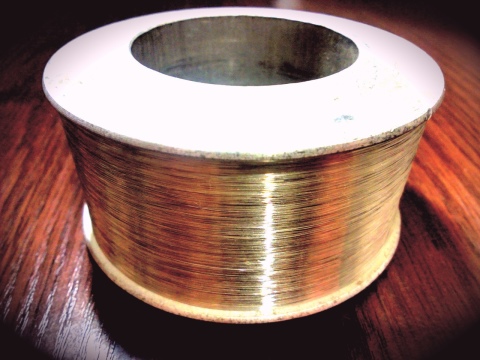

Where to get nichrome wire

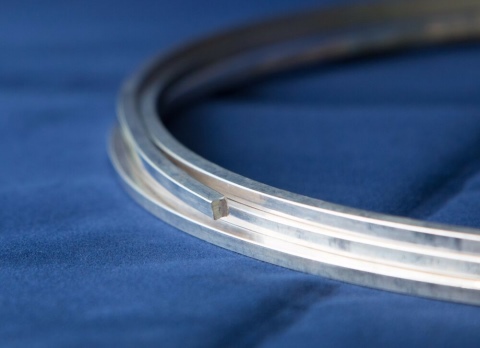

The product is sold in rolls (spools, coils) or in the form of a tape. Where to buy or get products from nichrome? Let's consider all possible options:

2.Purchase from a specialist store. It can be a store selling radio components, materials for designers and craftsmen such as "Skillful Hands", etc.

3. Buy from private traders selling spare parts, radio components and other small metal things.

4. At a regular hardware store.

5. At a flea market or a flea market in some old appliance. For example, in a laboratory rheostat known from physics lessons.

6. You can find nichrome wire at home. The spiral of an electric hotplate is made from it.

For a large order, the first option is suitable. If you want to buy a small amount, you can consider all the following items on the list

When choosing, you need to pay attention to the marking

for heating elements - H;

for resistance elements - C;

for tubular electric heaters - heating element.

Application in industry and in everyday life

Nichrome products are used in places that require high-quality metal. Especially in demand in industrial production.

In industrial production

One of the first places is occupied by metal products in the market of industrial and household electrical equipment. It has found wide application in industrial sectors using electric heating furnaces, kilns for roasting and drying, furnaces that heat up to high temperatures, and devices that have a thermal effect.

It is used in welding machines, household heaters and heating systems for glass and car rear-view mirrors, in resistors, resistance nodes and rheostats as a heating or resistor element. As noted above, the material is widely used among home craftsmen.

Note! Choosing nichrome wire for making equipment is not easy. When choosing, it is necessary to take into account such parameters as diameter, length and grade of alloy.

In the household

In the domestic sphere, it is used for cutting foam and polystyrene. Cutting these materials at home is quite problematic. There are several ways. Often a knife is used for these purposes, from which the material begins to crumble.

Craftsmen know how to cut foam at home so that it does not crumble. This will require a nichrome wire. It is needed in order to make a machine, the cutting tool of which is a heated string. With its help, you can cut polystyrene and make products from it with your own hands.

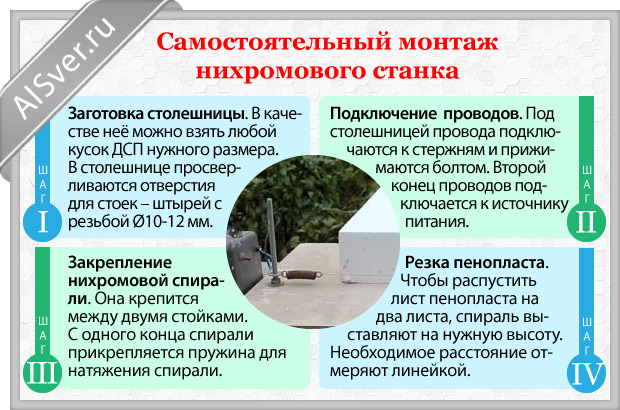

How to make a DIY Styrofoam Cutter

It is not difficult to make a machine. This will require:

- pipe lining (pipe with a thickness of at least 20 mm, foam thickness - at least 2 cm);

-springs for string tension;

For the manufacture of countertops, you will need a table, a board and a sheet of corrugated board.

