Tools and materials

Instruments

The raw material for making a homemade knife can be any new or old hardened steel cutting part. As a workpiece, it is better to use cutting discs for metal, hand and pendulum saw blades. An old chainsaw is a good option. From its chain, you can forge and carve a blade that is not inferior in quality and appearance to the famous Damascus steel.

In order to make a knife with your own hands, you will need the following equipment and materials:

- Bulgarian;

- grinder;

- electric drill;

- ruler;

- hammer;

- sandpaper;

- sharpening bars;

- files;

- core;

- epoxy adhesive;

- copper wire;

- marker;

- bucket with water.

Separately, you need to think about the issue with the handle. The finished product should fit comfortably in your hand.

For making a handle, it is better to use:

- non-ferrous metal (copper, bronze, brass, silver);

- tree (oak, alder, birch);

- organic glass (plexiglass, polycarbonate).

The raw material for the handle must be intact, without traces of cracks, rot and other defects.

Features of the saw blade

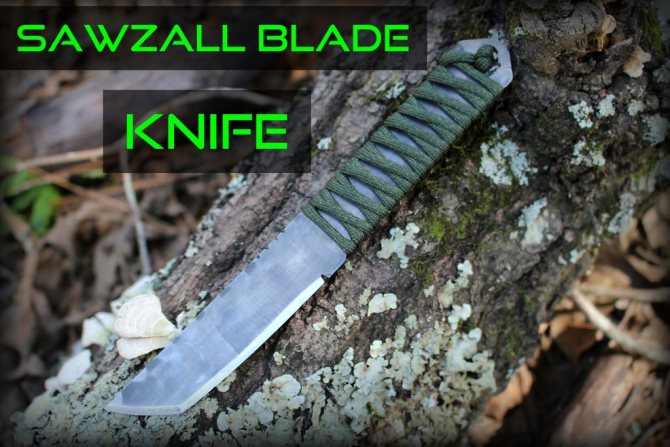

A power saw can be used to make a blade, in almost any condition. Even if it has deteriorated and rusted, it will still be suitable for homemade products. The product has enough advantages:

- the knife will be made for oneself, so that it will be unique and will lie well in the hand;

- a wide selection of material both in length and in width of the butt;

- does not need hardening;

- it is possible to make several knives from one canvas;

- such a blade will be in the price range of $ 100 and above, better than the "china" for $ 30-40.

This is indeed the case. Having spent not very much time, it depends on experience, you literally get a product with good cutting properties for a penny. Don't overheat it while making it, and you'll make a great knife.

Making a knife from a saw with your own hands

Looking at the finished blade, the layman will think - what's so difficult? Sawed off, sanded, sharpened and attached a handle. No. Making a knife is a whole science, gradually often turning into art. A self-made blade has multiple positive qualities:

- the handle is easy to make under the palm of the owner of the product;

- there is no need to worry about the quality of the workpiece and the final product;

- to give uniqueness to the product is not difficult.

Do-it-yourself saw knife.

Cutting and primary processing of the workpiece

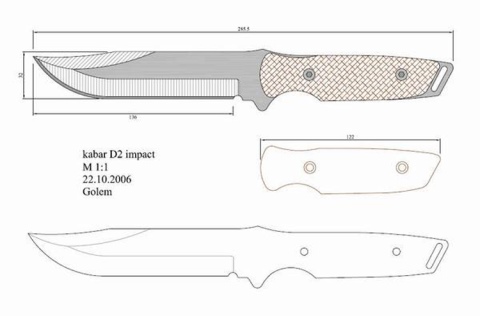

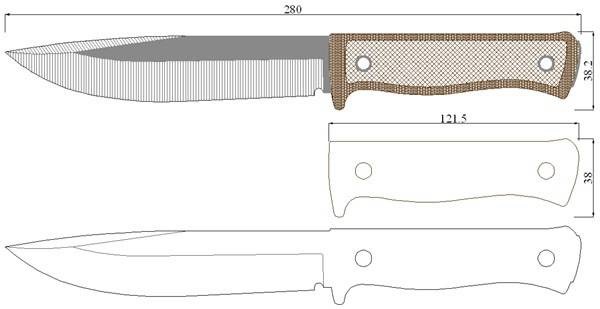

The initial stage of making a blade from a hacksaw blade, similarly from other materials, is a preliminary sketch. You need to have an idea of what the result will be. The markup will help to cut the blank of the required shape:

- right angles should be avoided, marking the layout is required with a small margin of 1.5 - 2.5 mm;

- it is necessary to know the future purpose of the blade, the shape of the sketch directly depends on the role of using the product;

- Along the way, it is worth remembering the laws of making edged weapons.

