What to focus on when choosing a motor pump for dirty water

When choosing a gasoline or diesel pump pump that is planned to be used to pump out dirty water, you should take into account a number of factors that directly affect the efficiency, reliability and durability of such equipment. The main parameters that are guided when choosing a motor pump are:

- the pressure of the liquid medium, which the pump for dirty water can form (the size of the particles of the sand pumped out by the pump or other solid inclusions in the liquid medium depends on this parameter, as well as the distance to which the pumped water will be transported along the horizontal section of the pressure hose);

- the performance of the device, that is, the volume of liquid that it is able to pump per unit of time;

- drive motor power;

- the fuel consumption of the drive motor.

Calculation of the height of the liquid rise

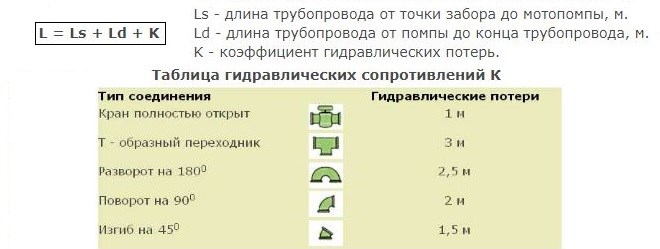

Calculation of the length of the pipeline from the point of water intake

When choosing a motor pump for pumping out dirty water, you should pay attention to the type of engine. If you plan to pump out clean or slightly contaminated water, you can opt for more budget models equipped with a two-stroke engine.

If, with the help of a motor pump, it is necessary to pump out liquids of various degrees of contamination, then for such purposes more powerful equipment should be chosen, on which a four-stroke type drive motor is installed.

Different models of motor pumps for dirty water differ from each other and in their sizes. The dimensions and weight of a mud pump are directly affected by its power and performance. So, the mass of individual models of gasoline or diesel motor pumps designed for pumping out heavily contaminated water can reach up to 70 kg. Naturally, moving such equipment alone and without additional devices will not be easy. That is why, when choosing mud pumps, one should compare the technical characteristics with the dimensions and weight of the device.

The best fire pumps

This type of equipment is connected to any fire extinguishing containers. It is unpretentious in maintenance and is capable of pumping liquid of any contamination.

The main difference between the devices is quick start-up without pre-filling the pump and high performance in pumping water for active extinguishing of the flame.

FUBAG PG 950T 838246 - for a large object

This motor pump is the best for extinguishing a fire at a large facility, with which you can begin to effectively extinguish the flame even before the arrival of the fire brigade, because the unit's capacity is 1300 liters per minute. This creates a strong jet that exits through an 80 mm diameter hole.

Entrance and exit are on the same side, which is convenient for quick connection. The design is enclosed in a powerful metal frame with two supports made of a shaped tube, so you can not stand on ceremony with the device when placing it - it will also withstand mechanical loads.

Pros:

- the four-stroke engine is easy to maintain, because oil and gasoline are filled separately according to the level;

- the device does not need to pre-fill the suction hose with water;

- durable frame, easy to carry;

- compact and high-quality assembly;

- motor power 7 HP pulls a large volume of water;

- stable position despite vibration during work;

- the motor pump is capable of pumping water of any contamination;

- the lifting height of the collected liquid reaches 26 m, which is suitable for extinguishing even a nine-story building;

- the device can suck in water from a depth of up to 8 m;

- small dimensions 535x430x410 mm are convenient for storage and transportation;

- the device will not clog if solid particles with a diameter of 30 mm get into it;

- the fuel tank holds 3.6 liters of gasoline, which will last for a long time;

- hose diameter 80 mm provides distillation up to 1300 liters per minute;

- the package includes a spark plug wrench, a screwdriver, an inlet filter and several gaskets for the nozzles.

Minuses:

- cost from 16,500 rubles;

- the starter lever comes out opposite the rack of the metal frame and requires you to move your hand to the side at the moment of the jerk, which is inconvenient when starting;

- starts only manually;

- weight 34 kg is heavy.

