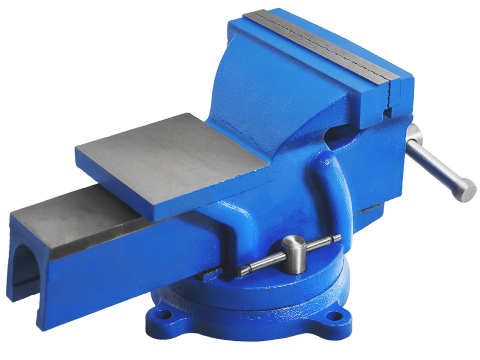

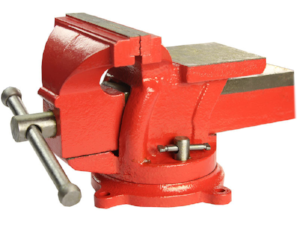

Bonus Section: Vise 2017 Bestsellers

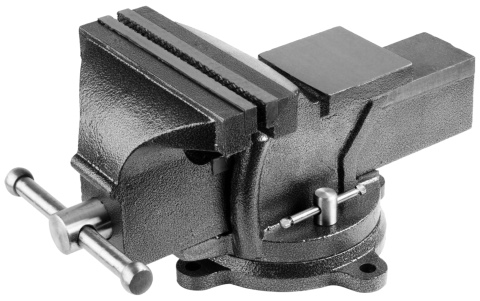

According to review and rating data collected in top stores, the model became the sales leader Intertool HT-0052... This is a classic locksmith's vice costing an average of 900-1000 UAH. Main characteristics:

Cast iron body and steel jaws - favorable price and clamping strength;

Universal jaw width 125 mm - suitable for most basic types of work;

Swivel mechanism - the ability to work with large parts in a narrow space.

This model has collected the largest number of positive and laudatory reviews from consumers and has been holding the first positions in sales ratings for 6 months.

That's all, now you know how to choose a locksmith vise and the highlights of the selection. And let your only problem in this will be the color of the model.

A vise is a mechanical device for holding the workpieces. This tool is used when it is necessary to protect the worker or free his hands. The most suitable attachment should be selected for different operations and workpieces. Experts will help you understand the intricacies of choosing a vice.

Best joinery vice

Joiner's vise is designed to clamp wood blanks in order to drill, plan or cut material with other tools. Depending on the design, they can be floor-standing, in the form of a stand, table-top or for the bed of various machines.

| Triton SJA100E TR281928 | Wilton WWV / 175 65017EU | |

| Jaw width, mm | 178 | 175 |

| Dimensions, mm | 810x330x295 | 390x260x140 |

| Rotation functions | ||

| Working stroke, mm | 955 | 210 |

| Weight, kg | 14,5 | 7,2 |

Triton SJA100E TR281928

Vise from Australian brand with 955 mm stroke and 178 mm jaw width. The clamping plate is moved manually, and the pull is carried out with a foot drive.

+ Pros of Triton SJA100E TR281928

- Large range of sizes of installed parts.

- Rapid change in the distance between the lips.

- Reliable fixation - they will hold the interior door leaf taken by the corner.

- To clamp the part, it is enough to press down on the pedal with your foot - the hands remain free and can begin to perform other processes.

- Mobile equipment can be folded up and transported to another site.

- To prevent the sponges from leaving dents on the metal, they are equipped with removable polyurethane pads.

- Convenient height above the floor of 980 mm does not require a workbench.

- The clamping force is 1000 kgf.

- Swivel movable jaw.

- Cons Triton SJA100E TR281928

- The cost is one of the highest in the category.

- The legs of the stand may wobble.

- If you grip a whole log, the metal on the sponge can deform.

- It will be possible to store only in a horizontal position - in a vertical position, the clamp switch interferes.

- For working with particularly large workpieces, it is practical to have two such vices at once, which increases the amount of investment.

Output. This is a versatile vise for clamping both large and small wooden parts. A working stroke of 955 mm allows even the door leaf to be fixed in them. Suitable for a spacious workshop where large structures are processed: fence posts, gazebos, interior doors, chairs, etc. Suitable for frequent transportation thanks to the folding legs.

Wilton WWV / 175 65017EU

Another model from the American brand Wilton, cast from thick cast iron and equipped with a steel screw. The movable part moves on the shaft and two more stainless steel guides.

+ Pluses Wilton WWV / 175 65017EU

- Smooth running of the clamping mechanism.

