Algorithm for replacing knives on an electric plane

To remove the knives from the electric planer and replace them with new ones (or properly sharpened ones), you will need a set of wrenches and, in some cases, a screwdriver. It is not required to assemble and disassemble the electric plane completely in order to change the working attachments. The replacement is performed in the following sequence:

- turn the drum, exposing it to such a position to gain access to the knife mounting bolts;

- loosen, but not completely, these bolt fasteners;

- remove the working attachment manually or using a flat screwdriver;

- the rest of the blades are treated in a similar way;

- put new knives in the nests, fixing them with bolts;

- put them in the correct position.

The main point is the need to place the blades exactly in their seats and secure them securely so that they do not fall out during tool operation. Due to the fact that the attachments of the working attachments may differ for different models of electric planers, it is recommended that you first read the operating instructions for the equipment used.

When two cutting attachments are installed on the drum of the electric planer, both must be changed at once. This will prevent an imbalance from occurring, which results in a decrease in the quality of lumber processing and the failure of the electric plane.

How to replace knives on an electric plane

To remove old bits, you need a set of wrenches. A screwdriver can also come in handy.

How to do:

- turn the drum of the electrical appliance so that the bolts are accessible;

- loosen the fixation;

- remove the working nozzle;

- insert new blades into the vacated grooves;

- fix them with bolts.

Important! To avoid imbalance, you need to change all the cutting parts at once. It's the turn of the adjustment

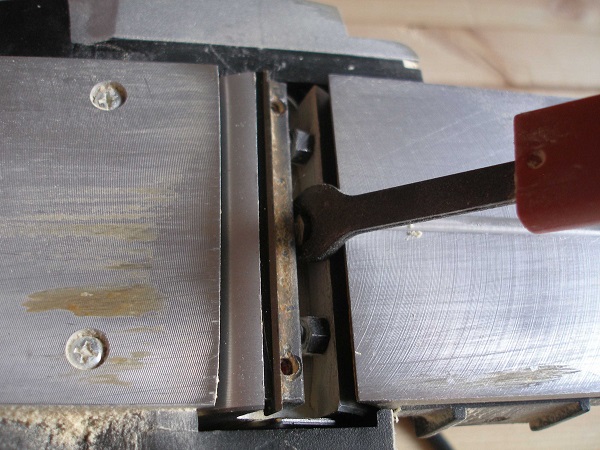

To do this, you need a complete hexagon and a metal ruler.

It was the turn of the adjustment. To do this, you need a complete hexagon and a metal ruler.

How to adjust the electric planer knives:

- Place the instrument on the table with the drum facing up.

- If necessary, wipe off resin from cutting accessories.

- Set the minimum planing depth.

- Place the blade in the slot between the soles.

- Place a ruler on the back plate.

- See if the edge is touching the consumable. If not, raise the bar. To do this, you can slightly loosen the fasteners using the hexagon from the kit.

- Tighten the fasteners.

All this must be done for each nozzle. For balance, the distance between the knives should be the same.

Correctly sharpening the knives of an electric plane yourself is not so difficult. If the situation is not critical, you can do everything manually using a grindstone. If the blade is completely dull, a special device is needed. You can buy it or do it yourself.

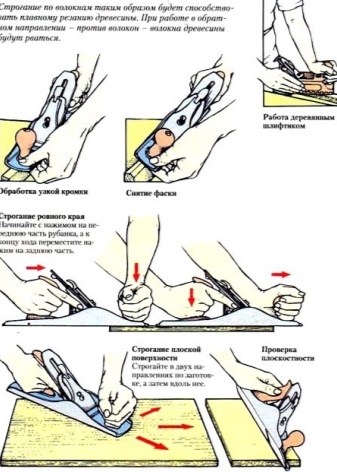

Planing process: nuances

For planing to be absolutely safe, the main condition is a rigid attachment of the workpiece. Planing can only be started after the workpiece has been firmly fixed. First, rough processing is carried out. For this purpose, the scherhebel is used. The movements of the instrument on which the scherhebel is installed must be directed across the fibers. Otherwise, a large amount of wood will be used for planing.

After processing small workpieces with a scherhebel, the surface must be cleaned with a double plane.