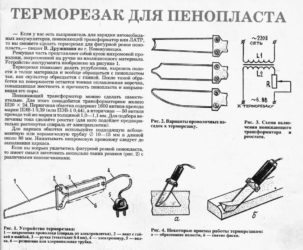

The step-down transformer can be made by hand from transformer iron. You will need to make a rheostat to pick up the current value. To do this, you can take a spiral from an electric stove, having previously stretched it into a string. The winding frame is constructed of an asbestos-cement or ceramic pipe 15-20 mm thick and about 80 mm long.

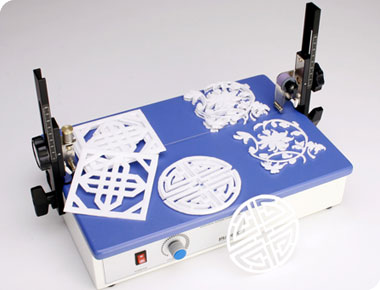

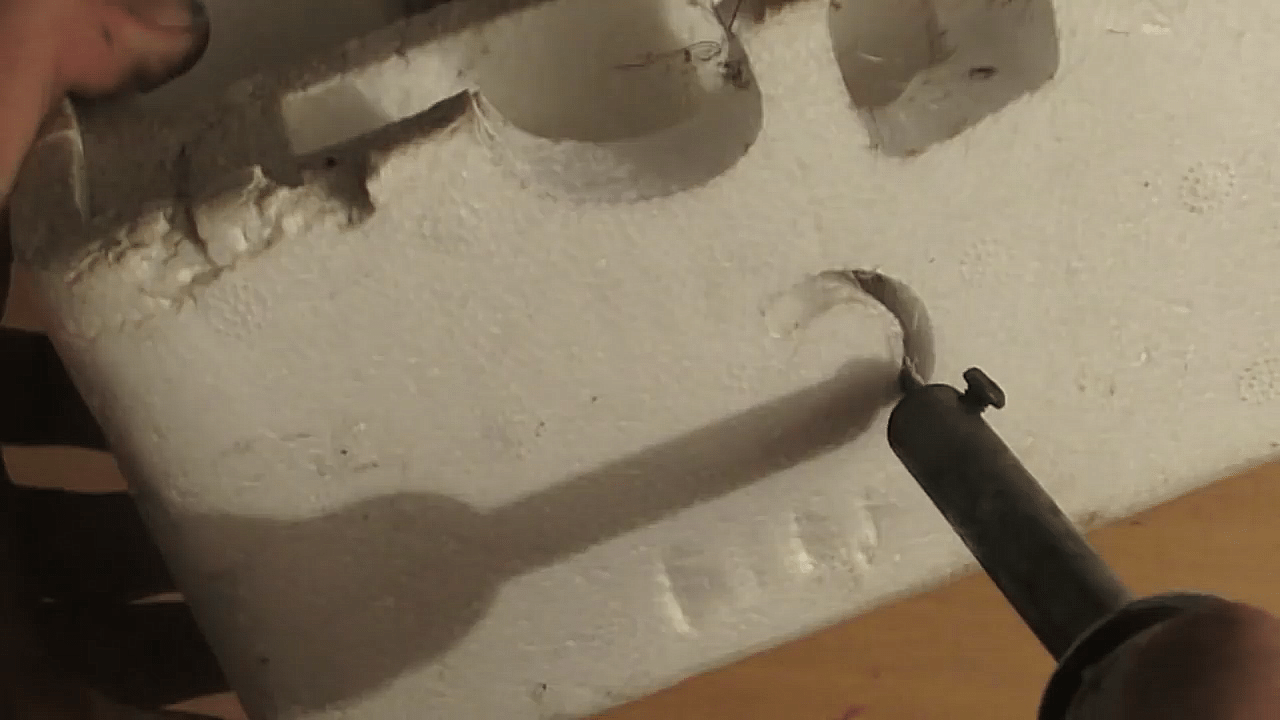

For curly cutting, a thermal cutter is used from a piece of nichrome wire. It is fixed to a handle made of insulating material. A homemade foam cutter does an excellent job, including curly cutting of material.The device allows you to make recesses, cut out cavities, work with foam the way a sculptor works with clay.