- Increased resistance to deformation.

- Two holes and two grooves for securing the vice to a workbench or bed.

- Through holes are provided in the sponges to secure through them pads made of any material (wood, plastic, rubber), having an even greater height and width.

- 210 mm stroke for large workpieces.

- They squeeze wooden parts very powerfully and do not release over time during prolonged manipulations on the workpiece.

- The wide pitch of the thread allows for fast spreading and convergence with a minimum number of revolutions.

- Cons Wilton WWV / 175 65017EU

- The metal lips are not equipped with anything initially, so additional investments are required to complete the joinery vice.

- For some buyers, the cheeks in the vise were not parallel - one edge had already closed, and on the second there was a slit.

- Front lip play 5 mm in different directions.

Output. It is a great choice for a home workshop. The joiner's vice will help you to grip large parts thanks to the 70 mm jaw height and 175 mm width.

Advantages

The advantages of a vice are usually considered in accordance with their type.

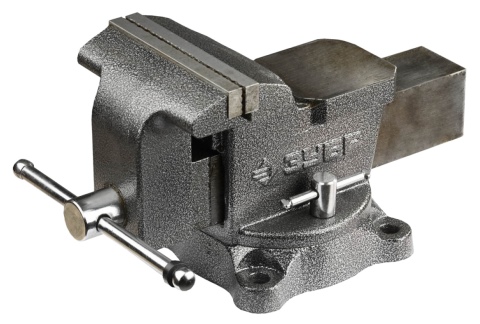

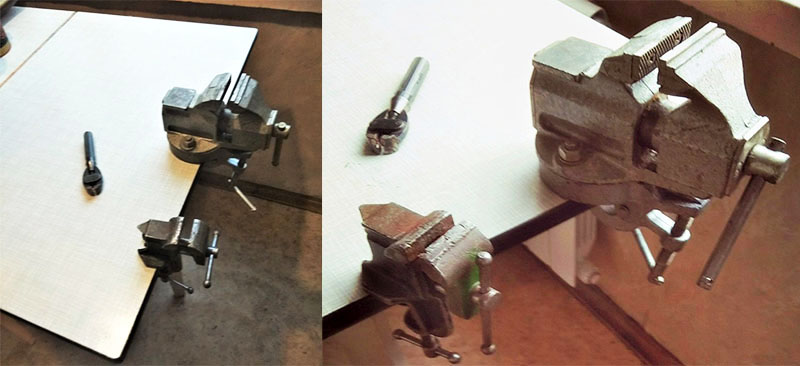

Pros of a locksmith vice

- The jaws are most often hardened, which gives them additional wear resistance.

- Anvils, present in most models, are resistant to mechanical damage.

- Swivel models support up to 360 ° swivel.

- Weight and dimensions are often small.

Pros of a chair vise

Chair models differ from other types in a set of advantages:

- The possibility of clamping long workpieces is provided.

- Due to the spring, when the screw is loosened, the jaws open quickly, no full turns are required to lower the workpiece.

- Simplicity and strength of the structure.

Machine tools

- The increased clamping force makes it suitable for clamping large metal parts.

- The high-strength housing can withstand severe mechanical stress.

- Most often, a protective coating is provided to resist corrosion of the housing.

- Suitable for high precision work.

- There is no backlash - the fixation of the workpieces is rigid.

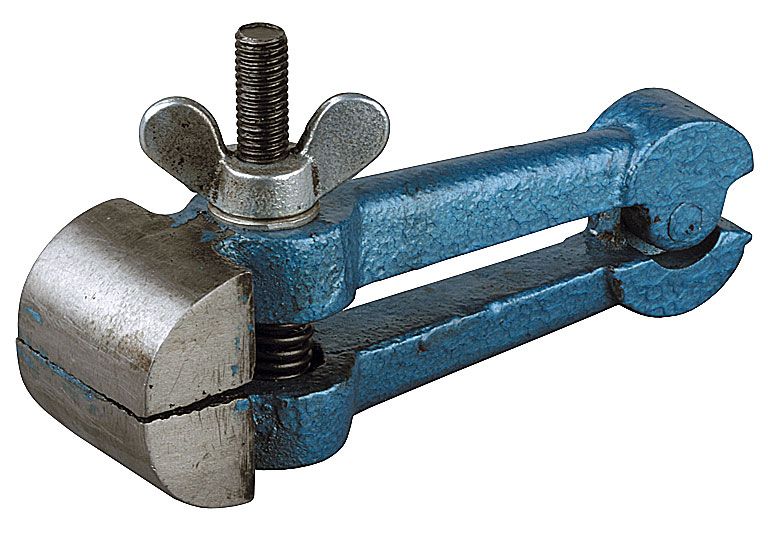

Pros of a manual vise

- Supports easy disassembly for auditing.

