Which hiller is better for a walk-behind tractor?

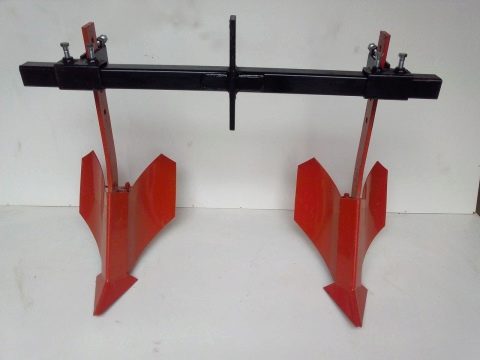

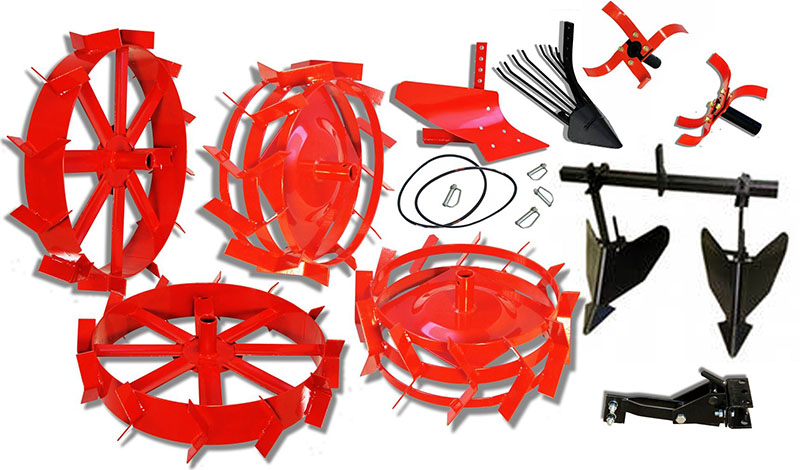

Modern manufacturers of agricultural machinery are trying to meet the ever-increasing demands of users, so each brand produces specialized hillers, fully adapted to the specifics of a walk-behind tractor of a certain manufacturer. For example, for Neva, MB 2, MB 1 and Agro units, you can purchase the following types of additional assistants:

Riggers for potatoes for a walk-behind tractor, having a clearly marked working width

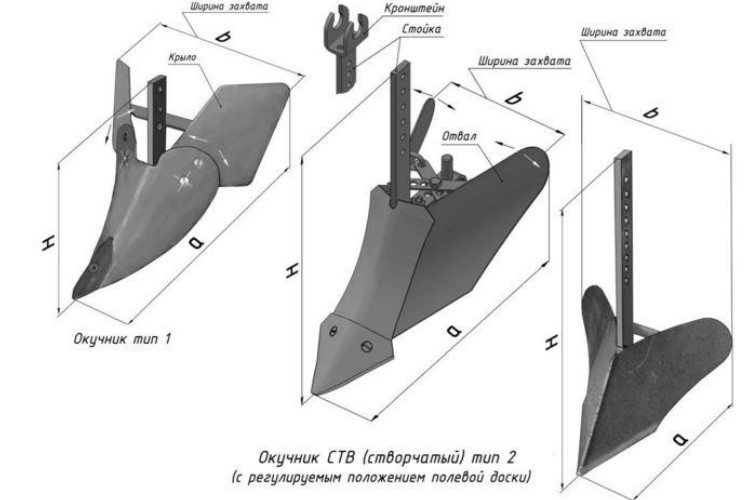

Such an object is considered one of the simplest and has another name - lister. It is used for processing narrow-plan row spacings, the width of which does not exceed 30 cm. As for the design features, the hitch consists of several wings fixed relative to each other. This option is suitable for low power walk-behind tractors (about 3.5 hp). Thin stand contributes to the appearance of additional protection of the device from overloads. The negative aspects of such a development include the impossibility of working with wet ground, since the soil simply sticks to the wings, preventing the equipment from performing its task;

Hiller with variable working width

The main advantage of this type of tool is the ability to adjust the working width. With its help, it will be possible to process rows of completely different sizes. Suitable for more powerful cars, because it consumes more energy. Often, such devices are in the form of double-row hillers, which make it possible to perform the necessary operations with even greater efficiency. For adequate operation, it is necessary to plant the grousers of the walk-behind tractor on extension cords;