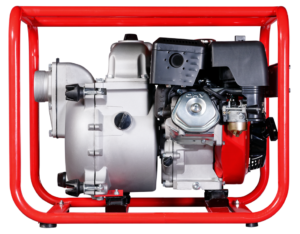

PATRIOT MP 4090 S 335101640 - the performance leader

This is the best motorized fire pump for quickly extinguishing a flame over a large area, since the device has a capacity of 1500 liters per minute.

At the same time, the height of the liquid rise reaches 30 meters, which allows it to be used for extinguishing the upper floors of high-rise buildings (suitable for buildings of 10-11 floors).

The device is assembled on a steel frame and screwed to the profile base. The pump inlet and outlet are connected at one corner of the housing.

Pros:

- 3 years warranty from the Russian manufacturer;

- quick putting on the nozzles on the nozzles thanks to the 45-degree rotation system;

- the engine is moved slightly to the side to improve air cooling;

- four-stroke engine with minimal maintenance, stable rpm and affordable AI-92 gasoline;

- distills water of any pollution;

- high productivity up to 1500 liters per minute;

- the power unit has a power of 9 hp. thanks to the volume of 270 cm3;

- pulls liquid from a depth of up to 8 m;

- inlet and outlet holes have a diameter of 100 mm;

- spacious fuel tank for 6.5 liters;

- distills solid inclusions up to 30 mm in diameter;

- stability on any surface;

- long service life;

- squeezes water to a height of 30 m.

Minuses:

- cost from 22,500 rubles;

- weight of 42 kg is heavy to carry;

- the oil filler neck is inconveniently located (covered with a fuel tank);

- a large body 630x450x520 mm is harder to place in the trunk of a car during transportation;

- only recoil starter for winding.

The best of the best

For pumping clean water

Hyundai HY 81

It is fully consistent with modern technical means for draining natural and artificial reservoirs, springs, irrigation or raising water to an average height. Low weight and small dimensions make the installation convenient and maneuverable. When pumping, the presence of solid particles in water with a fraction of up to 5-6 mm is allowed.

- The volume of the internal combustion engine is 212 cm3.

- The diameter of the working branch pipe is 80 mm.

- Productivity - 1 m3 / min.

- Dimensions - 530x425x435 mm.

- The capacity of the gas tank is 3.6 liters.

- Suction depth - 8 m.

- Head - 28 m.

- Weight - 27 kg.

- The cost is about 13.5 thousand rubles.

For firefighting needs

Konner & Sohnen KS 50 HP

A high-pressure motor pump capable of distributing the supplied water in 3 directions at once and operating on gasoline. The body is cast from aluminum and is effectively protected from impacts by a metal tubular frame. The smart motor guarantees minimal power loss with low fuel consumption.

- The volume of the internal combustion engine is 210 cm3.

- Working branch pipe diameter - 40/40/50 mm.

- Productivity - 0.5 m3 / min.

- The capacity of the gas tank is 3.6 liters.

- Head - 70 m.

- Weight - 8 kg.

- The price ranges from 19 thousand to 20 thousand rubles.

Mud

Koshin KTH-100X

It copes with the dirtiest water, so it is quite suitable for eliminating housing and communal services problems. The high-performance revolving engine HONDA GX340 is distinguished by its high-quality performance and almost silent operation. The filter reliably protects against the ingress of large solid particles. The pump comes complete with a filter, 2 hose fittings, 3 clamps, and a spark plug wrench.

- The volume of the internal combustion engine is 337 cm3.

- Working branch pipe diameter –100 mm.

- Rated power - 7.1 kW.

- Productivity - 1.6 m3 / min.

- Dimensions - 780x570x652 mm.

- Weight - 85 kg.

- Head - 25 m.

- Approximate cost: 142 thousand - 143 thousand rubles.

Where are motor pumps used?

