Do-it-yourself mini tractor attachment

With a serious approach, a mini tractor can become a serious assistant for both a professional farmer and an amateur gardener or gardener. Modern industry offers a mini tractor for literally any volume of agricultural production, taking into account any specifics. However, the price of a new branded mini tractor, unfortunately, is not available to everyone. There are various ways to save money on the purchase of a means of mechanization of agricultural labor.

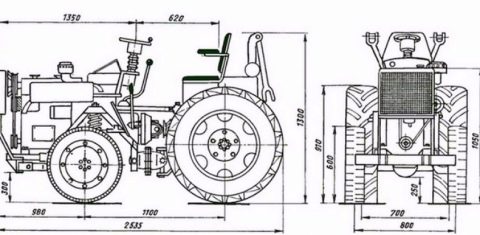

Mini tractor from a walk-behind tractor

For example, you can order a mini tractor from China and the countries of Southeast Asia via the Internet. You can use online exchanges and purchase used equipment. But even such reduced spending may seem excessive for those who are engaged in gardening at an amateur level, but need the "iron" support of their hard work.

What is hitch?

In this case, a tractor assembled from a walk-behind tractor can be useful.

Differences between other modifications of the grader

If you want to make attachments from steel sheet, then you should take options at least 3 millimeters thick. You should not buy thicker steel, as it will be very difficult to shape it. To ensure rigidity, make the posts of stronger steel, narrow strips will be easy to bend.

Holes are made in these racks to help you fix the attachment to the walk-behind tractor. In total, this design provides 4 parts: a pair of rods, a working blade, brackets and rods. A steel plate knife is bolted onto a shovel. A minimum of 4 stiffeners must be installed on a steel grader. Brackets are mounted on the frame of the motor power unit.

The rods are attached to the blade and brackets. When inoperative, it is necessary to lower the working blade in order to relieve the load from the frame of the power unit of the cultivator. The swing mechanism of this grader is manufactured according to the same principle as in the variant described above.

Buying ready-made attachments can punch a decent hole in your budget, so it's worth paying attention to the DIY instructions above. Having a gas cylinder or an old barrel on hand, you can make this design yourself

In terms of time, the work usually takes no more than three hours. Additional materials for making a grader will cost you much less than a factory made knife. It is quite simple to use a walk-behind tractor to clear snow from areas: set the shovel at an angle of 30 degrees and lower it.

A self-made grader will do an excellent job of handling the snow mass. Users find it easy to level construction sites, paving slabs or equipping beds.

Homemade snow shovel

Dump barrel

To make a snow shovel for the Neva walk-behind tractor on your own, you first need to collect the necessary tools and materials. So, we need:

- an old steel barrel with a capacity of 200 liters;

- a strip of iron with dimensions of approximately 850x100x3 mm;

- 1 m of a square pipe with a section of 40x40 mm;

- bolts М10, М12 and М8, as well as washers and nuts;

- a set of drills for metal;

- pliers;

- set of wrenches;

- a sheet of thick durable rubber;

- small but thick steel sheet;

- grinder with discs for metal;

- welding machine;

- hand electric drill.

After all the tools, materials and drawings have been collected, you can start making a do-it-yourself blade for the walk-behind tractor. The simplest solution would be to make a bucket from an old 200 liter barrel, since it initially has the optimal roundness. In this case, it is not necessary to heat the metal sheets and bend them, giving them the desired shape. So, you need an old barrel, from which you need to cut off the lid and bottom with a grinder. The resulting pipe should be cut lengthwise into three equal segments. These two thirds must be connected together along the contour using a welding machine, and the remaining third must be cut with a grinder into strips that will be used to ensure sufficient rigidity. Attach the shovels one strip at a time, and distribute several pieces evenly along the entire length of the blade.

Homemade snow plow design

Now, to further strengthen the entire structure of the blade, you need to make a knife at the bottom of the bucket. This will require an iron strip with dimensions of 850x100x3 mm. Using an electric drill, drill three holes with a diameter of 5-6 mm and a distance between them of 100-120 mm in the knife. This is to reinforce the rubber pad, which will prevent the bucket from damaging the road surface. The knife is bolted to the working edge of the bucket.

After assembling the snow shovel and blade, you need to make and install the blade mount. Weld a piece of pipe to a homemade motoblock blade in the center of the structure. In the middle of the pipe, by welding, fix a semicircle made of a thick sheet of metal and make several holes in it to set the required angles of rotation and fix the motoblock blade.

Next, you need to take another piece of square pipe and make an L-shaped holder out of it. The short side of this holder is installed in a pivoting semicircle, and the other end of the pipe is bolted to the frame of the power unit. To adjust the height of the blade, two bolts are used, screwed into the recess of a square pipe, which is welded to the hitch and is put on the L-shaped holder. The video shows a snow shovel for a walk-behind tractor and working with it.