Note! After processing, the surface is covered with a melted crust, which closes the pores and increases the strength of the foam

With the help of home-made devices, in which nichrome wire has found application, it is possible not only to cut the foam, but also to burn it on wood.It can also be used in home-made household heaters, welding machines, and heating systems for car windows and rear-view mirrors.

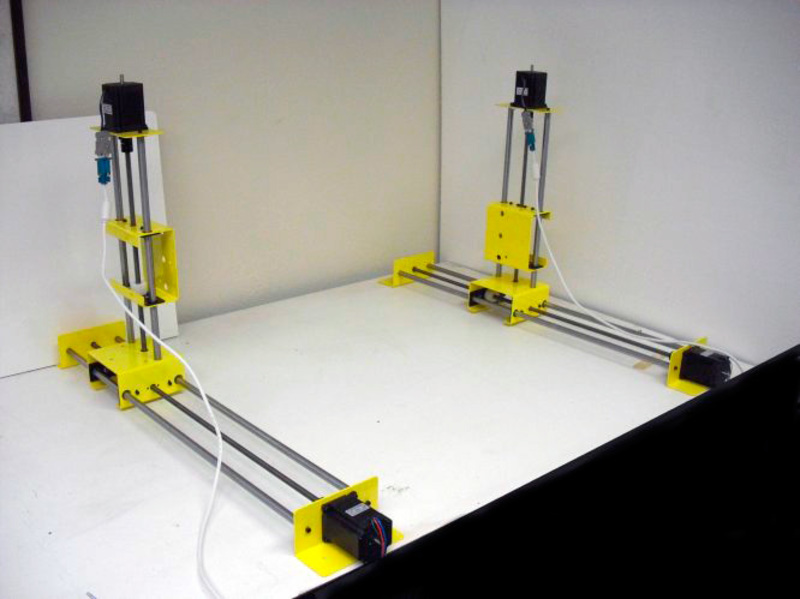

Cutting devices do not have to be hand-made. There are industrial machines and accessories on sale that meet the needs of amateurs and professionals. These devices are manufactured in accordance with safety standards and regulations.

What to make of?

Everyone, having at hand the minimum number of parts, is able to assemble a nichrome cutter with their own hands to perform the simplest household tasks. Such a jigsaw made of nichrome dragging, subject to the assembly scheme, will last not a single year.

On the Internet, masters do not hesitate to share crafts. If you assemble the tool yourself, it will take as much money as assembling a jigsaw. But the functionality will be very different.

The cutting element is nichrome wire.

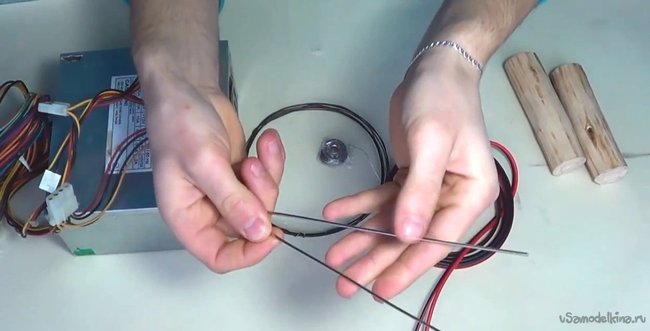

For manufacturing, you will first need to make a handle with a clip at one end. The wire is attached on one side, on the other, a weight is installed and the contacts are connected to the power supply.

As soon as the device is plugged in, the cutting element will become very hot. It is due to the temperature created that it is possible to cut the plywood sheet without difficulty. This is the same as cutting butter with a hot knife.

The edges will be slightly burned like after using a laser cutter.

Experts advise to work on the street, because during the operation of such equipment, the material smokes a little. A room with well-organized ventilation is also suitable.

How to make a nichrome cutter with your own hands, see below.

