdriver sets

Miniature screwdrivers designed to work with small mounts in mobile phones or household appliances.

Screwdrivers with bits

Screwdrivers with bit sets are a set with a variety of tool attachments. If we are talking about quality options, then they are very convenient to use. However, over time, the grooves for the nozzles become unusable, just like the handle from frequent use.

Specialist kits

Professional screwdriver sets include specific options and bits (nozzles).Usually, these kits are quite large, and you can find in them: TORX, PH shapes, wrenches, hexagons, dielectric screwdrivers and much more. Best suited for specialized workers.

Electric Torque Screwdrivers

Powered torque screwdrivers: Electric screwdrivers, pneumatic screwdrivers as well as pulse and cordless torque controlled screwdrivers make up a huge class of modern precision assembly tools for mass assembly production.

Electric torque screwdrivers for assembly production are produced in a wide range of forces and have design features - depending on the specific requirements of threaded connections and the field of application:

Electric screwdrivers 220V and 36V:

- Models: straight, pistol, angle

- Torque range 0.6 - 6.4 Nm.

- Speed 500 - 2500 rpm

- Disconnection is by current.

- Push and lever start

- Torque and tightening cycle controller

Low torque screwdrivers 12V and 24V

- Direct models,

- ESD anti-static models available

- Torque range 0.005 - 2.5 Nm

- Speed 500 - 1350 rpm

- Lever start, soft stop models

- Torque and tightening cycle controller

Precision screwdrivers

- Brushless motor with shut-off clutch

- Direct models

- ESD anti-static models available

- Torque range - 0.05 - 8 Nm (40 Nm).

- Speed 650 - 3000 rpm

- Push button, push and lever start

- Soft stop models

- Models with built-in memory chip

- Torque and tightening cycle controller

The list contains typical series of electric screwdrivers - when studying the program of each specific manufacturer, you can significantly expand or clarify the range of tools.

Controllers and software-controlled screwdrivers, automation of the assembly process

For mass production, it is not the tool itself that is important, but a complex system that works to obtain the maximum result - with 100% quality control of the technological process.With the use of software controllers, quality assurance and control of the assembly process is performed using advanced tool management functions:

Let us explain on a visual graph - the change in torque in the process of tightening the connection. At 3 main stages of the process, various parameters are monitored and adjusted:

- 1 - screw installation: The moment and the angle of rotation are recorded. If the hole or fasteners are of poor quality, a signal is given and an error is noted.

- 2 - Screw tightening: The angle (speed and speed) is monitored and adjusted and the torque is monitored. Depending on the material, you can select the rotation speed, if there is a defect in the thread, the moment changes and this is immediately recorded.

- 3 - Fastener tightening: Fastener tightening begins from the seating point - the moment increases. The torque is monitored and regulated and the angle (speed) is monitored - until the tightening torque.

All process parameters are programmable and controlled. The operator receives signals - light and sound.

In mass production, every connection is controlled this way, and all assemblies in a batch with a cycle counter. At the end of the entire assembly process, all deviations and violations in the batch are recorded: the data is processed, displayed in detailed reports and archived.

The controllers are compact, convenient - a wide range of this equipment is produced for working with electric, pneumatic and hand tools. The controller can work with a group of tools, controlling the sequence and strategy of assembly operations. Further development of the topic of automation of assembly processes - the use of various manipulators to increase the speed of operations - up to robotic complexes, but this is another topic.