About the elements

They are needed when cultivating the soil. Therefore, the quality of processing and the complexity of the procedure itself depend on the model: load on the motor, ease of control and labor intensity.

How to assemble the cutters?

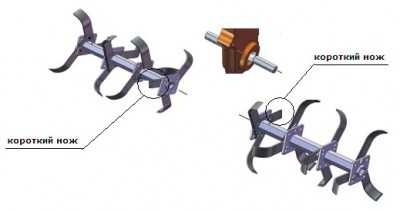

As a rule, the milling cutter is included with the walk-behind tractor. But that may not be enough. Sometimes an increase in the depth or width of processing is required, so the device can be supplemented with other products. This solution also allows you to improve the process of moving the walk-behind tractor. In addition, this will increase the service life of the mechanism.

If the soil is clayey, then it is better to use two pairs of tiller-cultivators. And even if the soil is light and has already been worked before, additional elements will not become a hindrance.

Depth adjustment is possible due to the adjustable coulter. It is a durable element located vertically in the hitch of the walk-behind tractor. And the final loosening depth is influenced by the diameter of the cultivator cutter.

If you want to make do-it-yourself cutters for a walk-behind tractor, you should start by determining their types. Two types of construction can be distinguished:

- "Crow's feet";

- with saber knives.

The last option is the most demanded, it can be called standard. After all, these types of products have been tested by time: their effectiveness is quite high. They have an optimal shape and material. Knives are made of high quality high strength steel. Additionally, the material undergoes thermal hardening and high-frequency current treatment.