Alternative to a jigsaw

For those who do not have the ability or desire to use ordinary wood to create cut (sawn) and use plywood as a material, cutting with a jigsaw is not always the best option for work. Plywood - the material is quite fragile, it is easy to break off. And it is often sawn with the formation of untidy "rags" of fibers along the edges of the cut. In addition, a jigsaw is not always the best tool for wood, especially if you need to cut several identical parts.

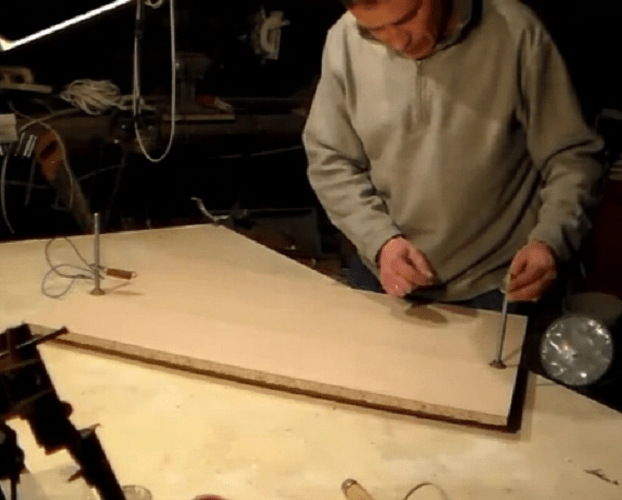

As an alternative to a regular hand jigsaw, you can use a thin nichrome wire connected to a step-down transformer. In fact, instead of cutting out, in this case, burning is obtained.

Tool making

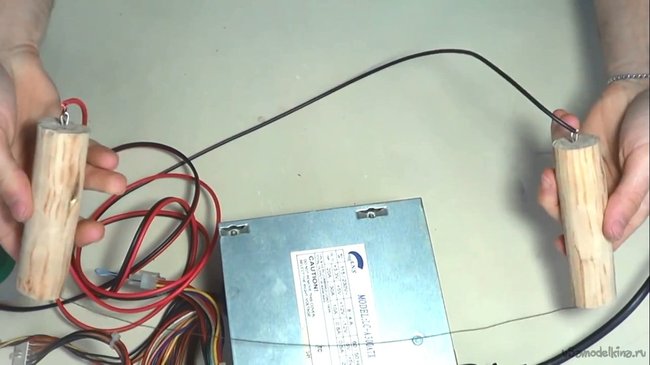

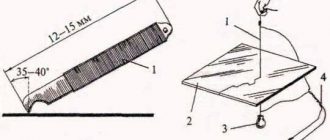

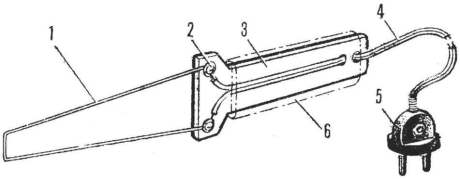

The design of the tool can be of two types: "fishing rod" and "jigsaw". In the first case, the tool consists of a wire of a certain length, to the ends of which terminals from the secondary winding of the transformer are attached, in addition to one end, a handle made of a material that does not conduct current and temperature (preferably wood) is attached, to the second - a load, the size and weight of which allows you to keep the working part in tension. Instead of a weight, you can attach a handle to the second end of the working part.