Valentin Kozhedub | Topic author: Rebeca

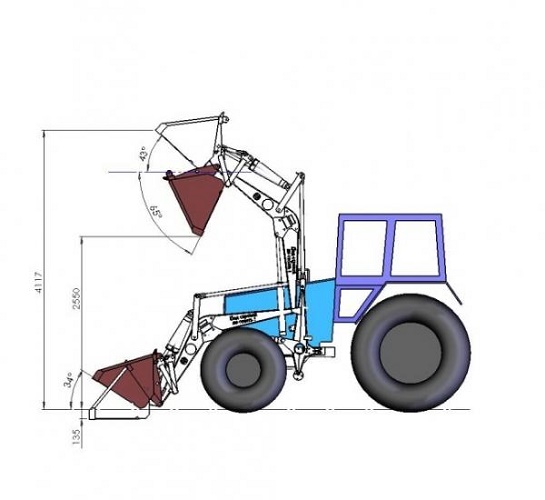

testing the loader as a crane.

V (Caris) why would it be? ! the hitch is designed for lifting the load! from the front dartal can be broken faster. and in this version, if you start to take a heavy load, then the tractor will just bulge up and that's it.

Maxim (Rebeca) and my papals were breaking

V (Caris) from the rear load? then the gap was cracked, and the loader finished it off.

Maxim (Rebeca) did not stick in the front with a knife, but a loaded cart pushed and broke. From whom I bought this tractor from him, the central screw tore out with a piece of hydraulic tank, his bucket was hung

V (Caris) I sympathize ... anything can happen ...

This is interesting: How to make a homemade plow and other equipment for a T-25 tractor - we cover in detail

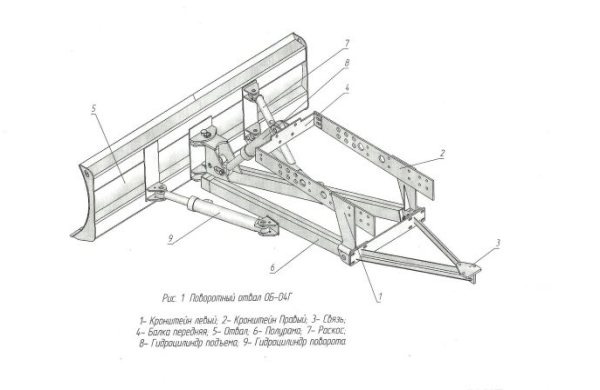

Types of dumps

Mini tractor rear blade

According to the method of placement and fastening, several types of this equipment are distinguished:

- Front. It has its own hydraulic cylinder with which the equipment is driven.

- Rear-mounted. It is located at the rear of the mini-tractor and is driven by turning on the hitch of the unit.

The front-wheel drive version is most often seen on construction sites, during road works and when clearing snow. Blades can have significant differences, but each of them has its own important characteristics:

- The width of the shovel, depending on the model of the power unit, can range from 1200 to 2000 mm.;

- the power of the mini-tractor used for the installation of light equipment must be at least 16 hp and for heavy equipment - at least 20 hp;

- the weight of the device can vary from 65 to 105 kg.It all depends on the task and the required processing width.

The front blade attachment to the mini-tractor allows you to use the unit as a small bulldozer and level paths on the site, clear snow or remove uneven terrain.

In addition, front-wheel drive implements add additional mass to the powertrain, thereby increasing tractive effort. However, when hitching a shovel, many are faced with the problem of how to raise it to the transport position. The best option is to equip the mini-tractor with a hydraulic cylinder, but not all units are equipped with an additional hydraulic valve. In this case, you can use the hydraulics designed to raise the rear linkage. To do this, install the bracket with the block, and fasten the cable to the grader by means of a bolted connection. After that, transfer the cable to the block located above the blade and then to 2 blocks located under the bottom of the power unit and fix the second end to the rear linkage lifting arm. When the rear linkage is raised, the front-drive shovel will also rise, and vice versa. In this case, no additional equipment is required to lower and raise the shovel. Fastening of the front-wheel grader is carried out in the places provided by the unit design.

You can buy a ready-made blade or make it yourself, as most powertrain owners do. A homemade dump for a mini tractor allows you to save money and at the same time create equipment that will meet all the requirements of the owner of the unit.

Step-by-step instruction

The whole process of making a homemade bulldozer at MTZ consists of the following steps:

- First, you need to make two brackets that will be connected by a crossbeam. This entire structure is bolted to the side members. Secondly, plates with a stiffener and a hinge at the bottom are welded to the brackets.

Diagram of a homemade bulldozer

- Now you need to attach the hydraulic cylinders. It is better to make them parallel to the subframe, since the load on the blade will be greatest in the lower part. The plow is divided into two parts centered on the semi-frame hinges. The remaining halves are divided into 3 parts, and 1/3 from the center is selected for mounting the hydraulic cylinders. Alternatively, a set of pipes can be cut. Two pipes are of the same length and two are different. By changing them, you can adjust the blade rotation. It will cost less than hydraulics and will perform significantly better than a fixed blade, although it will take longer to get ready. The pipes will be attached to the hinges, making them much easier to install.

