Review of popular models

| № | Name | Diameter range drills (mm) |

Drill fixing system | Weight, kg) | Abrasive wheel material | Average price (rub.) |

|---|---|---|---|---|---|---|

| 1 | Sturm BG6017S | 3÷10 | Conductor | 1,5 | Electrocorundum | 1 900 |

| 2 | "Instar" STCH 60090 | 3÷10 | Conductor | 2 | Electrocorundum | 2 100 |

| 3 | Parkside PSS65A1 | 3÷10 | Flat holder | 1,35 | Electrocorundum | 2 700 |

| 4 | "Diold" MZS 0.2 | 3÷13 | Cartridge | 1,9 | Electrocorundum | 3 100 |

| 5 | Darex Drill Doctor 500 X | 2.4÷12.7 | Cartridge | 2 | Diamond | 20 500 |

In addition to shops offering new machine models, there is also a market for used sharpening equipment. At these sites, for a very reasonable price, you can purchase professional machine tools from both Russian and such well-known foreign manufacturers, for example, the Swiss company Meteor.

Drill sharpener for metal

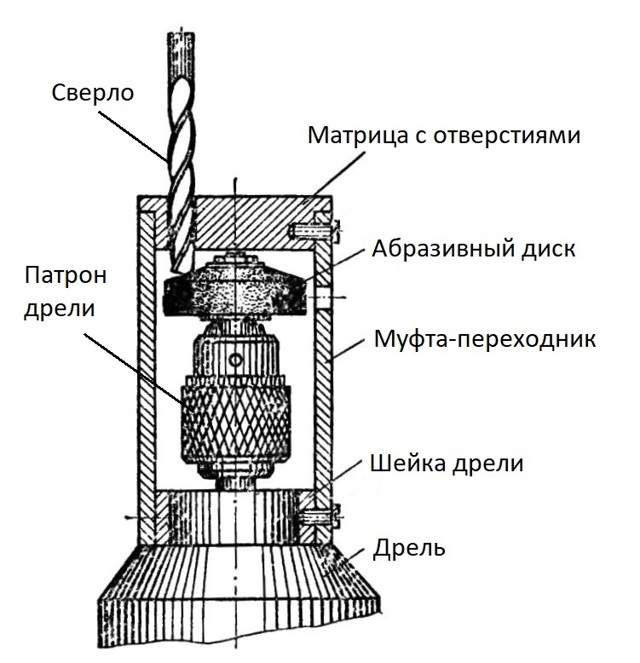

The design of this sharpener is simple and reliable. It consists of the following parts:

- Plastic case.

- Grinding (abrasive) wheel inside the body, the shape of which allows you to make the correct sharpening angle.

- Holes are made in the body, where drills (with a diameter of 3.5-10 mm) are inserted for sharpening.

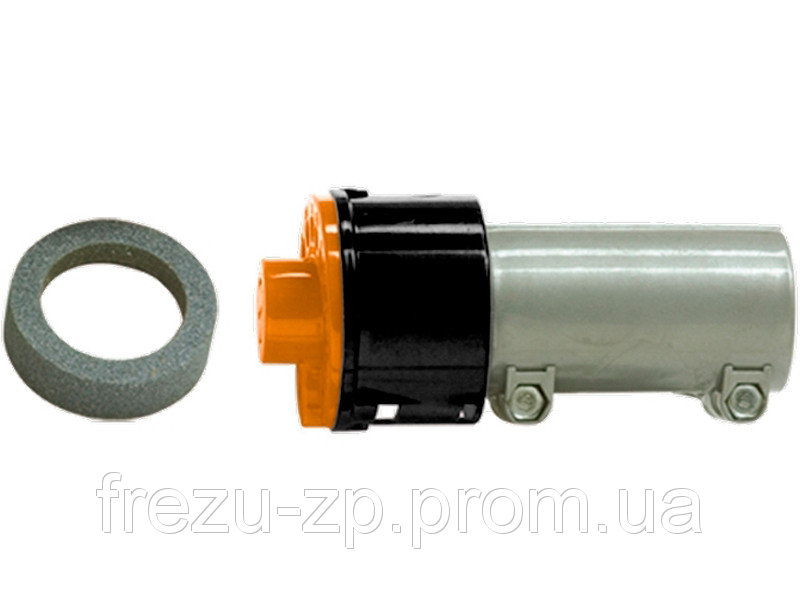

The circle rotates by means of an electric drill, the chuck of which is connected to the nozzle by a rubber coupling. The holes themselves, where the drills to be sharpened should be inserted, are made so that their cutting edge, when sharpening, contacts the circle in the only correct position.