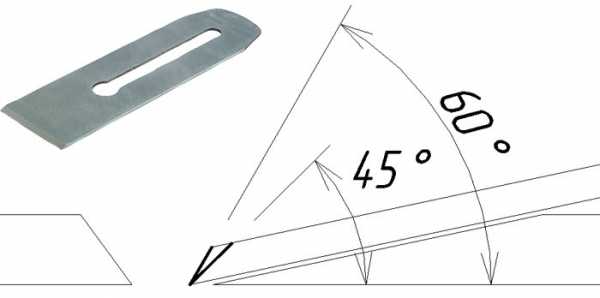

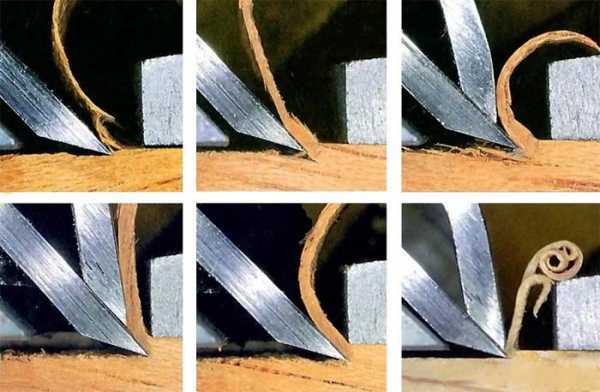

Planer sharpening angle diagram.

The movement must be performed along the fibers. The result is a flat surface without roughness.

An electric planer is often used to chamfer a part. Depending on the width of the required chamfer, the edge of the workpiece is processed with a plane.Tool movement at an angle allows you to obtain the desired chamfer angle.

If a special side stop, usually supplied in the kit, is attached to the electric plane, it becomes possible to perform folding. In this case, the stop must touch the workpiece to be processed.

Stages of preparing the tool for work

To prepare the plane for work, you need to do the following:

- adjust the knife overhang;

- adjust the position of the chipbreaker (if any);

- adjust the mouth gap.

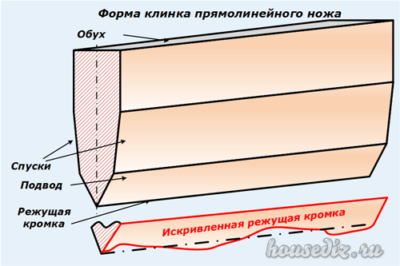

The overhang of the knife affects the thickness of the removed chips, the speed of work and the cleanliness of the resulting surface. For rough processing it should be about 0.5 mm, for finishing it should be less. The process of setting up a metal plane is not difficult, but it is very different in different models. In any case, adjustment is made by turning the adjusting screw. Usually the screw has a left-hand thread, and when turned clockwise, the overhang increases.

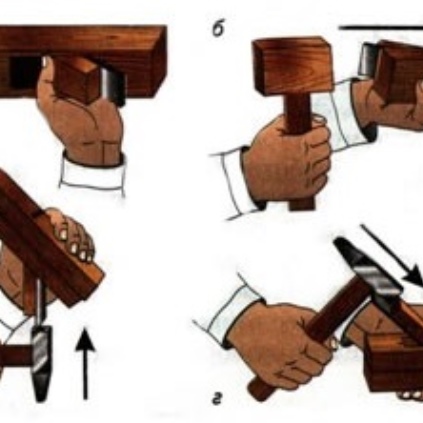

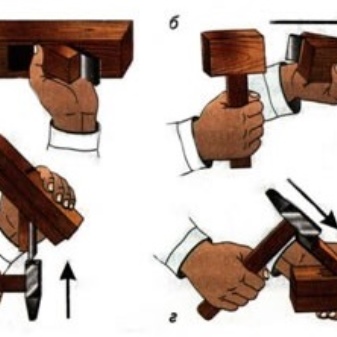

Follow the steps below to set up the wooden planer correctly.

- Hit the back of the case with a hammer a couple of times. This will loosen the wedge that is holding the blade. Then it must be removed.

- Adjust the overhang of the knife to a shallower depth than required. It is advisable to look at the end of the tool in order to visually control the position of the blade.

- The knife has one-sided sharpening. On most models, it is chamfered back into the body.