- They do not require fasteners and organization of the working space.

- Backlash in the hinges is minimal, and often absent altogether.

- Suitable for small precision work.

- The handle is often covered with santoprene, so the tool does not slip out of the hands when working.

- Clamping of flat parts with an extended contact area is possible.

- The most common material of manufacture is carbon steel.

- The only type of vice, suitable for quick and correct work with mounted aluminum profiles, metal tiles.

Pros of joinery vice

- Suitable for work with soft materials.

- Fixing the jaws flush with the surface of the workbench allows you to machine large parts in a single plane.

- Increased stroke of the solution of the sponges.

- A wide range of fastening systems is available, models without beds are suitable for clamping directly on the finished structure, do not require preliminary disassembly.

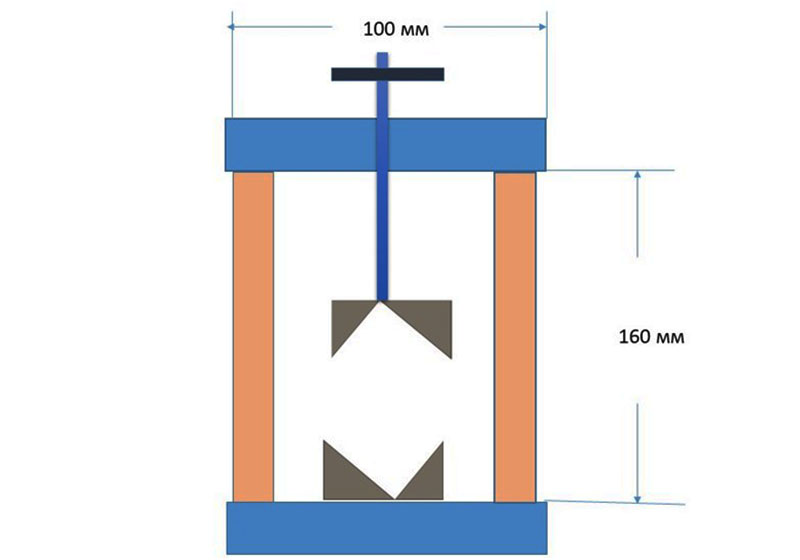

Interesting: Mini-plant for foam blocks

Variety of vice

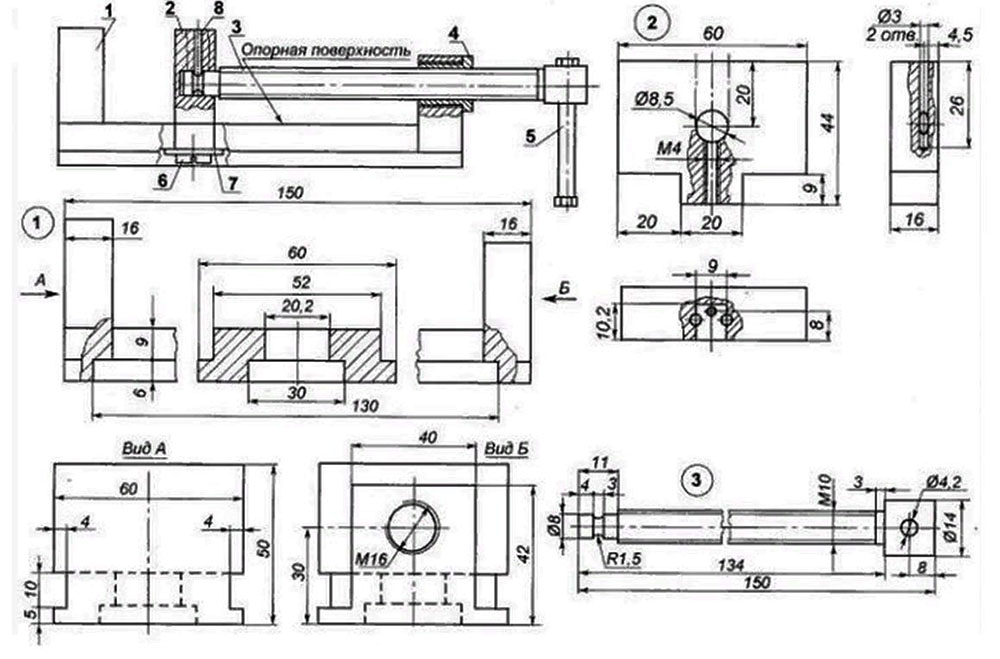

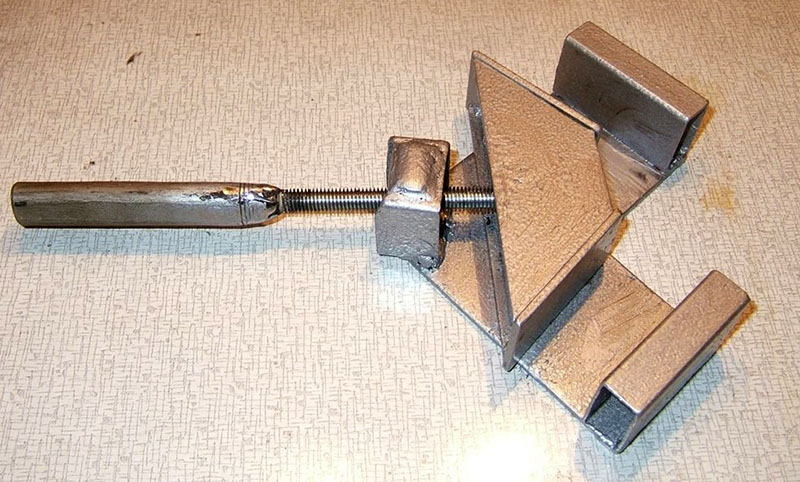

There are three main types of drill vise.

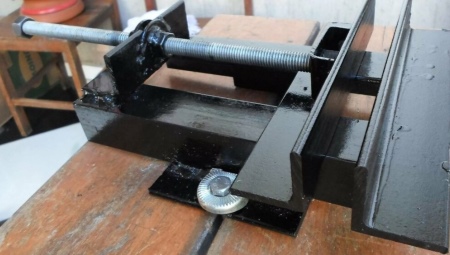