On our resource, the legislative aspect regarding the wearing of knives is considered separately. After finishing making the layout, you should transfer it to the saw blank. It is necessary to outline with a sharp object, a marker is used when absolutely necessary. Seeing the outline of the sketch is the main task.

Blank for making a knife from a saw.

Having fastened the workpiece in a vice, the future blade is cut along the contour. The part must not be overheated, it is necessary to water it with water, excessive heating of the steel will lead to the fragility of the product. It is permissible to expose small areas to high temperatures, the margin for marking was made for a reason. It is better to remove them on a grinder.

It is permissible to make a rough revision with files. Having removed the burrs, it is worth starting to make the handle. There is no need to harden the blade, factory heat is enough.

Making a pen

The previously made decision on the overhead method of attaching the handle gives the full right to use a drill. A drilling machine is a luxury, with such a "miracle", it is not shameful to resort to its help:

- According to the sketch, there is a need to make two or three holes in the shank. Depends on the length of the handle.

- Split the prepared block of wood strictly in half.

- Having made the fitting of wooden blanks to the shank, sand them to a tight abutment. In one of them, a recess for the shank should be cut.

- Fitting the parts perfectly, holes are made in the wooden lining.

- Rivets are cut from a copper bar. Final fitting and preliminary assembly.

- Wooden blanks in the rough, are adjusted to the anatomy of the owner's palm.

- Final sanding of the handle, making a brass bolster.

- Assembling the parts of the handle with coating the shank and linings with epoxy glue.

- Driving in copper rivets. Drying the product.

Knife handles.

One day is enough for the glue to dry. On a grinding machine, adjust the handle completely. Sand with fine sandpaper.

Slopes and sharpening

In conclusion, the blade is sharpened according to the necessary needs. The RK sharpening angle depends on the purpose of the knife. There are plenty of ways to display the correct RK.

Previous

Do-it-yourself Rapid knife

Next

How to make a knife from a chain with your own hands

Cutting and primary processing of the workpiece

Sawing the workpiece is fastest with a grinder with a thin cutting disc for metal. If it is not possible to use a grinder, then you can use a manual hacksaw for metal

It is important to place the file correctly in the hacksaw. The saw teeth should be directed forward and the hacksaw should cut when moving "away from you"

Cutting and preparing the workpiece

First, using straight cuts, the approximate shape of the knife is cut. Then the folds are cut out. They are easiest to cut out with several oblique cuts converging at one point.

It is important to leave an allowance of 2-3 millimeters before the drawn outline. This is due to the fact that when using a grinder, the metal at the cutting site overheats

Grinding off 2-3 mm with a file and emery paper can remove the overheated edge of the metal.

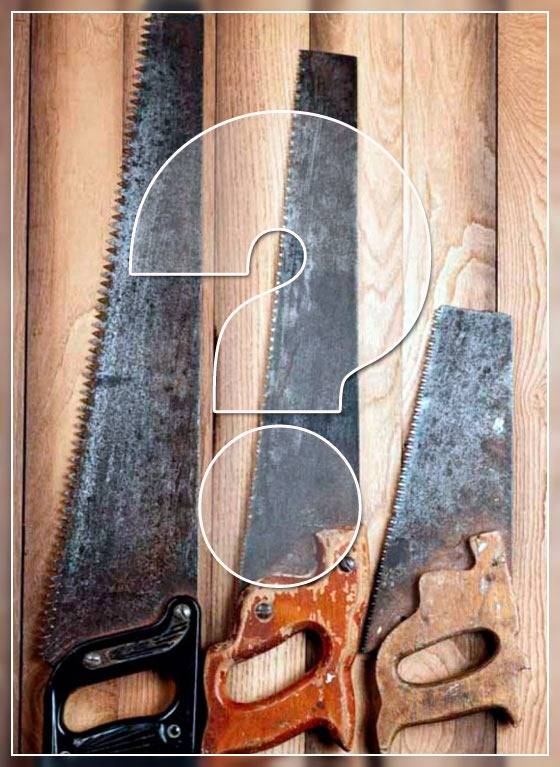

Hacksaw blade

If it is decided to use a blade from a hacksaw as a metal blank, then it is necessary to take a blade from a pendulum saw. This saw performs heavy metal work (such as rails) and meets the requirements for rigidity and strength. The size of such canvases ranges from length / width / thickness, 400-500: 30-40: 2 mm. The color is determined by the type of manufacturing processing the saw has been subjected to and can be black or gray.