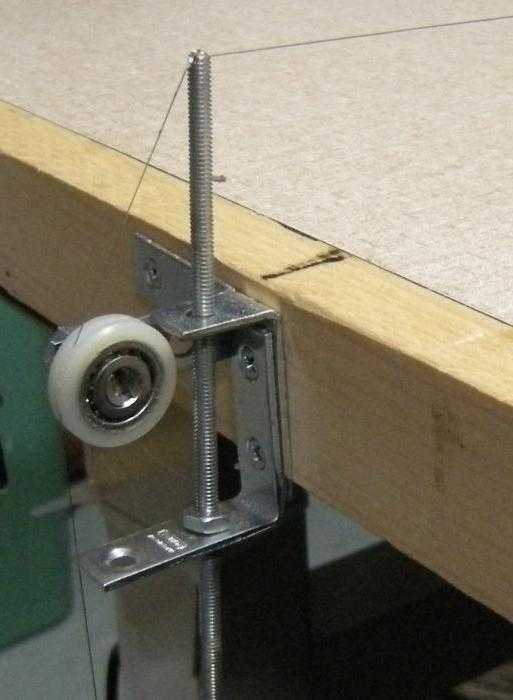

The second option is a little more convenient for work and resembles a regular jigsaw - nichrome is stretched on the jigsaw frame, but the clamps are made of non-conductive material. In this case, the terminals are attached to the wire BEFORE the clamps. The figure below shows how you can tighten the nichrome on the jigsaw frame using a special clamping bar. The terminals are attached after being pulled. It is not necessary to bring the working part to the state of a "ringing string", as is usually done with a file. It is better to use a flexible frame, since the length of the working section of nichrome may have to be adjusted.

The length of the wire in both cases depends on the power of the used transformer. If a length of 100 mm is enough for 6V power, then a longer piece will be needed for a higher voltage. Nichrome is used because other material with a small wire diameter will not withstand the required heating.

Nichrome is usually taken with a diameter of 0.3 mm to 1 mm (the diameter depends on the thickness of the cut material layer).

The transformer can be used with a power from 6 to 24V, the source of the transformer can be an old TV, filmoscope or other equipment.

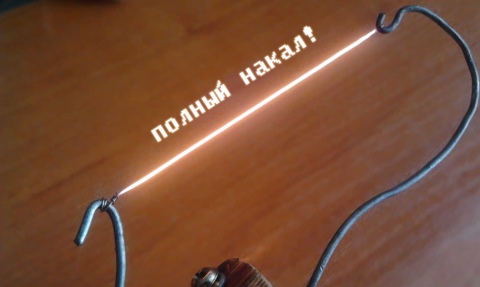

The length of the working part is selected from the following considerations: the nichrome should heat up to dark red when the current is connected. Lower heat will make wood and plywood difficult to saw, especially if the board is thicker. If the temperature is higher, the wood fumes can ignite. Thus, the length is selected empirically on a specific transformer. For the convenience of adjusting the length of the working part or its recovery after a rupture, it is advisable not to cut off a piece of the required length at once, but simply wind several turns on one of the contacts, which can be used as bolts and nuts.

Additionally, a switch is needed on the wire coming from the transformer - to interrupt the current in the circuit when transferring the wire from one fragment of the pattern to another and when the wire breaks (burns out).

Below is the view of the tool, its schematic diagram and the burning process itself.

Rough sawing

If we are talking about cutting wooden parts, then in most cases we mean the sawing process. This technique is used as widely as possible, starting from the transformation of whole trunks into boards and bars of the desired size and ending with the fitting of parts to the given dimensions.

The sawing process can be carried out using different tools:

| Tool type | Principle of operation |

| Saw-hacksaw |

|

|

|

|

Of course, only the main types of tools used for sawing are described here, but this will be enough to navigate the general principles of work.

Homemade Styrofoam Cutter

A homemade cutter is intended for minor jobs. It is not possible to cut the entire sheet of expanded polystyrene for them. To cut styrofoam at home, you must:

- Make 2 holes in a wooden block 10-11 cm long. They should match the diameter of the pencils. You need to step back from the edge by 1-1.5 cm. The depression should be slightly deeper than half of the bar in order to fix the pencils. Thanks to this distance, you can cut the foam sheet of almost any thickness.

- Glue both pencils into the holes with hot glue or PVA.

- In each of the pencils, make a small hole on top for the copper wire.

- Bend the copper wire with round-nose pliers so that small rings are formed at its ends. Then install in the holes in the pencils.

- Glue the battery connector perpendicular to a wooden block. Additionally, it will act as a handle.

- Stick the switch on the block so that you can de-energize the string.

- Then connect 2 wires to the connector. After that, connect to the switch, and then bring each one to a separate pencil. To prevent the wire from sagging and interfering with work, it is fixed with electrical tape. To ensure a reliable connection quality, you need to solder the wires to the connector. The joints must be insulated with heat shrink tubing or electrical tape.