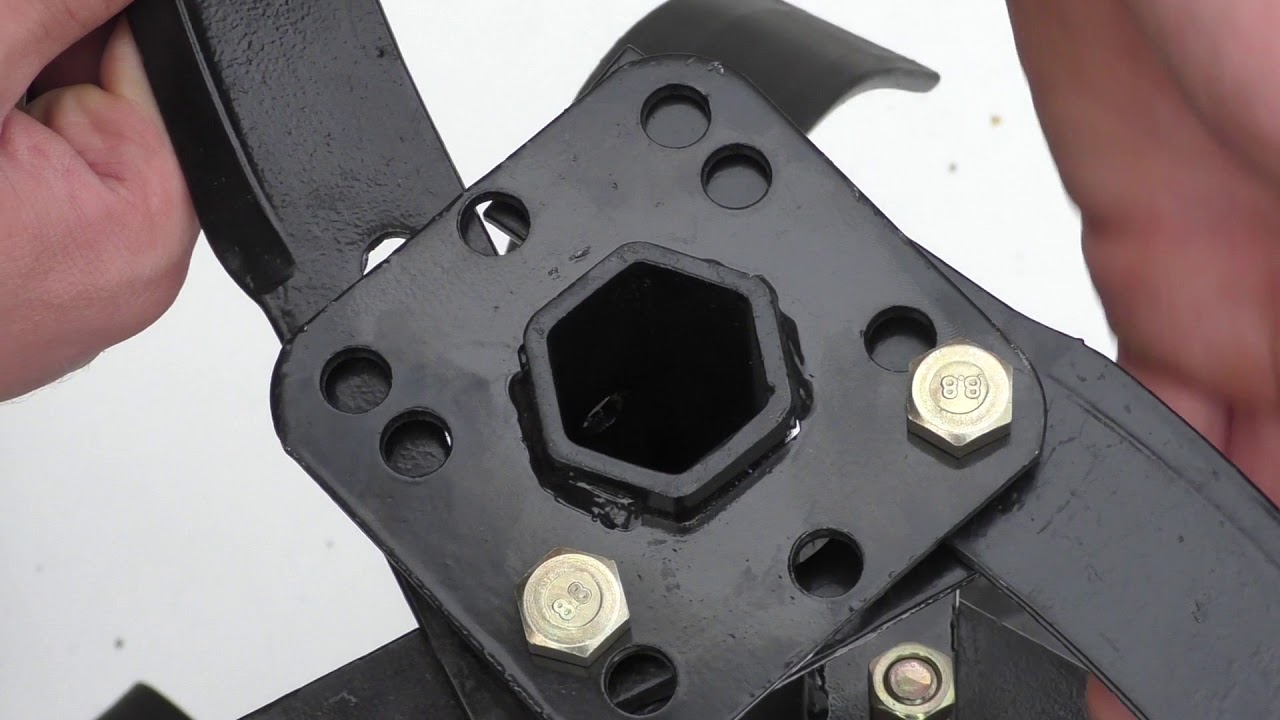

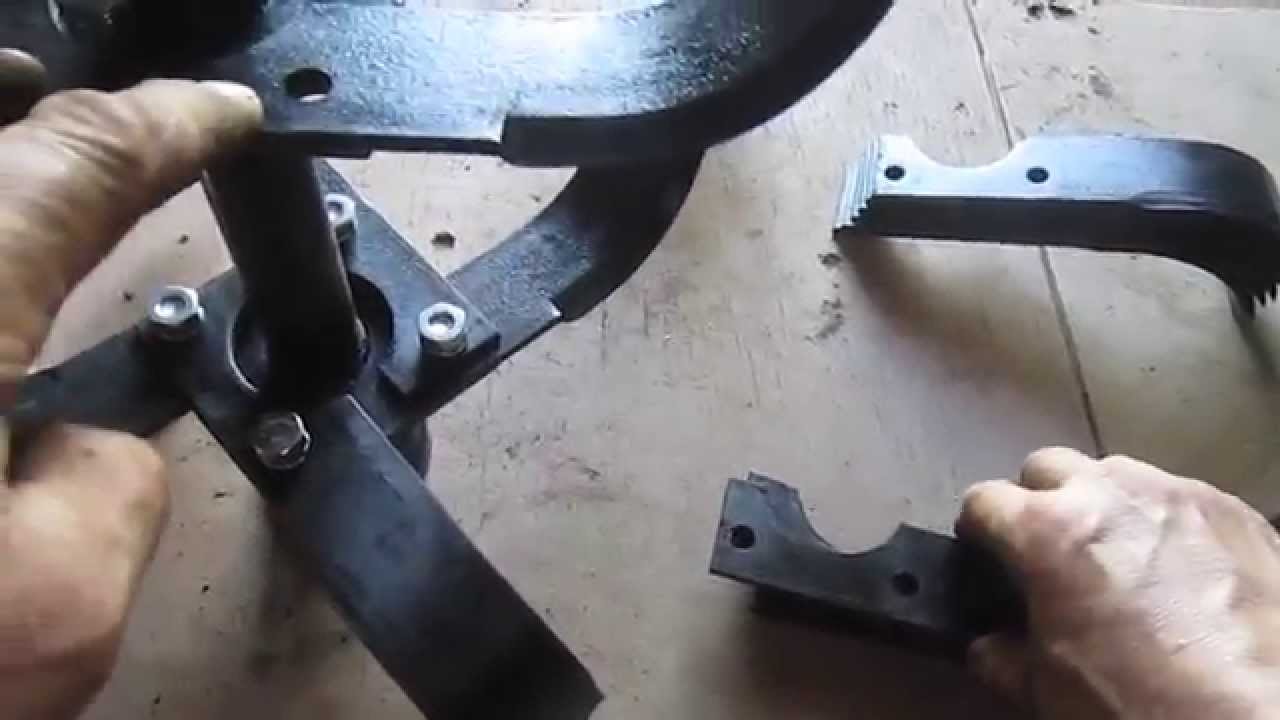

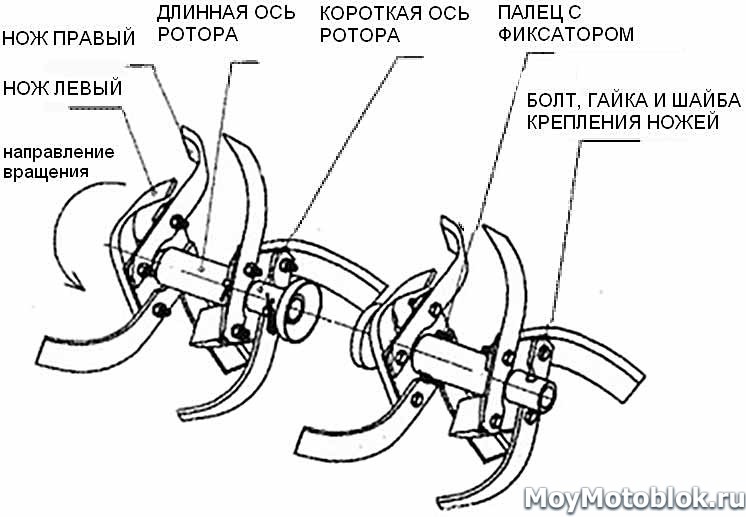

It should be noted that the cultivator cutters have a collapsible design. This feature is due to the fact that the material does not accept welding well. As a result, before installing the product on the walk-behind tractor, its preliminary assembly is required.

With regard to products "crow's feet", such products are used for hard soils. They have a solid construction, non-separable. Due to this, their strength is high.

Characteristics of crow's feet:

- weight - 16 kg;

- speed - 2-5 km / h;

- height - 38 cm;

- length - 38 cm;

- width - 41 cm.

Such products are effective in weed control and virgin soil cultivation. However, their disadvantage is the material of manufacture - carbon steel. This affects the strength of the products: therefore, the virgin soil must be processed very carefully so as not to bend the products. However, this allows, firstly, welding, and secondly, repairs.

It should be noted that the cutter is a self-sharpening tool. Additional manipulations in this direction are not required.