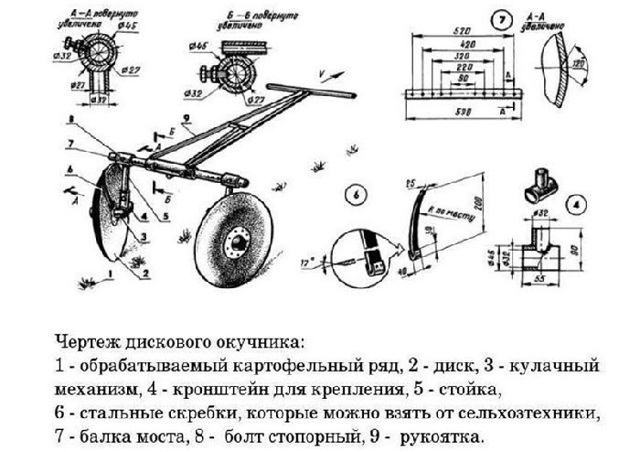

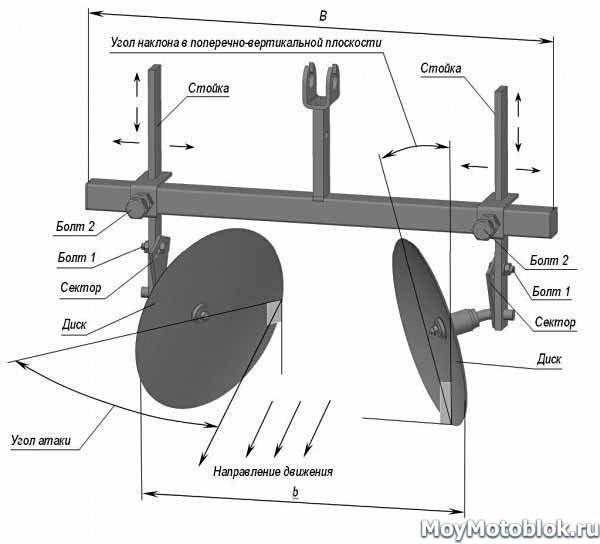

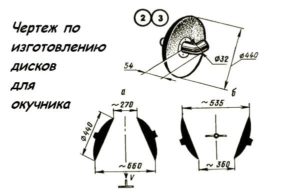

Disc hiller

It is considered the most convenient, since it can be used to qualitatively prepare furrows for planting seeds. A feature of the part is the placement of the dump discs at a certain angle. The productivity of use is much higher than that of the previously considered models;

Dutch type hiller

The specificity of the development of such a plan is the rotation of the wings in several planes. It seems that the bottom edge of the wings follows the contour of the ridge. This approach allows you to make your care more productive with the least amount of energy. Affordability is also a significant plus;

Propeller hiller of the active plan (rotary)

The technical device allows you to efficiently perform the hilling procedure, to throw up the earth exactly to the roots of plants. An important point: you can work with such a device in the second forward gear of the walk-behind tractor, which not every car can boast of. The overdrive will allow the hiller to rotate at a speed of 160-180 turns per minute, due to which the soil is "thrown" from the row spacing to the rows themselves.