Before starting the manufacture of the knife blade, it is necessary to check the integrity of the metal. This can be done by ear, but it requires some experience and skill. The whole canvas makes a ringing sound, the damaged one - deaf. If it is difficult to do this by ear, then it is imperative to inspect the metal workpiece thoroughly.

The angle of inclination of the blade should be 20 degrees.

Moreover, this should be not only the blade, but also the allowance, which will then be hidden in the handle. After that, on a metal-working machine (or a carefully fixed grinder with a circle), it is necessary to gradually and carefully remove the excess.

This should be done slowly, as the metal can heat up. To cool it down and continue working, take a bucket of water. This container should be enough for the workpiece to be placed completely in the water. The same machine makes the contours of the blade.It should be borne in mind that a feature of this steel is that with a sharp change in the temperature of the metal, the smallest cracks can form in it. This can lead to the fact that even with a small force, the knife breaks. Therefore, overheating of the metal during its processing should not be allowed. The point should be especially carefully carried out, because with a decrease in thickness, the metal heats up faster.

Working tools and materials

Judging by the reviews of experienced knife masters. Any former saw blade can be used as a workpiece. Two-handed, mechanical saw, band saw, hacksaw for metal or wood - any of the selected options, guarantees strength and durability. All of them perfectly keep the sharpening, thanks to the steel from which they are made.

In the production of sawing tools, factory hardening is used. Making a knife from a saw is fraught with a laborious process, the workpiece is difficult to process due to the redness of the metal. The efforts spent on manufacturing the product will more than pay off in the end result.

You will need a tool used in the manufacture of knives:

- electric drill, with a set of drills of various diameters;

- grinding machine (the presence of one will simplify the work);

- Angle grinder "Bulgarian", circles for different purposes;

- files of various grain sizes;

- ruler, pencil, paper, marker;

- vice, hammer and sandpaper with various grains;

- container with water.

You may need a welding machine to weld on the shank. It is necessary to unambiguously determine the type of handle - invoice or mounted. Both types are easier to make from wood. Let's dwell on the first option. Required materials:

- a piece or a whole saw;

- wood bars, epoxy glue;

- a rod of copper, tin, brass or bronze;

- tools for working with wood: core, chisel, etc.

It absolutely does not matter in what condition the saw blade is mined. The final product will not be affected.

Shaping the workpiece

The rough workpiece is brought to its final shape with a file or emery. In order to avoid overheating of the future knife from the saw, when processing it with emery, it is necessary to periodically lower it into a container with water. This will allow the workpiece to cool down. When processing the workpiece with a file, additional cooling is not required. It would be most optimal to roughly process the workpiece on emery, and then fine-tune it with a file.

Knife blank processing

During finishing, special attention should be paid to the smoothness of the folds.

It is important to ensure that the fold is even, without depressions or bulges. Miniature depressions are easy to check with a file

To do this, use the marker to paint over the checked end of the workpiece. Next, a file is carried out with light pressure along the workpiece along the entire bend. There are depressions in the places where the marker trace remains

Miniature depressions are easy to check with a file. To do this, using a marker, the checked end of the workpiece is painted over. Next, a file is carried out with light pressure along the workpiece along the entire bend. There are depressions in those places where the marker trace remains.

Processing continues until no depression remains.

Further, the workpiece is cleaned of burrs and sanded with sandpaper. You can start with 60 grit and just finish with 320. The workpiece will still be heat treated, so the final grinding of the blade will be later.

Making a knife from a canvas

Making a knife

If the blade is large and does not have strong wear, then several blades for different purposes can be made from it. The effort and time spent are worth it.

A knife from a circular saw with your own hands is made in the following sequence:

- A pattern is applied to the canvas, the contours of the blade are outlined. Scratches or dotted lines are drawn on top of the marker with a core.So the drawing will not be erased when cutting the workpiece and adjusting it to the desired shape.