Modern motor pumps can easily be attributed to the number of universal devices, since they can be used in many areas of human life, for example:

- When performing drainage and pumping water;

- For water supply of a country house;

- When extinguishing a fire;

- For irrigation of fields and watering of a vegetable garden;

- For drainage of pits, streets, premises and water bodies both under normal conditions and during construction.

Often in municipal services, gasoline motor pumps are used to pump dirty water. They are also used for draining sewer wells, basements, cellars, etc.

As for the construction area, here the device can be useful for preliminary draining of a wetland where work is planned. The Ministry of Emergency Situations constantly use water pumps, and not only in case of fires, but also in cases when it is urgently required to pump out a large amount of water.

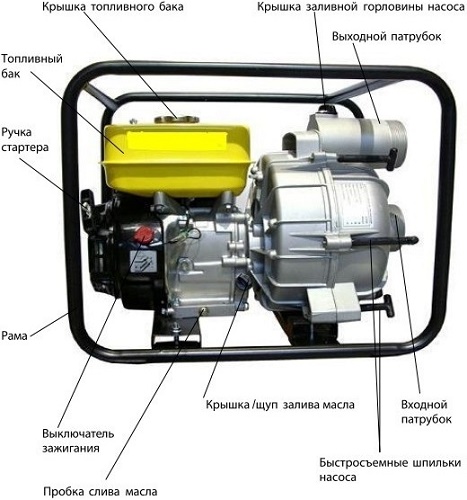

Device and design features

Scope of use

In general terms, this unit is a self-priming centrifugal pump, with some exceptions. It is adapted for operation in difficult conditions and can be used to pump water with a significant amount of contaminants.

The device is equipped with a diesel or gasoline engine.

And its design features of the body and the mud pump itself are designed to work with liquid media containing admixtures of sand, silt and even gravel. This was achieved thanks to a specially designed filtration system.

The presence of additional options for the mud pump allows you to use it for irrigating large areas or extinguishing fires. But besides this, it copes well with pumping water from reservoirs, flooded basements and garages, pits and wells.

Motor pump diagram

The scope of application of such pumping units is quite wide and extends to a wide variety of industries:

- Land reclamation;

- Road construction;

- Communal.

It is possible to use such equipment even in areas of natural disaster.

How to make the right choice

The main criteria when buying such equipment as a gasoline or diesel motor pump for dirty liquid and water is the fuel consumption and the pressure created by the mechanism during operation. Such devices have an order of magnitude higher degree of productivity, since they are designed to work with liquids, which sometimes contain rather large fractions of contaminants.

To cope with pumping water, a gasoline or diesel motor pump for dirty liquid and water must have a four-stroke engine. Push-pull versions of the drive unit are more commonly found in models for clean and lightly contaminated fluid. In addition, each version of such devices is designed for pumping water from different heights.

We watch the video, aspects of choosing a reliable model:

Gasoline motor pump for dirty water may differ in operating speed, weight and dimensions. When choosing, it should be borne in mind that the high performance of equipment directly affects the dimensions of the equipment. Some versions weigh up to 70 kg, therefore, if you need a more compact and mobile device, you should first compare the level of efficiency of the device and its overall dimensions.

Popular models

Caliber BMP-1900/25

This is a gasoline pump for dirty water Caliber BMP-1900/25. Its power is 1900 W, the design provides for a four-stroke engine and a 1.6 liter fuel tank.

The device is designed for suction of liquid from a height of up to 8 m. Also, all existing models are designed to eject liquid to a certain height, which is also indicated in the accompanying documentation.

Model HONDA GX 120

A gasoline motor pump for dirty liquid and water from the FUBAG manufacturer of the PTH 600 ST model is more expensive - 25,500 rubles.Its power is not much higher - 2100 W, as well as the operating speed - 600 l / min. The device operates on the basis of the HONDA GX 120 four-stroke engine. The fuel tank is slightly larger - 2 liters. This design provides large inlet and outlet openings - 50 mm.