- Install the wedge.

- Correct the position of the knife. To increase reach, hammer against the upper, non-sharp edge of the knife. To reduce it, blows need to be made on the end of the plane. Hit the sides to get the knife and wedge straight. The edge of the knife should be clearly parallel to the sole of the planer.

If the height of the knife is too low, the blade will not cut, but will slide along the surface. Next, set the position of the chipbreaker. It should be at a distance of 1-5 mm from the sharp edge of the knife. The more - the easier it is to plan, the thicker the chips are and the worse the quality of the processed surface. It is secured with a screw or an eccentric clip. Adjust the mouth gap. The smaller it is, the higher the quality of the product, but the lower the productivity.

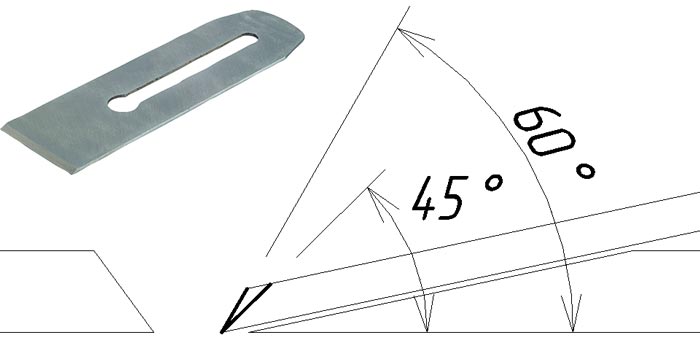

Some models allow you to adjust the angle of the knife. It is different for working with different types of wood.

- 45 degrees - for planing softwood. Most planers have such an angle of inclination.

- 50 - for hardwood.

- 55 - used in profile planers for processing soft materials.

- 60 - in profile planers for hard wood.

The sole of the planer is checked periodically. It should be flat. To check, attach a ruler to it in several directions and look at the gap. Small gaps are allowed, but not at the "mouth", not at the beginning or at the end of the sole. It should be borne in mind that these gaps on the metal plane seem to be larger due to the reflection of light from the shiny surface. In reality, they are less than 2 times.

If the sole is uneven, do the following:

- remove the blade from the planer;

- fix the sandpaper on an absolutely flat surface;

- sand the sole until the correct result is achieved.

The quality of the outsole is defined as follows:

- if there are many small shiny spots evenly distributed over the sole, it is flat;

- if the shiny spots are large and few, sanding should be continued.

The main method of checking is the removal of test chips. The chips should be the same thickness across the entire width of the planer. Skillful hands are the main thing when working. Therefore, we will tell you how to use the plane correctly.

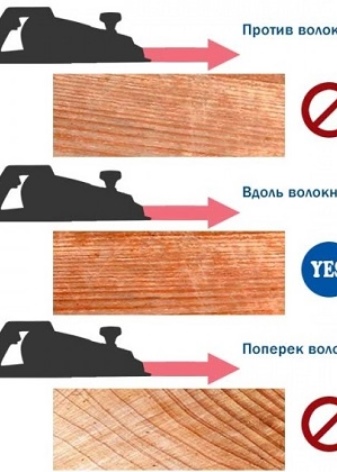

We process wood: what you need to know?

Before processing lumber, you need to determine the direction in which you plan to plan. Usually planed in the direction of the grain of the tree. If the lumber is made from several planks, then you need to plan diagonally.

To prevent the edge of the board from getting uneven, you need to use an angle stop, which is attached to the base of the electric plane from the side and is perpendicular to its axis.

When you have finished planing a wide board, you will need to align the boundaries between the aisles. This stage is called looping. For this, a special grinder is used, which will remove all roughness.

The world's first electric plane was produced in Japan in 1958. Its appearance on the market is due to the desire to facilitate manual labor, which is a very tedious, monotonous and time-consuming task in wood processing.

This power tool can significantly save the family budget - untreated wood is several times cheaper than planed wood.

In order not to damage the tool or the material being processed, and also not to cause yourself an accidental injury, you need to know how to work with an electric plane.