- Workpieces are cut from the circular saw blade. To do this, it is better to use a grinder with a metal disc. Leave a margin of 2 mm from the contour. This is necessary in order to remove the material burnt by the grinder. If you don't have a grinder at hand, then you can grind the workpiece with a vice, a hammer and chisel, or a hacksaw for metal.

- Everything unnecessary is grinded on the grinder. This process will take a lot of time so as not to overheat the steel. To prevent this, the workpiece must be regularly lowered into water until it cools completely.

- The blade is outlined. Here you need to be careful to maintain the contour of the knife, not to burn it and maintain an angle of 20º.

- All straight sections are aligned. It is convenient to do this by placing the workpiece on the side of the grinding wheel. The transitions are rounded.

- The part is cleared of burrs. The blade is ground and polished. For this, several replaceable wheels are used on a grinding machine.

Separately, you should dwell on how the pen is made. If wood is used, then a monolithic fragment is taken in which a longitudinal cut and through holes are made. After that, the blank is pushed onto the blade, holes for fasteners are outlined in it. The handle is fixed to the blade using rivets or bolts with nuts. In the case of a bolted connection, the heads of the hardware are recessed in the wood and filled with epoxy glue.

When the handle is assembled from plastic, 2 overlays are used, which must be symmetrical. To give the knife originality, the plastic pads are painted on the inside. In the linings, you can make cavities filled with jewelry, products from non-ferrous and precious metals, small compasses and photographs.

After fixing on the blade, the handles are sharpened until they acquire the desired shape and smoothness.

Hardening

Heat treatment will give the knife the necessary hardness, it will not become blunt during operation.

For hardening, the knife from the saw must be heated to a temperature of 750-920 degrees. If you do not reach this temperature, then the steel will not be hardened, and if it is heated too much, then the blade will be unnecessarily brittle.

At home, it is not possible to determine the exact temperature. However, there is a way out. A simple magnet is suitable for temperature control. As soon as the blank for the blade stops magnetising, it is heated to the required temperature.

After the temperature of the workpiece has reached the required limits, it must be kept in this state for about 1-1.5 minutes for each 1 mm of thickness. In the case of a homemade saw blade, the holding time for hardening is 3-5 minutes. It'll be enough. Then the workpiece is dipped into vegetable or machine oil preheated to 50 degrees

This procedure should be followed carefully. Oil vapors can flare up from a hot workpiece, so have a fire extinguisher handy

A little about the hardening furnace. If it is not possible to use industrial equipment, then the forge can be made by hand. To do this, it is necessary to make a fire of such a size so that it is possible to evenly warm up the workpiece. Further, as the wood burns out and coals appear, a homemade knife is placed on them. A household hairdryer or a mattress pump can be used as bellows.

Materials and tools

To make a homemade knife, you need the following equipment:

The graph of the dependence of the thickness of the knife on the hardness of steel.

- Woodworking Machine. If not, you can use an electric jigsaw to pre-cut the handle. For final grinding, sandpaper of different grain sizes is used.

- Nails or better copper wire for rivets.

- Wood.

- Grinding and sharpening machine. In his absence, you can use a grinder, a hammer drill, a high-power drill. In addition, you need nozzles or circles with which you can do these operations. One of these tools should be rigidly secured and then work done.

- Files with various types of cuts.

- Marker.

- Brass plate and rod if the handle will not be riveted.

- Epoxy adhesive.

Knives should have a comfortable handle. For her, the most suitable material is wood. Most often, birch and oak blocks are used. These rocks are the hardest, less susceptible to moisture with prolonged use. They are pleasant to the touch and have a beautiful texture. Since the manufacture of the knife handle does not require a large amount of starting material, for these purposes you can use 1 parquet board, a piece of board or bar

It is important that the piece of wood is not damaged, cracked and free of chips or other defects.

After the blade is sufficiently hardened, you need to cool it.

In order to make a knife, it is necessary to use certain grades of steel. It should be remembered that its characteristics depend on how the metal was hardened technologically. For example, with an increase in hardness, the fragility of metal products increases. Steel grades P6M5 or P3M3F2 are suitable for the knife. In this case, a metal thickness of 2 mm will be sufficient.