Features of operation and maintenance

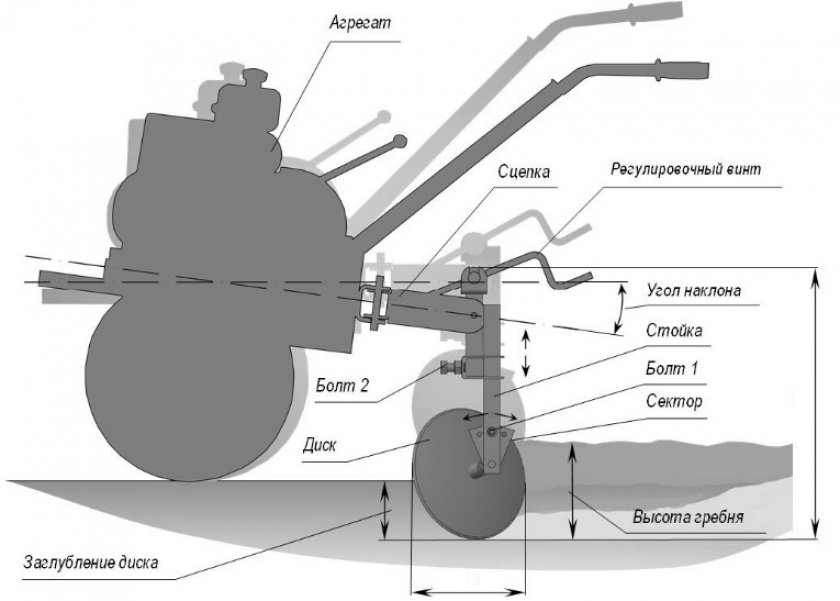

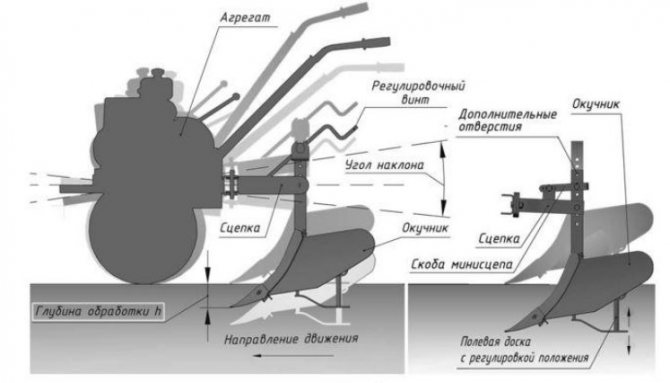

Installing a hiller on a walk-behind tractor requires adherence to the rules for adjusting the angle of attack and depth of immersion, while it should be less than a plow. Wheels and a hitch are installed on the hiller, after which it is attached to the main unit. The tiller is installed on a flat surface, while the tiller is lowered and connected by means of a hitch.

When installing attachments, the operator tries to ensure that the tiller's stand is vertical. It is this position that is necessary for the correct setting of the optimal angle of attack. After that, the hitch is lowered to the ground or even deepened a little into it.

It is important that the equipment is positioned below the star support

Before starting the main work on plowing or hilling the land, it is necessary to carry out a trial run in a small area.

It is important to work in good weather, after checking the sharpening of the working elements. In addition, before starting work, it is necessary to assess the condition of the soil.

Along with this, it is necessary to determine the optimal speed of work, since a correctly selected indicator will contribute to greater efficiency and quality of work. For example, if the speed is high, the hiller will simply spread the ground in two directions instead of creating a slide and furrow. When the equipment in the process of work goes too deep into the soil, it is necessary to tilt the rack forward, for which the toe is raised.

When it is necessary to plant potatoes using a hiller and a walk-behind tractor, marks must first be made with a distance of about 65 cm. After that, furrows are created and the planting material is laid out in them. After that, the wheels need to be replaced with rubberized ones, setting the wings to the widest possible position. Having put the unit in the aisle, they pass the entire row with a walk-behind tractor, covering the planted potatoes with earth.

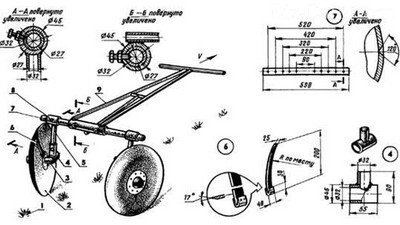

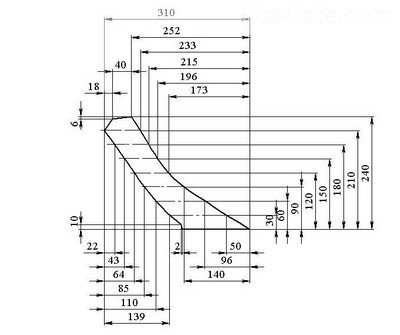

Setting up the disc hiller primarily provides for its correct direction relative to the furrow. The device should be positioned parallel to the beds with a given angle and working width.

This will determine the depth of tillage (furrow depth). If a moving type hiller is installed on the walk-behind tractor, it is necessary to adjust the width and height of the ridge.

In the disc model, the working width can be adjusted. To do this, the lower points of the discs are set aside by about 40–70 cm (the specific value will depend on the distance between the rows). When adjusting, make sure that the discs are located symmetrically in relation to each other.