Sharpening procedure:

- Insert the drill into the desired hole diameter.

- Turn on the drill. Only one edge of the tool is sharpened.

- Then the drill should be turned 180 ° and the other edge sharpened.

These operations must be repeated until the result is a high-quality sharpening of both edges.

Advantages and disadvantages of the device

Each device has its own advantages and disadvantages. And this drill bit is no exception to the general rule.

The benefits include:

- Does not require the user to be a sharpener. Anyone can use this device without prior training.

- Low price.

- Availability of a spare abrasive wheel.

- In conditions of remoteness from the nearest workshop or garage where there is an electric grinder, it is difficult to overestimate the value of this equipment.

- When working at height, when there is no way to constantly go down and go up to the place of work, in order to sharpen the cutting tool somewhere, the value of this equipment increases.

Even an experienced locksmith who has sharpened more than one hundred, or even a thousand drills in his life, over the years, with deterioration of vision, experiences difficulties with sharpening any tool. Of course, you can use glasses, but this is not always convenient in certain working conditions: altitude, frost (the glasses fog up), high humidity, etc. With this device, the use of glasses is minimized.

Disadvantages:

- This device is not a professional tool and is not intended for shop-floor sharpening. Rather, it serves to dress the cutting tool.

- The sharpening angle cannot be changed.

And yet, given all the pluses, which are more than minuses, this equipment can be successfully used for its intended purpose.

Features of working with the tool

A special feature of the standard attachment is that the drill holes are made so that the edges are next to the grinding wheel at a certain angle. There are also simplified versions - without a regulating cover. They are simpler than a standard device, but not very convenient to use. You have to constantly monitor the correct positioning of the cutting edge and the sharpening surface.

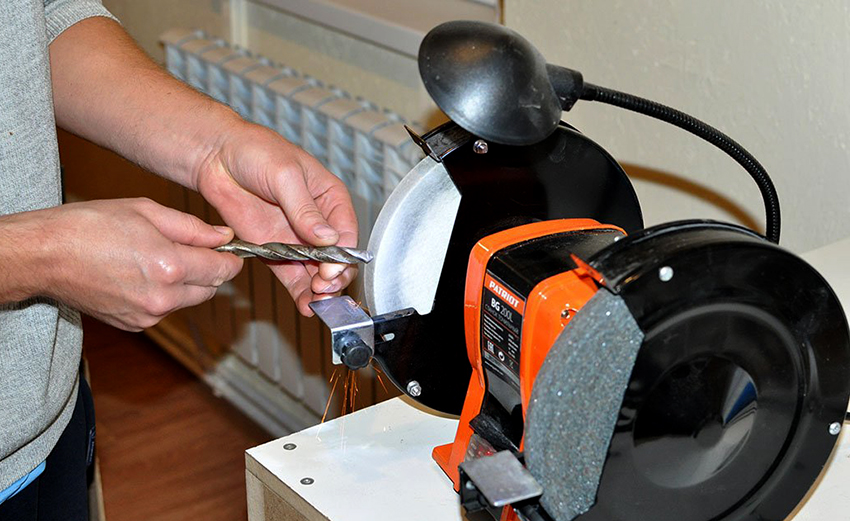

Anyone who has a drill at home can perform work on sharpening drills. The work algorithm is simple and does not require any special skills:

• the drill is inserted into the hole corresponding to its diameter

• after turning on the drill, the emery grinding wheel begins to rotate, in the process one edge is sharpened drill

• for sharpening the second cutting edge must be turned in the hole by 1 800

The drill is checked for readiness, if necessary, the sharpening process is repeated several times.

An important parameter is the angular velocity of emery

Drill sharpening technology assumes a high rotation speed at the point of contact between the disc and the working edge of the drill. At the same time, the contact time should not exceed 2-3 seconds (so that the drill does not overheat). The larger the abrasive diameter, the more efficient the edge processing. Therefore, it is preferable to purchase a nozzle designed for large discs. Usually, the body in such devices is made in the form of a mushroom.

Another advantage of this design: more holes can be placed on the die. This allows you to expand the range of drill diameters, which increases the sharpening accuracy. With a small number of holes, several drill sizes are machined in one diameter. For example, in a 5 mm hole, drill bits 4.2 mm, 4.5 mm, 4.8 mm are sharpened. There is a skew along the axis, the corner of the edge is not cut accurately. The smaller the pitch of the diameters (respectively, the more holes), the better the processing of the drill will be.