- Remove the braid from the other end of each wire and screw it to the copper wire. Solder the connection.

- Thread the nichrome thread into the copper wire rings and fasten to them. The string should be taut between the pencils. When heated, it stretches and sags a little. The tighter the tension, the less sagging.

- Insert the batteries into the connector and start cutting the foam sheets.

Thus, you can make a simple device for cutting foam with your own hands. And another option for making a machine, see the video:

Criterias of choice

Before choosing a cutter, you need to know what points you need to pay attention to first. The most important thing is the wire, the further use of the tool depends on it and its characteristics.

If the letter H is present on its surface, then it is ideal for creating heating elements.

The most important thing is the wire, the further use of the tool depends on it and its characteristics. If the letter H is present on its surface, then it is ideal for creating heating elements.

If there is a bounding box in the torch design, the cutting depth is also limited. In the manufacture of the unit independently, this element is not used in the structure, therefore material of any thickness can be processed.

What is nichrome and what is its value

Nichrome is a special alloy with a high concentration of chromium and nickel. The composition also includes iron, aluminum, silicon, manganese and other chemical elements, the combination of which gives the metal unique characteristics.

Nickel Chromium Base Alloy Properties

The most common alloys based on nichrome are ferronichrome and ferrochromal (fechral). From them, wire is obtained by drawing. The quality of its production is regulated by the current state industry standards. GOST 8803-89 and 12766 apply to wire with good electrical resistance. Chromium gives hardness and strength to metal, and nickel gives plasticity. The maximum heating temperature is influenced by the percentage of nickel in the alloy. The more it is, the higher the temperature, which can reach 1000-1300 degrees.

The value of the alloy and products from it

Products made of nickel and chromium alloy have increased resistance to electric current. This means that much less nichrome is needed than other metal to obtain the same amount of heat generated. This reduces the weight and dimensions of the devices and devices in which it is used.

High resistance is provided by numerous parameters, the main of which is the grade of the raw material used for the manufacture, as well as the thickness. The thicker it is, the lower the resistance on which the heating level depends. The metal does not burn, does not deform, does not lose its characteristics when exposed to high temperatures.

The useful properties of the alloy include plasticity, which allows the wire to be shaped to the desired shape. The section can be in the form of a circle, oval, square and trapezoid, with a diameter of 0.1 to 1 mm. The value of the alloy also lies in the fact that, unlike most metals subject to corrosion, it does not rust, since it has anti-corrosion resistance to aggressive liquid and gaseous media.

Advantages of chrome nickel alloy products

The main advantages of nichrome wire, thanks to which it has become widespread in many areas of production, is in demand among inventors and home craftsmen:

-high heat resistance;

-Anti-corrosion resistance;

-hardness, strength and mechanical stability;

-elasticity;

-high level of specific electrical resistance;

-small weight;

-resistance to aggressive substances.

The only drawback of nickel-chromium alloy wire is its high cost, which does not affect demand in any way.

DIY Styrofoam Cutting Machine

Cutting machines are more convenient in that the cutting thread is fixed in them and only the foam needs to be moved. This improves the accuracy of the movements. In the manufacture, you will need the same tools and equipment as in the previous case.

The corner ruler marks the place where the filament will go. If the surface is level enough, this can be done with a plumb line. To do this, a self-tapping screw with a wide head is screwed into the end, and a thread with a load is screwed onto it. A hole with a diameter of 6 mm is drilled in the selected place. To prevent the string from burning the wood, a plate of textolite or metal is installed. Place the material flush with the surface.

A wire is threaded into the hole, the lower end of which is put on a self-tapping screw. The screw is screwed in next to the hole. The length of the spiral should be such that when heated, the latter turns red. Since the wire lengthens at high temperatures, a compensating spring must be used to avoid sagging. A spring is put on the upper self-tapping screw, and a nichrome thread is attached to it.