Another option - SturmBP8750GV has higher power and level productivity: 4700 W, 750 l / min, respectively. The capacity of the fuel tank is 3.6 liters, which provides a rather long period of operation without refueling. But, despite the fact that the characteristics of this model are higher than those of the previous ones, you can buy a motor pump for pumping out dirty water in this version at an affordable price - for 18,000 rubles.

Features of operation

Such a technique is operated in rather harsh conditions, as it is designed to pump out liquids with large fractions of contaminants, but it is still necessary to adhere to the rules for using such an apparatus. This will significantly extend its service life. Considering the design features (the presence of an internal combustion engine), it is not recommended to use the device in an unventilated room in order to avoid accumulation of exhaust.

A home-made motor pump for pumping out dirty water requires adherence to operating rules in the same way as a purchased product. For example, you cannot refuel the fuel tank while the engine is running, and after turning it off, some time must pass before the drive unit has completely cooled down. During operation, there must be no flammable substances in the immediate vicinity of the unit.

We watch the video, operation and the first start-up of the equipment:

You should carefully handle the equipment during its operation, because the mechanism heats up quite a lot, which is again due to design features, in particular, the air cooling system. Before each start-up, check the device for leaks. Additionally, the strength of fastening of all joints is monitored

During operation of the device, it is important to ensure that there are no kinks in the hoses. The appliance must stand on a level surface for greater stability.

If long-term and regular use of the device is not expected, then it is not necessary to buy it, since today it is proposed to rent a motor pump for pumping out dirty water.

Thus, if you choose the right pump, you can successfully pump liquid with sufficient head force to the required distance. Correspondence of the characteristics of the pump for pumping water to the height at which it is planned to work, as well as the level of water pollution, will make it possible to obtain a highly efficient device that can last a fairly long time, provided that the requirements for the operation of such equipment are met.

Main varieties

Depending on a number of parameters, motor pumps are divided into different types, each of which differs in its technical and operational characteristics and, accordingly, in areas of application. One of these parameters is the type of engine with which the pump of the motor pump is driven. So, on this basis, motor pumps are divided into:

- gasoline;

- diesel;

- gas;

The drive motors of the petrol and gas motor pumps are very similar in design. Quite often, the engines of gasoline equipment are simply adapted to operate on gas, which is done by equipping them with a special gear device.

A special gas module for a motor pump is a combined device that allows the use of two types of fuel

Another parameter, depending on which motor pumps are divided into different types, is the degree of water pollution, for which such equipment is intended to be pumped. According to this parameter, the following types of motor pumps are distinguished:

- designed for pumping clean and slightly contaminated water;

- able to work with both slightly contaminated water and with a liquid medium characterized by a medium degree of contamination;

- designed for pumping thick and highly contaminated liquid media.

Motor pumps for pumping clean and slightly contaminated water

Motor pump for clean water and pumping for slightly contaminated liquids - this is a device equipped, as a rule, with a two-stroke type engine. The capacity of motor pumps of this type is not too high and amounts to about 6–8 m3 per hour. Without prejudice to its technical condition, this equipment is capable of pumping liquid media containing solid inclusions, the particle size of which does not exceed 0.5–0.8 mm.

Motor pump for clean water from the popular manufacturer CHAMPION GP80

Motor pumps of this type, characterized by their compact dimensions and low weight, are very popular among the owners of small summer cottages and country houses without being connected to a centralized power supply network.

Motor-pumps for pumping slightly and moderately contaminated liquid media

A motor pump for slightly contaminated water, as well as for pumping liquid media with a medium degree of contamination, belongs to the category of high-pressure or fire pumping equipment. Equipping such a device with a four-stroke drive motor makes it possible to obtain with its help a flow of a liquid medium characterized by a powerful head, the value of which reaches 60 meters of water column. The performance of motor pumps of this type is also at a decent level and, depending on the model, can reach 400-600 liters per minute. Using such devices, it is allowed to pump liquid media containing solid inclusions, the size of which reaches 1.5 cm.