Fixed

This is a stationary equipment with a simple design.

The vice is fixed on the machine in one position. Fixed vise allows you to make only one hole in the workpiece. If it is required to drill a part in several places, after the first processing it is removed from the machine, rotated at a different angle, clamped in a vice, and appropriate manipulations are carried out. This is done several times until the completion of the work.

A distinctive feature of the fixed vise is the increased rigidity of the structure. Of the shortcomings, the point is that it takes a lot of time to carry out the corresponding operation. The main advantage is an affordable price.

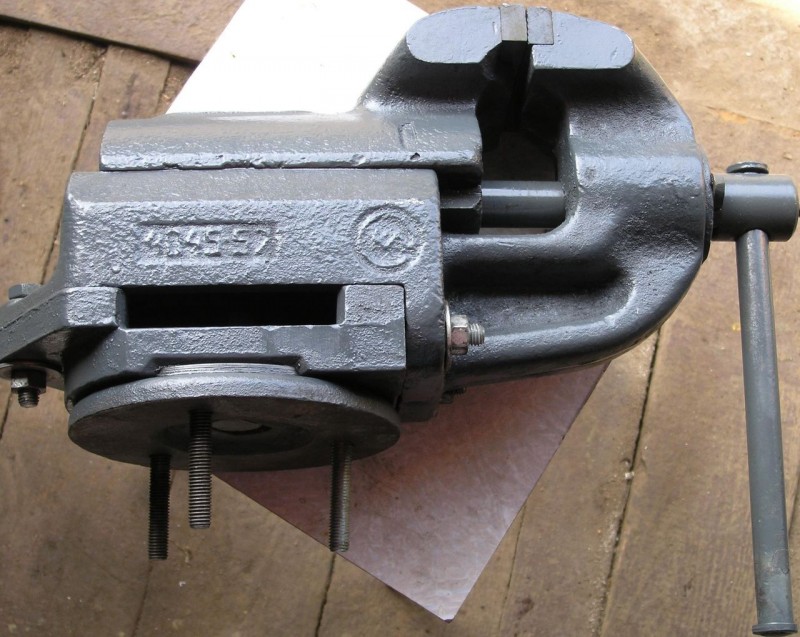

Swivel

Devices of this type appeared on the market at a time when it was required to make efficient and reliable clamping devices for processing workpieces in serial production conditions. Due to the presence of a special turntable, the jaws with the part fixed in them can rotate 360 degrees.After drilling in one place, such a platform can be easily rotated to the required angle without unclamping the part, and drill a hole in another place.