The strength of a homemade knife does not depend on the thickness of the metal. It is influenced by its geometric dimensions: length, width, shape of the blade and escapement. With the right choice of these components and careful metalworking, an excellent knife is guaranteed. These steel grades are used in the manufacture of discs, blades, tools such as circular saws.

How to make a knife handle

The easiest way is to glue the handle from two cut and prepared pieces of wood or plexiglass. It is much easier to make it than to attach it to the tail of a knife. Naturally, you can choose an unpretentious option and wrap the handle with electrical tape, but why try so hard to end up ruining the aesthetic appearance of the knife?

And here comes the most crucial stage of work. Since you will have to drill in the shank of the knife, the blade can easily burst. Therefore, be vigilant and careful.

Steel is a hard but brittle material. With an even pressure distribution when the saw is in operation, it is almost impossible to break it. But with spot drilling, the pressure increases and the metal can crack easily. Therefore, it is better to drill a hole at low machine speeds and do not forget to add oil to the drilling site. In this case, a screwdriver is an ideal tool for achieving this goal, since it has less revolutions, then the possibility of part breakage is not so high.

After completing the previous step and making holes in the handle, drill the same holes in the halves of the handle. Make a copper or aluminum rivet. For insurance, you can glue the area where the rivet will be with glue, but it is better if you have epoxy.

Shank drilling

The handle on the shank can be fixed with rivets or glue. The most reliable way to attach the handle is to use rivets. To install them, it is necessary to make holes in the shank. The holes are marked on the shank so that they are approximately in the middle of the future handle. To prevent the drill from slipping off at the initial stage of drilling, the holes are punched out.

Since the circular saw is made of alloy tool steel, it will not be easy to drill through. Conventional metal drills won't last long here.

Drilling should be done with cobalt drills or a ceramic drill with a victorious tip.

During the drilling process, it is important to add oil to the drilling area and to keep the drill from overheating. Drilling hardened steel is a difficult task

Therefore, it is possible to make holes in the shank electrochemically. To do this, a wire is attached to the workpiece, then the shank is completely covered with bitumen mastic or plasticine. In places of future holes, the protective layer is scratched to bare metal. Further, a saturated solution of sodium chloride is prepared, into which the blade shank with a wire and an unnecessary metal plate, also with a wire, are lowered. Both wires connect to the battery or car charger. A "plus" is fed to the future knife from a circular saw, a "minus" is applied to the plate. The etching process is accompanied by gas evolution. After 30-50 minutes, the holes will be ready

Drilling through hardened steel is a difficult task. Therefore, it is possible to make holes in the shank electrochemically. To do this, a wire is attached to the workpiece, then the shank is completely covered with bituminous mastic or plasticine. In places of future holes, the protective layer is scratched to bare metal. Further, a saturated solution of sodium chloride is prepared, into which the blade shank with a wire and an unnecessary metal plate, also with a wire, are lowered. Both wires connect to the battery or car charger. A "plus" is fed to the future knife from a circular saw, a "minus" is applied to the plate. The etching process is accompanied by gas evolution. The holes will be ready in 30-50 minutes.

Making knives at home

Making a homemade scabbard at home includes the steps:

- making a piece of paper (you need to put a blade wrapped with tape on it, add 1.5 cm from each edge and circle);

- creating patterns from leather or dense fabric (the pattern is circled 2 times in a mirror image);

- cutting out of the material 2 side inserts 1.5 cm wide and a T-shaped part, which will then become a fastener;

- processing the edges of the cross element with wax, grinding on the felt wheel of the machine;

- stitching with a nylon thread of a T-shaped part and one of the main patterns;

- gluing the inserts of this part of the scabbard;

- fixing the second half of the pattern with glue to them;

- turning the edges of the workpiece on a grinding machine;

- stitching glued parts;

- polishing the surface of the scabbard, smearing with cream, if it is leather;

- making holes at the ends of the clasp to secure the button parts.

Watch the video on how the knife is made:

The simplest homemade knives

Homemade knives, as simple as possible, are obtained from:

- scissors of different sizes;

- bayonet shovel;

- an old knife;

- saw, hacksaw;

- automobile springs.

You can even make a product from a fairly thick stick. The simplest version is a homemade knife with a wooden handle. And if you use a file as a basis, you can do without power tools.