Preparation for work with an electric plane and rules for its installation

First, you should read the instruction manual. Further, preliminary preparation is carried out by checking:

- the position of the front of the sole;

- the degree of freedom of rotation of the working drum with the cutting elements fixed on it;

- the presence of various damage to the plug, power cord, case;

- freedom of movement of the power button;

- the correct position of the knives.

The operability and completeness of the electric planer must be checked even at the time of purchase. The rotation of the drum is checked by moving it by hand. The function of the button is by pressing it. The integrity of the unit is determined visually. When no defects are found, a test switch-on of the equipment can be carried out.

Before planing with an electric plane or performing other operations with it, it is recommended that you first practice processing on unnecessary boards or bars. This will allow you to "fill your hand" and adapt to the technique in order to get an acceptable result in the absence of the necessary practical experience.

It is recommended to start setting up the electric planer by adjusting the position of the front part of the plate with the plug disconnected from the network. To do this, you need to use a ruler or a piece of regular glass of a suitable size. All actions are performed in this sequence.

- The front (movable) part of the sole is set with the help of a special regulating handle in a position that provides the minimum depth when planing.

- Place the power tool upside down on a level workbench or work table.

- The drum is scrolled so that one of the knives is located above its axis.

- A ruler or glass is placed on the sole: in this case, they must lie in the same plane.

When the overlay on the slab is tilted, then this defect is eliminated as follows:

- remove the adjusting handle and the front of the sole;

- clean the opened cavity from shavings and dust;

- lubricate the mechanism;

- put the stove in its original place;

- install the handle;

- check the position of the sole with a ruler.

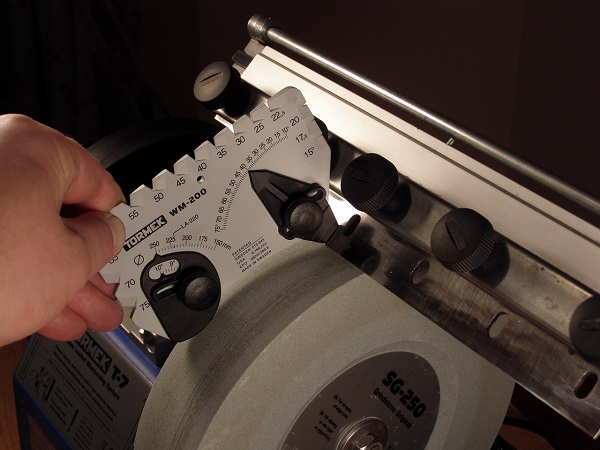

Check blade alignment using a metal ruler. To do this, it is applied to the edge of the plate. Then they look to see if the blades located on the drum touch the ruler. When the knives do not come into contact with the ends of the lining, they begin to adjust them. Using the wrench (hex key) supplied with the power tool, loosen the blades on the drum.

Using the considered method, the position of the blades is adjusted for models with both one knife and two or three. After completing the adjusting adjustments, they will be installed in the desired position.

When the blades are in the correct position, they should not touch the sole when the drum rotates.