Factory cutters "crow's feet"

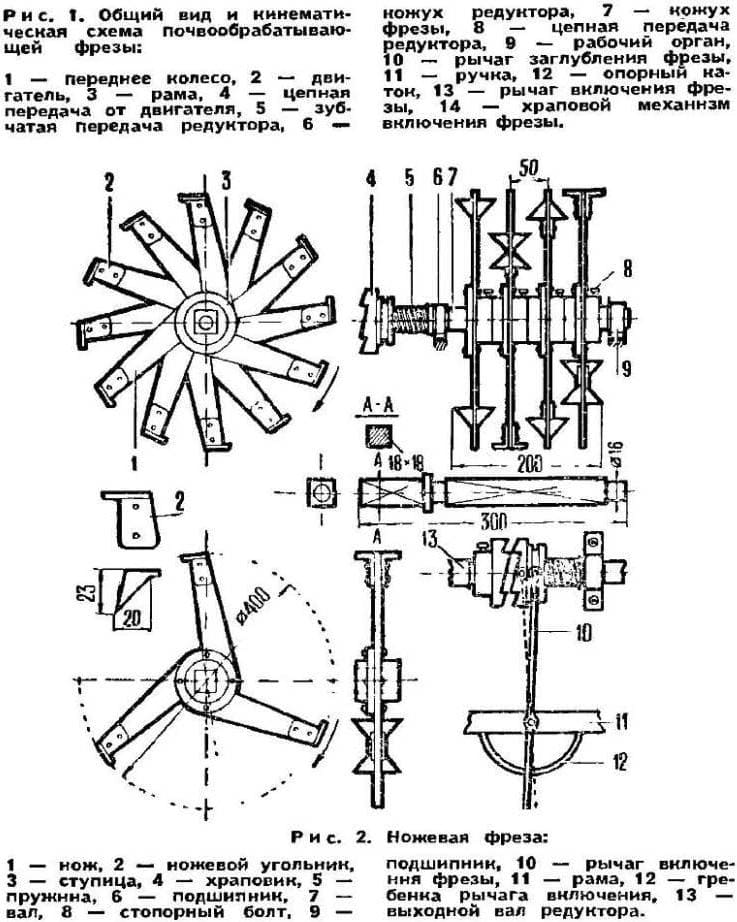

Not so long ago, milling cutters, which were called "crow's feet", began to be used for motoblocks. They have proven themselves well, they are most often used for processing hard and difficult soils. It is these cutters that are used when cultivation needs to be carried out in difficult conditions, on stony soils. The construction of the crow's feet is made solid, which provides the highest indicators of equipment durability. The cutters are available in standard sizes:

Crow's feet mill.

- the width of the knives is 41 cm;

- the length of the knives is 38 cm;

- construction height - 38 cm;

- the mass of the cutter is 16 kg;

- the permissible operating speed of a motor cultivator with such knives is 2-5 km / h.

What are the advantages of the crow's feet cutter, can you install it yourself? It is convenient for soil cultivation, weed control. The rest of the models cannot do the job better. For stony and hard ground, the crow's feet cutter is simply irreplaceable.Of the advantages, it should be noted that the steel of the cutter in this case is weldable. If necessary, you can make repairs at home, rather than buying new knives, as it is costly.

This type of cutter also has disadvantages. The main disadvantage is that conventional carbon steel is used for manufacturing. The strength of the structure itself is at a high level, but the material loses a little to other varieties. Such a cutter should be regularly inspected when work is carried out on clay soils, during the cultivation of virgin lands. The cutter blades can be bent or simply broken. However, the repair is not too difficult, a welding machine is usually used for a broken knife, after which the fracture is carefully polished.

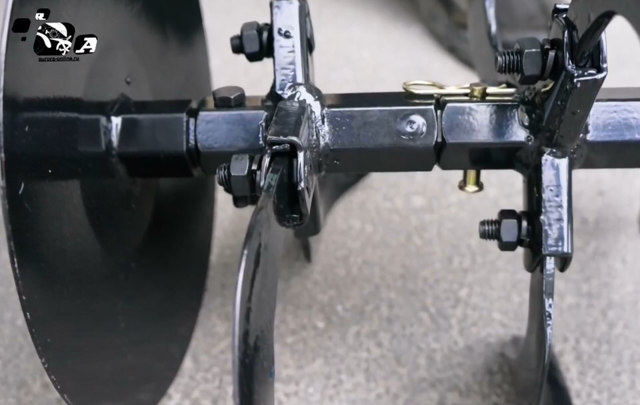

When assembling the circuit, you should work together, since the weight of the structure is significant

It is important not to confuse the direction of installation of the knives on the axis. When assembling, the sharpening must point towards the cultivated soil

To strengthen the cutter, a stopper is used, it is placed on the output axis.

Rotary mower for motorcycle tractor

This is the most common type of mower, which not only enjoys great success in the market, but is also actively manufactured by many craftsmen on their own. The success of such equipment lies in the reliability and simplicity of the design, as well as in the high productivity.

The principle of operation of such a device is very simple: several discs are mounted on a metal bar (frame). Several knives (2 - 8) made of hardened steel are mounted on the hinges on the discs. As the discs rotate, the knives unfold and cut the grass. Thanks to such a simple mechanism, the rotary mower can be corrected independently in the event of a breakdown.

Today, these mowers are already sold together with a grass catcher. This brings additional convenience when working with such equipment. You can also make a rotary mower with your own hands, but we will talk about this a little later.

Rotary mowers are single-rotor and double-rotor. The first ones smooth the cut grass in one direction relative to the equipment, and the second ones - in the center between the rotors.

Such mowers are designed for motor tractors with a power of 10 - 25 hp. Models of such technology are distinguished according to mobility, functionality, strength and performance. AgroService SB-1200 is popular among semi-mounted rotary mowers. Among the budget mounted mowers for a mini tractor and at the same time high quality is the DM 135.