Watch the video on how to make a knife from a bearing:

From scissors

Scissors can even make 2 knives for household needs, if they are:

- divide into 2 parts by pulling out the mount from the center;

- take one half, process the blade on a grinder to the desired thickness (blunt side - butt, sharper side - blade);

- make descents, sharpen a sharp edge;

- make lining of suitable size from wood, make in each recess, corresponding to the thickness of the metal part of the handle;

- attach wooden parts with glue and a fastener screwing into the hole left from the scissors;

- give the handle its final shape, clean it from "burrs", grind.

The knife will turn out with a ring at the head of the cutting left over from the scissors.

From a piece of metal

Any type of product can be made from a piece of metal, if it is large enough. First, a sketch is prepared on paper, then a blank is cut out according to this template. They process it on the machine, bringing the blade into the desired form.Drill 2 bolt holes on the shank.

If the metal needs hardening, they do it with the help of a forging furnace, steel tempering is performed. After cleaning, grind and polish the metal part. After the pads have been cut out, they are attached to the handle using manufacturing glue and metal fasteners. If they stick out, this part should be cut and sanded so that it does not interfere with holding the knife.

From a shovel

Any kind of knife can be made from a shovel, as long as they do not have to cut very hard objects. Because this steel is usually of low quality, it bends easily, even if the tool is bayonet. The manufacturing steps do not differ from what was described above. But due to the fragility of the metal, it must be hardened. And the handle should be made with wooden lining, as long as the shank.

From an old knife

You can make a new tool out of an old knife simply by replacing the shank pads. To do this, the product will have to be disassembled. You can change the appearance, and hence the purpose of the tool, if it is large enough. One has only to cut a blade of a different shape and combine it with an updated handle. It is not necessary to harden the steel, as it has already been heat-treated at the factory.

From a stick

A fairly sharp weapon can be made from a stick, that is, a knot with a diameter of 3-4 cm:

- cut a piece about 15 cm long;

- carve a blade about 6 cm on a lathe, the remaining 9 cm will be a shank;

- thin a sharp edge using a machine with an emery attachment;

- bring the blade to the sharpest possible sharpness with an abrasive bar.

The product cannot be compared in quality with metal, but it is quite possible to cut it.

From other scrap materials without tools

The knife can be made from scrap materials and, in addition to those mentioned above, from:

- a mechanical saw, the blade of which has good cutting properties;

- hacksaws for wood, worthy kitchen tools are obtained from it;

- automotive springs requiring forging and heat treatment;

- a large drill, but it also needs to be heated and shaped.

After reworking the material at hand into a flat sheet, the manufacturing technology is still the same:

- drawing on paper;

- cutting out a metal blank;

- sharpening, hardening, finishing;

- handle manufacturing, assembly.

Sample drawing of a knife on paper

Sample drawing of a knife on paper

A knife without tools such as a band saw, a grinder can be made from a file. It is enough to heat it up with a blowtorch and let it cool down so that the metal can be processed with a hacksaw. She gives the desired shape to the workpiece. Then heat treatment is carried out, grinding with hand tools and emery. And you can assemble the product.

Making rivets

The glue attachment of the handle to the shank is not reliable. To avoid breakage of the handle, the wooden plates must be fastened with rivets. The rivets are made of metal that does not corrode. These can be non-ferrous alloys or stainless steel. You can also use copper or brass tubing as rivets.

Making rivets for a knife

A blank of the future rivets is sawn off from a bar of a suitable length. It should be 2-3 millimeters longer than the thickness of the handle. Clamping the rivet in a vice, flare one end with a hammer. It should look like a fungus on one end of the bar. Next, the rivet, pre-lubricated with epoxy glue, is inserted into the holes in the handle and is also flared on the other side of the handle. To expand a rivet made from a tube, it is best to use a ball from a bearing.

Metal handling techniques

In order for the blade to be strong and tight, during its creation it is necessary to adhere to the rules for handling iron.

The semi-finished product should not have noticeable and unexpressed defects. Before starting work, the workpieces must be examined and tapped. A holistic element sounds loud, and a defective element is muffled.

Circular disc for making a knife.

When creating a project and drawing of the cutter configuration, avoid corners. In such areas, steel can break. The transitions must be made smooth, without sharp turns. The bevels of the butt, safety guard and handle must be grinded off at an angle of 90 degrees.