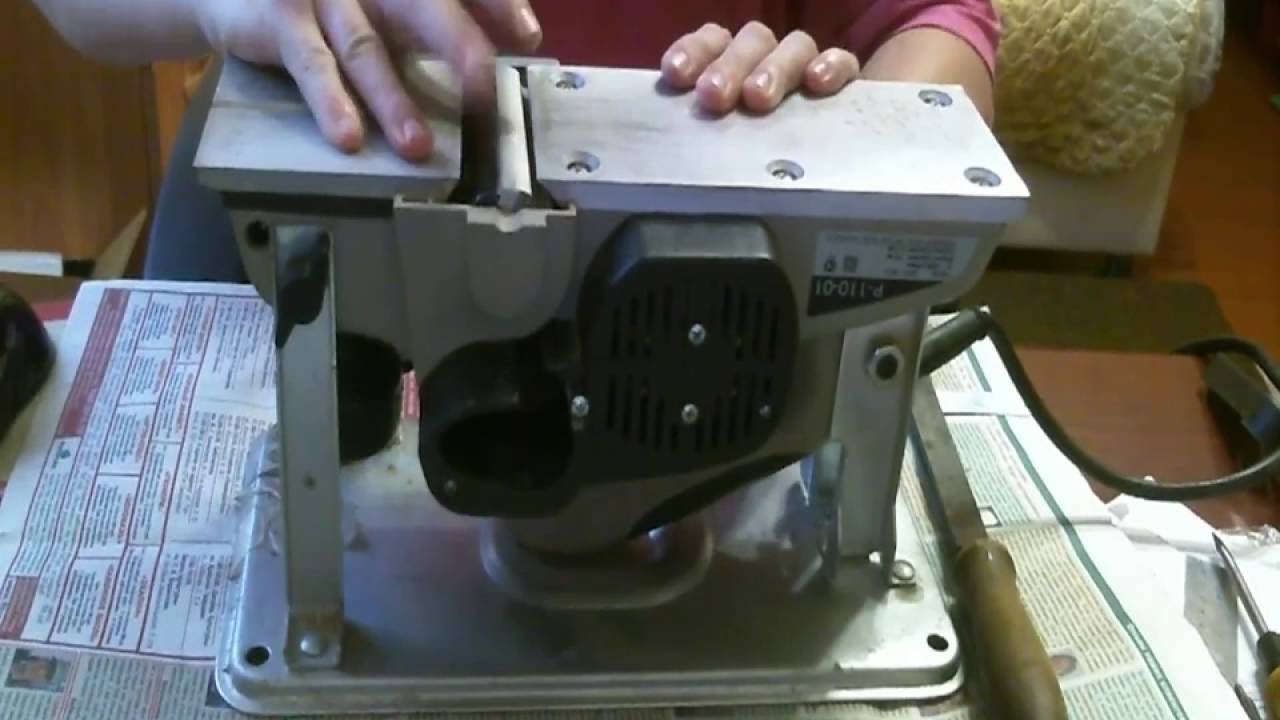

Some models of electric planers include a support-stand. This makes it possible to perform work using this device in two ways:

- by placing it in a stationary position, when the power tool is fixed motionlessly (rigidly) to the workbench or table;

- using the electric planer as a portable equipment.

Electric planer with support-stand included

The rigidly fixed tool is, in fact, a planer. A piece of wood is driven over it, pressing it with sufficient force. At the same time, it is convenient to carry out working operations with the help of a partner. Small lumber can be handled alone.

The easiest way to prepare an electric planer for work is to turn to specialists for help at a service center. Self-tuning of the tool should be carried out according to the recommendations set out in the manufacturer's instructions.

Hobby: how to choose a hand plane and set it up for the job

What kind of man doesn't like to make his own hands? This is a process comparable to meditation, and for the result to be no less pleasant, it is important to select an instrument, to have everything you need at hand. Today we're going to answer a few of the most common questions about how to complete your home toolkit, with an old, tried-and-true hand planer.

The main one is plane number 4 (the plane number is usually indicated on the tool itself). The number 3 plane is almost the same and is usually considered a beginner's or women's plane, so its presence in the master's home kit is, by and large, not entirely necessary.

Starting from number 5, not quite planers in their pure form begin, but rather semi-jointers, they usually include a tool with a sole up to 60 cm.The fifth number is quite versatile and suitable for a variety of tasks, for which English masters, for example, gave him the name Jack (Jack is considered a jack of all trades in English folklore). Its fundamental difference from the "four" is a longer sole. "Six" is a semi-jointer that already has all the features of a jointer, for example, a wide long sole. With its help, they usually level out large surfaces when it is required that it be even, but ideality is not needed. If you have enough strength and weight, stop your choice on number 6, otherwise take the "five".

There are still numbers 7 and 8, but their presence in the home set is already at the discretion of the master. The "seven" is still a full-fledged semi-jointer, and the "eight" is already such a specific tool with a large and long sole for craftsmen with great strength and weight.

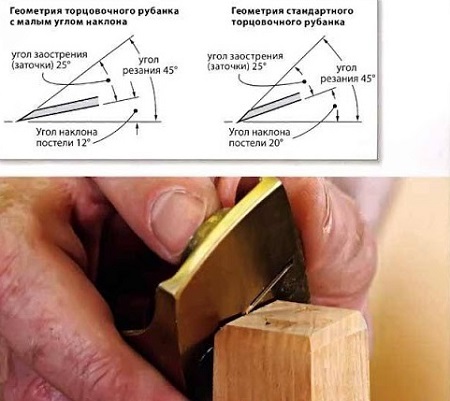

If you move in the other direction from the main plane number 4, then the next necessary plane in your set is the so-called end plane, the smallest of the whole family. Its sole is 2 times smaller than that of the "four", it fits easily in one hand. The main advantage of this planer is precisely its ergonomics - the fact that it is so comfortable to lie in the hand, while the hands of the master are as close as possible to the area of the instrument. The closer - the more accurate the movement.