With such devices, the soil is treated three times per season:

- when the seedlings grow up to 15 cm;

- when they grow up to 23-25 cm;

- at the time of flowering.

Attachments for planting potatoes with a walk-behind tractor

Attachments to the walk-behind tractor are used to perform various works, such as planting, weeding or hilling crops. For planting potatoes with a walk-behind tractor, a hiller or a mounted potato planter is most often used. These devices differ from one another both in appearance and in the way they are used. The second option can be called more automated. Let's consider them in more detail.

There are a great variety of attachments for motoblocks

There are a great variety of attachments for motoblocks

Related article:

How to plant potatoes with a walk-behind tractor with a hiller

A hiller is a tool for a walk-behind tractor that is capable of making furrows in the ground. Their depth is adjusted by the operator. The hiller can be single-row or double-row. Planting potatoes in the ground using a hiller can be called partially automated. After all, after the furrow is ready, it is required to manually place the seed in it, and then cover it with earth. Of course, the hiller successfully performs the most difficult work (manual digging of holes), however, it will take a lot of planting time, especially if the area is quite large. That is why a device such as a potato planter is most often used for such purposes.

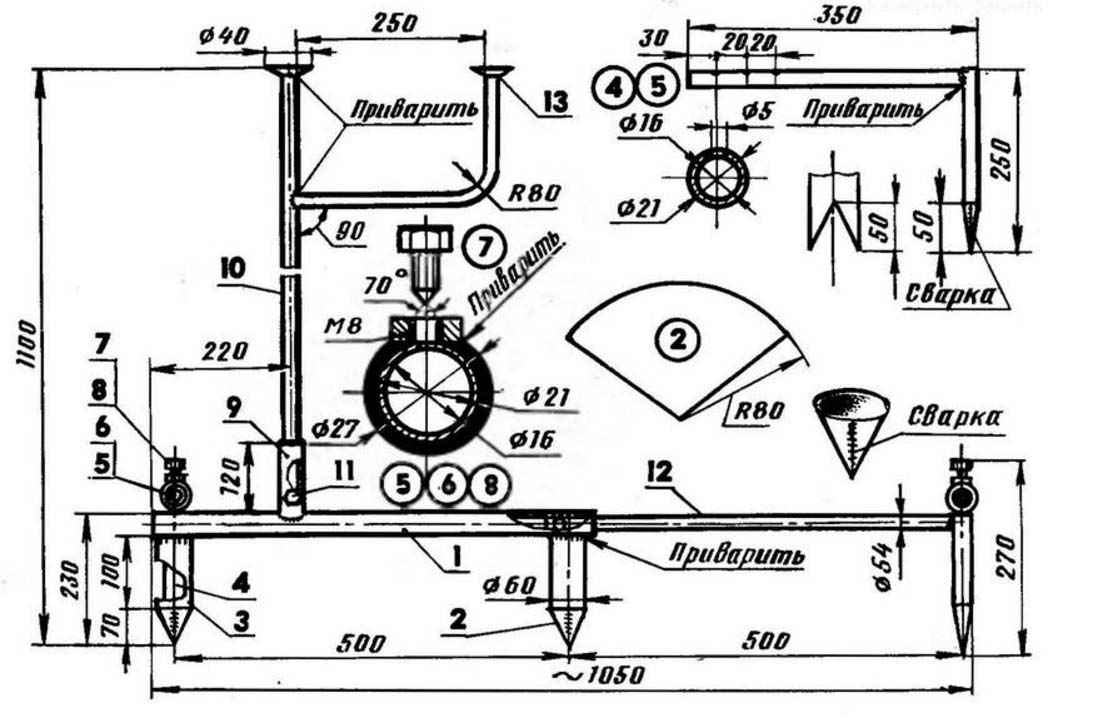

Potato planter: the principle of work with attachments

The potato planter allows you to fully automate the process.

If we divide this attachment into parts, 4 main ones can be distinguished from them:

- the hopper into which the seed is poured;

- mechanism for feeding it;

- baking plow;

- a mechanism that fills the furrow.