When cutting and processing, the metal must not be overheated. This leads to a decrease in strength. An overcooked blade becomes fragile or soft. During processing, the part must be regularly cooled, completely dipping it in a container with cold water.

When creating a knife from a saw blade, you must not forget that this element has already passed the hardening procedure. Factory saws are designed to work with tough alloys. If you do not overheat the product during milling and processing, it will not need to be hardened.

Forming the cutting edge

Before proceeding with the formation of the cutting edge, it is necessary to carry out preparatory work. It consists in marking the edge of the workpiece. The markings are placed exactly in the center and serve as a guide for making a symmetrical escapement.

To do this, the marker is painted over the edge that will be cutting and, using a drill equal in thickness to the workpiece, the marking is scratched. The drill has a tapered edge. Therefore, if you position the drill and the workpiece on the same plane, the tip of the drill will be exactly in the middle.

Edge cutter

Then, using a file with a large cut, you can start shaping the cutting edge. In the absence of the proper skill to create a smooth edge, you can use a simple device. It consists of a base, a corner and a guide with a platform for sanding paper. On the platform with the guide, sandpaper with a grain size of 180 is glued. Several holes must be drilled vertically one above the other in the corner in advance. The knife is fixed flat on the base and the guide is inserted into the hole at a height so that the angle between the plane of the base and the platform with sandpaper is the same that was chosen to form the slopes. An angle from 22 to 30 degrees is universal.

Having made an even descent to the middle of the thickness of the workpiece, the knife is turned over, then the same descent is made on the reverse side. Using such a simple device, you can easily form an even blade.

How to make a knife from a mechsaw with your own hands

The thickness of the fur saw is usually 2-2.5 mm, unless you find another option. This is enough to complete all knife tasks. They are light in hand, keep sharpening for a long time and will be completely legal. With a long one just do not lose. And for the rest of the qualities, the knife will not fall under the article on melee weapons.

Do-it-yourself fur saw knife.

Making a knife

This process can be roughly divided into several stages. For a detailed and understandable description, we will do this:

Of course, the first step is the layout drawing. If experience is not enough, do not disdain this moment, it is really important. Measure the "saw" workpiece itself, the model should not protrude beyond the edges, and do not forget about the shank and the handle. All these points must be taken into account initially.

Use a black marker to transfer the sketch onto the saw blade. We clamp it in a vice and cut off a piece of the desired length with the help of an angle grinder. At the same stage, cut out the shank so that you do not return to the vice and the "grinder"

After rough work, "remove" all burrs with a file.

Special attention is paid to future descents. This process is the most important and must be taken seriously.

We take almost the "blade" and paint over it with a black marker, then use a caliper for marking. We measure the slopes in accordance with the layout. Then carefully and, most importantly, symmetrically draw a strip along the blade, using a caliper. A scratched line should appear on the black paint. We do the same on the other side.Be sure to circle the markings with a silver marker, preferably with aluminum powder.

To remove the descents it is best to use a special device, in more detail in the article: “How to make descents on a knife”. It will be much faster and, most importantly, more accurate. And now about a marker with aluminum dust, when working on a grinding machine, the workpiece will warm up. A simple one will simply "burn out", namely the one described above, on the contrary, will freeze and will not fall off. Thanks to this little trick, the descents are perfect. The belt on the grinder is not needed for making slopes with very fine grains, P80 and P120 are enough. You can bring it to perfection later, but this is a rough version.

Start making descents from the handle, after removing one side, we do the same on the other. After making sure everything is in order, you can walk in a felt circle with pasta. Then the blade should be wrapped with masking tape several times - this is both protection against cuts and preparation for working with the handle.

The handle will be made of symmetrical wooden overlays. We drill holes in the shank. We mark the bar and divide it into exactly two parts. In accordance with the holes on the blade, we drill them on the linings. Then you need to cut along the handle, in accordance with the shank. Having marked out and tried on everything, we take the shape of the handle, here focus only on your taste. Read more in the article: "How to make a handle for a knife".

When the parts are ready, you can connect them with rivets. The knife is almost ready, it remains to process the handle in hot wax. If you don't have one, you can use natural oils, latex-based formulations, silicone, or special wood impregnations.

Homemade knife from a power saw.