Thus, the minimum set of hand planers for a home craftsman will be a set consisting of a "four", an end plane and number 5 or 6 - depending on your personal preferences. The rest of the intermediate options are purchased as needed and depending on the work performed. Now let's move on to setting up.

How to set up a plane for work

When buying a new plane, do not be lazy and immediately buy a screwdriver for it. There are 2 screws on the plane that are involved in setting up the tool - the corresponding slotted screwdriver should be selected. Preference should be given to screwdrivers with a short handle - it will be more convenient to set them up.

When buying a planer, make sure that the so-called eyelet does not dangle. Then, at home, you need to tighten all the screws on the tool, since they could loosen during the transportation and storage of the product - due to temperature changes, shaking, etc.The most popular are now double hand planers for fine planing. Their knife consists of two parts - the knife itself and the chipbreaker, the gap between them must be adjusted so that it is, but minimal, about a millimeter.

And one more trick in the adjustment: the upper screw of the planer that controls the eccentric, or latch, must be tightened so that it can be snapped in with effort, but with one finger. If you do not pull, then the plane's knife, or as it is popularly called, the piece of iron, will crawl inside during work and cease to fulfill its function. If you overtighten this screw, as many people like, then the adjustment of the knife will become more difficult, and you need to adjust it after adjusting the screws, when the plane is already in a state ready for work.

To adjust the knife, you need to adjust it with a latch so that it protrudes from the hole in the sole by 1-2 millimeters. Usually, the knife is first exposed with a small margin, its shoulders and angle are adjusted, and then gradually removed, visually leaving the desired protrusion. To do this, in each next position, you need to look along the sole of the planer until you reach the required 1-2 millimeters of the length of the knife peeking out of the opening of the sole.

a source

Safety rules when working with an electric plane

An electric plane is a device, when working with which safety precautions must be followed. The main damaging (traumatic) factors are:

- a high-speed rotating tool drum with knives located on it;

- electric current flowing through the device.

- The workplace must be kept clean and well lit.

- Do not use power tools in rooms where there is a significant risk of fire or explosion due to the presence of flammable liquids, dust or gas.

- Do not allow unauthorized persons or children to approach the working tool, but it must be stored in a place inaccessible to them.

- It is forbidden to be distracted by other tasks while working, as this may cause loss of control over the instrument.

- Do not allow power tools to come into contact with water or carry them by the cord.

- If an extension cord is used, then it must be suitable for the load, and also have continuous insulation.

- The power cable should be kept away from very hot objects and temperature sources, from moving parts of various mechanisms, as well as from sharp edges and various liquids (especially oily).

- It is forbidden for the body to come into contact with surfaces that are grounded (for example, radiators and heating pipes) while working with the plane.

- Do not use a power tool while under the influence of alcohol or drugs, or under the influence of drugs or fatigue.

- Preventive maintenance of the device should be performed regularly.

- Do not touch the drum while it is running.

READ MORE: Instructions for adjusting the door closer how to adjust adjust the door device according to the closing force Adjusting the mechanism with your own hands

Sharpening electric planer knives at home

With regular use of an electric planer for processing wooden surfaces (planing, sampling a quarter, chamfering), its cutting edges become dull. If the knives are reusable, you can sharpen them yourself. Sharpening is carried out according to the same principle as for hand planers. The differences are only in the number of cutting edges that need to be sharpened.

Do not use power tools with dull blades for the following reasons:

- the load on the electric motor increases, as a result of which its wear is accelerated;

- the quality of the surface treatment of sawn timber is significantly reduced.