These are devices that allow you to make several holes on the workpiece without removing the element from the device, while the part can be rotated at different angles.

When selecting a rotary vise for a drilling machine, take into account the overall and landing dimensions.More advanced models of rotary vices, due to the presence of cross guides on their base, allow not only turning the clamping jaws to the required angle, but also moving them in a horizontal plane along two axes.

Making such a device with your own hands is much more difficult than a fixed vise, but if you wish, you can. Such an attachment for a drilling machine can significantly increase the productivity of technological operations, which is especially important for mass production. There is another type of rotary vise for a drilling machine.

Their base-platform with a rather complex structure allows you to turn the jaws with the part clamped in them in three planes. Such a high-tech vice, to follow the manipulations, with which it is very interesting even from the video, are called global.

Globe rotary vise, due to its functionality, allows you to make inclined holes in parts. To solve this problem, it is not necessary to painstakingly select the correct position of the part in the jaws, which always takes a lot of time.

To make an inclined hole using a globe vise, it is enough to simply fix the workpiece in them, and then use a special dial to turn the movable platform of the device to the required angle. The described types of vise differ in varying degrees of versatility.

Expert opinion

Dmitry Levin

For work on a drilling machine in a home workshop, it is best to choose the simplest non-rotating vice. As mentioned above, they are easy to do with your own hands. However, before you start making them, you should stock up on drawings and watch the corresponding video on the Internet.

Universal

Such devices are used to perform any operations. Universal vices, in turn, are longitudinal-rotational and rotary in a 3D plane. The first devices allow you to rotate the workpiece in two axes. The second devices make it possible to perform work of any complexity. The disadvantage of a universal drill vise is the high cost.

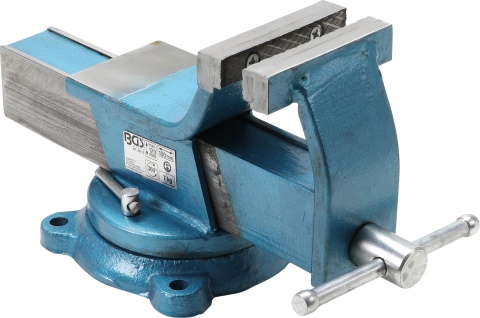

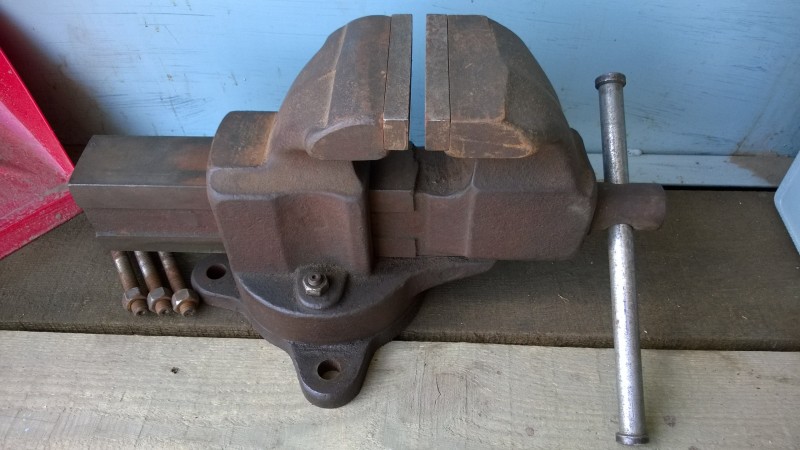

What is the best locksmith vice to choose when buying?

Now about

what tips to follow when choosing a locksmith vice in a store,

buying them from hands or ordering in the online store

There are several criteria and

details that you need to pay close attention to. Among these

details, highlight the following:

- Rsize

locksmith vice;

- mmaterial, from

which they are made of;

- NSAG thread

swivel mechanism;

- Rsponge size

and their structural surface;

- nallegiance

additional functions.

Vise size.

First of all, when shopping, you need to pay attention to the size of your

future locksmith tools. If you are confident that you will always work

with small parts or blanks, it is best to pay attention to

a small vice that will be handy in this case, easy to carry, and

cost an order of magnitude less than a large vise

That is, there is no

it makes sense to overpay for a large tool if you need a small vice. it

first, and perhaps the most obvious.