When using a potato planter, it is only important to correctly install the attachments on the walk-behind tractor and adjust the dimensions for deepening. If everything is done as it should, the operator will have to fill the seed material into the hopper, start the walk-behind tractor and monitor its operation, setting the direction of movement

The potato planter, which will be pulled by the walk-behind tractor, will independently make a furrow, lay seed material in it and fill it with soil. In terms of time, we can say that the average speed of a potato planter is about 12 acres per hour. Small errors may be due to the density of the soil, the model of the walk-behind tractor or the size of the seed.

PHOTO: mup-apu.rf Such equipment can be made with your own hands

PHOTO: mup-apu.rf Such equipment can be made with your own hands

In order for the reader to understand the process, we suggest watching a short video about planting potatoes using a walk-behind tractor.

However, it is not enough to plant potatoes on the site. During the season, it will need to be hilled, weeded, and after that it will also need to be dug up. We will analyze other equipment for the walk-behind tractor, which will help to perform these works.

Views

Hillers are attachments that help hilling plants. In addition, such a nozzle is used to create furrows, placing seeds in them, followed by filling them with loosened soil. Hillers can be of different types.

- Lister. They are a model with a constant row width, that is, two fixed wings look like a monolithic structure. With the help of such a nozzle, hilling occurs with the formation of a row 20-30 cm wide. A cultivator equipped with lister equipment does not change the width of the soil, and therefore the row spacing will have to be adjusted to the existing equipment.

- The working knives of the nozzle with a variable grip width have an adjustable design and are able to move, changing the width between the rows at the discretion of the owner. For such a nozzle, the cultivator must have a capacity of at least 4 liters. with.

Disc hillers can be considered more effective in this case. Those who have tried to work with them are unlikely to prefer other equipment.

When choosing disk nozzles, you should pay attention only to high-quality models made of alloy steel of the largest sizes. Bulk ridges they turn out to be much higher.

The Dutch-type hiller does not match the performance of the disk, but it is much better than conventional equipment, since the wings are able to move not only in turns, but also vertically.

- An active (propeller) hiller can compete with a disk hiller in efficiency. With the help of his propellers, he loosens the soil, grinds the weeds. Its embankments are of better quality and air.

- The plow-shaped hiller is often used for working with potatoes. It can be single-row and double-row, that is, it differs in the number of rows processed. With a two-row hiller, the work is more stressful, it is more difficult to manage it. Its wheels should be replaced with large diameter lugs.

Views

Manual and automated hillers can be subdivided into the following types:

disc is a simple tool suitable for one person;

It is clear that the disc options are easier to use, they are often automated by linking them with motor vehicles. The ridges of the earth after the disc hillers are higher. There is also a negative point in these devices - the price. In comparison with the plow hiller, it is four times higher. Externally, the tool looks like a frame with wheels on which the disks are suspended. The distance between them can be changed in accordance with the row spacing. The discs are set at a certain inclination, which is not recommended to be adjusted in relation to the vertical. Without a constant equal distance between the circles, the tool will pull sideways.

The simplest type of hand plow has a predetermined working width, wings (plows), shifted relative to each other, which are stationary. This is convenient if the row spacing has already been determined, and the tool fits them. Another advantage of the fixed width hillers is the possibility of using light cultivators weighing up to 30 kg. The advantage lies in the compactness, and the negative side is hidden in the limited work in wet areas. This is where the tool will stick in the soil.

A variable width furrower is the most common option. The adjusting mechanism is simple, but it allows you to move or extend the wings, adjusting them to the desired width for the row spacing. The tool can also be automated, but only with heavy walk-behind tractors. The wings of such a hiller move the earth in both directions at once. After the tool passes, the piece crumbles back into the line that it cuts. For a more efficient harrowing process, a more powerful walk-behind tractor is required, otherwise it will seem harder to pull the hiller than to work with a hoe or hoe.