An energy source is connected to the ends of the filament, which can be a battery with a voltage of 11.7-12.4 V. To regulate this indicator, a thyristor regulator circuit is used. The regulator can be taken from an electric grinder. You can also control the voltage using a spiral on a polystyrene foam cutting machine.

This coil is mounted on a wooden block to which the upper edge of the filament is attached. Connects to the wire in series. Its function is to lengthen the nichrome thread and, accordingly, reduce the stress. This can be achieved by changing the place of connection to the nichrome spiral. The smaller the distance, the more the thread heats up and the more the foam melts.

If a transformer is connected to the machine, it must be galvanically isolated. In this case, a transformer with taps must be used.

With the help of such a simple machine, the foam is cut with your own hands. Additionally, you can make various devices. You can make a miter box during the repair with your own hands or a tray that will help you cut the material evenly at the right angles.

How to choose a cutting wire

A suitable cutter can be made from nichrome wire (X20H80), which is used in the construction of most household appliances as a heating element. In terms of mechanical characteristics, nichrome is comparable to ordinary steel, while it has a high resistivity and a heating limit up to temperatures of +1200 ºC. For the manufacture of devices for cutting, wire with a diameter of up to 10 mm is available.

Precise and smooth threading of the foam is possible when the cutting line is heated to a temperature that is two to three times higher than the melting threshold (+270 ºC). It should be borne in mind that such a process involves the consumption of energy and the absorption of heat by the material itself in proportion to its density. Therefore, for efficient and safe cutting, it is necessary to select a wire of suitable thickness in order to prevent metal melting at maximum heating.

Calculation and preparation of the electrical part

For the safe operation of the device, it is necessary to correctly mount the conductive elements that are connected to the power source through the captive terminals. AC or DC can be used to cut the material. The power of the source is calculated based on the fact that for effective cutting of 10 mm of wire, up to 2.5 W will be needed (for 500 mm - 125 V).

For the safe operation of the device, it is necessary to correctly mount the conductive elements that are connected to the power source through the captive terminals. AC or DC can be used to cut the material. The power of the source is calculated based on the fact that for effective cutting of 10 mm of wire, up to 2.5 W will be needed (for 500 mm - 125 V).

The voltage is proportional to the resistance and is calculated using formulas or tables. But on average, with a wire diameter of 0.8 mm, a length of 500 mm and a resistance of 2.2 Ohm, a current source with a voltage of 12 V with a load current of 12 A. current.

Sources of electricity and connection diagram

Safe cutting is ensured by connecting to a regular household 220 V network through a car transformer. To adjust the voltage in the single primary winding, a knob is provided, with the help of which the graphite wheel is moved and the voltage is removed from the corresponding section. This parameter can be changed in the range from 0 to 240 V. The connection to the power supply is made through the terminal box.

When connecting a homemade foam cutting machine to the mains, you need to make sure that the phase does not fall on the common wire. All necessary parameters and wiring diagram can be found on the transformer housing. Before connecting to the network, you need to check the operation of the device using a multimeter.

An easier way to apply current to the wire is to use conventional step-down transformers with secondary taps. In this case, it is not necessary to select the voltage value, since this value is always constant and sufficient to heat the wire to the desired temperature. You can select the desired value during the initial configuration of the transformer, providing a certain number of winding turns in the circuit.

You can also heat the wire for cutting the foam with the help of household appliances. In this case, the following nuances are taken into account:

- connection via adapters with reliable isolation of contacts;

- connection of the cutting wire with a conductor not energized ("zero");

- selection of the power of the electrical appliance according to the expected heating temperature (soldering iron, vacuum cleaner, heater, charging unit with transformers).

To make a thermal knife for polystyrene or foam rubber, it does not take a significant investment of time and effort. For this, a wire of almost any diameter is suitable, but with unknown parameters (diameter, resistance), power must be increased gradually, first connecting low-power current sources. Reliable isolation of the contacts and control of the phase position, which should not be connected to the wire, are of great importance.

Have you tried cutting styrofoam with a regular knife? It does not work, as the material crumbles. I'll walk you through how to make a DIY Styrofoam cutter and provide three simple, step-by-step instructions for assembling a Styrofoam and Plastic cutter.