Trailed rotary mowers are safer and require less power from a mini tractor. Basically all the work comes from the traction of the wheels. The attachment of such equipment can be both from the back and from the front using a PTO shaft.

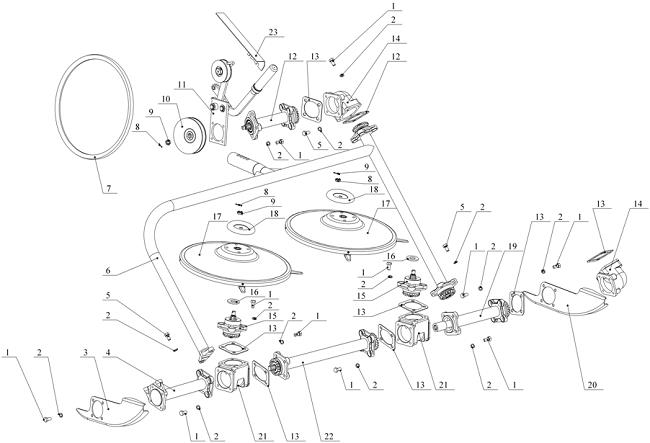

- Bolt М8-6gх16.58.016

- Washer 8 65G 016

- Right ski

- Transmission housing

- Bolt М8-6gх20.58.016

- Side transmission

- Belt А-950-II

- Cotter pin 2,5x25.005

- Nut М10-7Н.5.019

- Pulley

- Stretching device

- Top transmission

- pad

- Reducer housing angular

- Main transmission

- Washer

- Disc with knives

- Protective washer

- Left transmission

- Ski left

- Reducer housing

- Medium transmission

- Shroud

DIY cultivator: assembly instructions

To create a cultivator, you can use a chainsaw, starter, grinder or washing machine.

From a chainsaw

The method of making a cultivator from a Druzhba chainsaw with your own hands has already proven itself for a long time. The principle of creation is quite simple. As a result, the equipment is lightweight, compact and reliable, with a very powerful engine. The speed is approximately 2.5 km / h and the power is 4 hp. with., which is quite pulling on a decent walk-behind tractor.

So, the process of assembling a cultivator from a chainsaw does not differ much from the general collection mechanism, but it has its own nuances:

The main shaft is equipped with a collar flange. In the future, this will allow you to attach bridge gearboxes without any problems.

Asterisks (usually from "UAZ") and a two-row chain are taken and installed on the future mechanism. Thanks to them, the distance from the gear bridge to the ground becomes an order of magnitude greater. The timing sprockets, unlike others, increase the distance to the ground by as much as 15 cm.

Case-type bearings are attached to the main axle, and then a gearbox is already designed or purchased. It requires a standard centrifugal clutch.

A steel pipe is taken, and with its help the structure is supplemented with cutters

When assembling the cultivator cutters, it is important that their cutting part is facing in the direction of the walk-behind tractor.

After assembling the cutters, a load is attached to the frame, sufficient to maintain the center of gravity.

Handles are made that are comfortable to work with and durable so that the device can be guided without problems.

A cultivator made from a chainsaw must be tested on site in order to immediately determine if there are any malfunctions. If there is, then they are eliminated, and then the mechanism is introduced into permanent use.

From starter

It will not be difficult to create such a cultivator if a starter from a car is stored in the home arsenal. If there is such a need, then the shaft is slightly shortened in the future. It is also advisable to replace the front cover, having previously made many small holes in it (up to 5 mm in diameter) for air intake from the attached fan. The prepared starter is combined into a design with cutters. Then the almost finished device is installed on the most common cultivator working platform and tested.

From the grinder

A homemade cultivator from a grinder does not have a lot of power, but nevertheless it copes well with weeding the site. The grinder in such a device acts as an electric drive. Everything else is taken from old non-working cultivators.

Important! An ordinary grinder is capable of up to 600 revolutions per minute, therefore, when creating a cultivator, a pulley with a groove for a V-belt is used for it, and not cutting wheels. It is necessary to weld the grinder's suspension unit to a frame made or taken from an old cultivator, and so that the product can be connected to electricity, they take an ordinary extension cord on a coil

It is necessary to weld the grinder's suspension unit to a frame made or taken from an old cultivator, and so that the product can be connected to electricity, they take an ordinary extension cord on a coil.

After the cultivating base is put together, you can try out the machine. The cutters of such an assembled device should produce 300 rpm.

From the washing machine

Many owners have an old and unnecessary washing machine somewhere in the garage or in the shed, which is still capable of working, but is no longer relevant. Based on its engine, it is possible to make a small electric cultivator. So the old technique will find life and still serve for the economy. To create such a cultivator, you will need, in addition to the electric motor from the machine, the following parts: a two-wire wire, a gearbox, an ordinary wheel (diameter - 1.5 m), a metal corner (no more than 3 m in length), a toggle switch, springs from a car as knives, a launch button and a drum with a piece of tin.

Cultivator

When everything is found, you can start collecting directly. And the first stage is welding. This is followed by the preparation of the knives. For each knife, it is necessary to observe its own trajectory of movement, which does not intersect with any other.