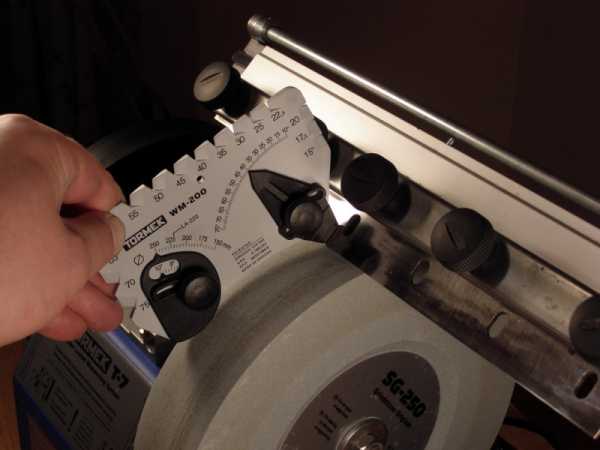

Specialists of service centers or special workshops will help you to sharpen the cutting edges of the working nozzles correctly. If it is not possible to turn to professionals, then you can do all the work at home. To sharpen the blades yourself, you can use the following tools:

- machine for sharpening knives;

- ordinary whetstone (abrasive stone, whetstone);

- emery;

- file for metal;

- grinding wheel.

You will also need a special clamp to hold the part to be sharpened.

Sharpening the blade with an abrasive stone is performed as follows.

- Remove the working attachments that need to be sharpened from the drum of the electric planer.

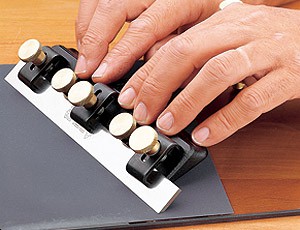

- The knives are fixed with special screws in the clamp so that their cutting edges lie in the same plane.

- Fixed blades with light pressure, smoothly drive over the surface of the abrasive, making sure they sharpen at the same time.

- Examine the sharpened parts for deviations, repeating the whole process when they are found.

- Check the sharpness on any piece of the board.

- Install the knife plates on the drum, adjusting their position.

It is recommended to moisten the abrasive stone with water before carrying out work. It should be borne in mind that a coarse-grained abrasive is intended for primary processing, and a fine-grained abrasive is intended for finishing. It is recommended to keep the original angle of the blade (approximately 30 degrees).

The considered manual method is well suited for dressing sharpening. If the edges are very blunt or have jagged edges, then sharpen them on the machine. In this case, you should be careful not to remove excess metal from the blades.

With your own hands, all actions should be carried out carefully, carefully handling the blades to avoid injury. High quality sharpening performance will appear with experience and skills

The condition of the blades of the electric planer - their adjustment and sharpness - should be checked before starting the processing of lumber. Not only the quality of planing depends on this, but also personal safety. All operations for replacing, sharpening, adjusting the working attachments must be performed only with the power tool disconnected from the mains. To give the initial sharpness to the cutting edges, it is enough to use a regular whetstone.

Today in the construction market there is a huge number of easel tools and accessories that speed up and simplify work. These include an electric planer, because it is often used in construction or repair.

Today in the construction market there is a huge number of easel tools and accessories that speed up and simplify work. These include an electric planer, because it is often used in construction or repair.

Any tool, whether it is a woodworking machine or an ordinary plane, has some additional elements in the complete set; in a plane, they are knives. If the blades begin to peel off layers poorly, this means that they have become unusable, and they need to be sharpened correctly.

However, before disassembling the tool, you should figure out how to set the blades on an electric plane. Before you adjust the knives on the electric plane, you need to learn about the method for disassembling the device.

How to use?

Each master has his own style of work, but the general features are the same.

- You need to plan smoothly, avoiding jerks. You need to stand to the side of the workbench with one foot forward.

- You need to plan along the direction of the grain. If the workpiece is wide, it is best to first guide the plane diagonally and then level it flat. To do this, you need to use a special ruler.

- The workpiece must be stationary. Vibration is not allowed.

- If the tool is clogged with chips, then it must be pushed down through the "mouth". If this does not work, the chips are pushed up with a chip. Do not use metal objects for this purpose, as they will damage the sharpening of the blade. For this reason, the plane should not be placed on the workbench with its sole.

- Some craftsmen hold the plane at a slight angle in the direction of planing. This improves the finish but accelerates the wear on the outsole.