Technology of planting potatoes with a walk-behind tractor

Tips for proper landing with Pro, Viking, Crossser, Patriot, Cayman walk-behind tractors:

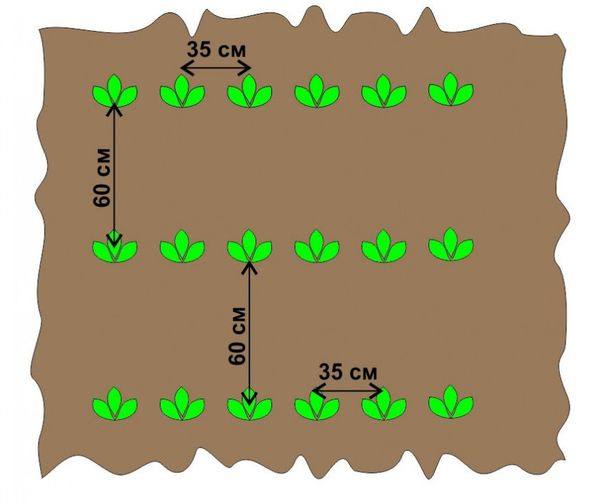

- The row spacing when planting potatoes with a walk-behind tractor should be from 55 to 65 centimeters.

- The furrows must be made even, this will simplify the care of the root crop.

- You can fertilize the soil before planting.

- The distance between the tubers is 25-30 cm.

The depth of planting potatoes under the walk-behind tractor is 10-12 cm.

The distance between the rows when planting potatoes with a walk-behind tractor should be the same. Pay attention to the track width, it should be even. When cutting furrows, try to keep them straight. If necessary, stretch the ropes to navigate along them.

Consider the main methods of planting: with the help of a hiller, an attached element - a potato planter, planting under a plow, planting in a ridge.

How to plant with a hiller correctly, at what distance and depth

For planting with the help of a hiller, wheels with lug elements are placed on the cultivator. The Tarpan motor cultivator is well suited. The grooves are cut. You will have to plant potatoes manually. Change the lugs to standard rubber wheels after disembarking.

Rearrangement of the wheels is necessary in order not to injure the seed. The track width is left the same - 55-65 centimeters, and again walk along the furrows. The tiller will cover the row with earth and compact the seed.

Planting with a hiller is a less expensive option. The set of the unit should only have metal and rubber wheels, and the hiller itself. The disadvantage is manual planting of potatoes. For large cultivated areas, a mounted planter for a walk-behind tractor is used.

This method is considered the least time consuming. The unit includes:

- The conveyor is a kind of conveyor that delivers seed.

- Furrow maker, for making a furrow.

- Dispenser for feeding potatoes at regular intervals.

- Disc hiller for making and filling furrows.

How to plant with a potato planter

By planting potatoes with a tiller for a walk-behind tractor, you can save three times more time than planting with a hiller. The process is fully mechanized. The potatoes are planted and huddled at the same time. The potato planter has its drawbacks.

First, the seed should be selected more carefully. The tubers must be the same size. Young shoots are not very long. Otherwise, the seed will be injured during planting. Secondly, this method of planting is more expensive.

Together with a planter for a walk-behind tractor, you can use a special device for simultaneously applying fertilizers to the hole, along with the seed.

We plant with a plow

It is necessary to install lug wheels and a plow on the walk-behind tractor. The soil is prepared by loosening, using a cutter. The plow for planting is inserted into the ground to the depth of the shovel bayonet.

It is more efficient to land two people. The first manages the walk-behind tractor, and the second puts the potatoes into the furrow. The work is done promptly. On the first pass of the row, seed is laid. And during the return passage, the sown furrow is covered with earth from the newly plowed one.

Ridge landing

Planting potatoes in the ridges with a walk-behind tractor is practiced in areas where groundwater is located very close to the surface. To do this, use a walk-behind tractor to form ridges with a height of 15 - 20 cm. The tubers are planted in the ridge.This option is only acceptable for well-moistened soils.

Basic selection rules

When choosing equipment for hilling potatoes, you need to proceed from the following parameters:

- Growing area. The more it is, the more complex the tool is needed: on 3-5 acres of summer cottages, you can work with a hoe or a hoe - but on large areas, more complex mechanisms are needed.

- Propulsion used. For manual hilling, you can use a simple lister or disc hiller, but for a walk-behind tractor you need a specialized nozzle. In industrial cultivation (ranging from 20-30 acres and more), you can either use special models of hillers for a tractor or at least a horse - or use a simple plow with ordinary plowshares: they are worse than normal hillers - but more accessible.

- The soil. The heavier it is, the more often you need to spud the potatoes - and the greater the need for a special tool. On the sandy soil of the east of the Belgorod region, an ordinary hoe is enough - but just forty to fifty kilometers to the east, on the dense clayey chernozems of the Voronezh region, it is already advisable to use a specialized hiller.