Material

vice

The second thing you need to pay attention to is the material from

which the vice is made. Overwhelmingly, locksmith vice

are made of steel - in more than 96% of cases

But, there is a small

the part is the quality of the steel from which they are made. Therefore, to buy

locksmith vice, you must pay attention to the manufacturer. Usually,

well-known brands and companies engaged in the production of locksmith vices make

your tool made of quality steel. Domestic manufacturers, to the great

Unfortunately, today they offer not the best steel quality. You can also

include Chinese vices, which cannot boast of their quality.

Therefore, pay attention to this detail.

Thread pitch

swivel mechanism

Everything is simple here - when buying, you need to pay

attention to how large the clamping step of the vise is. If you need

perform spot work, then you need a vise with a fine pitch that will allow

find the optimal clamp

If a rough clamp is needed, a vice with

wide step.

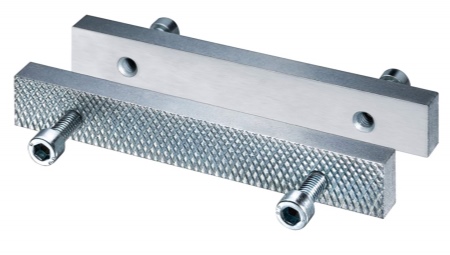

Size and

structure of the sponges. The part is clamped in special jaws, which have both

different sizes and different surface structures. So, the price of locksmith

vice, as a rule, will depend on the size of the jaws - the larger it is, the more

their price will be higher

Pay attention to the structure - sponges can have

mesh or dot surface. So, after clamping a part (for example,

wooden) in a vice; after work, traces of this structure may remain on it.

Therefore, it is better to take a closer look at the bench vice with flat jaws.

Additional

functions. Additional functions include, for example, the ability to

use a rotary locksmith vise as an anvil. This will

useful during small locksmith work, which will allow you to fix the part, and before

end to work with her. Since otherwise, you will have to every time

remove the part from the vice, process it, and re-clamp it. With the presence of this

function, there is no such need.

More about clamping tools:

- Joiner's clamp - types and where to use

- Construction clamp

- Homemade manual bending machine

- Stands and guides for drills

- DIY belt sander from a drill

- Circular saw from a drill

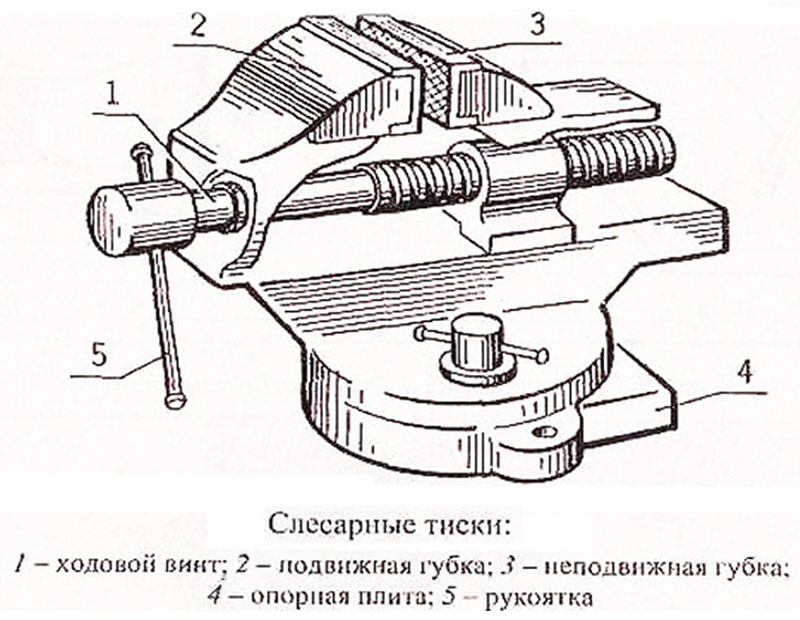

Purpose and principle of operation of the vice

The vice is used for sawing, planing, drilling, and many other workpiece processing operations.

Their main purpose is fixed fixation of the processed material relative to any plane.

Also, in some cases, the tool is able to replace clamps, for example, when gluing two workpieces, when they need to be pressed tightly against each other, while processing several parts at the same time.

Craftsmen use a vice where it is inconvenient, impossible or simply dangerous to hold the workpiece with your hands.

Interesting: Children's furniture for two boys