When working with large diameter abrasives, it is important to have a power reserve from the drill motor. A heavy disc must be spun and maintained at high rpm

Therefore, using such a nozzle on an instrument with a power below 600W will not work. Screwdrivers will not work either, since the upper engine speed limit is limited.

Other types of attachments

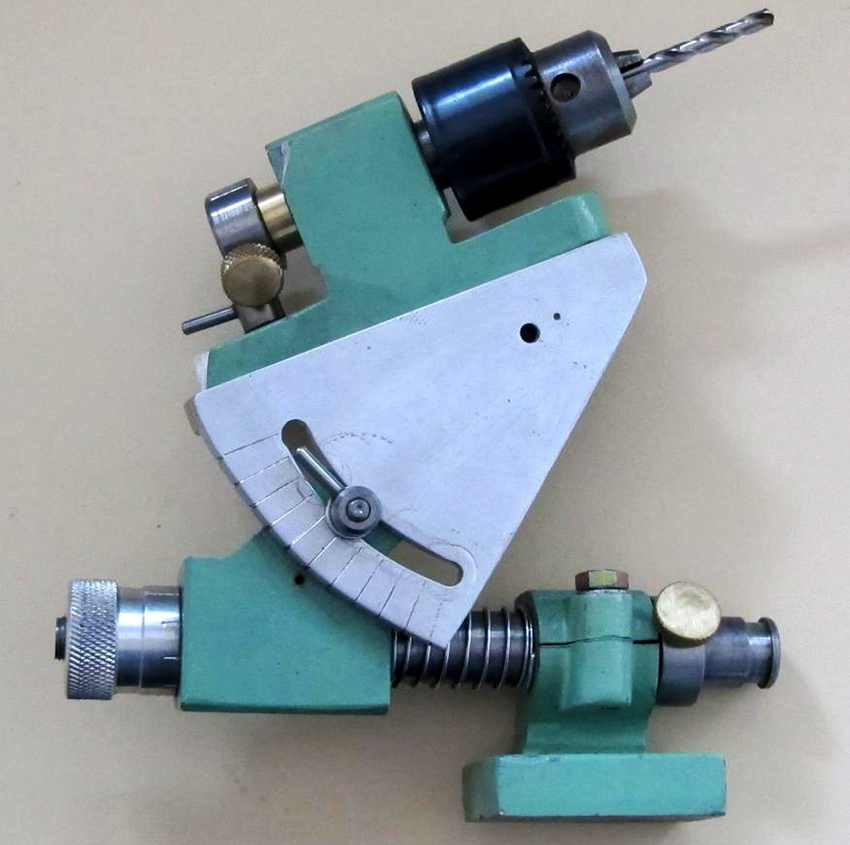

When it is not possible to make a hole in the usual way, you need to use an angle drill bit. The working head of such a device can be rotated at different angles relative to the axis of rotation of the drill chuck. The main disadvantage of the tooling is the increased risk of drill failure. Therefore, the most popular is the 90-degree angle drill attachment, which is fixed on the drill neck. The price of the product is on average 800 rubles.

For craftsmen who are engaged in the manufacture of furniture, various types of cutter attachments are in great demand. They can be undercut and pointed. With their help, you can make grooves of different shapes and depths, process holes and remove defects. The cost of the equipment is in the range of 350-450 rubles.

The design of the teeth of the nozzles-milling cutter provides a soft plunge into the workpiece, and can be repeatedly reground

To mix the solution of various consistencies, a drill mixer is used, which is selected taking into account the density of the solution. So for kneading glue, liquid putties and other fluid mixtures, spiral devices are used, which exclude splashing of the solution. To mix the concrete, hexagonal nozzles are used. Mixing mixtures using this nozzle will be performed quickly and efficiently. However, in order not to reduce the efficiency of the device, the volume of the mixture for mixing should be maintained. The price of the nozzle is 500 rubles.

Helpful advice! When choosing a mixer attachment for a drill, it is necessary to take into account the power of the tool. Increasing the load can cause the winding to burn out.

Indispensable in concreting is a nozzle-vibrator for concrete on a drill, the price of which is about 900 rubles. It is used to compact the concrete mass during its laying, namely, it is designed to remove bubbles and air layers from fresh concrete. A drill with a power of at least 1500 W is required for the attachment.