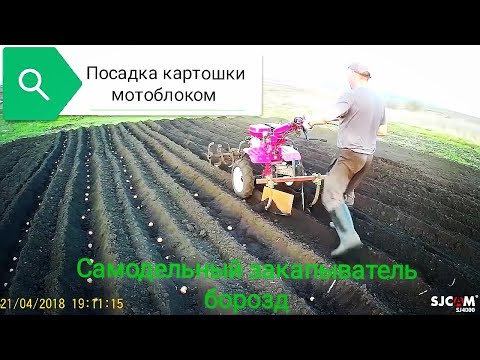

Planting potatoes with a motorblock

So, we have prepared the garden, now you can start planting potatoes with a walk-behind tractor. To do this, instead of cutters, we put lugs, having previously put on iron extensions on them.

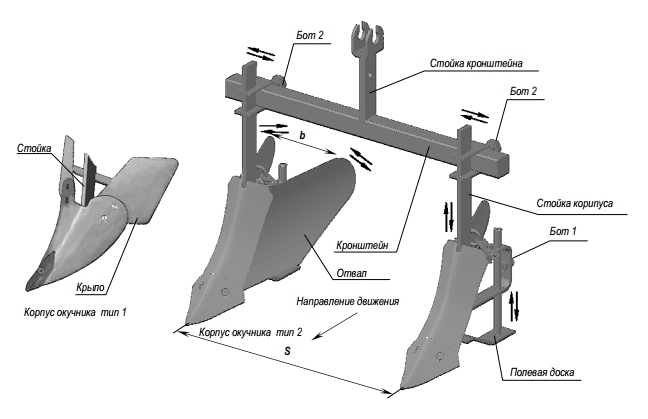

On the Neva-MB2, you must first remove the wings. We remove the central emphasis from the walk-behind tractor, in its place we hang the hitch.

Everything is done very simply, just insert metal pins into the holes. We attach a two-row hiller to the hitch. Before that, we make the distance between the hillers equal to 65 cm, this will be the width between the beds.

Let's mark the garden with a special marker, which we will make with our own hands.

To do this, screw short pegs to a long wooden handle with self-tapping screws so that they resemble a rake. In total, we need 3 pegs, the distance between them is also 65 cm. Take a marker and draw stripes with it. To maintain the distance, you need to run the extreme peg along the already drawn line.

Let us adjust the cultivator to the markings and at the first speed press to cut the furrows.

The hitch can change the position of the hiller, thereby increasing the depth of processing. To do this, turn the adjusting knob. Having reached the end of the garden, we turn around and go in the opposite direction.

You can put one hiller into the already made furrow, or you can, if the soil is soft, follow the marked lines. Having cut as many furrows as necessary,

let's start planting potatoes. We throw pre-germinated tubers in the ridge, keeping the distance between them 35-40 cm.

Before that, it would be good to process them in a special composition from the Colorado potato beetle, it is called Prestige. Looking ahead, let's say that the method works, the beetle is not on the leaves for a long time. But when the drug stops working, a few larvae still appear.

After planting the potatoes in the furrows, we begin to fill it up. Before that, on the hiller, we will increase the width of the wings, expanding the blades as far as possible, if the design of the equipment allows this. We put the technique in front of the ridges and, at first speed, cover the potatoes with earth.

This operation requires a certain skill, since you have to control two ridges.

To make it easier, you can remove one hiller, and put the second in the center.

Instead of lugs, we will install rubber wheels. We direct the cultivator to the center of the ridge and fill up the potatoes in the same way, bed by bed. If you do not have a two-row hiller, all the work of planting potatoes with a walk-behind tractor can be done single-row. But for this, the width between the ridges must be made equal to 70 cm. This size is optimal.In the end, if there are any irregularities, we will correct the beds with an ordinary hoe.

Watch the video

Mechanized maintenance of potato beds

For better growth of potatoes, it is necessary to huddle it, that is, sprinkle the stems with loose earth. During the season, this procedure is performed 2-3 times:

- The first hilling is carried out when the height of the bush is 15 cm, that is, in the middle - end of May. The height of the comb should not exceed 10 cm.

- The second time the potatoes are hilled when the plant height reaches 20–25 cm, that is, two weeks after the first hilling.