- However, if you do not plan to change the position of the blade, you can use two pipes instead of cylinders, which are rigidly welded to the blade and half-frame at the points of attachment of the hinges. Centerpieces can also be simply brewed.

In the video, a homemade bulldozer at work:

Homemade blade for the MTZ-82 tractor.

Pros and cons of using homemade mounted snow plows

Using homemade mounted snow removal equipment is not only numerous advantages, but also extremely serious disadvantages.

The main advantage of such snow blowers is a significant reduction in costs associated with:

- purchase;

- transportation.

After all, most of the details can be:

- remove from decommissioned equipment;

- for a penny to buy at the point of reception of black and non-ferrous scrap metal.

Another plus is that you can make non-standard equipment, ideally suited for some specific tasks.

Indeed, in most cases, the employees of these structures perceive the installation of any attachments as changes in the design of the car.

Therefore, after installing the unit, the machine must undergo a technical inspection, which will carefully check:

- conformity of the new equipment to the machine structure;

- the condition of the vehicle itself.

Often the decisive factor that leads to the ban on the operation of a communal machine with self-made attachments is the lack of various documents and certificates for equipment.

Therefore, before installing homemade attachments, it is necessary to probe the soil in the traffic police.

After all, the inspector can not only prohibit, but also suggest the necessary organization, where all the documents will be drawn up correctly.

Types of weights and independent production of a three-point structure

A do-it-yourself hinge for a mini-tractor is made from a steel profile by welding. But before doing this, you need to understand the essence of the design. The hitch is needed to connect the tractor implements. There are models of seeders and mowers for which the attachment provides the transfer of motor power.

The three-point hitch is made movable in two planes: vertically and horizontally. The hydraulic drive is usually only fitted to the front linkage. Now let's talk about the design. Almost all agricultural equipment is connected to a three-point hitch. An exception may be a mini-tractor on a caterpillar track or with a broken frame. Such a technique can be equipped with a universal hitch, which, when working with a plow, transforms and becomes two-point.

The three-point homemade hitch is a triangle welded from a steel profile. The mobility of the connection to the tractor is ensured by the central screw. An example of a homemade hinge can be seen in the photo.

Agricultural attachments

For use in agriculture, horticulture and animal husbandry, modern industry produces a wide range of attachments for a mini tractor. Depending on the type of work, factory fixtures are divided into different types.

Soil preparation equipment

Loosening and mixing of the soil, saturation of it with oxygen is carried out before laying the seeds. For these operations, cultivators, rotary tillers and harrows are used. With these attachments for a mini tractor, you can process farm fields and vegetable gardens. During spring or autumn plowing, weeds are destroyed by the plow. All these devices are 1-2 and 4-case.

Double plow

Front and rear attachments such as mowers and a shovel blade will help clear the overgrown virgin soil for a new field. Tall weeds and bushes are mowed with a mower, with the help of a shovel blade, the mowed branches are quickly removed from the site.

Shovel blade

Landing devices

Appropriate equipment allows to mechanize the process of sowing grain and vegetable crops, planting fruit and berry seedlings.

- For sowing grain and seeds of legumes, vegetable crops, 1, 2 and 3-axis grain drills are produced. The devices are a combination of furrow shaping tools, a seed reservoir and a seed spreading mechanism followed by a sprinkling of soil.

Seeder grain

- Potato planters, onion-garlic planters are intended for planting root crops. The device forms a deep, even furrow, where seed vegetables are fed from a reservoir with planting material through special tubes, after which they are mechanically covered with earth.

Potato planter

- The combination of a special attachment auger and seedling tanks simplifies the formation of rows when setting up a new garden.

Advice! Planting equipment is advisable to use on large farmlands. In small gardens, equipment simply will not turn around.

Aggregates for the care of beds and plants in the garden

Loosening, hilling, fertilizing, spraying, watering and other operations for the care of crops and garden plantings on large areas are also carried out using the appropriate plant equipment for mini tractors.Such equipment includes rake-tedders and hydraulic rakes, weeding cultivators, mounted sprayers, mulchers, watering equipment, mowed grass grinders, mounted fertilizer hoppers and much more.

Rake-tedders

Harvesting attachments

For harvesting root crops using a mini tractor, conveyor, drum and vibration models of potato diggers are produced. This equipment is connected to the rear hitch of a mini tractor, and is used for digging not only potatoes, but also beets, carrots, radishes and other root crops. The devices dig up the roots, clean them of the soil and pour them in an even layer onto its surface. Onion and garlic diggers are arranged in a similar way, and the devices differ in the size of the cutter and the block of digging. It remains only to collect the dug out fruits, for which an auto-picker trailer or manual labor is used.

Potato digger

For harvesting, other types of equipment are also produced: trailed fruit pickers or onion cutting devices, for example. When preparing feed for animals, farmers are in demand for mounted loaders and trailers, which can be standard flatbed or dumping type (1 or 2-axle).

The baler is also made in the form of a trailer, which helps to collect hay and press it into rolls or bales. Depending on this, a distinction is made between round and square balers. Ready compressed feed is convenient to store and move if necessary.

Round baler