Motor pumps for moderately polluted water (semi-mud) pump water with impurities up to 15 mm

With the help of a high-pressure motor pump, you can irrigate a large area located even at a considerable distance from the water source, quickly pump out water from a natural or artificial reservoir, and also effectively solve many other economic and domestic tasks. With such impressive technical and operational characteristics, motor pumps of this type in their dimensions and weight are not much superior to equipment designed for pumping clean water.

Motor pumps for pumping heavily contaminated water

A motor pump for water characterized by a strong degree of contamination is capable of pumping liquid media with high efficiency that contain solid inclusions with a particle size of up to 2.5 cm. 2000 liters per minute. In this case, the pressure that such a device is capable of creating is 35 meters of water column.

When choosing a motor pump for working with dirty water, it is recommended to give preference to proven professional models, which are distinguished primarily by workmanship.

The design of many models of motor pumps for highly contaminated water provides for easy access to the pump working chamber, which makes it possible to quickly remove crushed stone and stones from it, the size of which exceeds the permissible values. The dimensions of the inlet and outlet branch pipes allow connecting to them a suction and delivery hose for a motor-pump with internal diameters from 50 to 100 mm.

Key selection criteria

Devices of this category on the market are represented by an impressive product range

From the very beginning, it is important for the buyer to understand for what purpose he is going to purchase this or that sample, having a certain amount and taking into account the technical characteristics of the product

- Aggression.This indicator is decisive, because it depends on it whether the pump can fully meet the water needs and overcome the resistance of the line or whether it is not suitable for specific conditions.

- The delivery value reflects the degree of pumping intensity, and the higher it is, the sooner the unit will provide the required volume of liquid consumption.

- Resistance of the working body to abrasive wear. In some pumps, for the sake of safe operation, a coarse filter is provided, while others, in connection with this circumstance, have corresponding design features.

- Dimensions are relevant for safe transportation, as well as during operation and storage of the unit.

Do you think a motor pump is a useful unit?

Of course! So so

Principle of operation

Since there are several types of pumping equipment, they will function in different ways. So, if the motor pump is not self-priming, then it and the suction hose must be filled with clean water before starting work.

The principle of operation itself is quite simple. It is based on the fact that, under the influence of the engine, the pump wheel is set in motion. But since it is a structure of two discs, which are interconnected by blades, centrifugal force will act on the water. It, in turn, creates areas with high and low pressure, due to which the liquid is sucked in by the unit, and then ejected through the outlet.

Thus, the pumping of contaminated water from the flooded room into the sewer or drainage system is carried out.

How to choose?

In the process of choosing a gasoline motor pump, you need to be extremely careful. Only in this case it will be possible to select a unit that will fully fulfill the obligations imposed on it.

First of all, you need to decide in what conditions this equipment will work. Motor pumps can be used for clean, slightly polluted or heavily polluted water. Any type of motor pump can pump out clean water, but not all of them are capable of working in aggressive conditions. For example, most models on the market cannot be used for salt or alkaline water treatment.

The power of the device also matters.

Such units are equipped with a two-stroke power unit and are characterized by a capacity of up to 7 cubic meters per hour. The main advantage of such models is their low weight and small dimensions, which ensures the mobility of the device and allows it to be transported without problems. Such devices have proven themselves well in situations where electrical options are not possible.

Such performance is ensured by the fact that they are equipped with four-stroke power plants, which boast an increased service life. In addition, such equipment boasts an increased fluid pressure, which sometimes reaches 35 meters. Despite the fact that such motor pumps are not small in size, they can be transported in the trunk of a car, which makes them convenient to use.

If a motor pump is bought to purify excessively contaminated water, then the most effective will be a model capable of passing impurities up to 2.5 cm. Certain impurities may remain in the purified water, but the main advantage of such equipment is not in the quality of cleaning, but in the speed of operation - in an hour the device can clean 130 cubic meters.

Close attention should also be paid to the materials used in the production process. It is considered optimal if the constituent parts of the pump and its important elements were made of carbide materials.