- After 10-14 days, you can repeat the procedure again. Now try to fill the soil as high as possible.

It is most convenient to spud potatoes with a walk-behind tractor with a disc hiller

Hilling potatoes with a walk-behind tractor significantly reduces the amount of time spent on this type of work. They do it as follows:

- A hiller is installed on the walk-behind tractor, the angle of attack (rotation) of the device is adjusted and the depth of its immersion is adjusted.

- Rubber wheels are replaced with lugs.

- The unit is installed exactly in the center of the row spacing.

- The movement is carried out at the lowest speed of the walk-behind tractor.

Video: hilling potatoes with a walk-behind tractor

Instructions

In fact, planting potatoes with a walk-behind tractor is not difficult. It is necessary to follow certain instructions clearly, and you will definitely succeed.

Site preparation

Planting potatoes with a walk-behind tractor is carried out only after the soil has been processed. First, the site needs to be plowed, and then booked. This will allow the soil to become saturated with oxygen and become more lush. For plowing the soil, special cutters or a plow are used.

To crush breasts, you can use a walk-behind tractor or an ordinary rake. Of course, the second option is suitable if the personal plot is small. There are models of walk-behind tractors that loosen the soil while plowing to a depth of 20 cm.So sometimes there is no need to make a reservation

When preparing a site, it is also important to understand which vegetables can be planted after which

The video shows the preparation of the site for planting potatoes:

Processing should be done from the edge of the site. After plowing 2 m of soil, which are located perpendicular to the furrows. If you want the entire garden to be plowed to an equal depth, then using a plow, grab a part of the already prepared soil.

Now you can outline the rows. In order for potatoes to grow qualitatively, it is necessary to achieve free aisles. A distance of 60-70 cm must be maintained between the rows. Everything here is determined by the type of potato. When the holes have been prepared, then there is a direct planting of potatoes using a walk-behind tractor. You can also use fertilizers, but this article will help you understand how to make fertilizer from quail droppings.

Unit preparation

Before performing work, you need to prepare the cultivator itself. Instead of cutters, lugs will have to be mounted on the machine. But instead of the center stop, a hitch should be installed there. All these activities are completely easy to carry out. Now install metal pins and a double-row hiller in the existing holes. On it you can set the required row spacing.

To plant the tubers, you must use a distance of 65 cm. If you decide to use other types of hillers, then their installation should be carried out in the same way according to the instructions.

Landing technique

Today, two main planting methods are used - a potato planter and a hiller. We'll have to dwell a little on each of them in order to understand what differences exist between them and which method is still better.

Whichever unit you use, you need to understand that there should be a distance of 20-30 cm between potato seeds in a row, and planting material should be planted to a depth of 10-15 cm.

If you use a regular hiller, then attach it to the walk-behind tractor. For comfortable placement of potatoes in rows, it is worth moving the dumps and increasing the wing grip. If you use the Neva walk-behind tractor, you will need to dismantle the wings and the main emphasis from it. But if you use the Salute walk-behind tractor, then you do not need to carry out such events. It is imperative to fix the lug wheels on the walk-behind tractor.

The track should be at least 60 cm wide. Place potato strawberries in the already prepared grooves. Do this at an equal distance. Then take a walk-behind tractor, put rubber wheels on it, but the track width values should be unchanged. There should be a maximum distance between the wings. Now you can fill it with fresh soil next to it.

If you have large areas in your possession, then planting tubers will be convenient if you use a mounted type of potato planter. The design of this unit assumes the presence of a furrow maker, a conveyor and a disc hiller. Thanks to him, it is possible to plant and fill the planting material with earth in one pass along the row. You can create a potato planter for a walk-behind tractor with your own hands.

The video shows how potatoes are planted:

Summer residents also use the method of planting a walk-behind tractor under a plow. For these purposes, wheels and a plow are mounted on lug wheels. Thanks to the plow, the first furrow is outlined. Potato tubers should be thrown in a row, since at the end the unit with the plow turns around and only one side makes new grooves, and also floods the already planted tubers with earth.

But is it possible to plant onions after potatoes, and how the planting takes place, is described in this article.

Is it possible to plant tomatoes after potatoes, and how to do it correctly, is indicated here.

You may also be interested in knowing if you can plant tomatoes after potatoes.