To carry out turning work on wood, a home craftsman simply cannot do without a drill attachment for cutting wood, the average price of which is 2,000 rubles. To pump liquid, you can use a pump nozzle.

The material of manufacture of the impeller of the nozzle mixer affects what substances can be mixed with it.

A wide selection of different attachments, fixtures and fittings makes the drill a versatile tool that is indispensable when performing repair work and for other household needs in a domestic environment. This is a simple and optimal solution to avoid the purchase of expensive specialized power tools.

Positive points and disadvantages of using

Giving an assessment of the rationality of such attachments for an electric drill for sharpening drills, it must be noted that they are not at all intended for frequent and active use.

Some of their positive aspects include:

- Low price of products. This is due to the simplicity of the design of the device.

- Ease of use. It is quite easy to use the device, even a beginner can cope with it. In contrast to an emery machine, sharpening with a specialized bit is not only easy, but also very fast.

- Possibility of using the device for various drill diameters. A very important factor that makes it possible to sharpen large quantities of parts from a home collection with a single bit.

The described device has the following negative points:

- Inability to produce full-scale sharpening. Although the manufacturer says that the device is intended for sharpening parts, in fact, the bit is specialized, most likely, for straightening the cutting edge of a hooked drill.

- Unreliable fixation of the device to the electric drill chuck. The overwhelming majority of manufacturers produce nozzles with a plastic stopper, which is done in order to reduce the cost of the product.

- Impossibility to change the sharpening angle. The degree of sharpening is already included in the design in advance.

- Problems in use. In order to use the attachment, it is required to fix the electric drill in a static position, which will make it possible to comfortably use the device. At the same time, it is required to hold the electric drill with one hand, connect and disconnect it, and with the other hand manipulate the drill, directing it into the holes in the cover of the device.

Nevertheless, despite the imperfection, the device found its own user. Due to its compact size, low weight and relatively low cost, the nozzle is well realized.

Apart from the particulars, the analyzed devices are considered to be quite effective if practiced directly for their intended purpose.

Disadvantages and effectiveness

Opinions were divided about the effectiveness of using the nozzle. Like any not-so-expensive device, this one is also not without a number of disadvantages:

- Rather, with the help of a device, the cutting edges of the "hooked" drills are corrected.

- It is better not to sharpen completely worn edges, as the wheel will quickly wear out.

- Not the best fix.

- It is practically impossible to change the sharpening angle.

- When rotating, the chuck can touch the inner surface of the adapter (diameters must correspond here).

- It is inconvenient to hold and turn on the drill while guiding the drill with the other hand.

Nevertheless, the device was appreciated by many craftsmen, because it is compact, weighs little and costs relatively little. It can be used in "field" conditions, in small workshops and households. The skill of work is formed rather quickly.

Effectiveness is assessed in different ways. Some consider the design to be too weak to use it regularly, according to others, the nozzle is simply irreplaceable in certain conditions.

Judging by the reviews, we can conclude that without excessive demands on the device, it will show itself to be highly effective.

Drill attachment for plucking birds

Plucking poultry is a laborious process, especially when several carcasses need to be processed. Therefore, many farmers were constantly in search of new solutions not only to facilitate work, but also to reduce the total time. For this purpose, the Feather Drill Bit has been specially developed, which removes feathers from the bird in a matter of minutes. It is similar to a dishwashing brush, except that silicone fingers protrude with bristles here, which, when the shaft rotates, pull feathers out of the carcass. At the same time, the bird is brought up on different sides.

A drill attachment for plucking a bird, which can be bought for an average of 1,500 rubles. processes poultry carcasses in just 2-3 minutes, without leaving a single feather. The result is smooth, intact skin. The device is effective not only for processing chickens, but also gives a good result when plucking geese. The drill attachment can be used not only for fresh, but also for frozen poultry.

The plucking attachment for a drill is a metal tube-drum centered on the machine

Helpful advice! It is not recommended to scald the carcass with boiling water before using the nozzle, which will reduce the efficiency of the processing process.

The main advantages of the feather drill bit, which you can buy in any specialized store, is the speed, simplicity and mobility of use, which does not require certain skills and additional processing of the carcass before plucking. A significant disadvantage of the device is that after this mechanical process, damage remains on the carcass, which worsens its appearance. Therefore, if the bird is intended for sale, it should be plucked manually.