Of no small importance is the ability to understand and clean the pump, thanks to which it can serve for many years.With the right choice, it will be possible to use the motor pump more intensively and not be afraid for its integrity

Features of the device of a motor pump for heavily contaminated water

All devices for pumping water are supplied by the manufacturer with mesh filters, the holes in which are of different sizes, taking into account the nature of the sucked water.

Depending on the ratio of liquid and solid masses, the manufacturer has developed two types of mechanisms: membrane and centrifugal, equipped with an open impeller.

For pumping out the sewage system, as well as for cleaning rooms where animals are kept, only a membrane mechanism is used.

The body of the device is usually made of high-strength types of steel, which provides protection against mechanical damage. The body is made of cast steel, which guarantees the protection of the engine and the safety of the unit.

The body of the device is usually made of high-strength types of steel, which provides protection against mechanical damage. The body is made of cast steel, which guarantees the protection of the engine and the safety of the unit.

In most motor pumps, the body can be removed independently and without the use of any additional devices. By removing the housing, you can clean the impeller from blockages and particulate matter stuck in the filter.

All units are equipped with reinforced frames that guarantee protection and stability during transportation.

How to choose a motor pump?

Important indicators of the quality of the device are:

- price;

- motor pump power;

- compactness;

- engine type;

- the length of the hoses for suction and discharge of water;

- water rise height;

- water suction depth;

- the size of the dirt that passes through the filter.

If you want to buy an inexpensive motor pump for heavily contaminated water, then you should choose a gasoline

You also need to pay attention to the fact that the price of the device often depends on its power.

The most powerful units are produced for use in construction, their capacity can reach 120 m3 of pumped water per hour.

But the most in demand are household devices designed, for example, for cleaning the basements of country houses, which do not require such power.

Attention! Typically, the parameters of the pumped water are indicated not in cubic meters, but in liters, and the average rate is 500 liters per minute.

Prices for motor pumps for highly polluted water are very diverse. A domestic gasoline pump of Russian or Chinese production can cost from 10 thousand rubles, and a powerful European diesel unit will cost 80 thousand or more.

The average price will fluctuate in the range of 20-40 thousand rubles. You can also rent a motor pump for heavily polluted water, which in many cases is much more profitable than purchasing it.

Household motor pumps are small in size and weight, usually not exceeding 40 kg.

Once the water hoses are detached, they can be carried manually and do not take up much storage space.

When working with an internal combustion engine, it is advisable to have an initial knowledge of the principles of its operation.

If it is difficult to purchase diesel fuel in the region where the motor pump will be used, then a device that runs on gasoline should be preferred.

The quality of fire extinguishing and irrigation of crops depends on the height of the water rise. For pumps intended only for pumping water, this indicator is not important.

The height of water rise is often influenced by its temperature. The maximum water suction depth for any type of motor pump does not exceed 7-8.5 m. This should be borne in mind when planning the drainage of deep wells.

The height of water rise is often influenced by its temperature. The maximum water suction depth for any type of motor pump does not exceed 7-8.5 m. This should be borne in mind when planning the drainage of deep wells.

The pump filter can pass contaminants of different diameters in the range from 0.1 to 0.5 mm. The most commonly used standard grille size is 0.3 mm.

Output

There is no universal device among motor pumps. An installation that pumps clean water is distinguished by high productivity or an impressive head, but it is unsuitable for pulp.Aggregates for efficiently pumping slurry from flooded caverns and wells may be useless in extinguishing fires, and a fire pump is unable to remove chemicals.

Thus, when choosing, it is necessary to clearly determine the profile, and then choose the pump that is ideal for performing specific tasks.

How to choose a generator for a summer residence or at home: the main criteria and an overview of the best models - gasoline, diesel, gas, hybrid, their pros and cons

How to choose a concrete mixer for home and summer cottages: types, characteristics, rating and review of popular models, their pros and cons

The best mini tractors for summer cottages and houses: how to choose the best option, TOP-10 with a detailed overview of popular models, their pros and cons, features of working on them, attachments

Wood chipper: what it is, what to look for when choosing, how to make it yourself, a review of popular