For the motor itself, two windings are needed (starting and working). The starting winding is used only when the tool is started, but the worker must be connected to the network for the entire period of operation.

In principle, this is where all the key aspects of collecting the cultivator from the washing machine end. This data is enough to try to assemble the structure yourself.

Views

The classification of mowers for a mini-tractor is made according to several criteria, the fundamental of which is the type of construction. According to this criterion, two categories of devices are distinguished: rotary (disk), segment (finger) and flail.

Rotary models are the most popular type of equipment and are designed for mini tractors from 12 to 25 hp. with. The unit consists of a steel frame, discs welded to it and a support wheel. Each disc is equipped with several knives, which are fixed by means of pivot joints. Disc mowers can easily cope with areas up to 2 hectares, do not require special maintenance and are easy to repair. The principle of operation of the equipment is as follows: the power take-off shaft of the mini-tractor transmits torque to the pulley through an angular gearbox, after which rotation is transmitted to the disks through the supporting wheel. At the same time, the knives begin to rotate, mow the grass and lay it in neat swaths.

Rotary models can be single-row and double-row. In the first case, the mowed grass is laid to one side of the machine, and in the second - in the middle, between the rotors. The disc mower can be mounted both from the front and from the rear, and is carried out in three ways: mounted, semi-mounted and trailed. The first two methods are the most common, and such models are easy to configure and aggregate. Rotation of the rotors in them occurs due to the power take-off shaft. Trailed mowers are wheel-driven and are used with low-power tractors.

The advantage of rotary mowers is their high maneuverability, which makes it possible to mow grass in close proximity to trees and bushes. The advantages include the ability to adjust the angle of inclination of the discs, which makes it possible to work on hills with a slope of up to 20 degrees and areas with difficult terrain. And also among the advantages they note the high performance of disk equipment, an acceptable cost and a long service life. The disadvantages include the rapid failure of knives when stones and solid debris fall under them, the impossibility of using in fields overgrown with thick-bore bushes and low efficiency of work at low speeds.

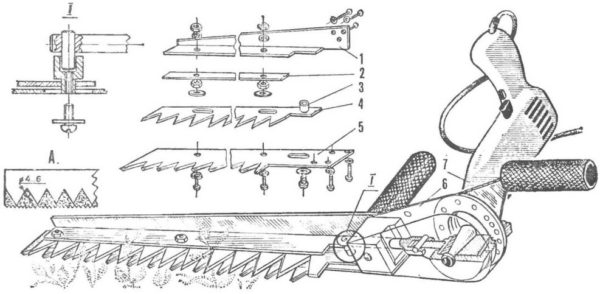

The segment models are designed for lawn mowing and hay making. They represent a structure made in the form of a frame with 2 bars fixed on it and sharpened plates located between them. The principle of operation of segment mowers is fundamentally different from the principle of operation of rotary mowers and consists in the following: the torque of the power take-off shaft is converted into a linear-translational motion of the working knives, which begin to move according to the principle of scissors. This moves one torch from side to side while the other remains stationary. When the tractor is moving, the grass falls between the two knives and is evenly cut off.

The segment mower can be either rear-mounted or located in front of the mini-tractor. The working knives are easily dismantled and in case of breakage they can be easily replaced with new ones. On the sides of the segment models, special skids are installed, which allow you to adjust the cutting height of the grass stand.

This is due to the ability of knives to completely repeat the relief of the site, moving in close proximity to the ground. Another advantage of the segment models is the absence of vibration during operation. This greatly facilitates the use of the equipment and allows the operator of the mini-tractor to work in more comfortable conditions. The disadvantages of the models are considered their inability to fold the cut grass in neat swaths, and, in comparison with rotary devices, rather low functionality.

The flail mower is a front-mounted structure mounted on the rear three-point hitch of a mini-tractor and is designed for tractors with a capacity of over 15 hp. with.The model is distinguished by high productivity and is capable of processing up to 6 thousand square meters in an hour. m of area. Thanks to the possibility of installing different types of knives, as well as the floating attachment system, mowing of grass is allowed on uneven areas. The cutting height of the grass stand is adjusted by raising or lowering the three-point hitch, by means of which the mower is attached to the mini-tractor.

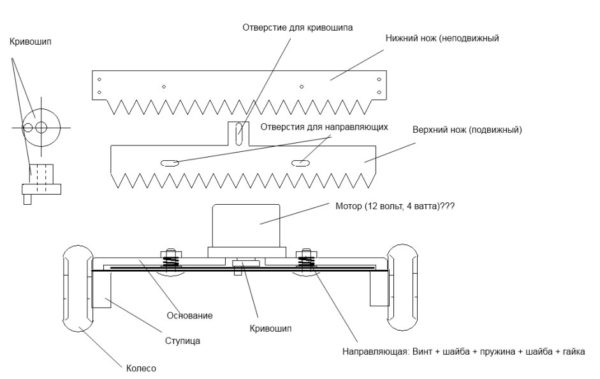

How to make an electric drill-based mower

When working in a small area or if it is not possible to make a hay mower with your own hands from a chainsaw, a conventional electric drill is suitable as an energy source for the device. It is better to use a rechargeable battery to ensure autonomy of work. But if there is an industrial extension cord at hand, and the area of the site is small, use the usual one.

During operation, the motor of the electric drill, using an eccentric mechanism and a connecting rod, converts the rotation of the shaft into reciprocating movements. When attaching a movable element - cutting blades - the desired result is achieved.

It is noteworthy that, depending on the needs, a home-made mower can be made mobile on a wheel base or portable. The second is convenient for processing ornamental shrubs, which are shaped by cutting off the tips of the branches.

What is needed to assemble a portable device (according to the designations in the diagram):

- Bed made of duralumin corner 40x40x3 cm.

- Duralumin overlay.

- Sleeve.

- Movable knife.

- Fixed knife.

- An eccentric mechanism that is installed on the neck of a drill. To do this, remove the standard cartridge and replace it with an eccentric. A bimetallic mechanism is recommended - the central part is turned from duralumin, and bronze is used for the outer part.

- Engine.

Assemble the structure in the reverse order, starting from the installation on the "neck" of the drill of the split flange, which is fixed with a clamp. This is followed by an eccentric and a steel connecting rod.

The connecting rod is fixed with a lining attached to the end of the eccentric mechanism. It is necessary to ensure that the cylindrical part of the rod slides freely inside the duralumin bar - this way it will serve as a guide.

At the final stage, the eccentric body and the mower frame are mounted and the ease of movement of all mechanisms is checked.

The photo shows a wheel mower based on an electric drill. Assembly requires a welded frame and a protective plate for the body

How to do it yourself

Collect mowing machine for walk-behind tractor it is difficult without experience in metalworking. You should not do this work when you do not have the right tools and accessories at hand. But if you understand the design well, prepare the necessary drawings and work strictly according to them, you can save money and make equipment that will not be inferior to the factory one.

Rotary mower

A difficult option, since you need to find a drive due to which the structure will work. It can be bought in the same place where they sell finished products; they usually sell spare parts there as well. Collect in the following sequence:

- Find a ready-made or make a new drawing. Think over the dimensions, features of attachment to the walk-behind tractor, the power transmission system from the equipment to the mower.

- Buy a drive for disks. It must ensure the movement of the axes towards each other.

- Select metal discs by size. Any options will do, the main thing is that they are made of steel and have the same diameter.

- Weld the frame. Think over how to fix the mechanism on it. Attach discs, for this you can make axles from a thick-walled pipe or a metal bar.

- Along the edges of the discs, fasten 3-4 knives at an equal distance. They are placed on small axles so that they move outward when rotated.

- Fasten the drive pulley and idler pulley. Here you need to take into account the length of the belt, you need to tighten it well.

Advice! In front of the discs, fix the frame from a pipe or corner, if a stone gets in the grass, it will not allow damage to the working parts.

Fasten all parts firmly. Use high-quality fasteners, tighten the connections with self-locking nuts, they do not loosen during vibration. Paint so that the metal does not rust due to high humidity and plant residues.

Segment mower

It is much easier to assemble it. But at the same time, you need to find an eccentric mechanism that will ensure the movement of the working part, it is difficult to do it yourself. You will need a welding machine, several rectangular pipes and bolts at least 8 mm thick. To do this:

- Find a drawing or make it from a ready-made sample. Dimension accurately.

- Weld the supporting frame. Both the working part and the assembly will be attached to it, with which the mower will be fixed on the walk-behind tractor.

- On the frame, make guides in which the bar with knives will move. The easiest way is to make them U-shaped.

- Assemble the element with knives, fix them on the bar. Check how it moves in the guides.

- Install two rods that will ensure the movement of the working part. Attach them to the eccentric mechanism. Install a drive through which power will be transmitted.

After assembly, check how the mower is placed on the walk-behind tractor. Put on the belt, make sure that the roller provides good tension. Carry out a test run at low speeds. If the movement is not straightforward, or there is some kind of backlash, figure it out and make changes to the design.

Mower-carriage

This option is the easiest to do, since there are no complex nodes in the design. The adapter can be adapted as a cart, which is used for plowing and other agricultural work. But it is not difficult to assemble it, following simple recommendations:

- Make a drawing. Consider factors such as processing width and trolley length. If it is ready, then adapt the parameters for it.

- Put the wheels on the axle, weld the drawbar to connect to the walk-behind tractor. Place the seat and leg support on top.

- Make a mower body. Weld it from sheet steel 1 mm or more. The size of the box should be 10 cm larger than the diameter of the knife.

- Install the bevel gear on top to rotate the axle through the pulley. Make a knife from steel, fix it at the bottom.

- Bolt the body to the trolley. Provide a system for adjusting the height of the location.

Tip: Make the mower detachable to use the cart for other purposes.

Provide ease of control of the walk-behind tractor. An important part is the belt drive, firstly, the tension must be good, and secondly, it is better to put the casing on top so that the moving part is closed. You don't have to make a seat, but put the wheels in the back for an emphasis and work as usual.

It is possible to assemble a mower for a walk-behind tractor with your own hands only when preparing a detailed drawing and having all the necessary parts. The rotation mechanism is easier to buy ready-made, since it is difficult to manufacture. It is necessary to precisely fit all the elements to each other and connect them with strong fasteners, which exclude the weakening of the connections from vibration.

Safety engineering

The main thing a master should worry about when assembling homemade equipment for a mini-talker is not how well it will work, but first of all, how safe it will be. Before starting to work with a self-assembled mower, check the strength of all connections. Take care of the safety of not only the tractor driver, but also the animals. When launching, no one should be within 50 m.

When working with homemade mowers, make sure that there are no people in the front. If the mowing grass is tall, such as reeds. Take the time to go and see. Remember safety first.

To assemble a mower for a mini-tractor with your own hands is just simple for a person with the skills of a welder, technician, mathematics.In addition, perseverance and hard work must be present. If you do not have all these qualities, then just spare your nerves and buy a ready-made model of a rotary mower.

What attachments for a walk-behind tractor can be made by hand?

It all depends on the qualifications of the home craftsman and the set of tools that he has. We advise beginners to start their experiments with the simplest designs - a fan potato digger or a hiller.

The design of the device for digging potatoes is shown in the sketch. It consists of a wide bent plate (paw) welded to the vertical bipod and the field bar. The teeth from the reinforcement are attached to the rear edges of the paw by welding.

It is easier to make a disk model from hillers. Its main elements are discs that can be cut from the ends of old gas cylinders. They have the right shape, diameter and metal thickness.

Quite a lot of design solutions have been invented for the device itself, you can be convinced of this by watching videos of self-made people, as well as various assembly diagrams.

One example of an adjustable disc hiller device

In addition to discs, you will need:

- two posts made of steel strip;

- two rolling bearings;

- bolts for attaching the struts to the frame and adjusting the pivot sectors;

- crossbeam from a profile pipe;

- T-shaped leash.

The main condition for the high-quality operation of such a mechanism is the accuracy of the manufacture of all parts and the symmetry of the installation of the disks. Otherwise, it will be taken away from the furrow while driving.

Homemade mowers for walk-behind tractors

Consider several varieties of homemade products.

Rotary mower with your own hands

This type of mower is used for lawn mowing and for mowing grass for hay.

It is important to remember that the model only cuts tall plants, it only crumbles low grass into small pieces.

The assembly of the mower is shown on the Neva walk-behind tractor and similar structures. To work, you will need the following elements:

- chains from chainsaws (gear);

- 2 discs from a grain-type seeder (in this version, a C3-3.6 seeder is used).

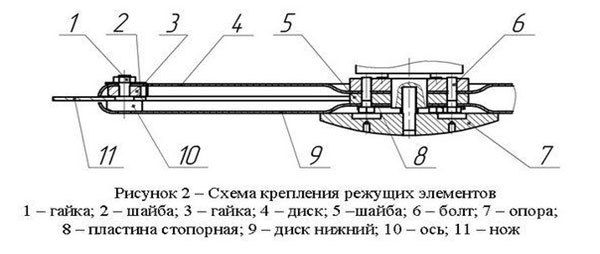

The knives are made from a hardened 65 g alloy. There are four knives on a separate disc. On each of the discs, slots with a diameter of 6 millimeters are made using a reinforced drill. The knives are attached using a bar, it is fixed to the opener independently of the main knife attachment structure. There is a small gap between the blade and the shank, about 2 millimeters thicker than the blade. Such a constructive solution is necessary so that, while working with the mower, the centrifugal force spreads the knives onto the walk-behind tractor and they cut the plants.

It is important that the structure can rotate freely in a circle (360 degrees). This is necessary to protect the knife when hitting hard ground, stones

Deep tillage

When developing new plots, it is necessary to develop virgin lands. Usually it is abundantly overgrown with sod, perennial grasses and weeds. It is quite difficult to cope with such territories with ordinary tools. More often they resort to cultivation using deep processing with a turnover of the formation. In reverse plowing, a part of the layer is cut, lifted and turned around its own axis. As a result, the ground from the bottom layer is on top. Weeds cannot grow for a certain period of time. Cultivated plants have a head start for advanced development.

A similar job is done in the fall. Rhizomes of nettle, wheatgrass, dandelion and other weeds freeze in November-December, when the air temperature drops below -15 ... -17 ⁰С (there is no stable snow cover yet). In the future, they lose the ability to grow.

In the future, a similar technique is resorted to every autumn. After 2 ... 4 years of autumn fall plowing, the amount of weeds on the site decreases many times over.

Organic farming advocates disagree with this approach.But the experience of several centuries proves that only such agrotechnical measures can be used to clean the area from weeds. Otherwise, you will have to use chemistry to combat weeds.

Deep plowing allows:

- wrap a layer of soil and allow plants to use substances for nutrition, which gradually shift to the lower horizons during the season. Such an operation allows to reduce soil salinization with mineral fertilizing, as well as to reduce the amount of applied fertilizers;

- aeration of the lower soil layers contributes to the emergence of aerobic processes of decomposition of plant residues. Usually, in the lower layers, the access of air oxygen is limited. Therefore, conditions are created when the rotting of the roots of the rod type extends over several years. Anaerobic processes (without air access) occur with a slow accumulation of humus;

- when the seam rotates, weed seeds end up in the lower layers of the soil, and they cannot germinate. The roots remaining on the surface freeze out. As a result, soil contamination is sharply reduced;

- freezing clods of earth in winter crumble more easily in spring. A light loose surface layer is formed, in which cultivated plants can receive more abundant nutrition;

- the introduction of organic matter before plowing makes it possible to organize active rotting of manure or green manure, if they were sown after harvesting the main cultivated crops.

Do I need to sharpen cutters for a cultivator

Having dealt with the cultivator and the types of cutters for it, let's move on to considering the main issue that this article is devoted to, namely, whether it is possible and necessary to sharpen such a working piece of equipment as a knife. The bulk of domestic manufacturers of agricultural machinery uses cutters from a plant located in the Smolensk region. For their manufacture, hardened steel is used, the cutting edge of the knives is processed with high-frequency currents. The cutters are bolted to the flange as this material is difficult to weld. This moment suggests that the metal of not very high quality is used in the welded cutters of most Chinese companies.

Good hardened steel does not tolerate a welded joint, only a bolted one

When creating the working edge of the cutter, it melts and cools quickly, as a result of which it looks uneven and slightly resembles a hacksaw blade, which can be seen at high magnification. In the process of work, the hardened steel blade does not dull, but crumbles, which leads to the formation of deeper "saw" teeth. Many people call these cutters self-sharpening, although this definition is not entirely accurate.

Now, what about whether you need to sharpen the cutters and how to do it at home. If sharpening is carried out using a grinder or on a grinder, the metal will overheat, and consequently, its structure will be disturbed and its strength will be lost. As a result, the cutters will dull faster, and this is at best, and at worst, the knives may begin to deteriorate and you will have to buy new ones.

From sharpening the cutter with the help of the "grinder", the metal overheats

Sharpening of cutters can only be performed on a high-temperature sharpening machine, and such equipment is hardly available in every farm. And there is no need to grab onto a file, which will help remove small cracks and make the edge even. As a result, this will lead to the formation of an even larger chip or breakage of the knife when it hits a stone during soil cultivation. If a chisel appears on the cutter, then just keep working. You will see that after a while it will disappear by itself.

Assembling the cutters on the bright walk-behind tractor. Milling cutters for walk-behind tractor

Equipment such as a milling cutter is necessary for any walk-behind tractor, since it can be used to carry out most of the work related to soil cultivation.Basically, the rotary tiller comes complete with the unit, but in cases where you need to change the width and depth of processing, you should purchase the equipment separately.

Additional cutters allow you to increase the functionality of the walk-behind tractor and simplify work with it. Experts recommend having several pairs of cutters in your arsenal.

Which cutters are best for a walk-behind tractor?

Such "knives" for tillage can be roughly divided into two large groups. Each of them has its own characteristics and is suitable for a certain type of work.

Saber cutter for walk-behind tractor

The most popular and versatile models that are effective in a variety of earthworks. In these models, the optimal shape of the knives is used, for the manufacture of which manufacturers choose high-quality durable steel.

The models have a collapsible design, so their installation and maintenance is as simple as possible.

Crow's feet

These models have appeared on the market relatively recently. With their help, any virgin land can be cultivated, they are also effective in the cultivation of hard and difficult soil.

Features of this type of cutters:

- solid construction, which provides high performance accuracy;

- the equipment fights weeds well;

- ease of use, the ability to replace spare parts at home.

Such models, in contrast to saber cutters, are made of carbon steel, which is slightly inferior in strength.

Homemade milling cutters for walk-behind tractor

Manufacturers offer different options for tillers for the walk-behind tractor. You can use one set of cutters or purchase two different types of devices, changing them depending on the conditions of soil cultivation.

Some craftsmen prefer to use homemade products, which, if properly assembled, will be no worse than factory ones.

The main advantage of self-creating a rotary cutter is that it can be adjusted to the specific features of the site.

How to assemble the right cutters on a walk-behind tractor?

Do-it-yourself cutter assembly should be carried out as correctly as possible

And here it is especially important to make sure that the active part crashes into the ground during operation. To do this, it is initially recommended to study the drawings, and then start manufacturing the equipment.

The following tools are required to create cutters:

- The rotor axis of the required length. It can be divided into two parts if you want to assemble a cutter from two blocks.

- Short axis.

- Reducer with clamps.

- Left and right knives.

- Bolts, washers, nuts.

Assembling the structure does not take more than an hour, but here it is important to install the knives in such a way that they do not interfere with the rotation.

- The long rotor axle is equipped with knives at a 30 degree angle.

- It is necessary to combine four knives on one block, fixing them to the gearboxes.

- Next, the correctness of the design is checked and all fasteners are tightened.

This design is very reliable and can withstand quite high loads.

installation of cutters on a walk-behind tractor

Do I need to sharpen cutters on a walk-behind tractor?

All soil mills are self-sharpening tools. Sharpening is not needed for them, as it can only spoil the structure. Only in some cases, if you have been using the cutter for a very long time and you see that it has begun to work poorly on the ground, you can sharpen the knives.

The rotary tiller is an important element of every machine. Homemade properly assembled cutters can be used on any modern walk-behind tractors, in particular on the Neva MB 1 and MB 2, MTZ and others. Such designs will aid in the cultivation of the land and make it easier to carry out agricultural tasks.